Patents

Literature

34results about How to "Uniform ablation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

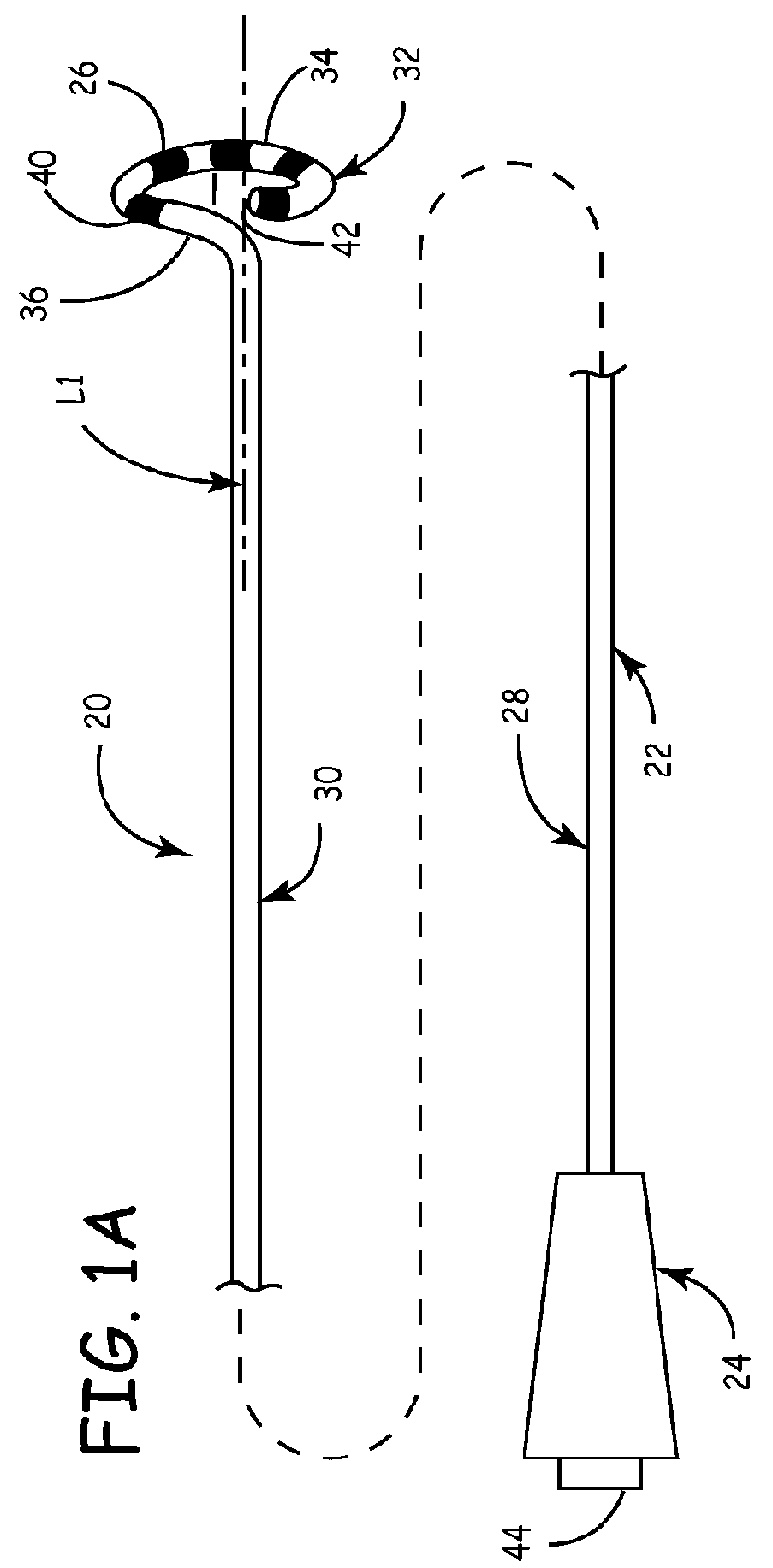

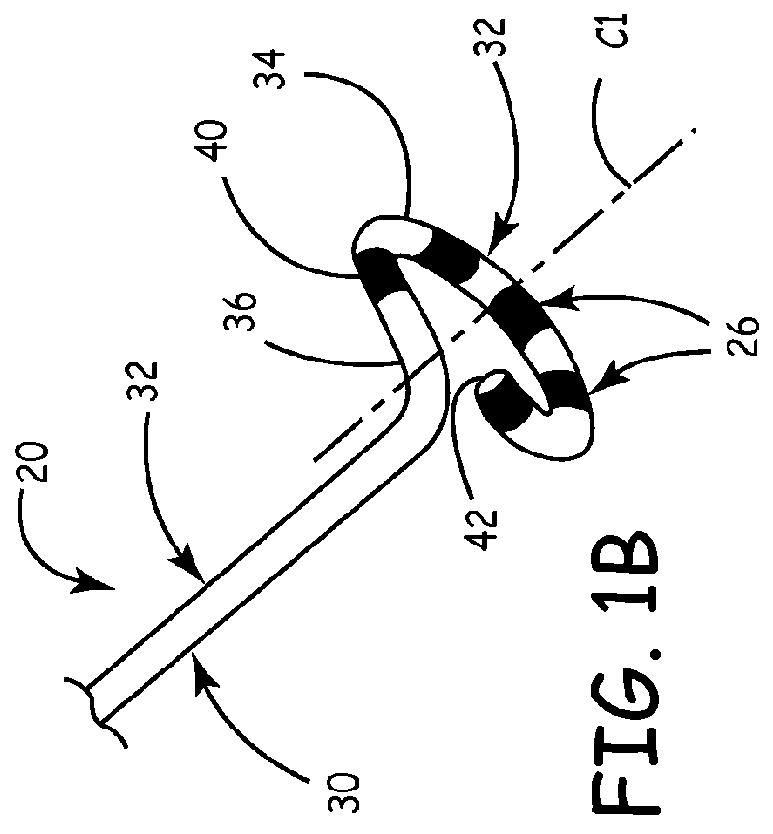

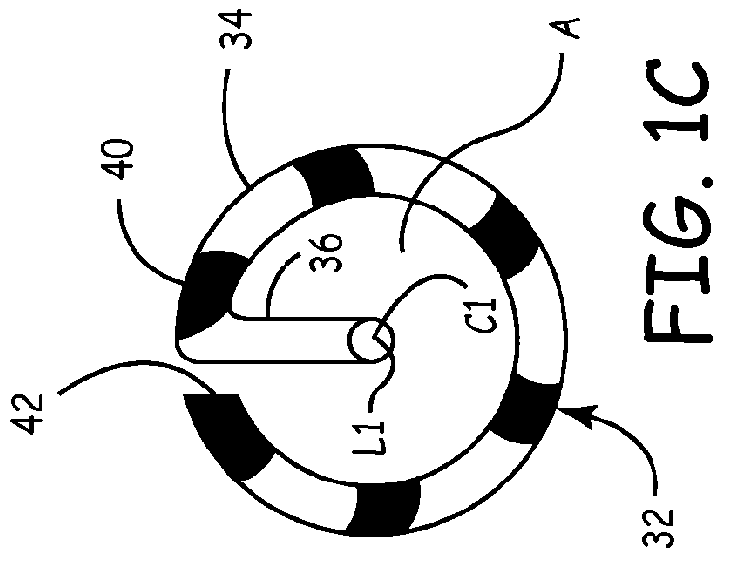

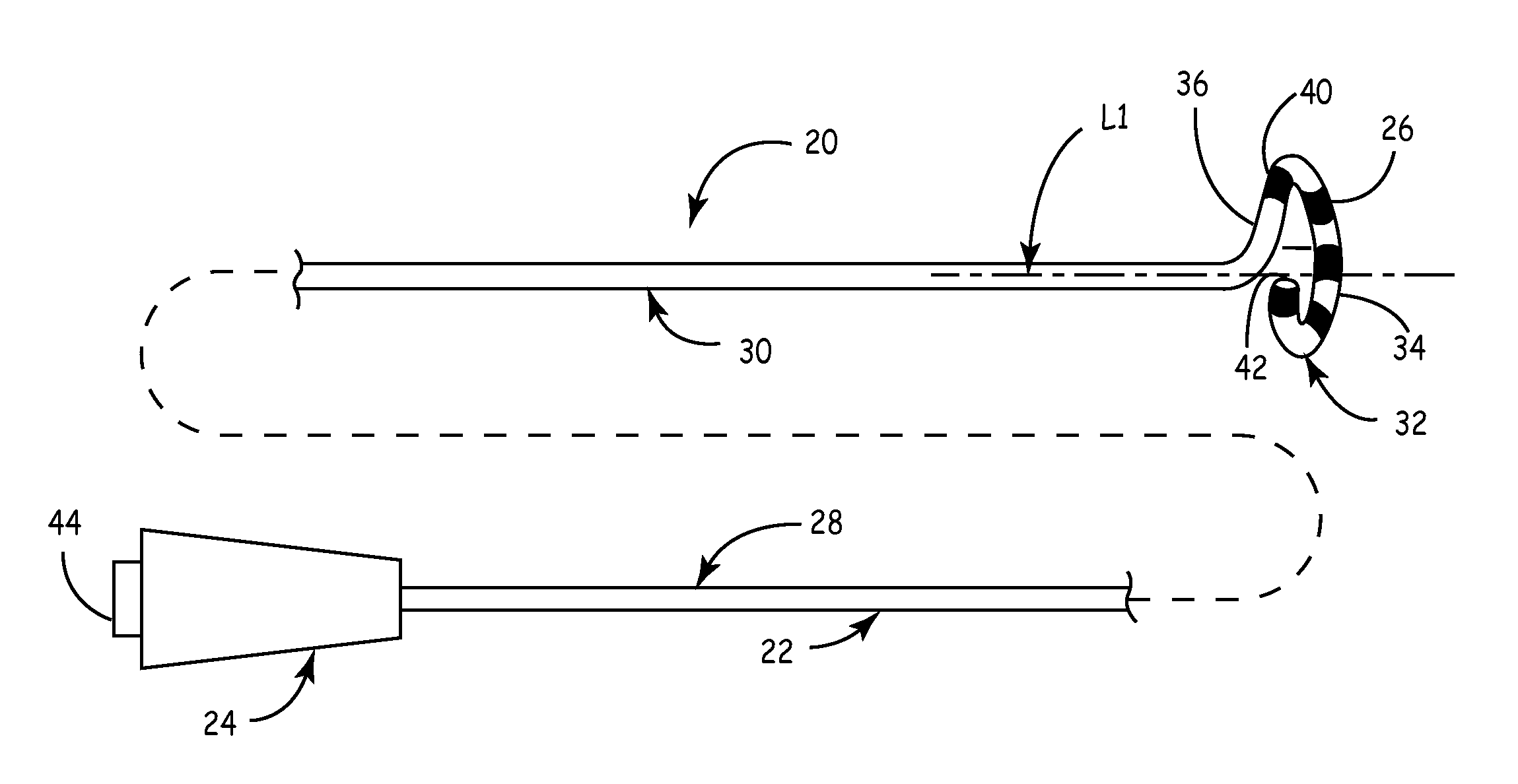

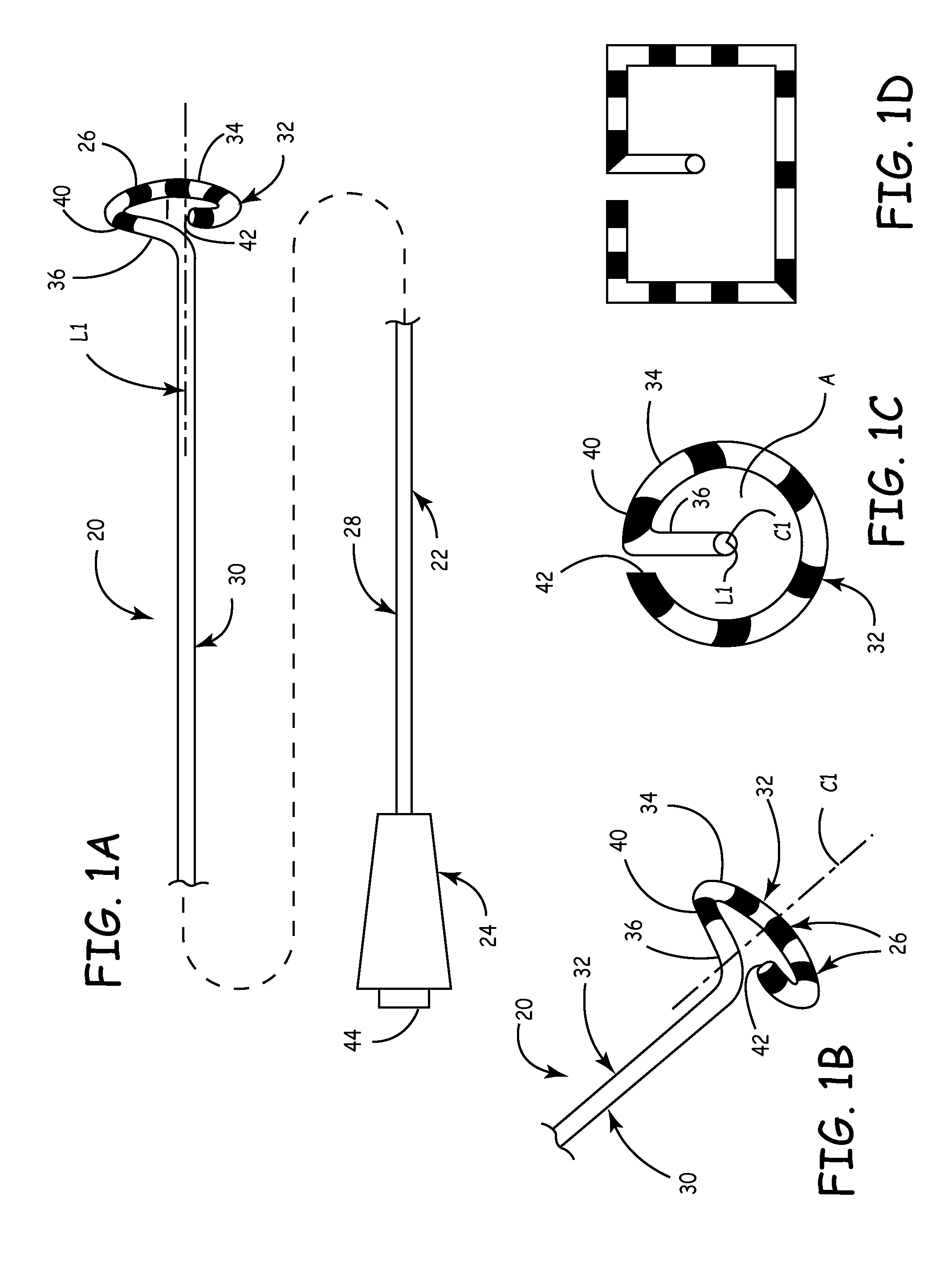

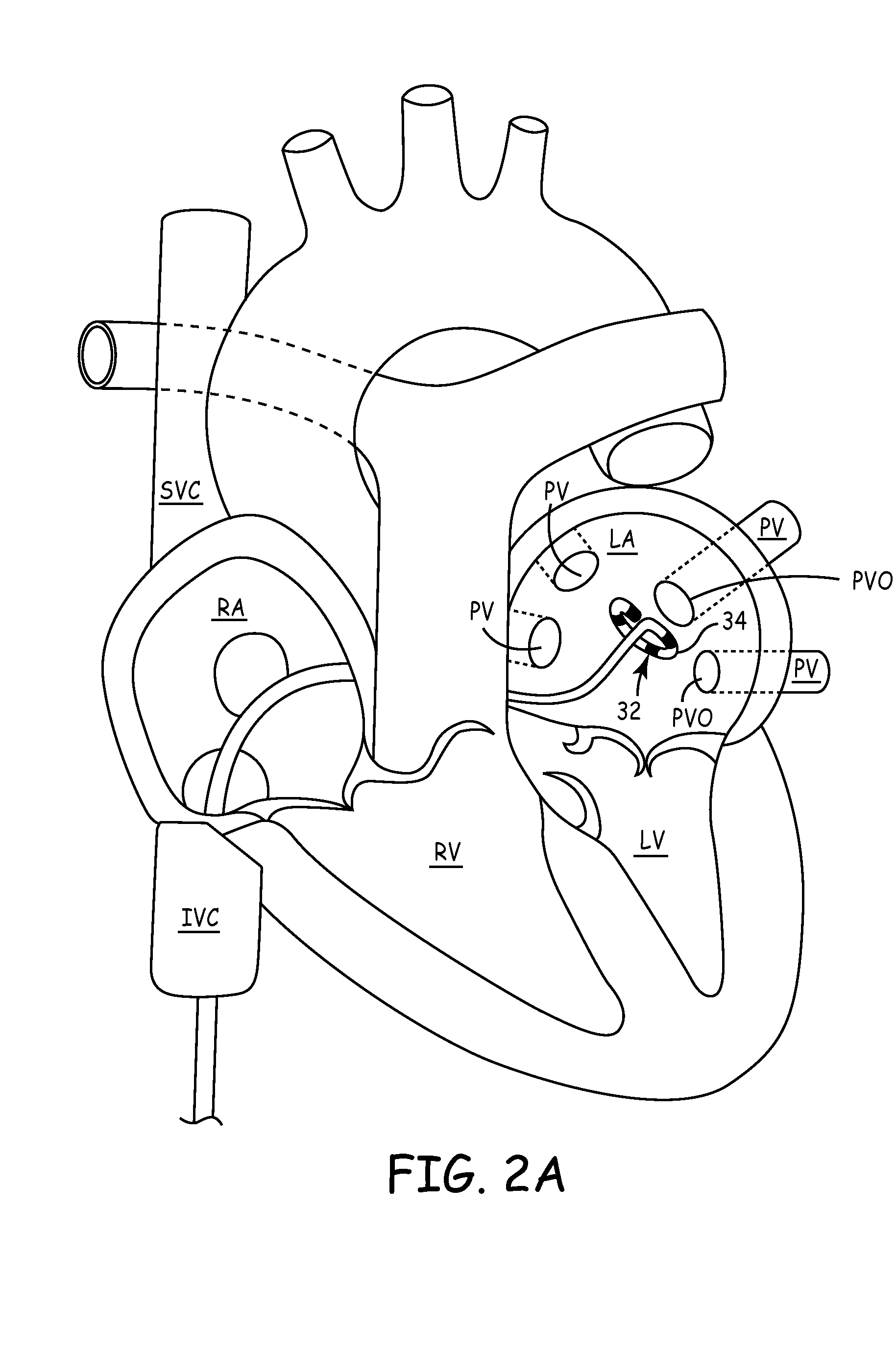

Ablation catheter assembly with radially decreasing helix and method of use

InactiveUS7771421B2Precise positioningUniform ablationElectrotherapyElectrocardiographyDistal portionCorneal ablation

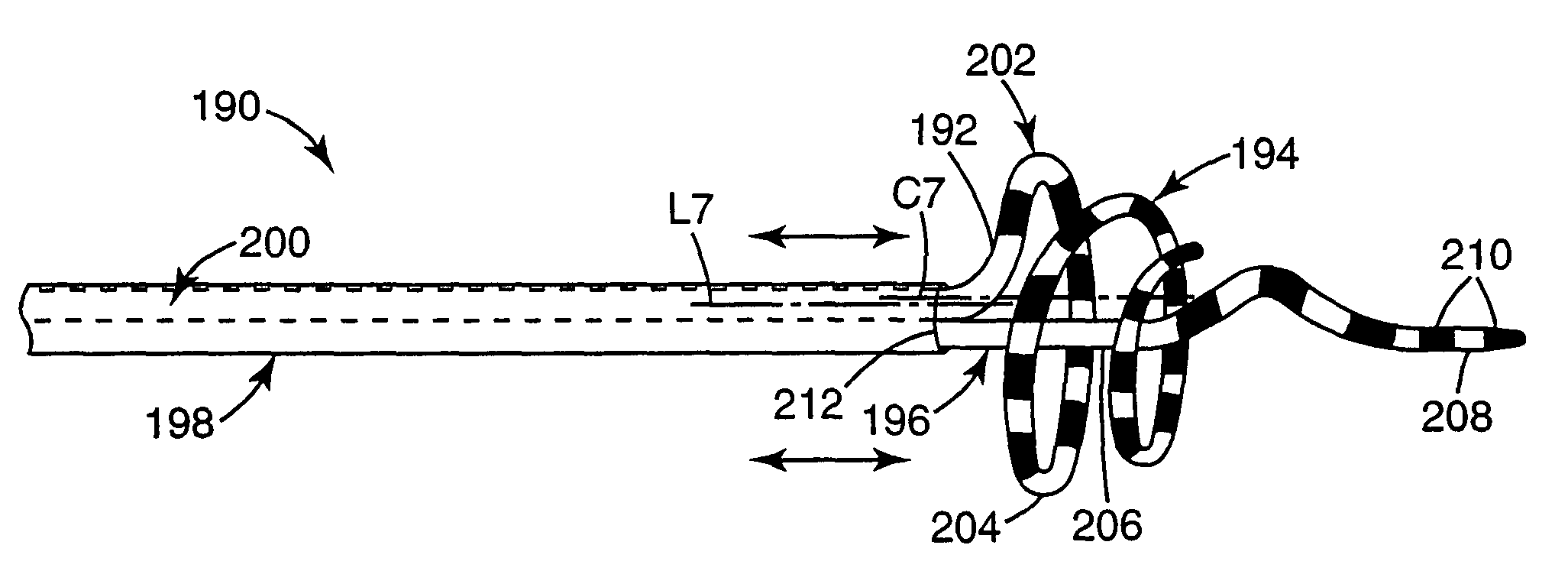

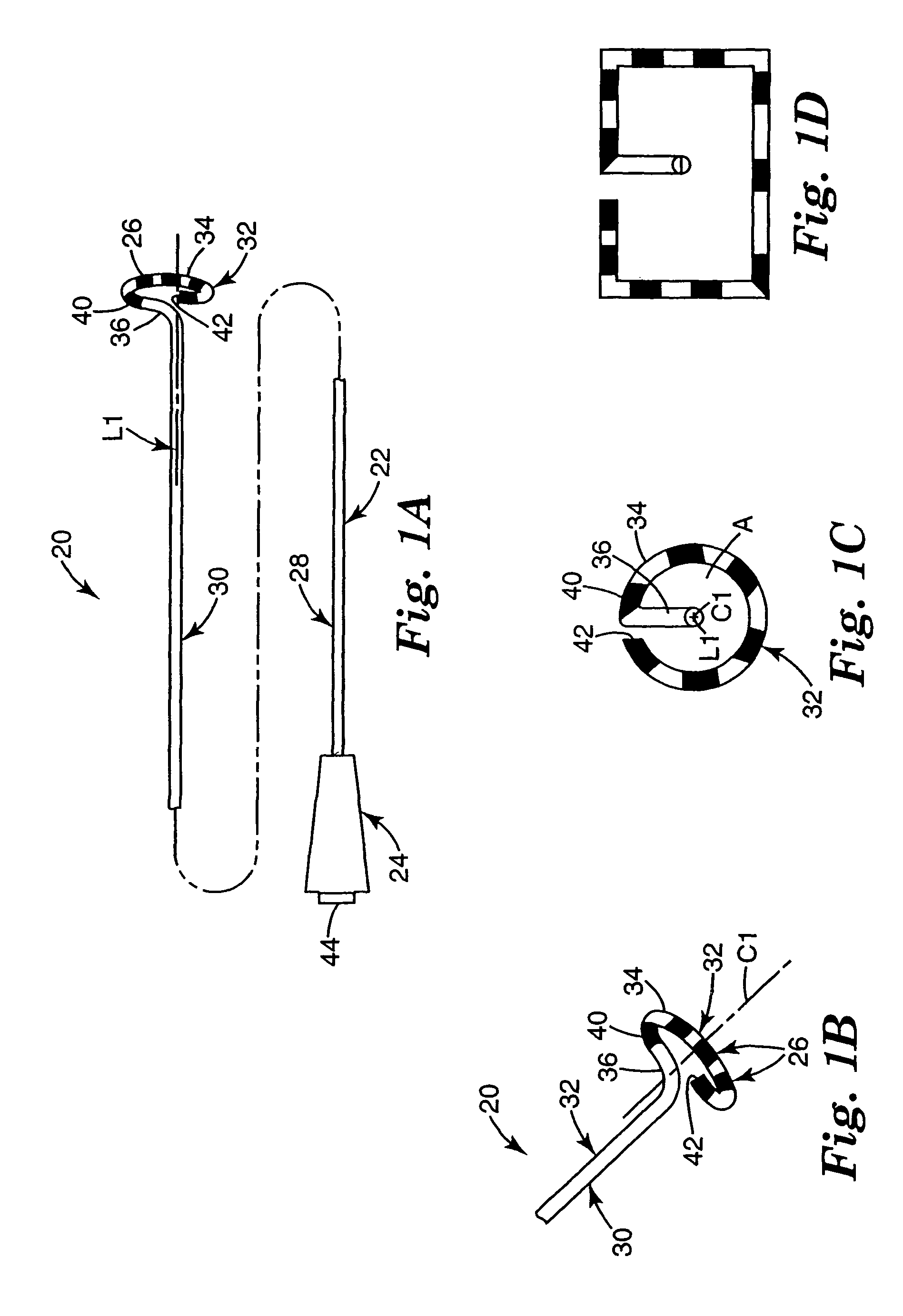

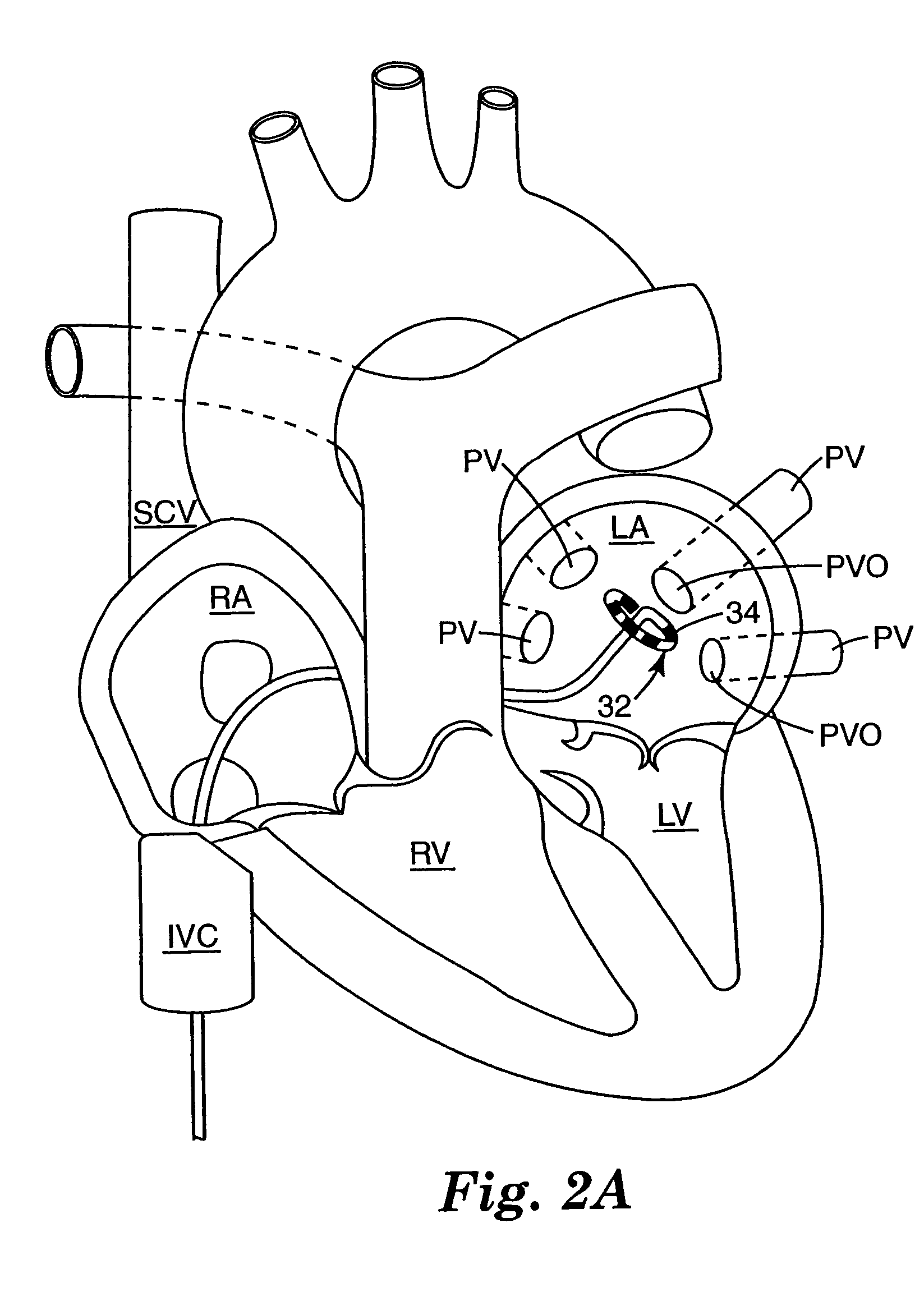

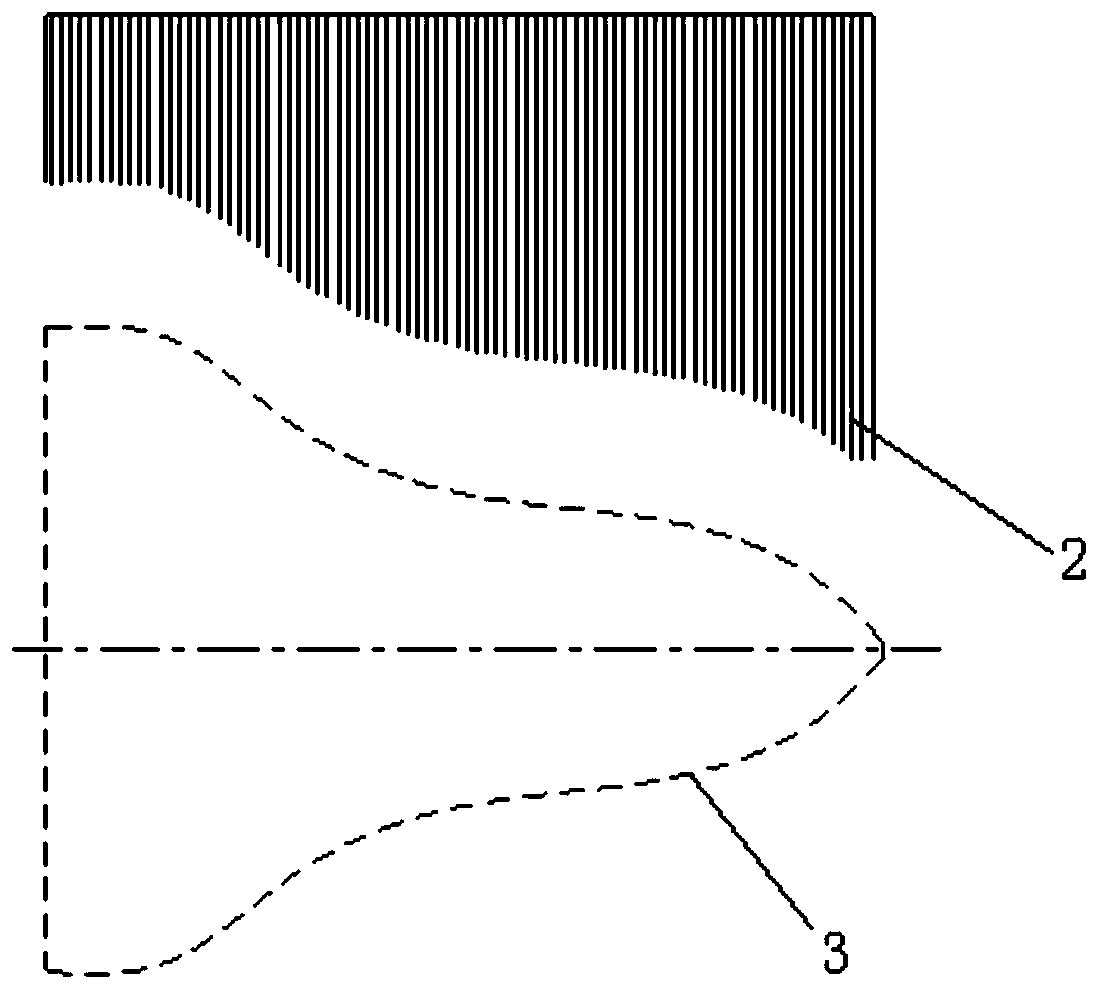

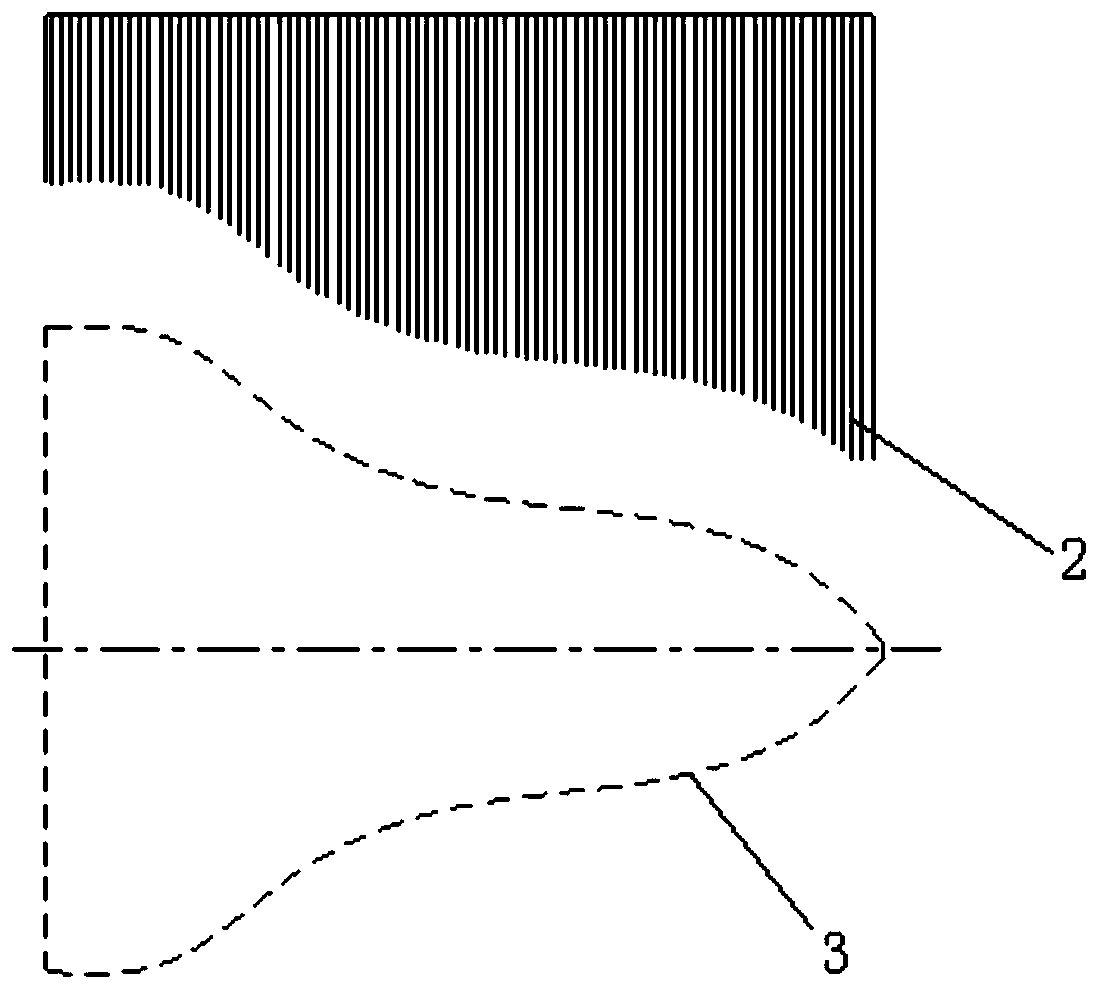

A catheter assembly for treatment of cardiac arrhythmia. The catheter assembly includes a catheter body and an ablative energy source. The catheter body includes a proximal portion, an intermediate portion, and a distal portion. The intermediate portion extends from the proximal portion and defines a longitudinal axis. The distal portion extends from the intermediate portion and includes an ablation section and a tip. The ablation section forms a loop defining a diameter greater than an outer dimension of a pulmonary vein ostium. The tip extends distally from the ablation section and is configured to locate a pulmonary vein. Finally, the ablative energy source is associated with the ablation section. With this configuration, upon activation of the energy source, the ablation section ablates a desired lesion pattern. In one preferred embodiment, the ablation section forms a distally decreasing radius helix, whereas the tip includes a relatively linear leader section. With this one preferred configuration, the tip readily locates a pulmonary vein and guides the ablation section to a seated relationship about a pulmonary vein ostium (or extra-ostial).

Owner:MEDTRONIC INC

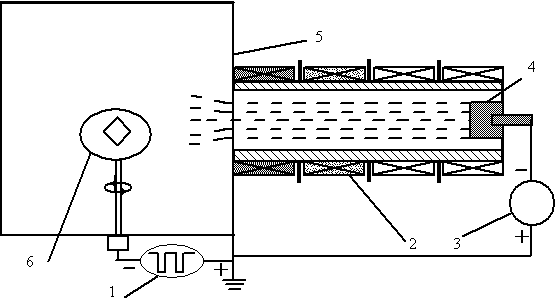

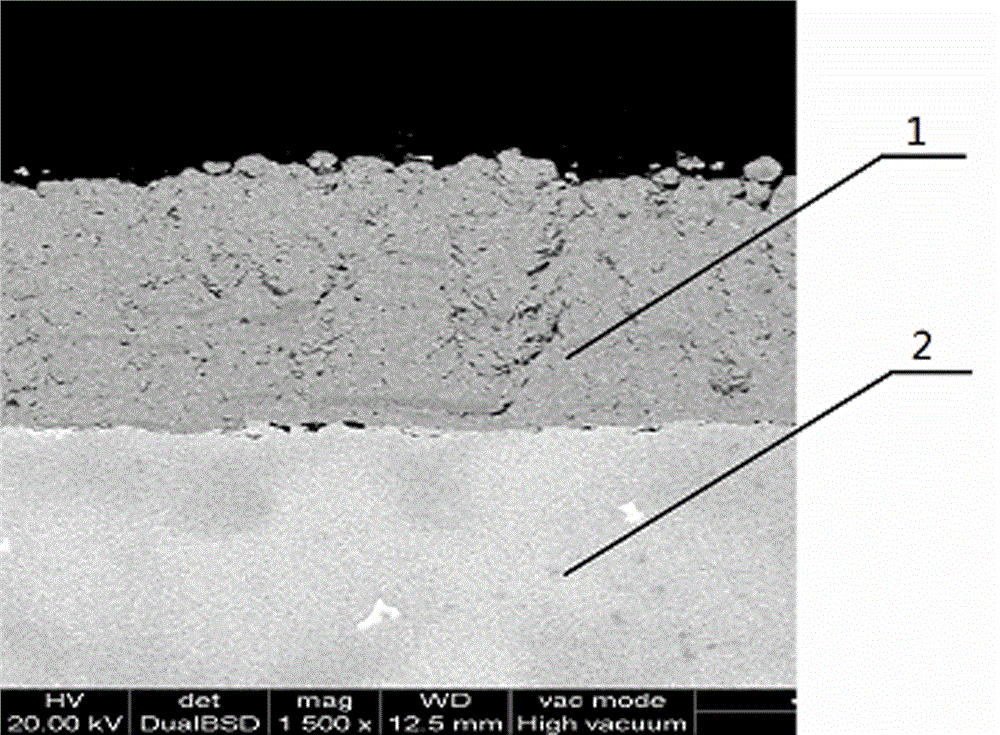

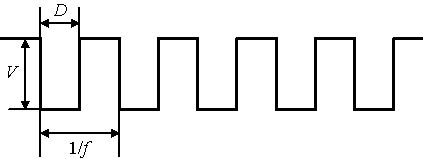

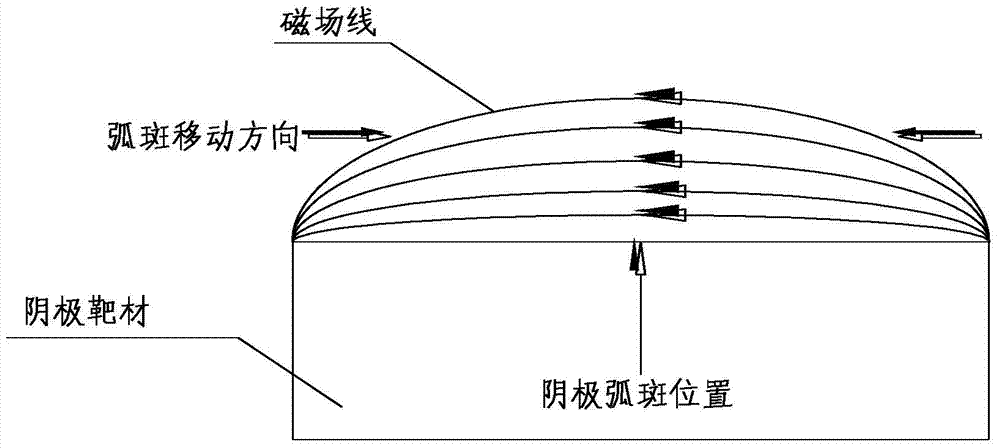

Multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method

ActiveCN103276362ALow ionization rateLow pulse duty cycle to generate high ionization rateVacuum evaporation coatingSputtering coatingPlasmaMagnetic filtration

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Ablation catheter assembly with radially decreasing helix and method of use

InactiveUS8257351B2Precise positioningUniform ablationElectrocardiographySurgical instruments for heatingVeinDistal portion

A catheter assembly for treatment of cardiac arrhythmia. The catheter assembly includes a catheter body and an ablative energy source. The catheter body includes a proximal portion, an intermediate portion, and a distal portion. The intermediate portion extends from the proximal portion and defines a longitudinal axis. The distal portion extends from the intermediate portion and includes an ablation section and a tip. The ablation section forms a loop defining a diameter greater than an outer dimension of a pulmonary vein ostium. The tip extends distally from the ablation section and is configured to locate a pulmonary vein. Finally, the ablative energy source is associated with the ablation section. With this configuration, upon activation of the energy source, the ablation section ablates a desired lesion pattern. In one preferred embodiment, the ablation section forms a distally decreasing radius helix, whereas the tip includes a relatively linear leader section. With this one preferred configuration, the tip readily locates a pulmonary vein and guides the ablation section to a seated relationship about a pulmonary vein ostium (or extra-ostial).

Owner:MEDTRONIC INC

Ablation Catheter Assembly with Radially Decreasing Helix and Method of Use

InactiveUS20100204692A1Precise positioningUniform ablationElectrocardiographySurgical instruments for heatingVeinDistal portion

A catheter assembly for treatment of cardiac arrhythmia. The catheter assembly includes a catheter body and an ablative energy source. The catheter body includes a proximal portion, an intermediate portion, and a distal portion. The intermediate portion extends from the proximal portion and defines a longitudinal axis. The distal portion extends from the intermediate portion and includes an ablation section and a tip. The ablation section forms a loop defining a diameter greater than an outer dimension of a pulmonary vein ostium. The tip extends distally from the ablation section and is configured to locate a pulmonary vein. Finally, the ablative energy source is associated with the ablation section. With this configuration, upon activation of the energy source, the ablation section ablates a desired lesion pattern. In one preferred embodiment, the ablation section forms a distally decreasing radius helix, whereas the tip includes a relatively linear leader section. With this one preferred configuration, the tip readily locates a pulmonary vein and guides the ablation section to a seated relationship about a pulmonary vein ostium (or extra-ostial).

Owner:MEDTRONIC INC

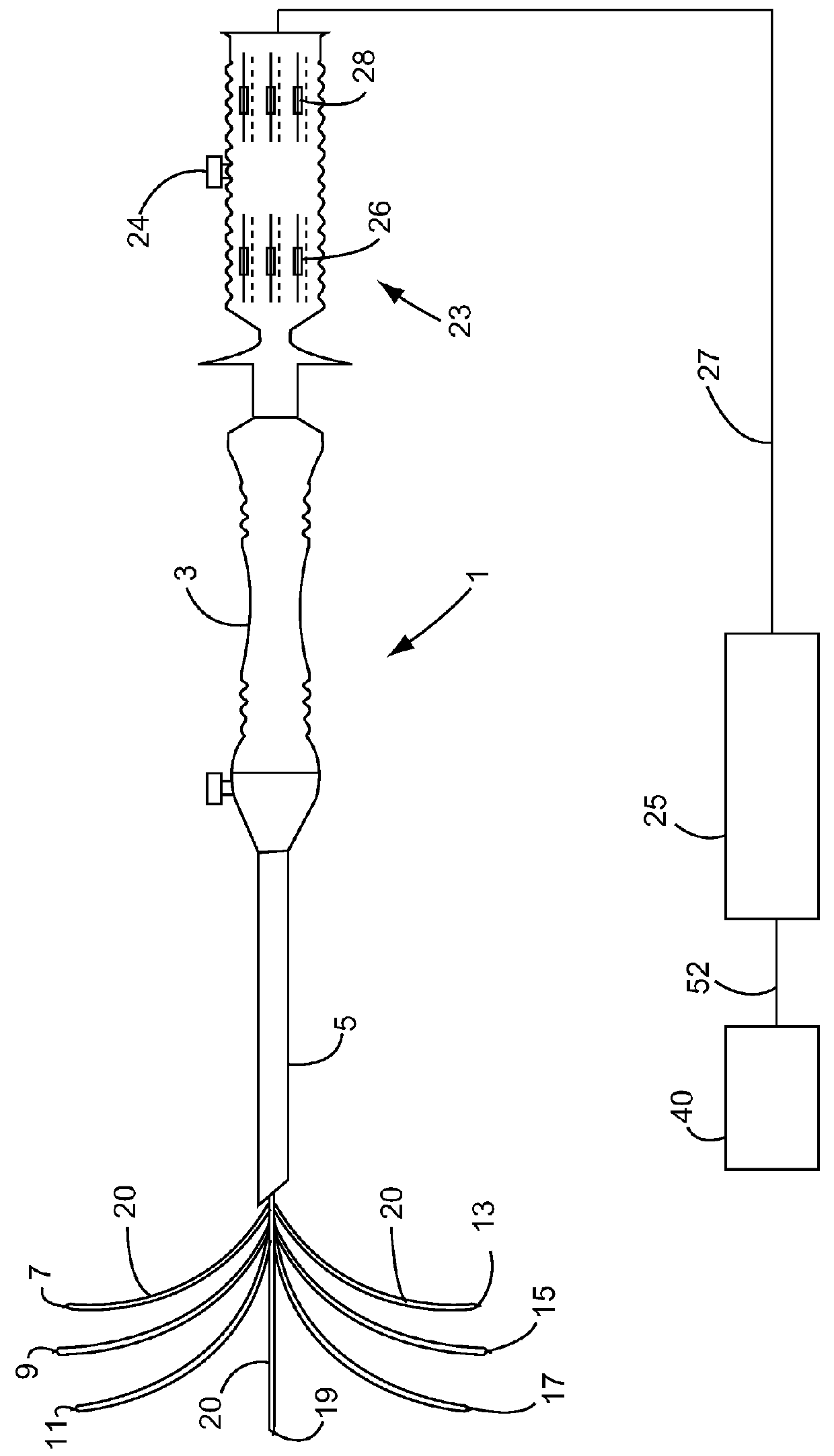

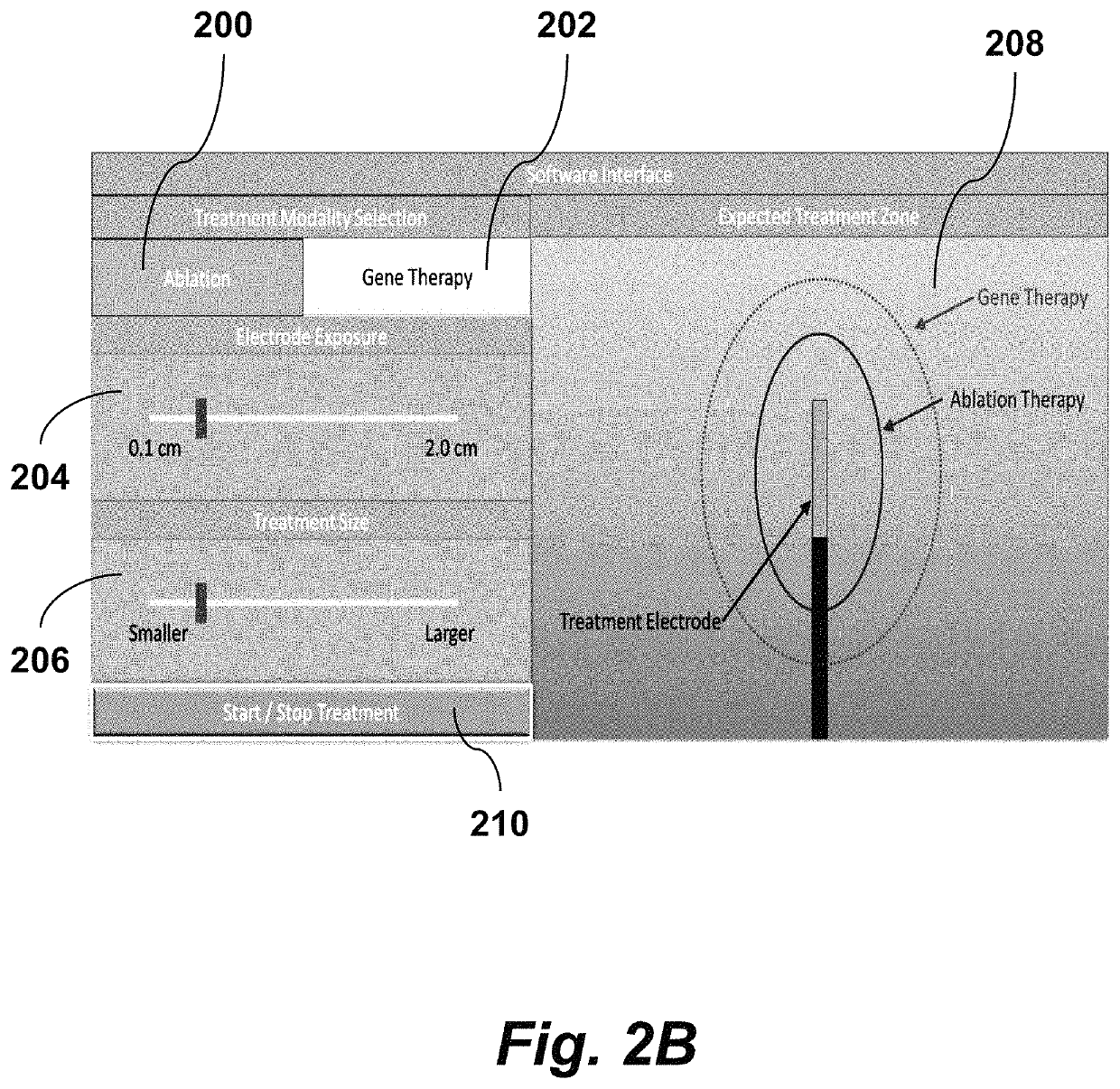

Multi-electrode energy delivery device and method of using the same

ActiveUS9339328B2Energy dispersion is less-efficientUniform ablationSurgical needlesSurgical instruments for heatingElectrical resistance and conductanceIrreversible electroporation

An energy delivery device for treating a patient includes a probe body and a plurality of elongate electrode elements that extend radially away from the probe body when deployed into tissue of the patient. The electrode elements are adapted to receive electrical treatment energy such as irreversible electroporation (IRE) pulses from an energy source. In one embodiment, each electrode element has a longitudinally varying electrical resistance at the electrode-tissue interface along the electrode so as to provide a uniform electric field along the length of the electrode. The uniform electric field allows a more uniform ablation of tissue within a treatment zone.

Owner:ANGIODYNAMICS INC

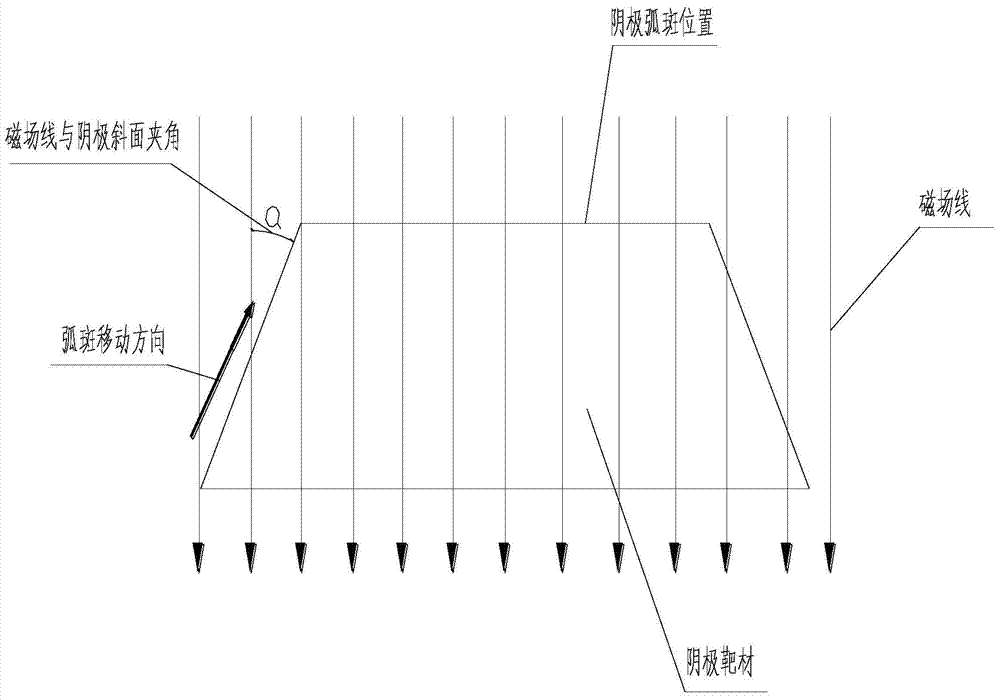

Preparation method of MCrAlY high temperature protection coating

InactiveCN106756819AImprove bindingStable jobVacuum evaporation coatingSputtering coatingSuperalloyHigh-temperature corrosion

The invention relates to a preparation method of a MCrAlY high temperature protection coating. The preparation method sequentially comprises the following steps that before plating, a base material is subject to surface scale removal and washing treatment; after vacuumizing is carried out to 5.0*10<-3> Pa, the in-furnace pressure intensity is 1.0 Pa to 3.0 Pa, the Ar gas flow is 200 sccm to 600 sccm, the back bias voltage is 500 V to 1000 V, the time is 30 min to 60 min, and glow discharge ion washing is carried out; and deposition of the MCrAlY coating is carried out, wherein the in-furnace pressure intensity is 0.8 Pa to 2.0 Pa, the Ar gas flow is 300 sccm to 500 sccm, the arc target current is 60 A to 120 A, according electromagnetic parameters, the voltage is 8 V to 50 V, the frequency is 1.0 Hz to 33.3 Hz, the permanent magnet parameter is 5000 Gs to 15000Gs, and the back bias voltage is 50 V to 200 V. According to the method, the protection coating which is good in film / base bonding force, compact in film layer, small in surface roughness, resistant to high temperature oxidation and excellent in heat corrosion resistance can be prepared on the high temperature alloy surface. The method can solve the problem that traditional arc ion plating target using rate is low, the aggregation state arc spot drop large particles are achieved, and the method is suitable for industrial production.

Owner:GUANGDONG INST OF NEW MATERIALS

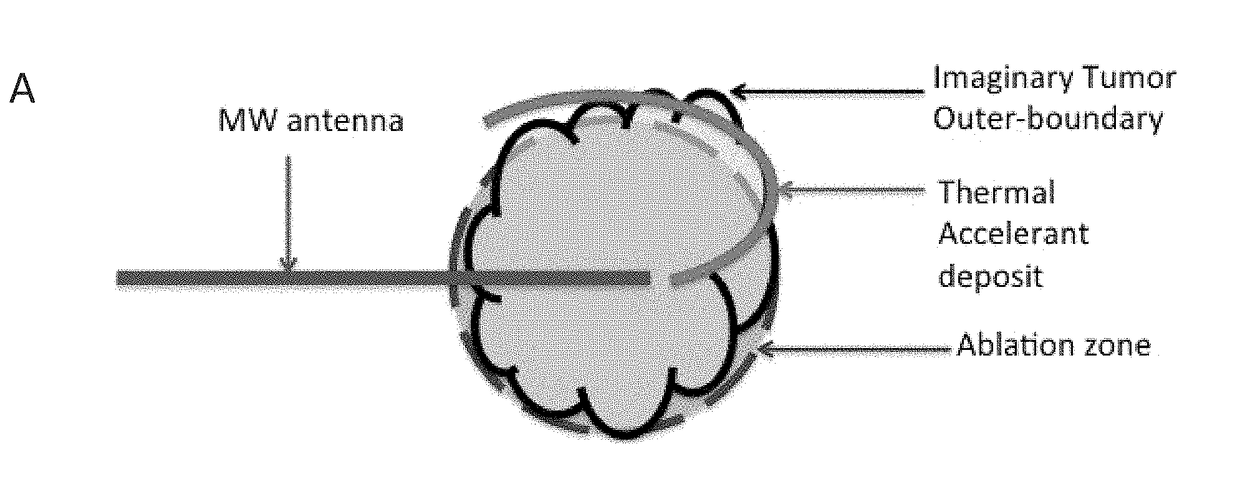

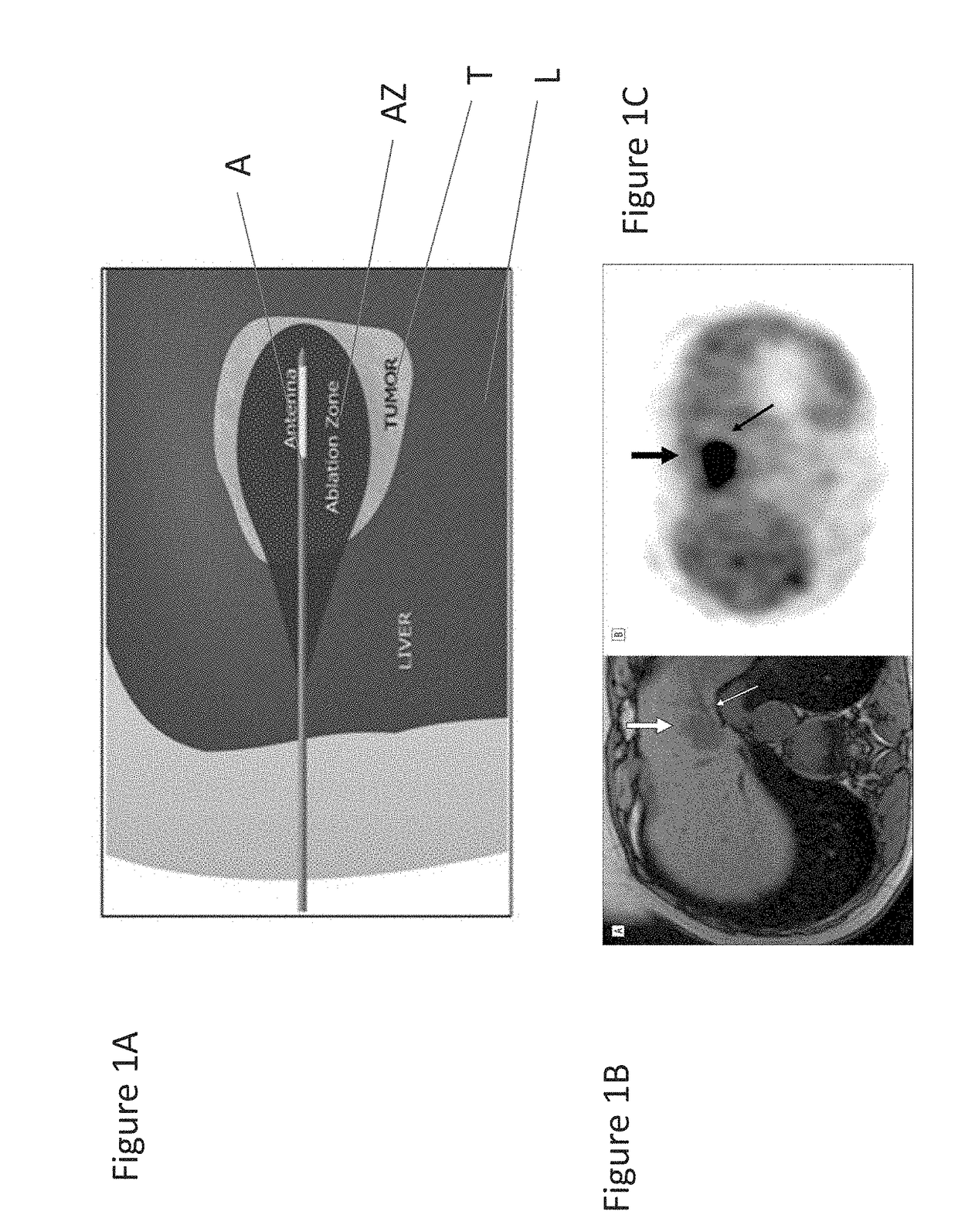

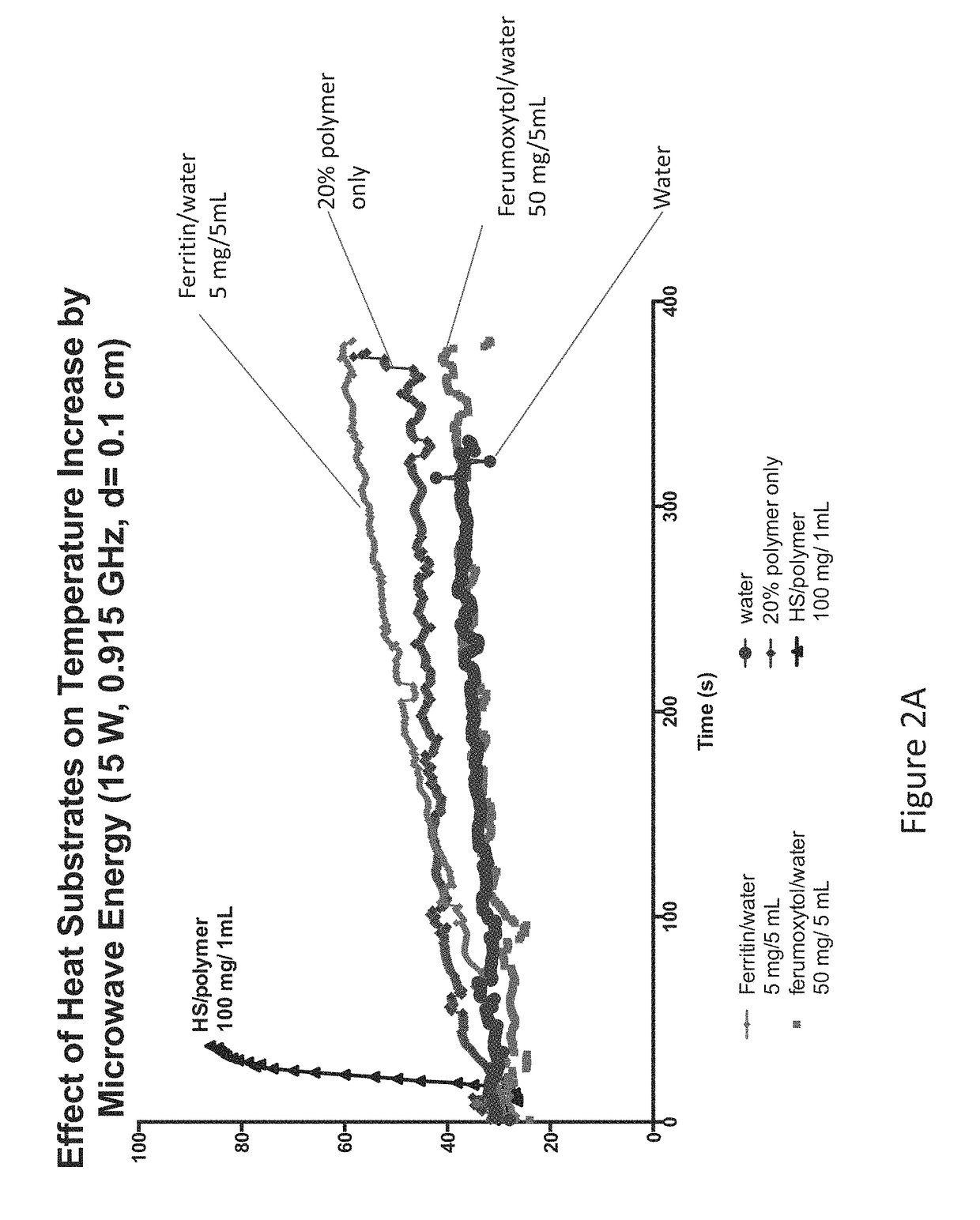

Thermal accelerant compositions and methods of use

ActiveUS20170182165A1Efficient heatingImprove completenessElectrotherapyEnergy modified materialsMicrowaveHeat sensitive

A thermal accelerant is delivered to a tissue site and localized to modulate the shape, extent or other characteristic of RF or microwave-induced hyperthermic tissue ablation. The accelerant may be provided via an image-guided hand piece or via a lumen added to a microwave antenna, and promotes faster heating, more complete ablation and / or a more extensive treatment region to reduce recurrence of treated cancers, overcoming natural limitations, variations in tissue response and drop-off or thermal loss away from the antenna. The accelerant is delivered as a low-viscosity but heat sensitive fluid, and is fixed in place to provide regions of preferential absorption or heating. Shorter exposure times to heat the far field may allow survival of vulnerable tissue such as vessels, and multiple antennae may be used for effective treatment of irregular or large tumors.

Owner:RHODE ISLAND HOSPITAL +1

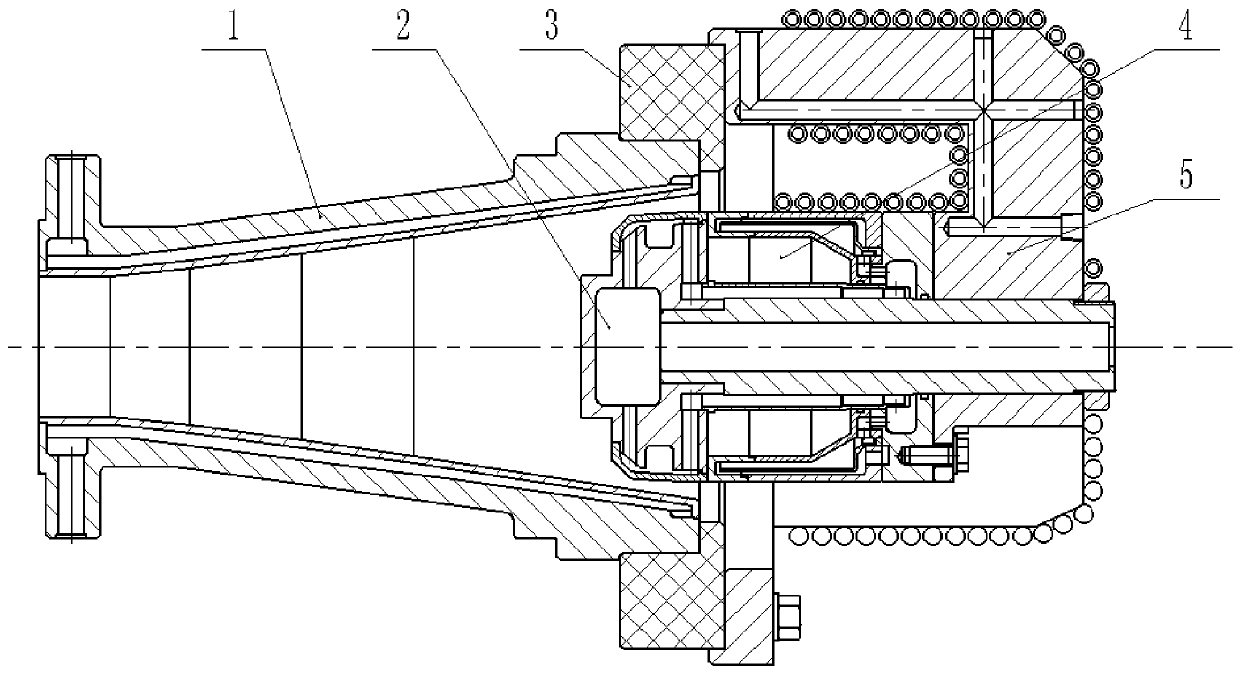

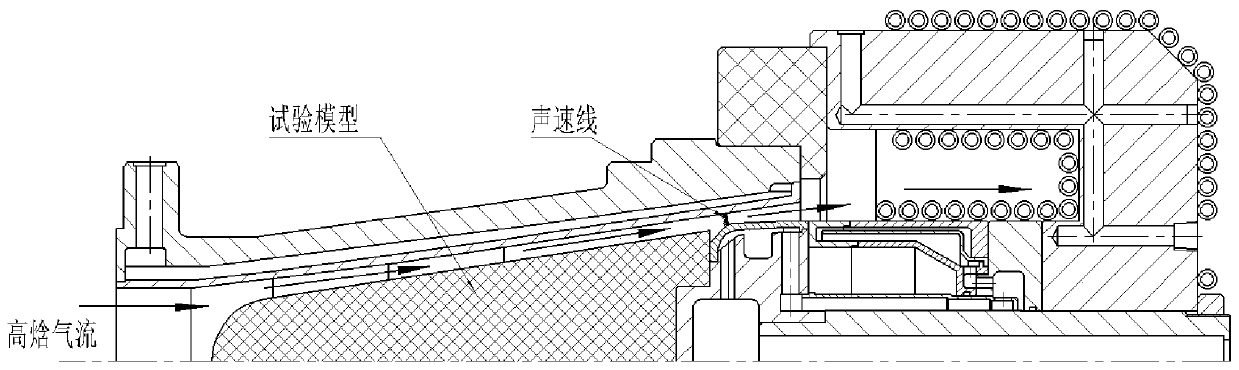

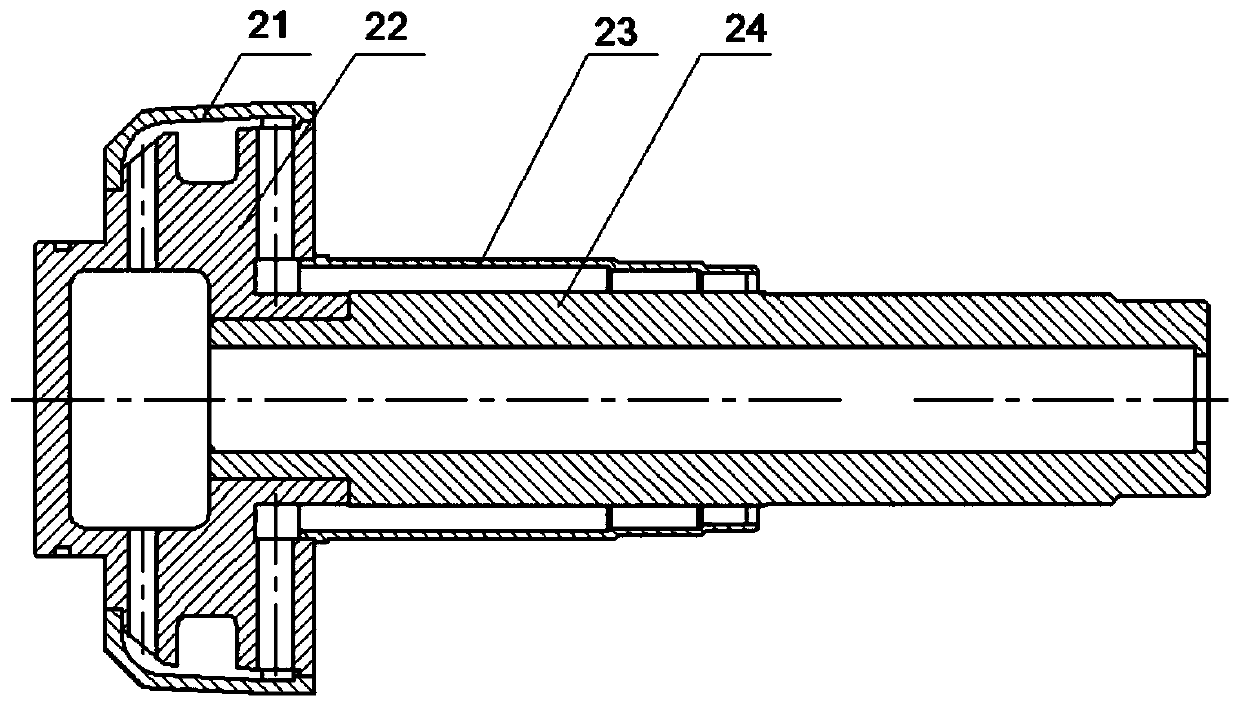

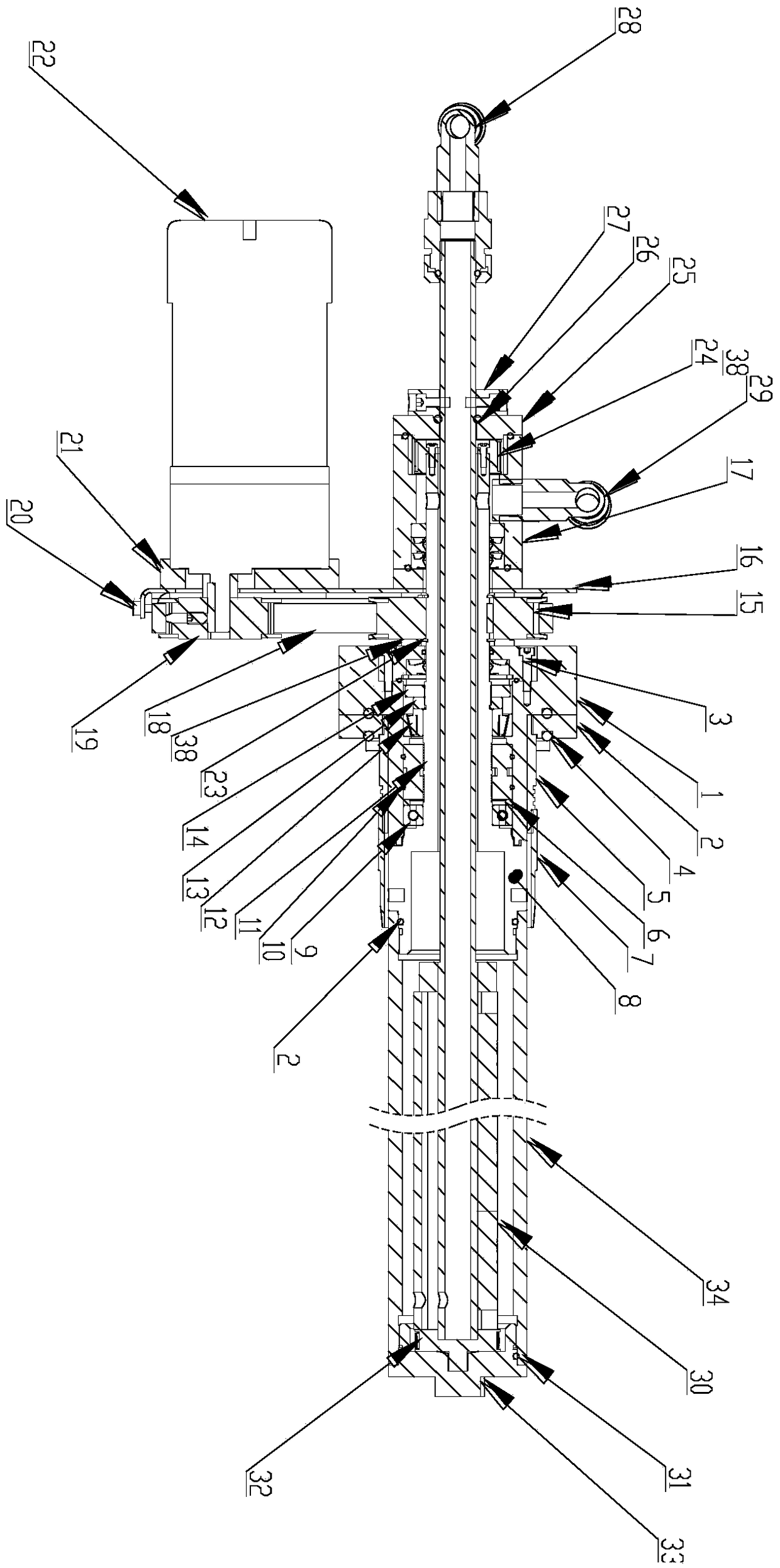

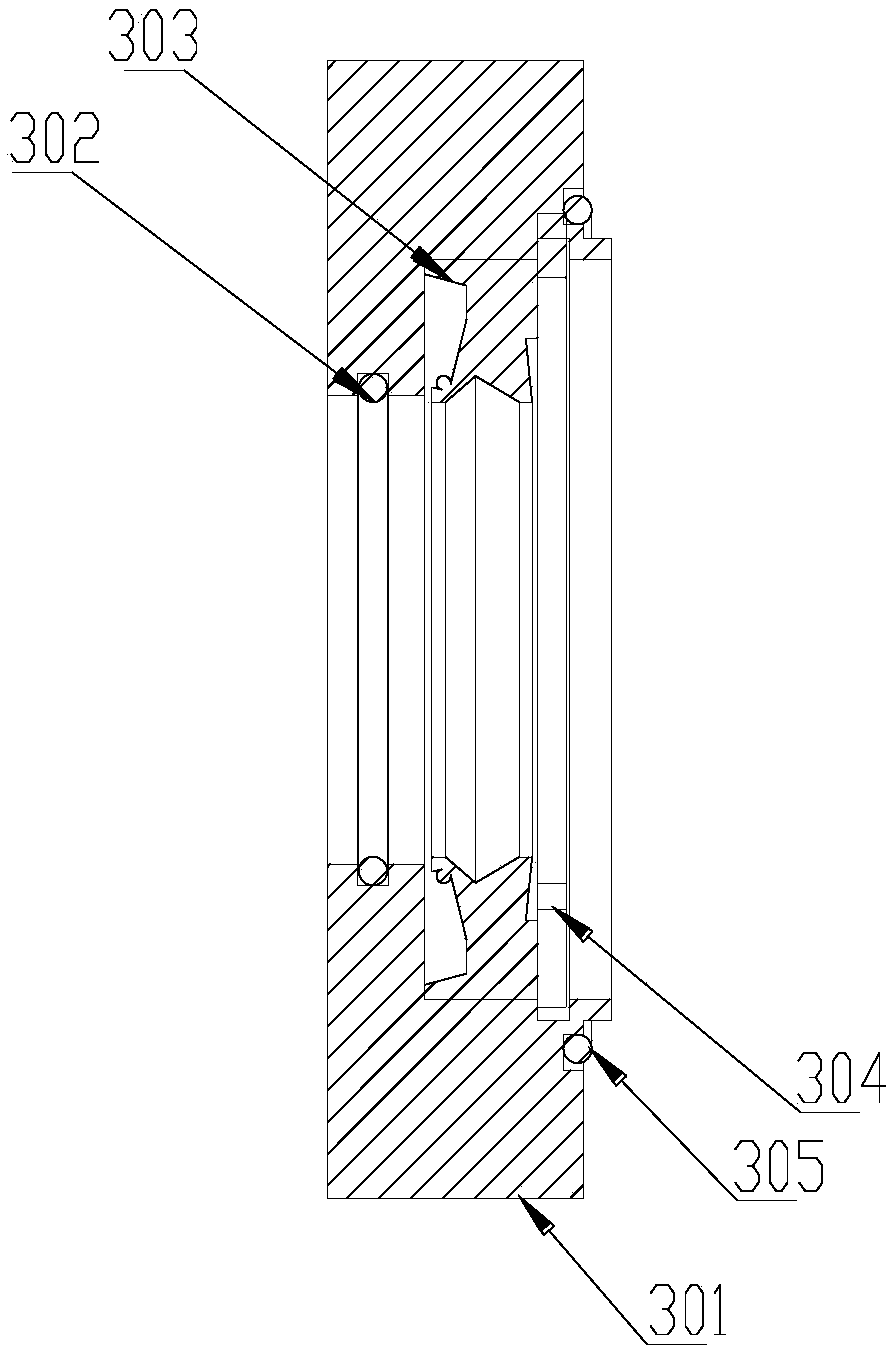

Subsonic-speed ladle cover ablation test device under high-entropy condition

PendingCN110712764AEnsure ablationReduce heating areaAircraft components testingEngineeringStructural engineering

The invention discloses a subsonic-speed ladle cover ablation test device under high-entropy condition. The device comprises a ladle cover spraying pipe, a throat way support rod, a transfer flange, atransfer section and a model bracket. The ladle cover spraying pipe and the model bracket are fixed on the transfer flange. The throat way support rod is connected with the model bracket by the transfer section; and a throat way part of the throat way support rod is positioned in the ladle cover spraying pipe. The overlap with the center axis of the ladle cover spraying pipe is guaranteed throughconnection between the throat way support rod and the transfer section. During testing, a test model is mounted on the throat way support rod, an annular channel between the outer surface of the testmodel and the inner surface of the ladle cover spraying pipe is a high-entropy airflow channel, and the flowing of air currents in the ladle cover spraying pipe is subsonic-speed flowing. The devicecan be applied to aerospace pneumatic thermal protection ground simulation tests in high-entropy airflow state.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

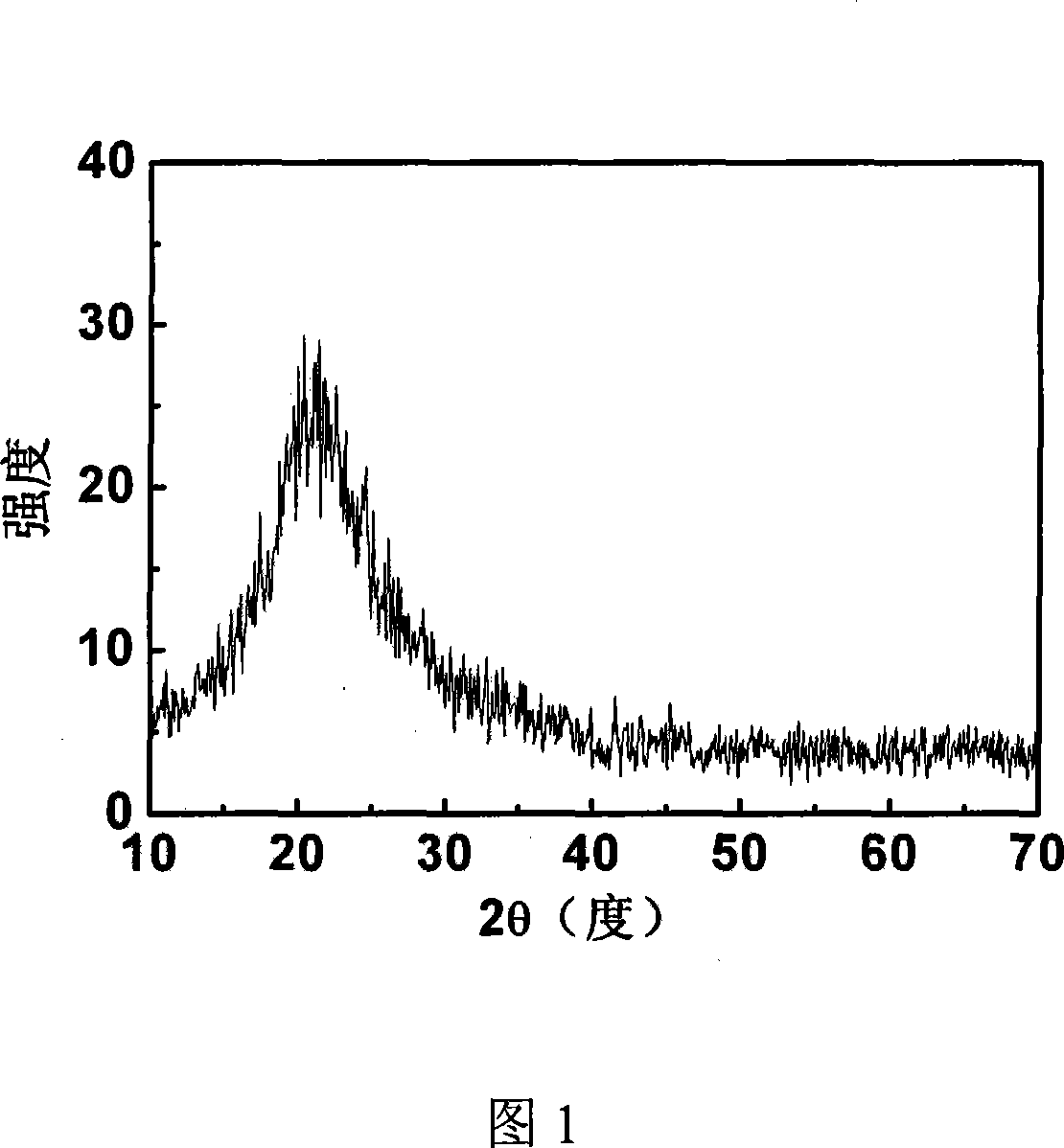

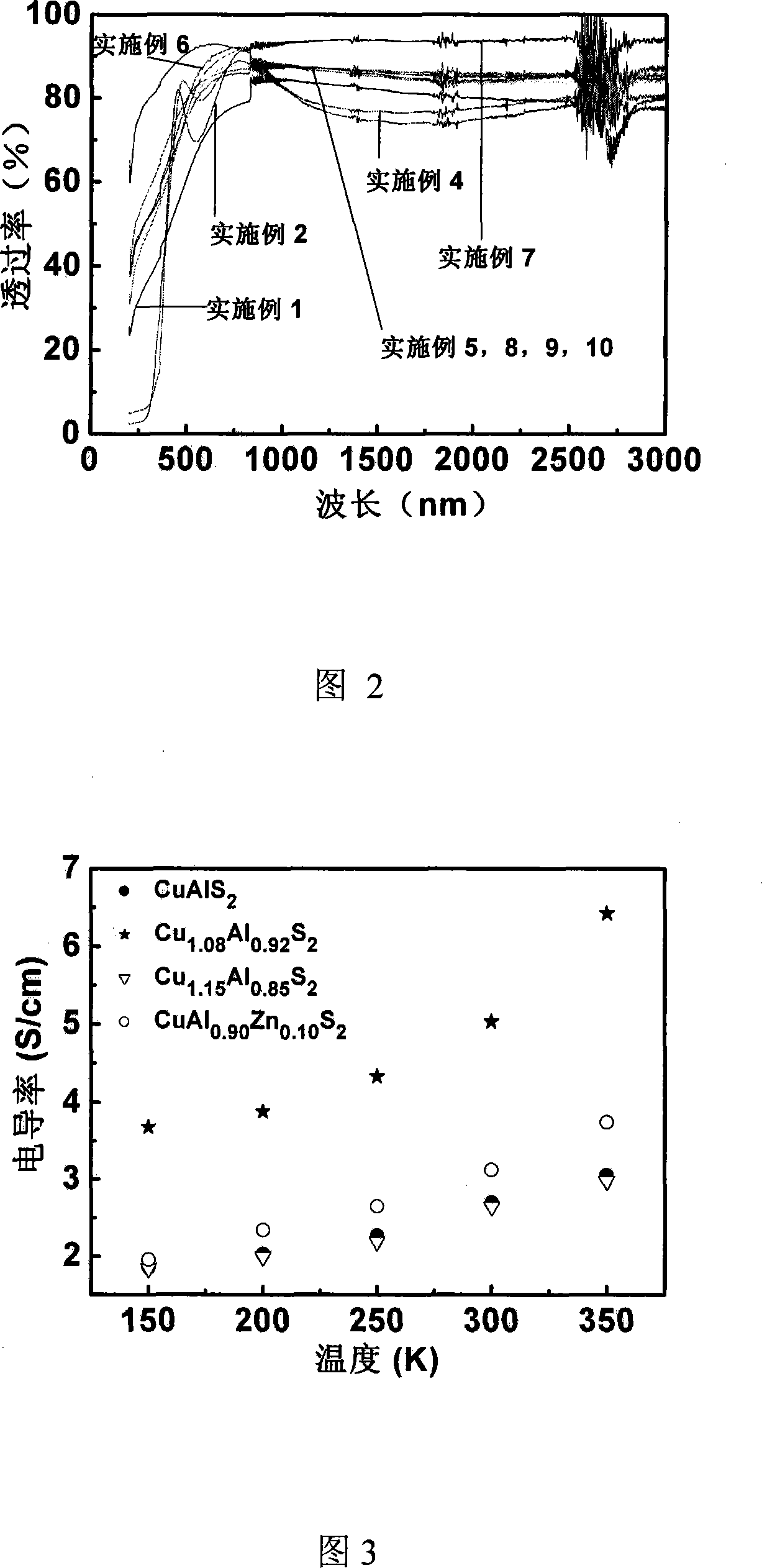

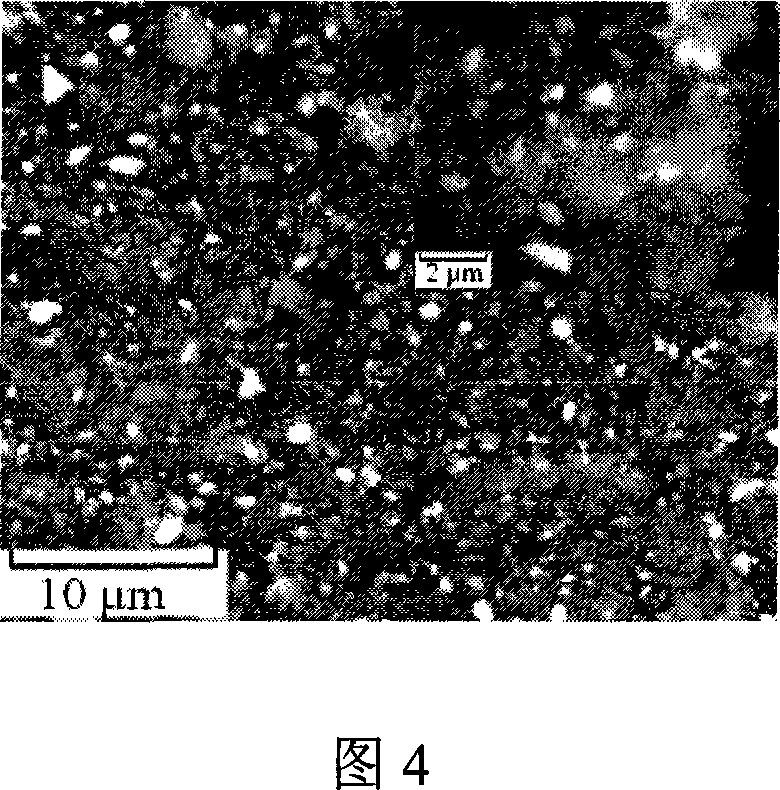

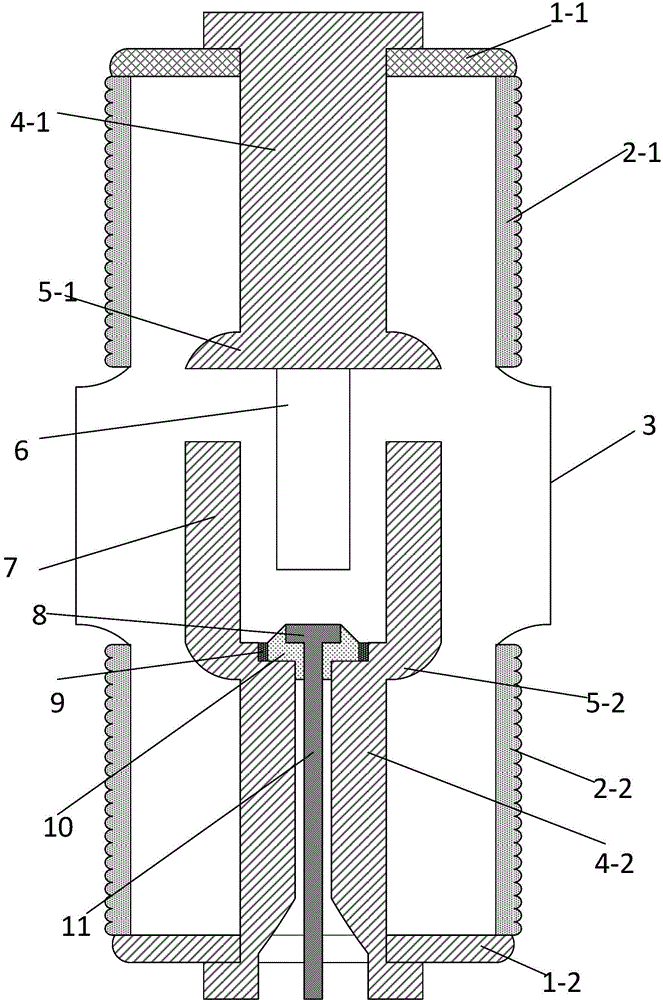

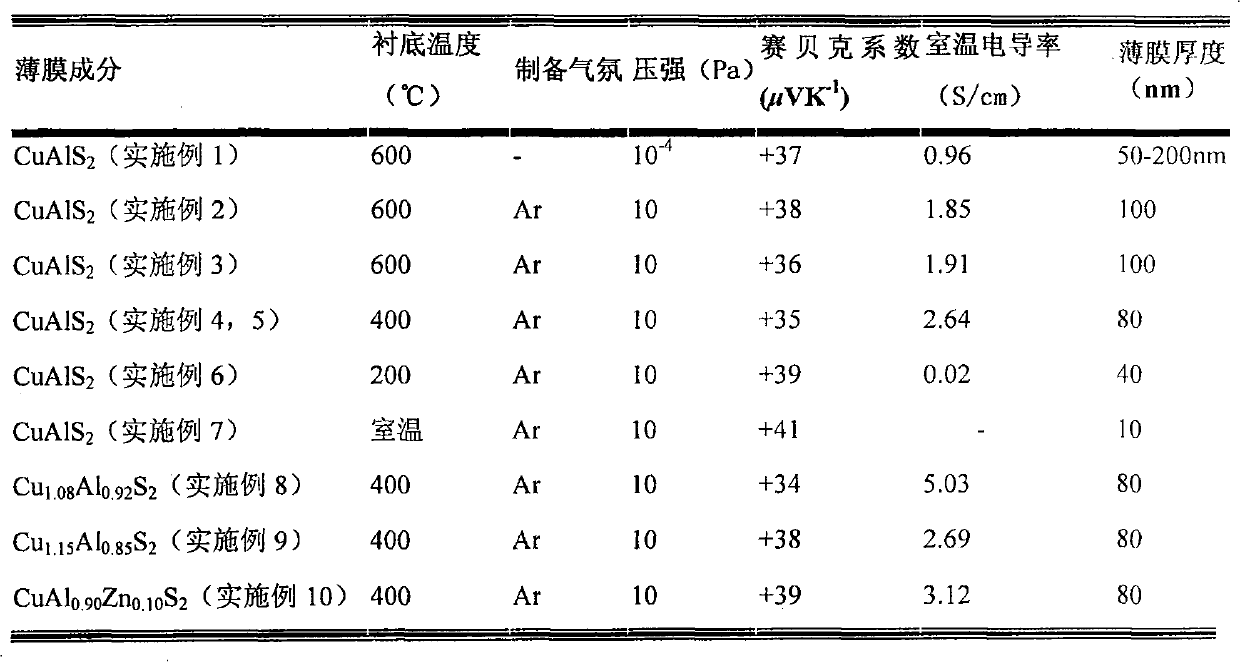

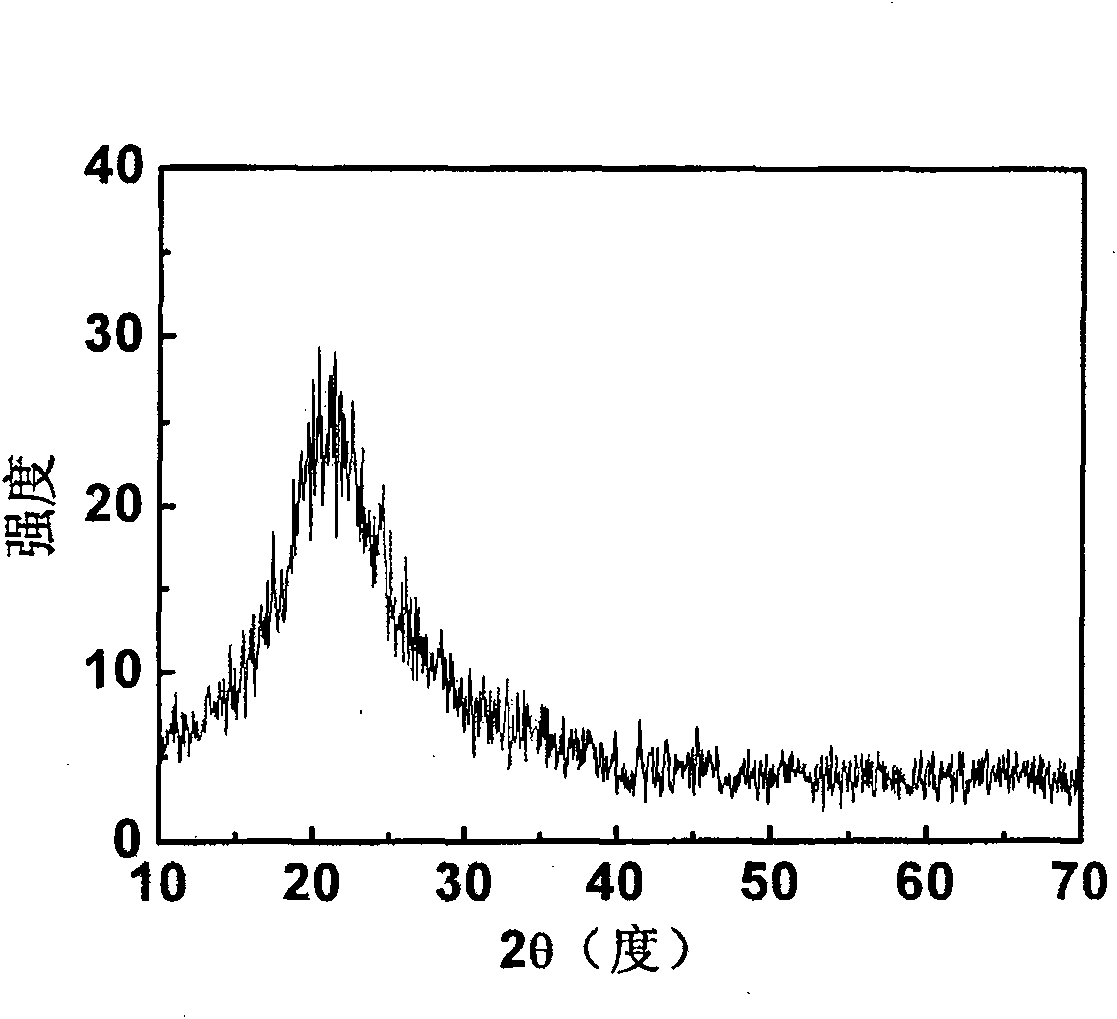

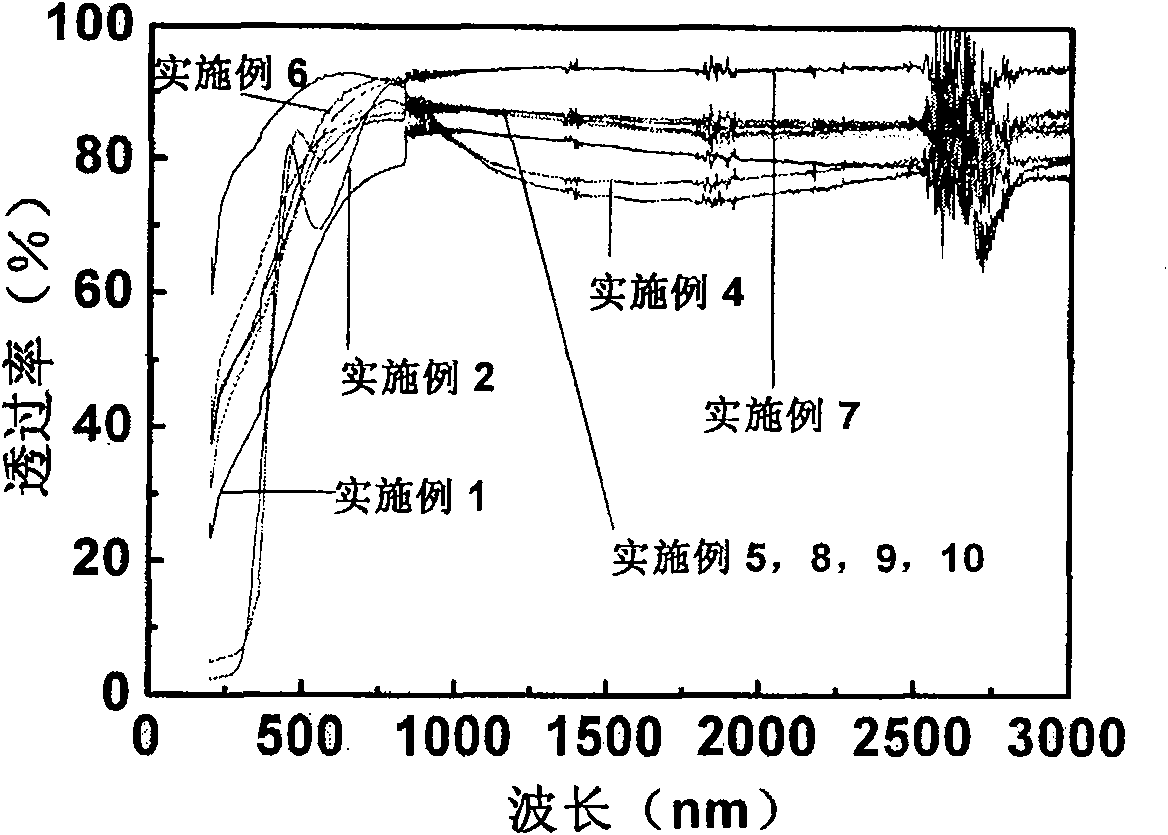

Method for preparing p-type copper-sulfur-containing transparent conductor film

ActiveCN101135040AUniform ablationVacuum evaporation coatingSputtering coatingElectrically conductiveSulfur containing

The present invention is pulse laser deposition (PLD) process for preparing p-type compound CuAlS2 in chalcopyrite structure and transparent doped conducting film. The PLD process prepares p-type compound CuAlS2 or doped film on the substrate of quartz glass, common glass or Si chip by using the compound block obtained through solid phase reaction and SPS sintering or no-pressure sintering as the target and under proper conditions of atmospheric pressure, substrate temperature, and laser strength and frequency. The prepared CuAlS2 film has p-type conductivity, high conductivity, high visible light transparency and other excellent optoelectronic performance, and may find its broad application foreground in electronics and optoelectronics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

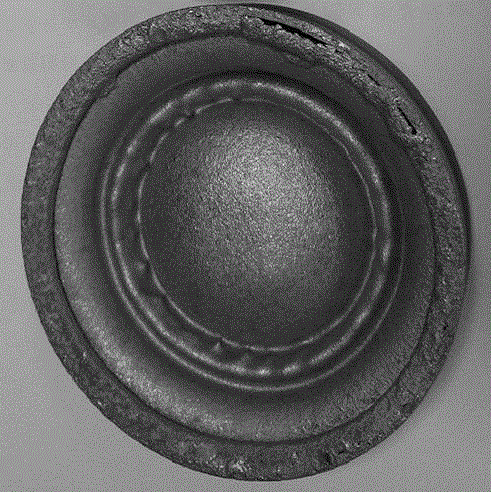

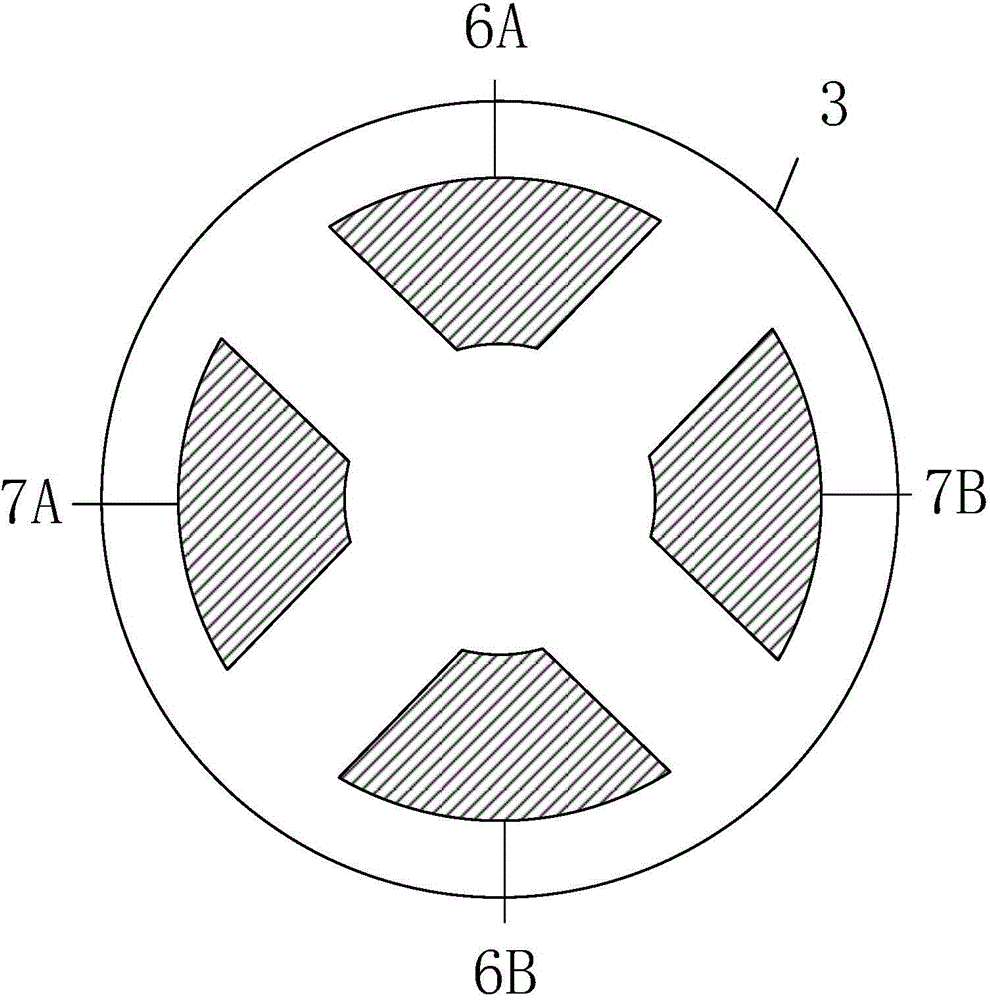

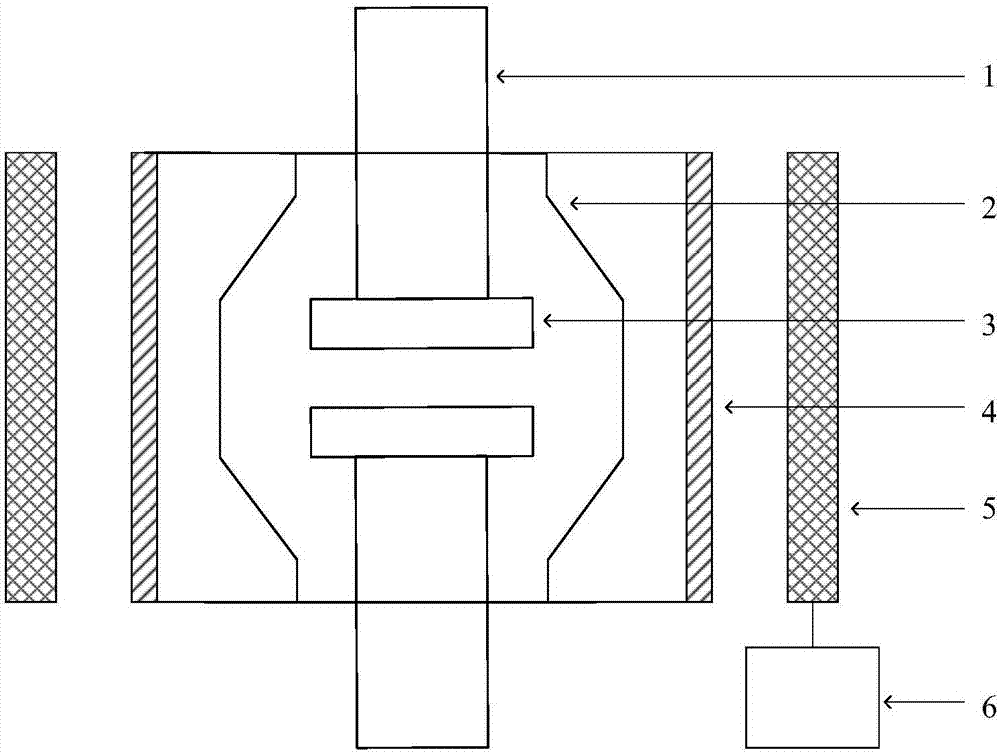

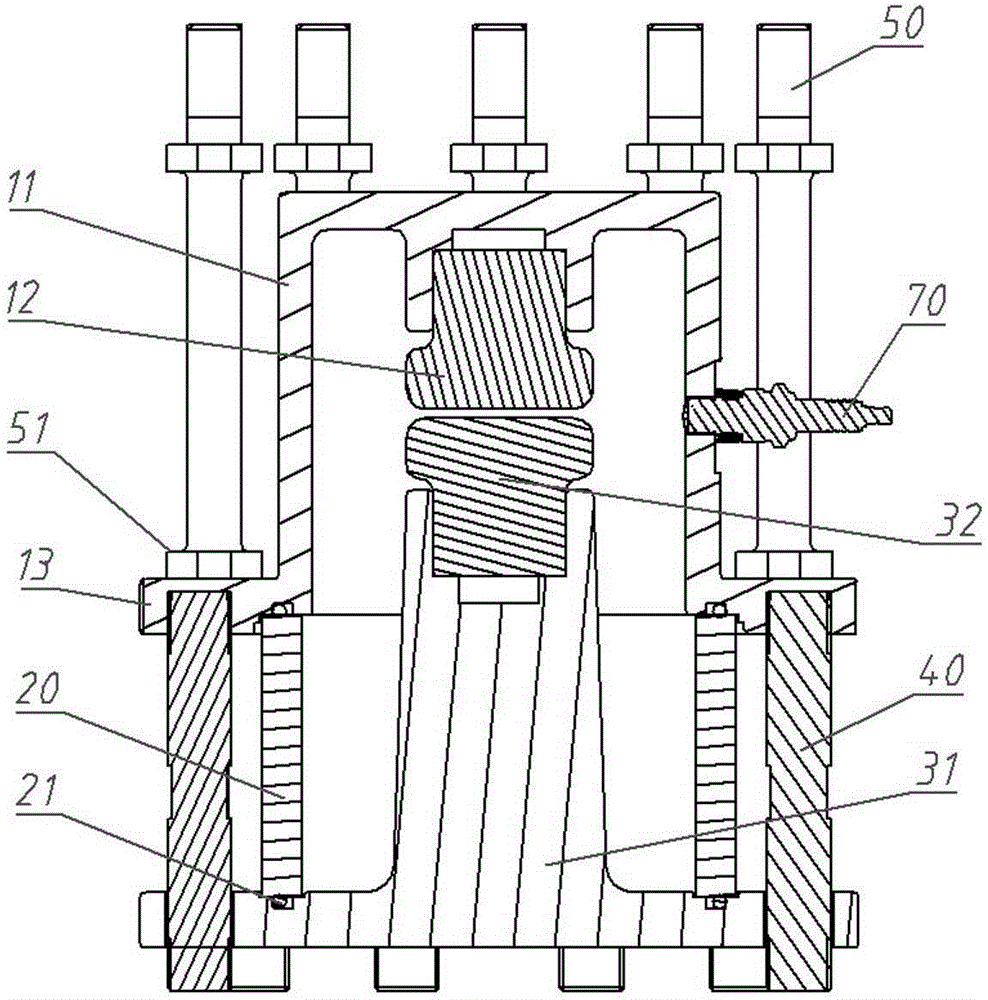

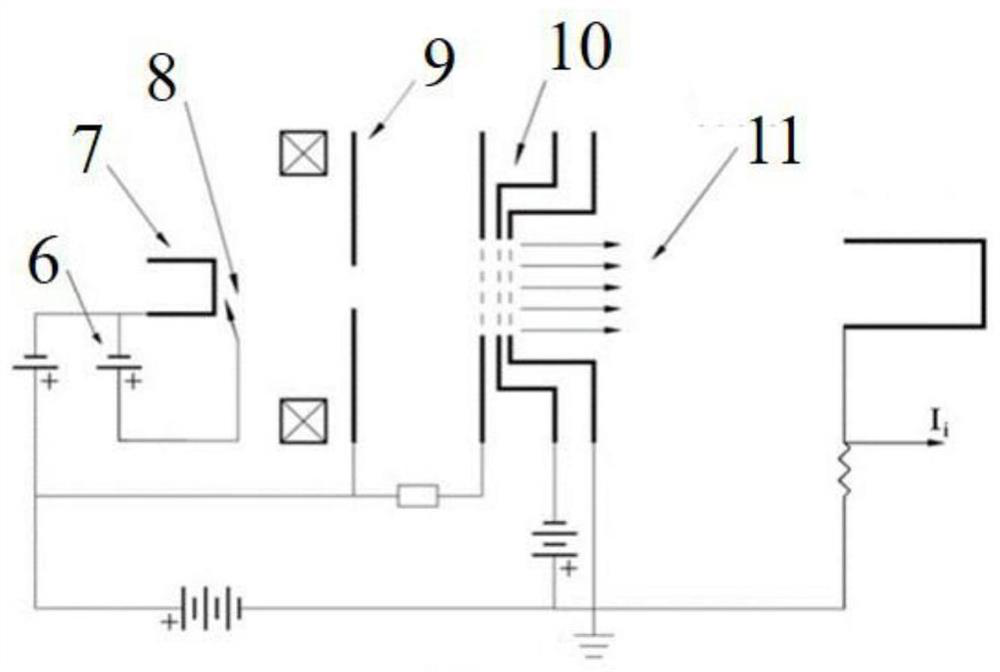

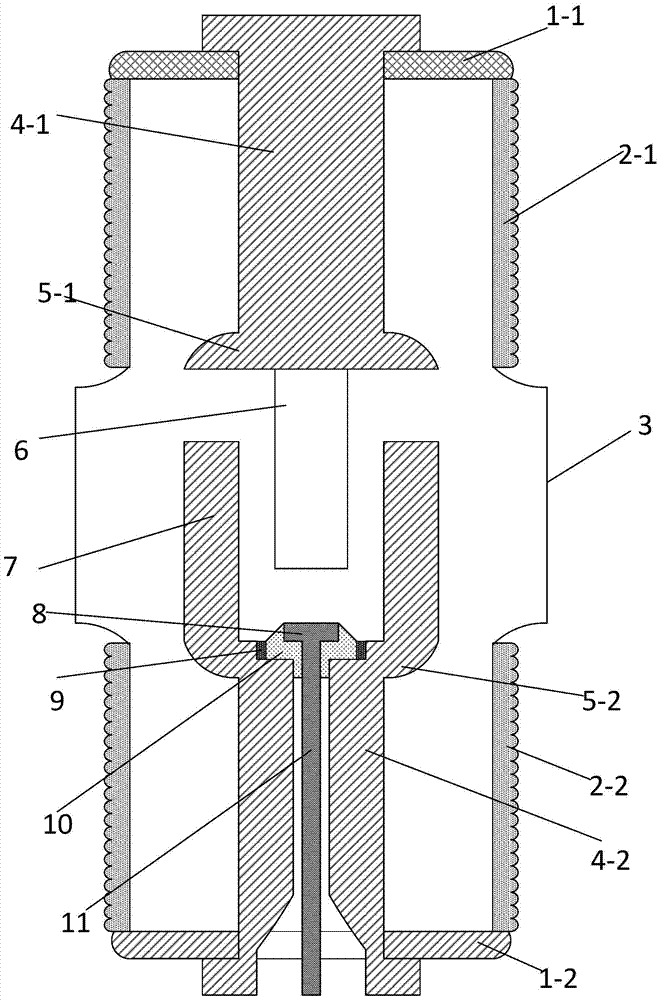

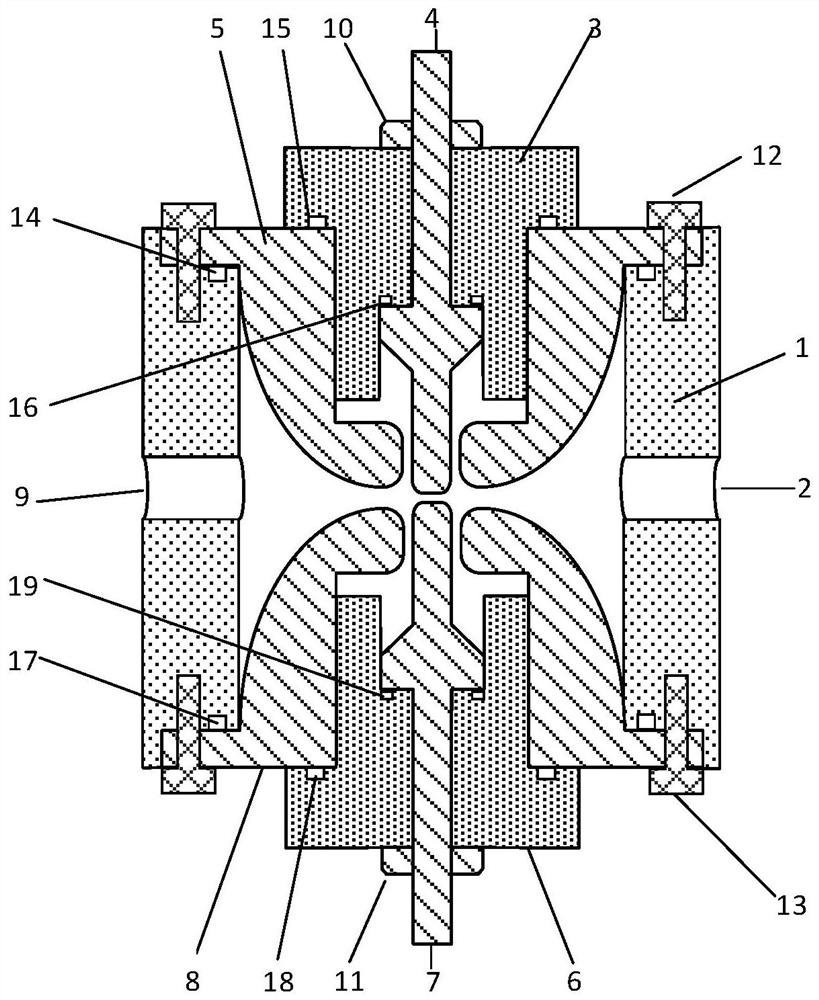

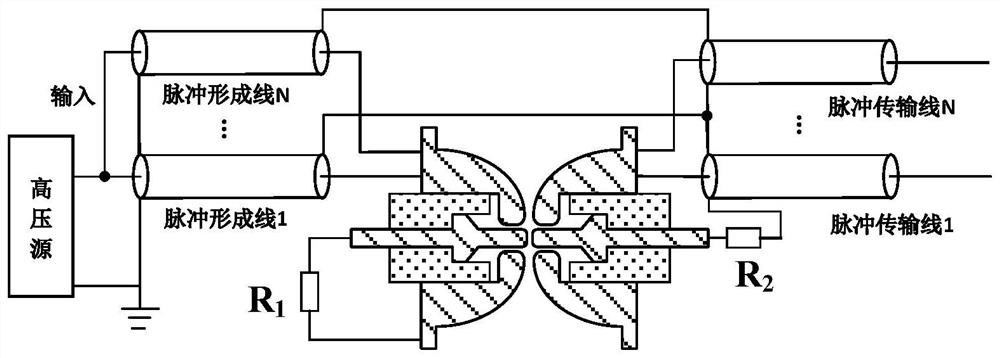

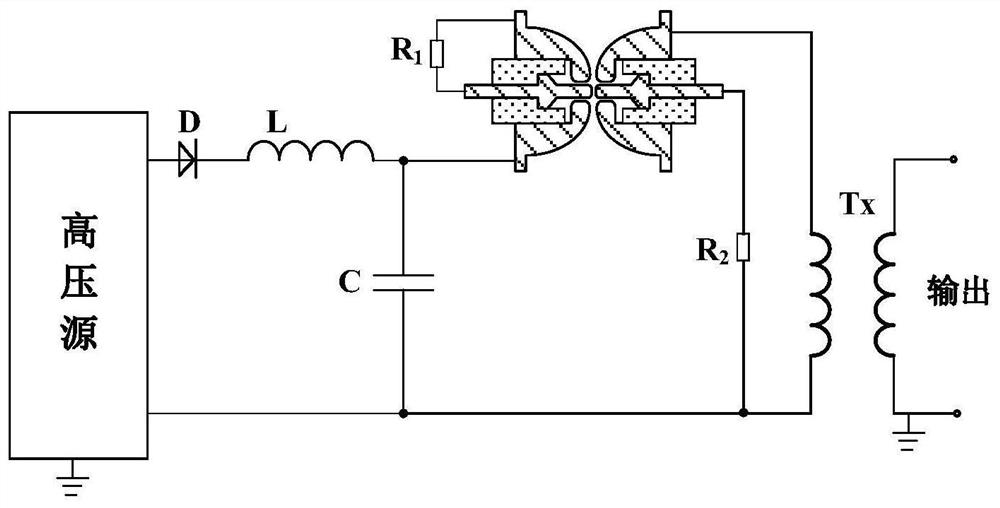

Surface breakdown type two-pair-rod electrode structural triggered vacuum switch

ActiveCN104617491AIncrease insulation distanceImprove the withstand voltage levelElectrical apparatusPower flowSurface breakdown

The invention discloses a surface breakdown type two-pair-rod electrode structural triggered vacuum switch. The triggered vacuum switch is of a three-section structure, comprising a corrugated ceramic housing at the upper section, another corrugated ceramic housing at the lower section, a metal shielding cover in the middle section, an upper electrode, a lower electrode, a triggering electrode, an upper electrode metal connecting rod, an upper electrode flange plate, a lower electrode metal connecting rod and a lower electrode flange plate; the upper electrode and the lower electrode are arranged in the metal shielding cover; the upper electrode flange plate is connected with the corrugated ceramic housing at the upper section; the lower electrode flange plate is connected with the corrugated ceramic housing at the lower section and forms a closed housing with the metal shielding layer; the upper electrode flange plate is connected to the corrugated ceramic housing at the upper section, and the lower electrode flange plate is connected to the corrugated ceramic housing at the lower section, so as to effectively increase the creepage distance between the upper electrode flange plate and the lower electrode flange plate. The triggered vacuum switch is high in working voltage, large in arcing area, high in transfer coulomb during conducting, long in service life under large current, uniform in electrode ablation degree, and high in power frequency withstand voltage after quenching of arc.

Owner:HUAZHONG UNIV OF SCI & TECH

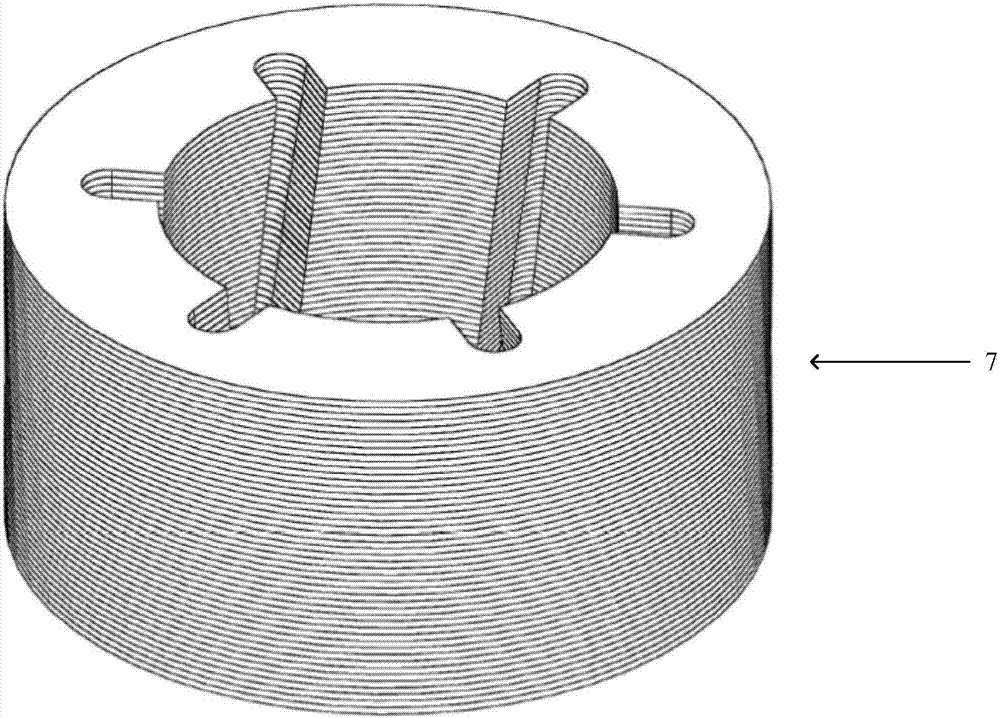

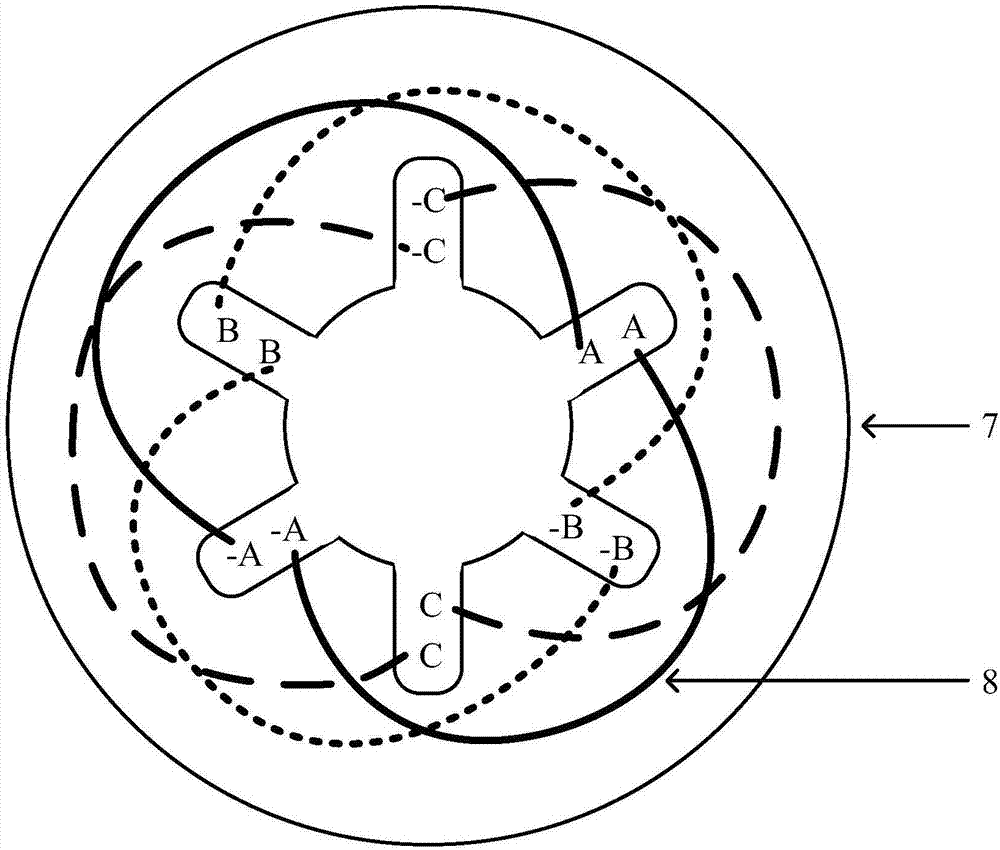

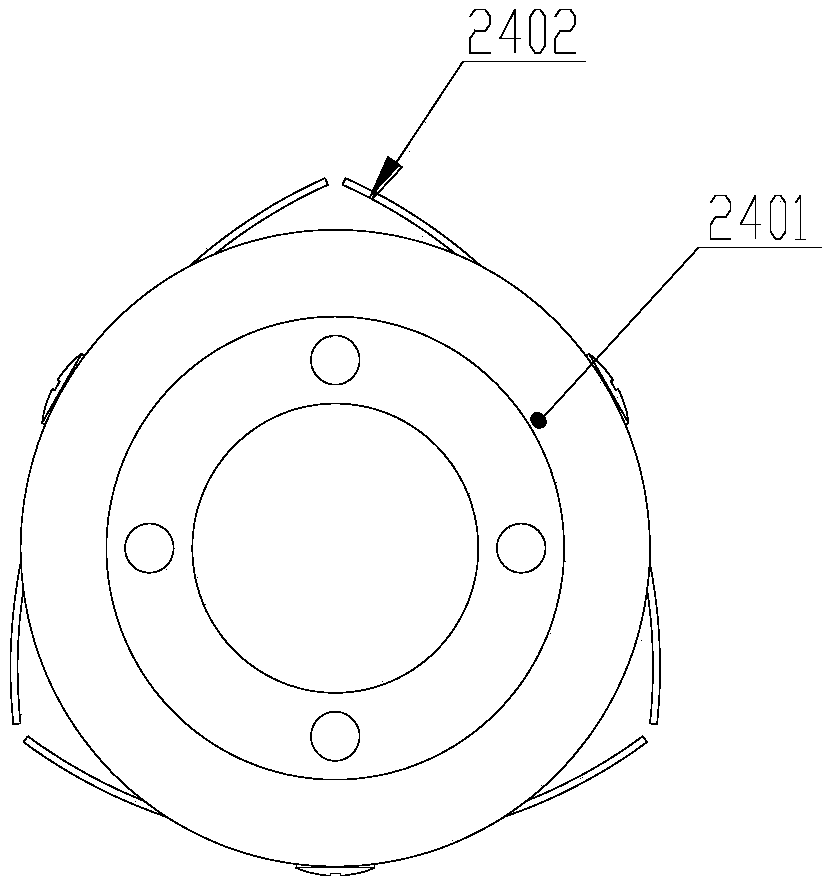

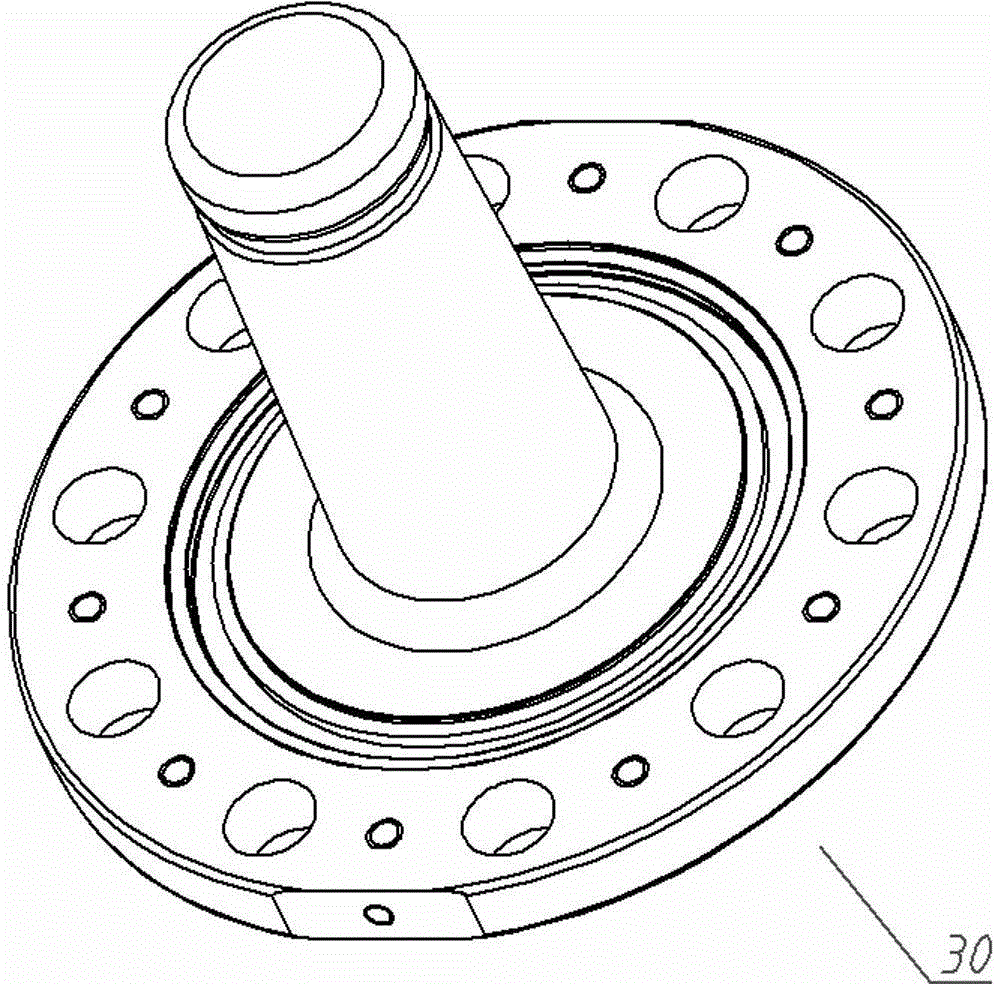

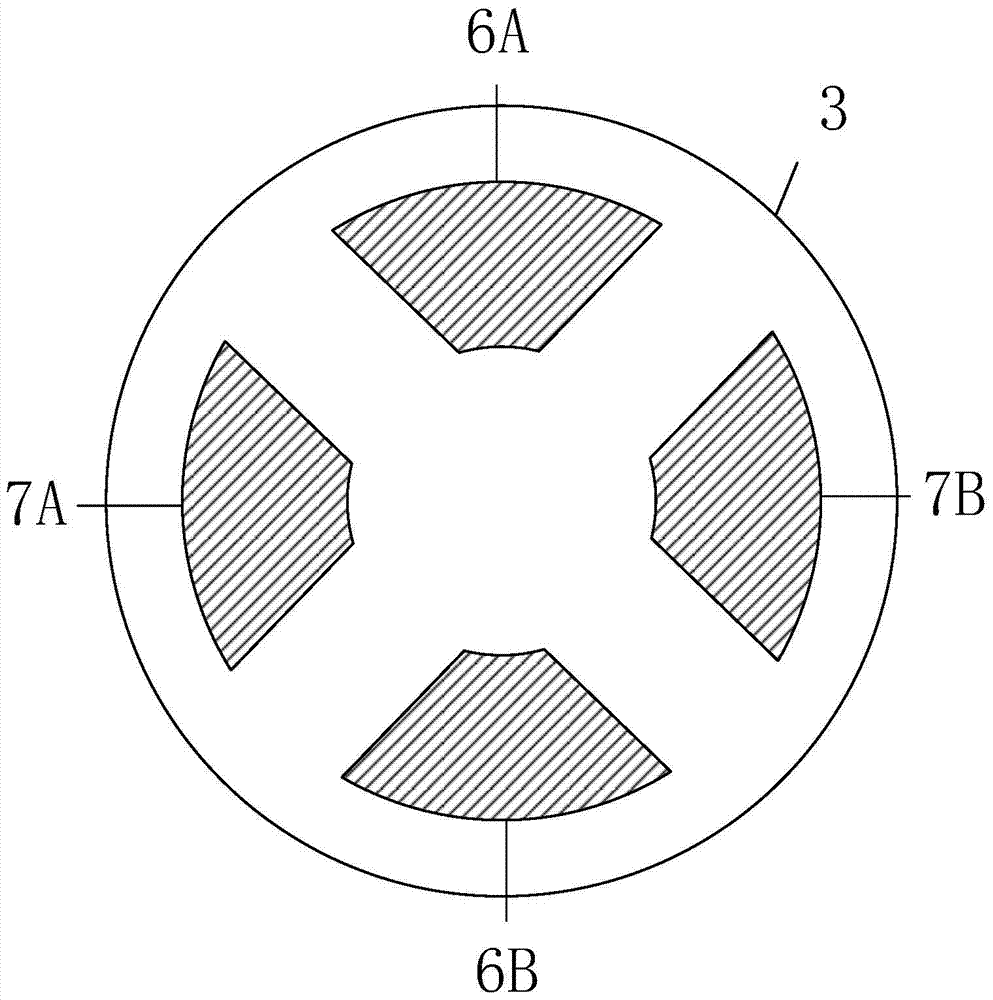

Adjustable rotating magnetic field vacuum explosion chamber

ActiveCN107342186AEasily brokenInhibit gas productionHigh-tension/heavy-dress switchesAir-break switchesTransverse magnetic fieldEngineering

The invention provides an adjustable rotating magnetic field vacuum explosion chamber. The adjustable rotating magnetic field vacuum explosion chamber comprises a pair of conductive rods, a shielding cover, a pair of disk shaped contacts, an insulation casing, a rotating magnetic field generation device and an amplitude and frequency adjustment device, wherein the insulation casing is arranged at an outer side of the shielding cover, the rotating magnetic field generation device is fixed outside the insulation casing, the rotating magnetic field generation device and the disk shaped contacts are coaxially arranged, the amplitude and frequency adjustment device is connected with the rotating magnetic field generation device, a magnetic field generated by the rotating magnetic field generation device is adjusted, the conductive rod is connected with the disk shaped contacts, and the disk shaped contacts are coaxially and oppositely arranged in the shielding cover. The adjustable rotating magnetic field vacuum explosion chamber is advantaged in that the rotating magnetic field generation device is completely disposed outside the insulation casing of the explosion chamber, gas generation possibility is avoided, the generated transverse magnetic field is more concentrated between the contacts, namely the arc portion, and closing and opening of the contacts are further facilitated.

Owner:CHINA ELECTRIC POWER RES INST +3

Method for preparing p-type copper-sulfur-containing transparent conductor film

ActiveCN100588737CUniform ablationVacuum evaporation coatingSputtering coatingSulfurAtmospheric pressure

The present invention is pulse laser deposition (PLD) process for preparing p-type compound CuAlS2 in chalcopyrite structure and transparent doped conducting film. The PLD process prepares p-type compound CuAlS2 or doped film on the substrate of quartz glass, common glass or Si chip by using the compound block obtained through solid phase reaction and SPS sintering or no-pressure sintering as thetarget and under proper conditions of atmospheric pressure, substrate temperature, and laser strength and frequency. The prepared CuAlS2 film has p-type conductivity, high conductivity, high visible light transparency and other excellent optoelectronic performance, and may find its broad application foreground in electronics and optoelectronics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

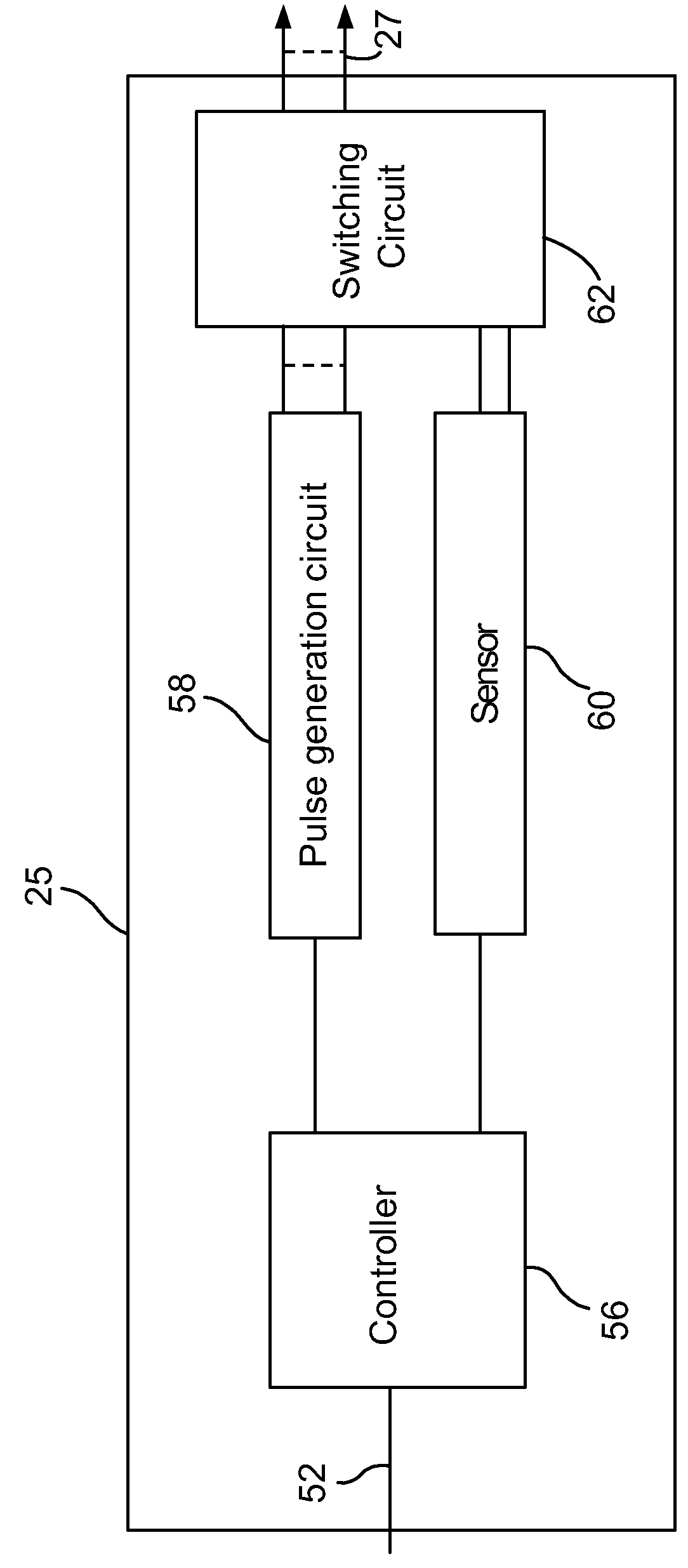

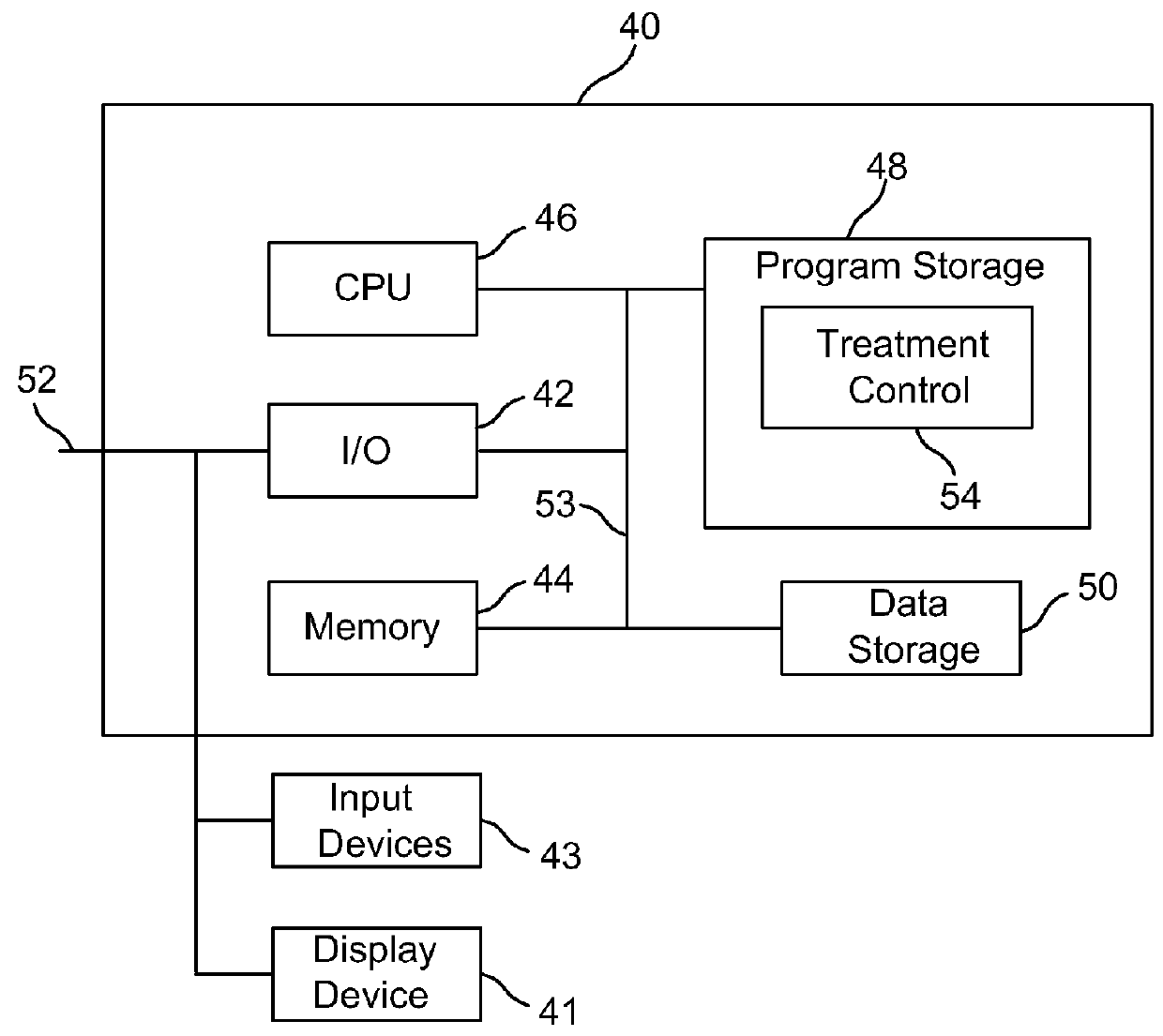

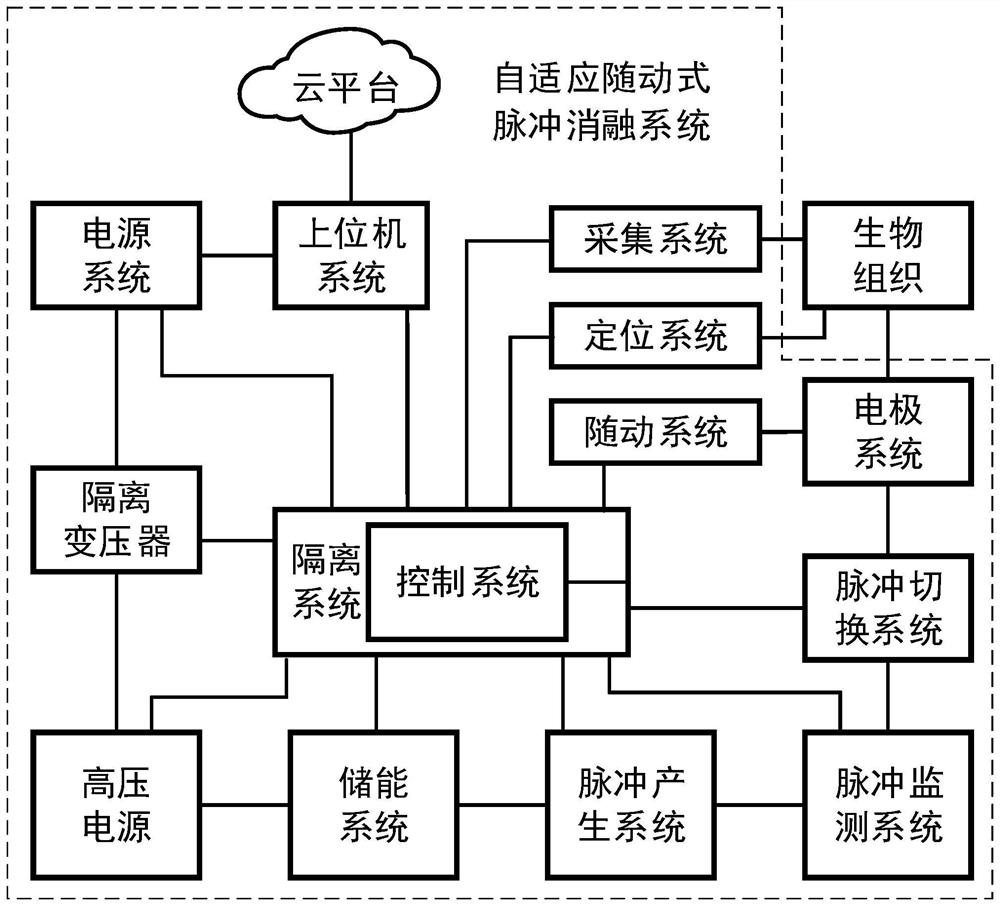

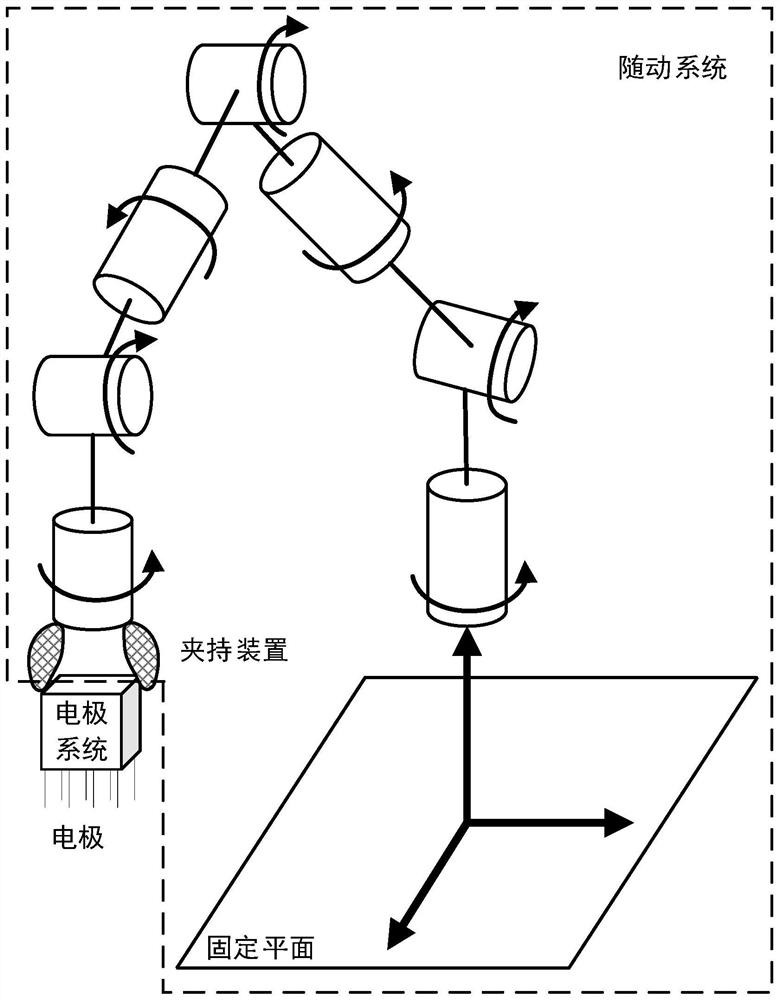

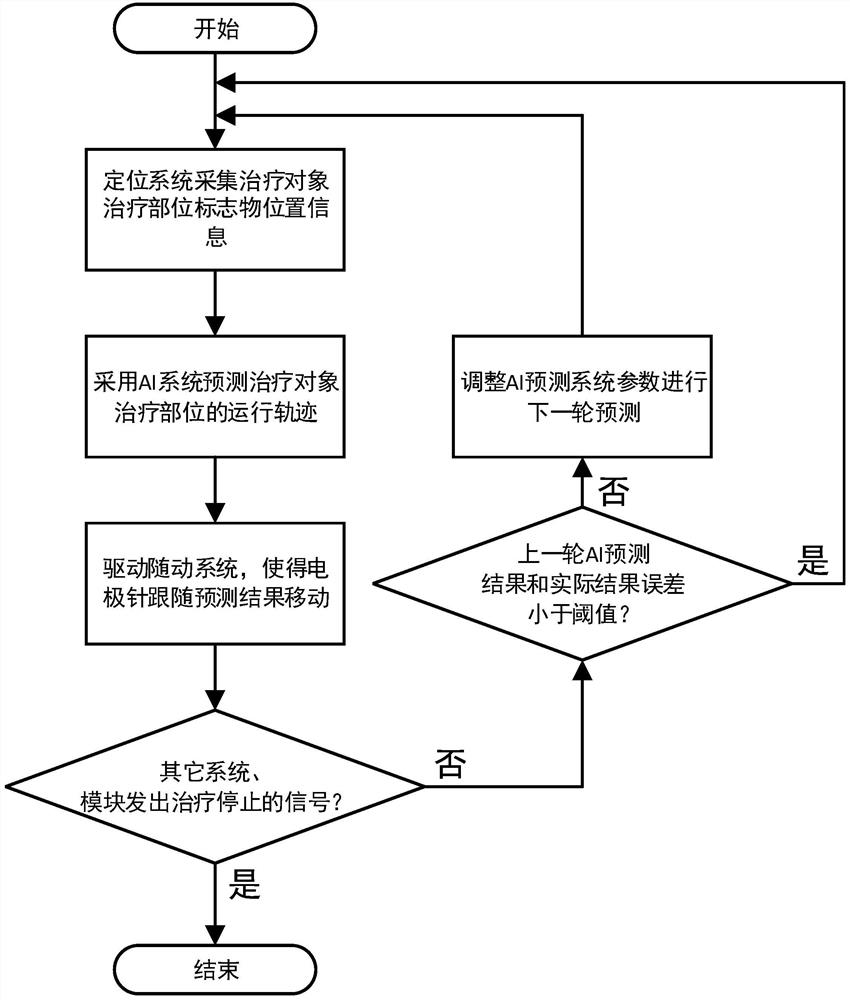

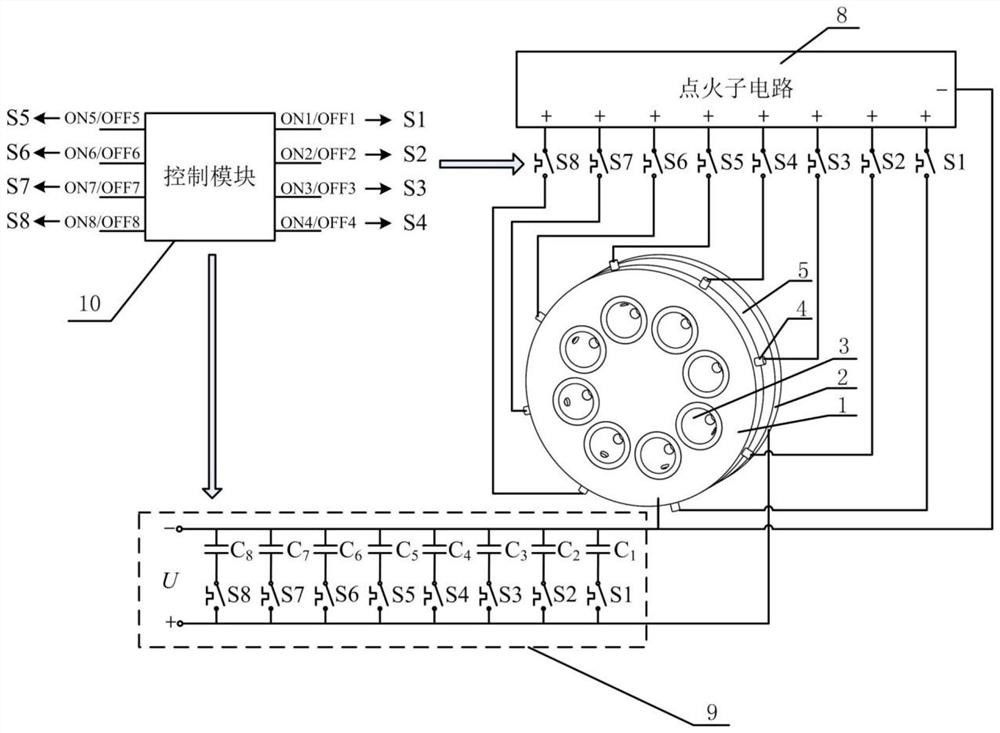

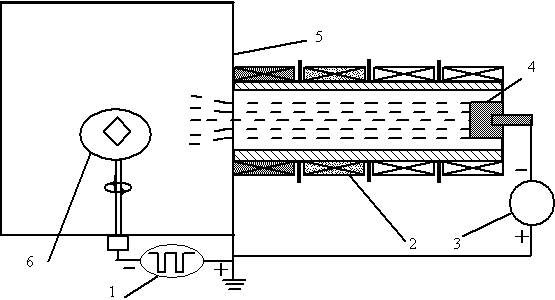

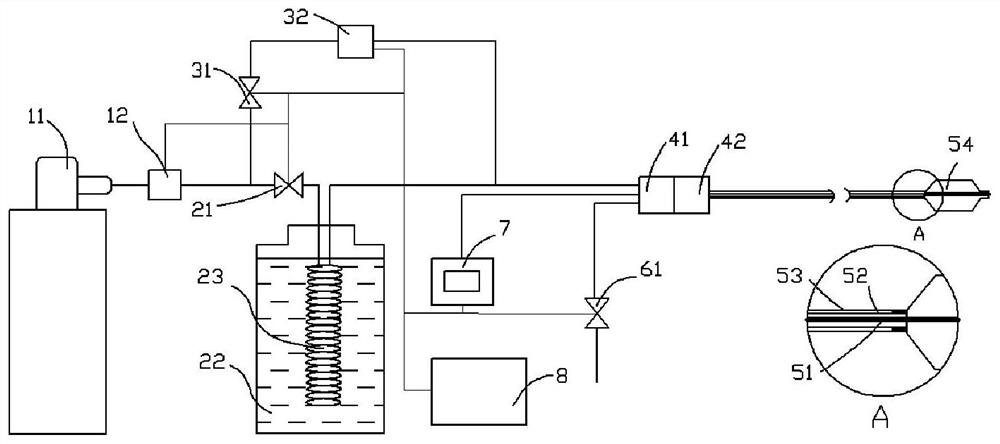

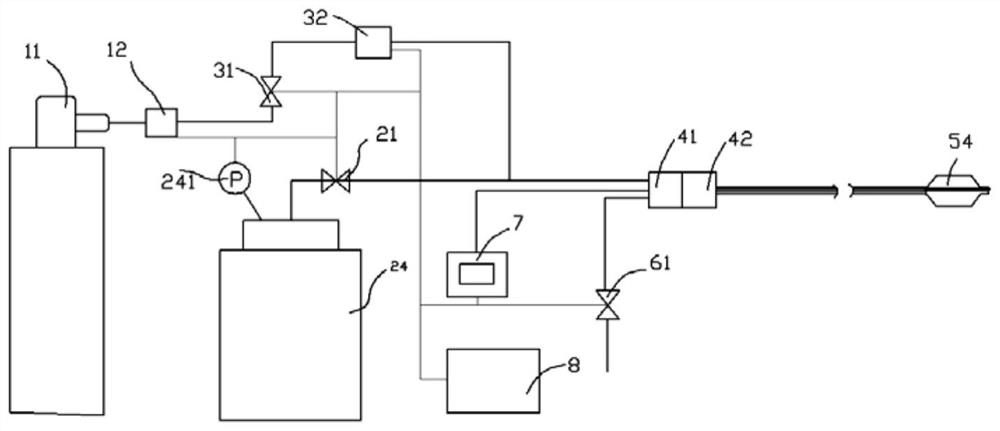

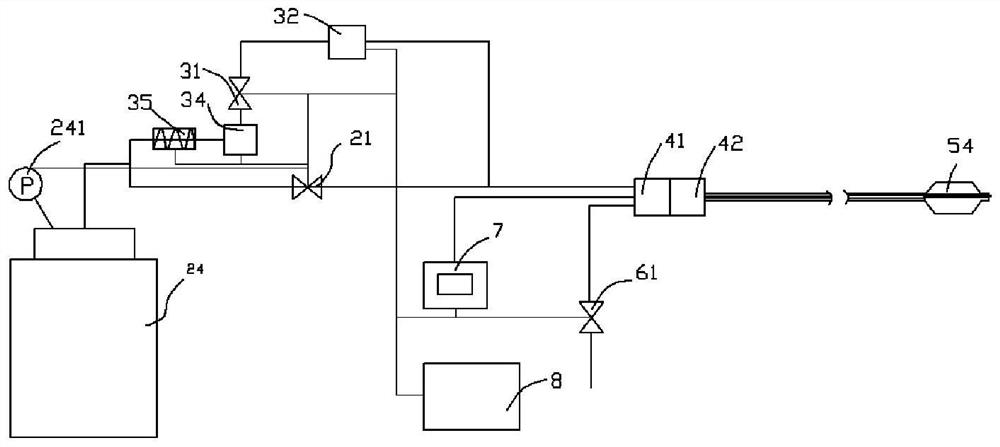

Self-adaptive follow-up pulse ablation system and method

PendingCN114533249AUniform ablationReduce the effect of anisotropySurgical instruments for heatingTherapeutic effectPulse monitoring

The invention provides a self-adaptive follow-up pulse ablation system which comprises a power supply system, an isolation transformer, a high-voltage power supply, an energy storage system, a pulse generation system, a pulse monitoring system, a pulse switching system, an electrode system, a control system, an isolation system, an acquisition system, a positioning system, a follow-up system, an upper computer system and a cloud platform. The optimal treatment parameter range is provided for each treatment process by adopting a cloud platform and an artificial intelligence algorithm, and the pulse (group) parameters are adaptively adjusted in real time in the treatment process, so that the shaking degree and the temperature rise condition of the biological tissue are both within the threshold range, the relative displacement and the relative rotation of the electrode and the treatment part are reduced, and the treatment effect is improved. The optimal treatment effect and the minimum side effect are achieved; meanwhile, the self-adaptive follow-up pulse ablation system and method can reduce the influence of anisotropy of biological tissues at the tumor part, so that the pulse ablation is more uniform, and the ablation effect is better.

Owner:重庆千恩医疗科技有限公司

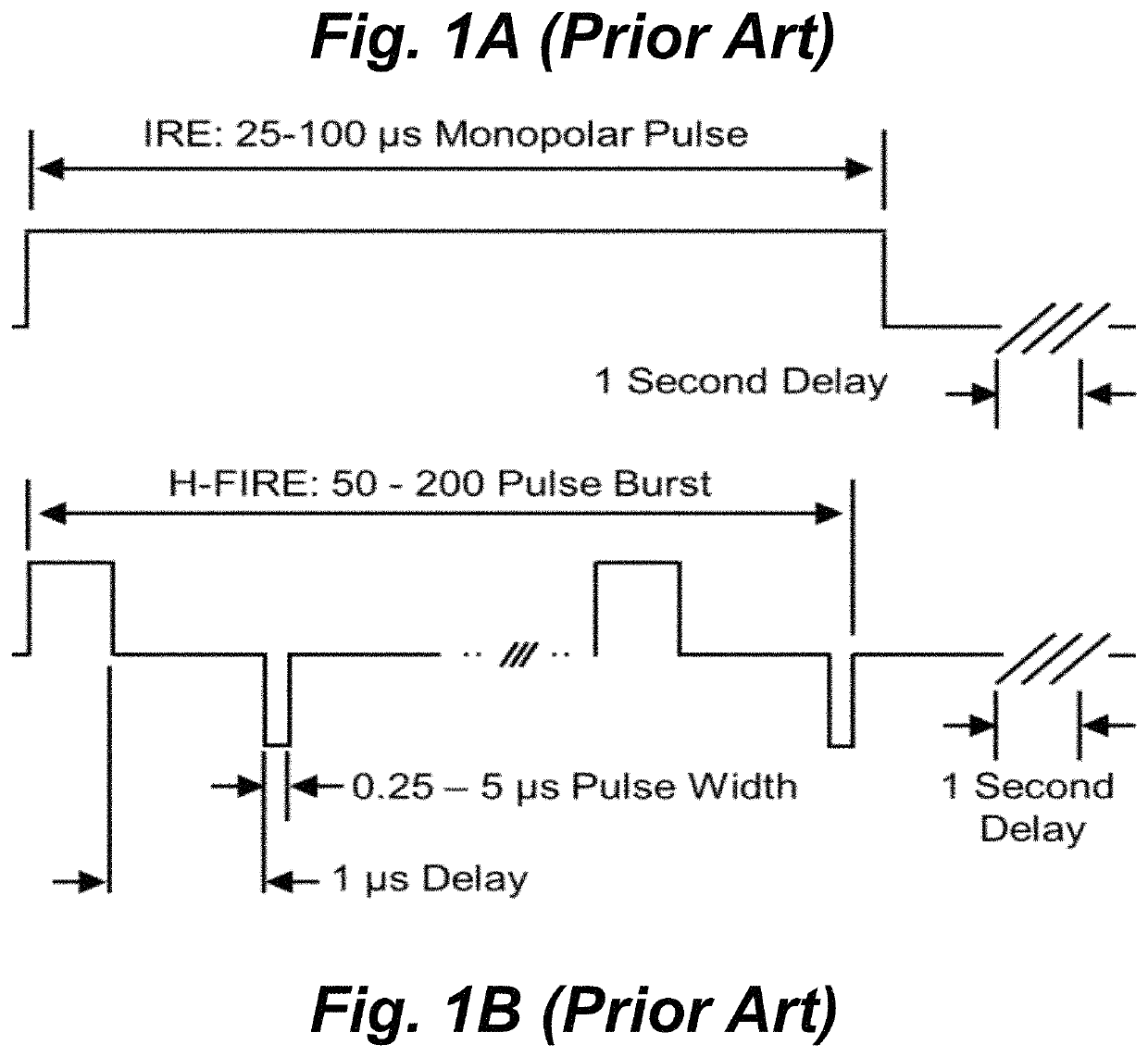

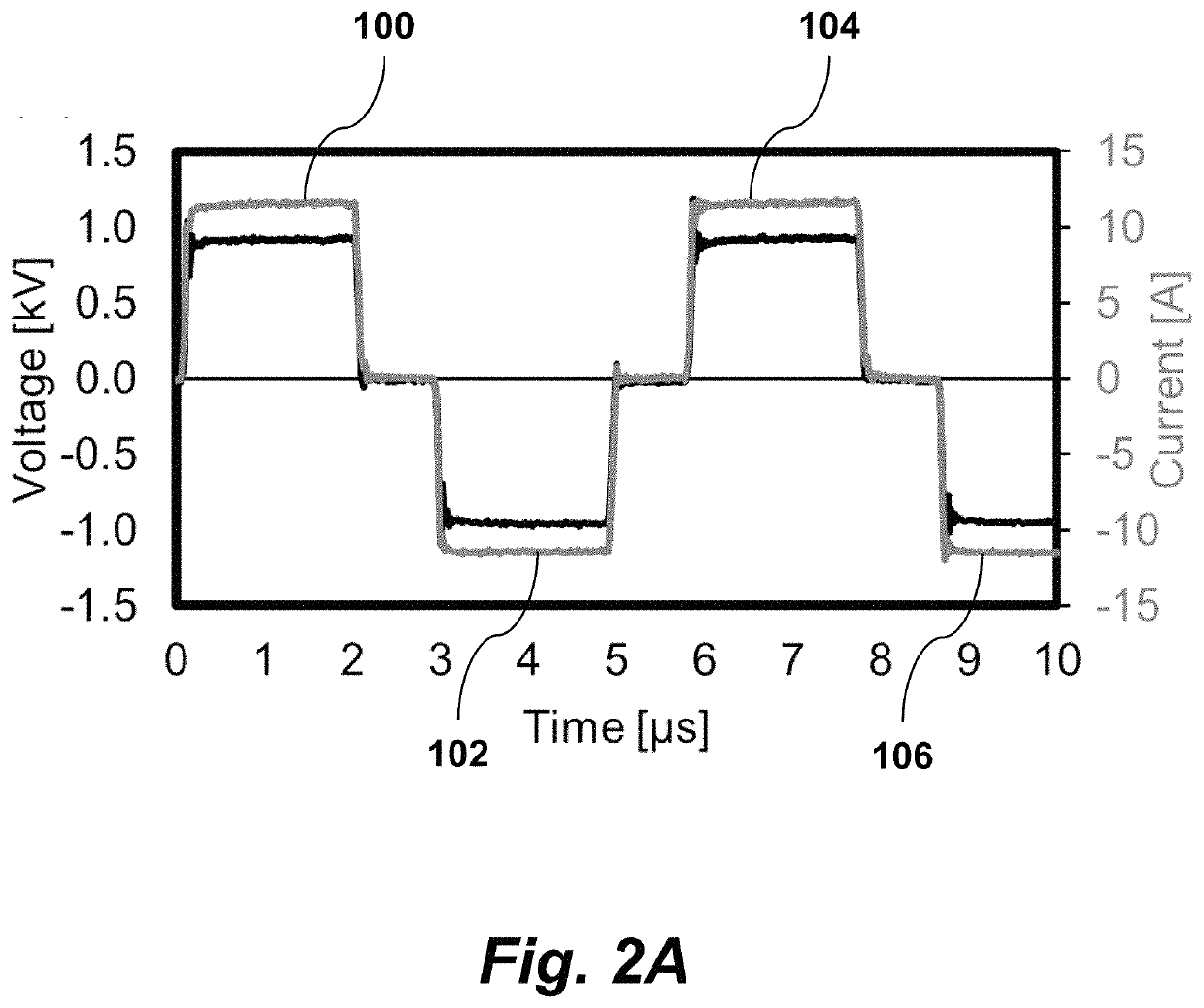

Methods for enhancing and modulating reversible and irreversible electroporation lesions by manipulating pulse waveforms

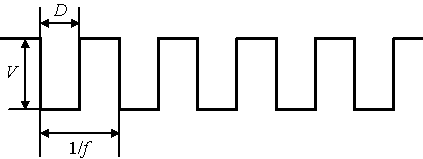

ActiveUS10589092B2Enhance and minimize effectEliminating muscle contractionsElectrotherapyInstrument handpiecesElectrical polarityIrreversible electroporation

A ratio of reversible electroporation and irreversible electroporation may be controlled by selecting a symmetric waveform or asymmetric waveform to either minimize or enhance irreversible effects on cells in the target tissue. Combined reversible and irreversible electroporation includes inserting one or more therapeutic electrodes into a target tissue, introducing an electroporation compound into the target tissue, selecting a pulse waveform that is either 1) asymmetric bipolar that has positive and negative pulses with different durations, or 2) symmetric bipolar that has positive and negative pulses with the same duration, and delivering to the target tissue a series of electrical pulses having the selected pulse waveform.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

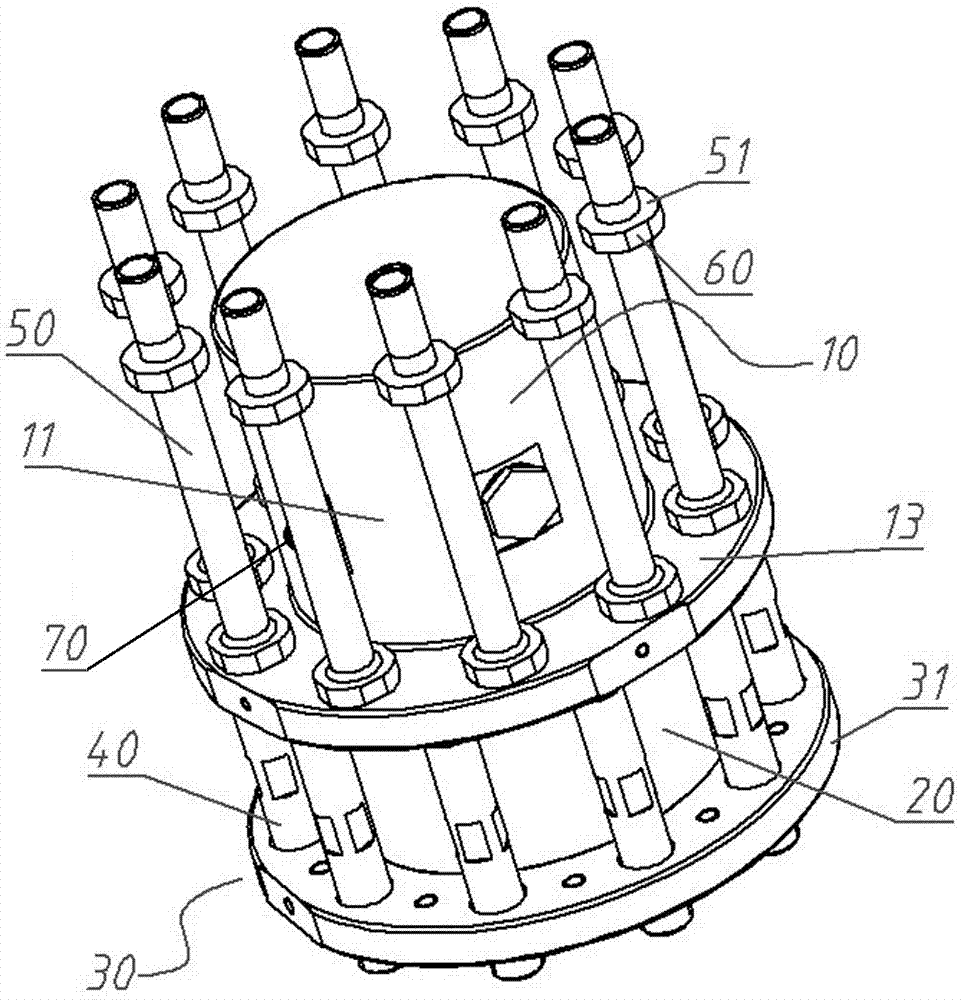

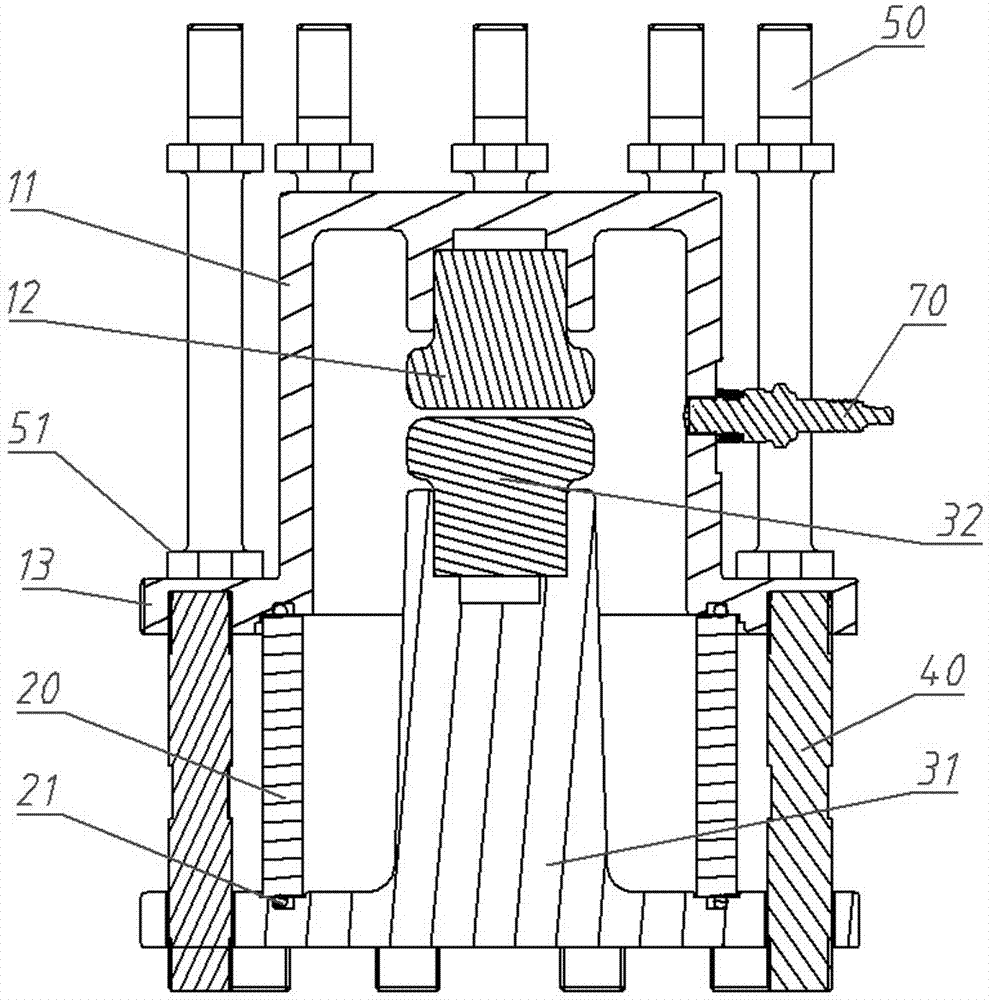

Novel rotary magnetic control circular column arc target device

PendingCN109295429APayloadSmooth startVacuum evaporation coatingSputtering coatingDrive shaftElectric machine

The invention discloses a novel rotary magnetic control circular column arc target device. The novel rotary magnetic control circular column arc target device comprises a shell, a first insulating mat, a vacuum sealed end cover device, a first O-shaped ring, a shielding case insulating mat, a shaft core retainer ring, a shielding case, a driving shaft core, a self-aligning bearing, a magnetic sealing device, magnetic liquid, a tapered roller bearing, a small round nut, a locking nut, a driving synchronous pulley, a motor bracket, a water distribution device, a synchronous belt, a motor synchronous pulley, a motor tensioning device, a motor insulating mat, a driving motor, a clamp spring for a shaft, a first rotating electric conductive device, a first end sealing cover, a second O-shaped ring, a second end sealing cover, a water inlet joint, a water outlet joint, a rotating magnetic bar device, a third O-shaped ring, a second rotating electric conductive device, a target material end sealing cover and a target material. The novel rotary magnetic control circular column arc target device facilitates the uniformity of a coating and the improvement of adhesive force, realizes the optimal process of ion plating, is stable and reliable in operation, and greatly improves the production efficiency.

Owner:SHANGHAI ZICHUANG COATING TECH

Two-electrode gas switch

ActiveCN105405729AAvoid pollutionAvoid influenceSolid cathode detailsCold-cathode tubesEngineeringGraphite particle

The invention relates to a two-electrode gas switch. The two-electrode gas switch comprises a first electrode base, a second electrode base, and two electrodes which are used for forming electrode gaps. The first electrode base is tubular. The electrode gaps are arranged in the internal cavity of the first electrode base. The radial side wall of the first electrode base is provided with a conductive connection structure which is used for enabling the first electrode base to be conductively connected with an external object. The conductive connection structure is arranged at one side, which is close to the second electrode base, of the electrode gaps in the axial direction of the first electrode base. The direction of current flowing through the radial side wall of the first electrode base is opposite to the direction of current flowing through the electrode gaps when current flows. The electromagnetic force generated by current flowing through the radial side wall of the first electrode base affects on the discharge arcs of the two electrode gaps to generate hooping constraint force on the discharge arcs of the two electrode gaps so that heat, the arcs and graphite particles are enabled to be concentrated, more graphite particles are enabled to be oxidized into gas, pollution of the graphite particles to insulating cylinders can be reduced and the service life of the switch can be prolonged.

Owner:XJ POWER CO LTD +3

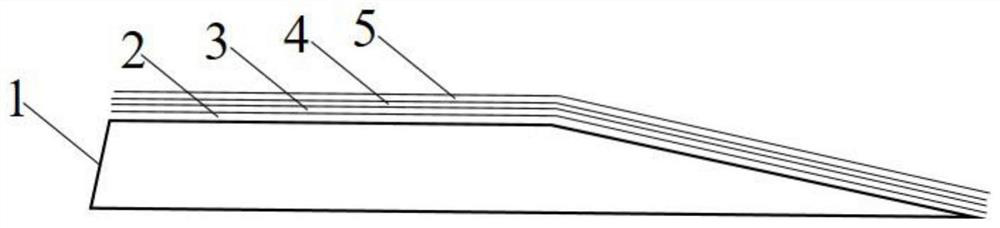

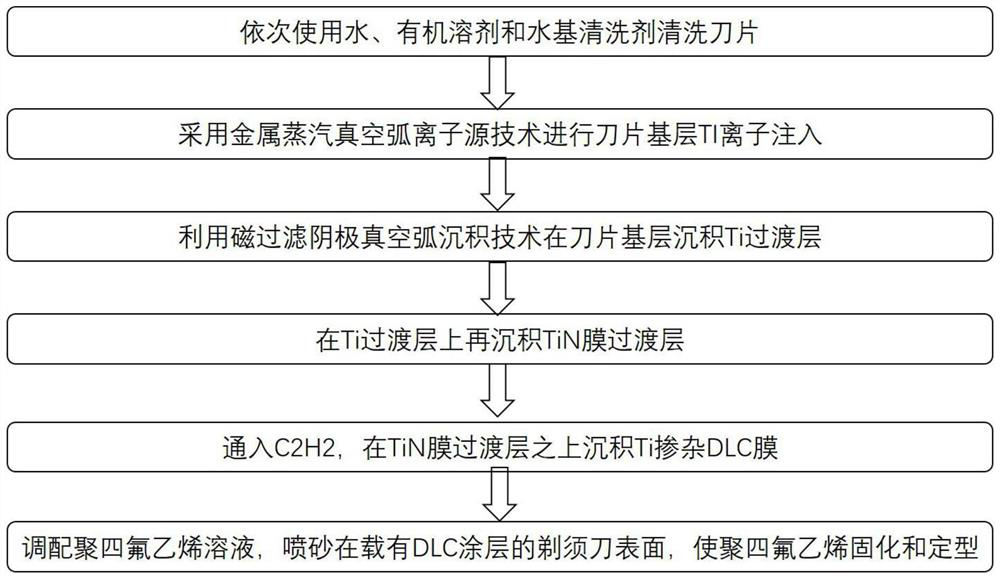

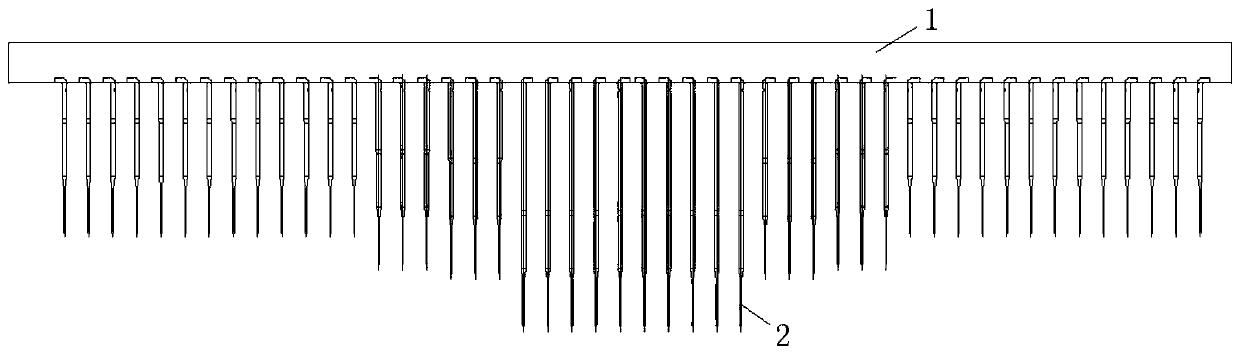

Shaving blade with multi-layer strengthening coating and preparation method of shaving blade

PendingCN111763945ASolve technical problems such as weak bonding force and easy coating peeling offHigh hardnessVacuum evaporation coatingSputtering coatingStructural engineeringMagnetic filtration

The invention discloses a shaving blade with a multi-layer strengthening coating and a preparation method of the shaving blade. A blade base with a blade edge is prepared by adopting a composite technology of magnetic filtration cathode vacuum arc deposition and MEVVA source injection, and a strengthening layer and a lubricating layer are arranged on the blade base, wherein the strengthening layeris composed of a plurality of nanometer layers with different hardness and comprises a Ti transition layer, a TiN transition layer and a Ti-doped DLC layer which are sequentially arranged from insideto outside, and the lubricating layer is a polytetrafluoroethylene layer. Multiple transition layers such as the Ti transition layer and the TiN transition layer are introduced between the blade basematerial and the DLC film layer, meanwhile, Ti ions are injected into MEVVA source ions, the surface hardness of a shaver can be enhanced, the interface lattice effect can be optimized, the internalstress of the coating can be effectively relieved, the bonding force between the coating and the base is effectively improved, the workpiece hardness and wear resistance are improved, and the frictioncoefficient is reduced so that the service life of the workpiece can be prolonged.

Owner:北京市辐射中心

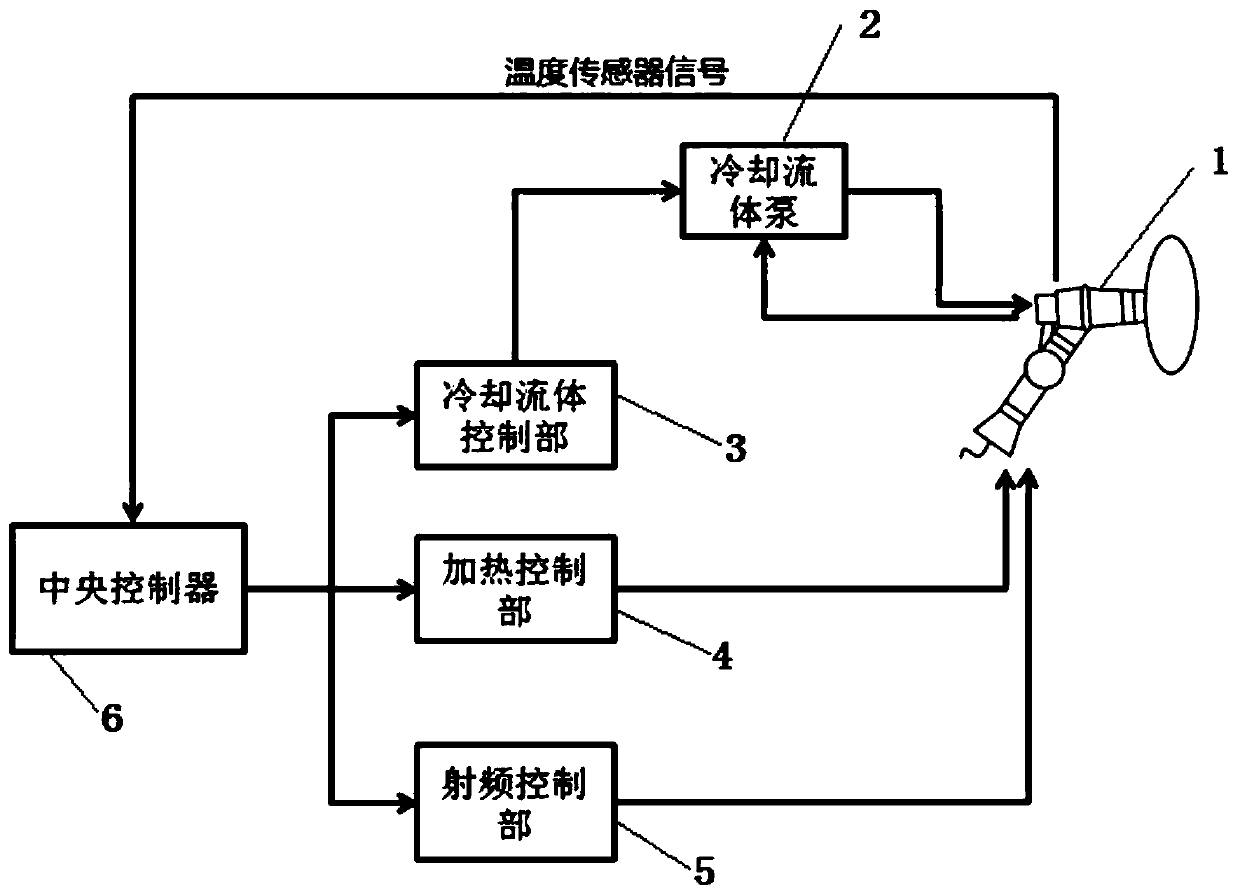

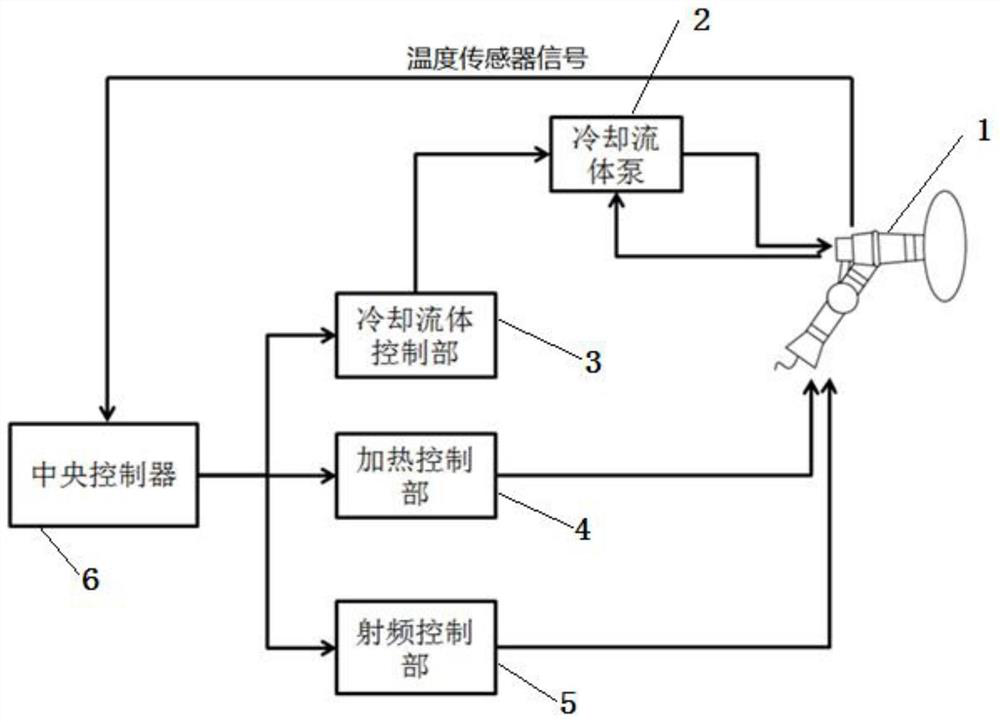

Device for removing eye bulged fat and control method thereof

InactiveCN110559559AUniform ablationReduced responseRadiation therapyFluid controlRadio frequency signal

Owner:徐晓婷

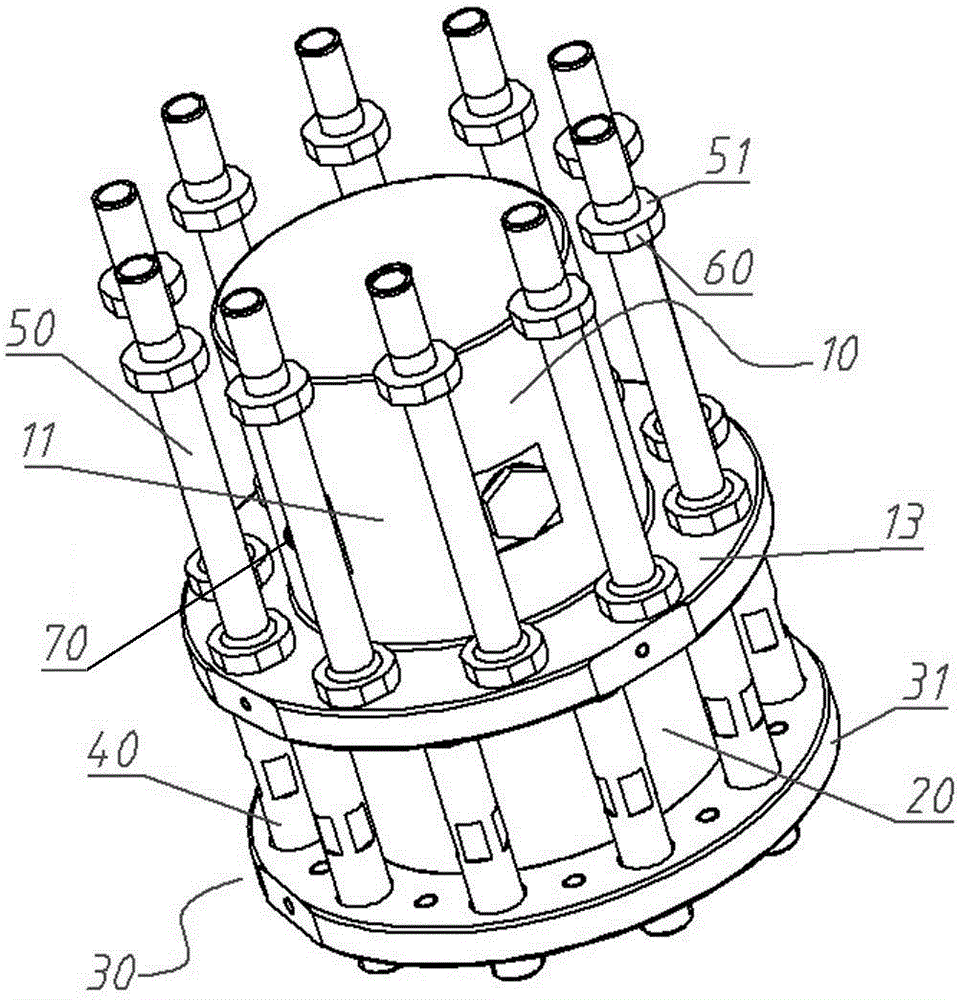

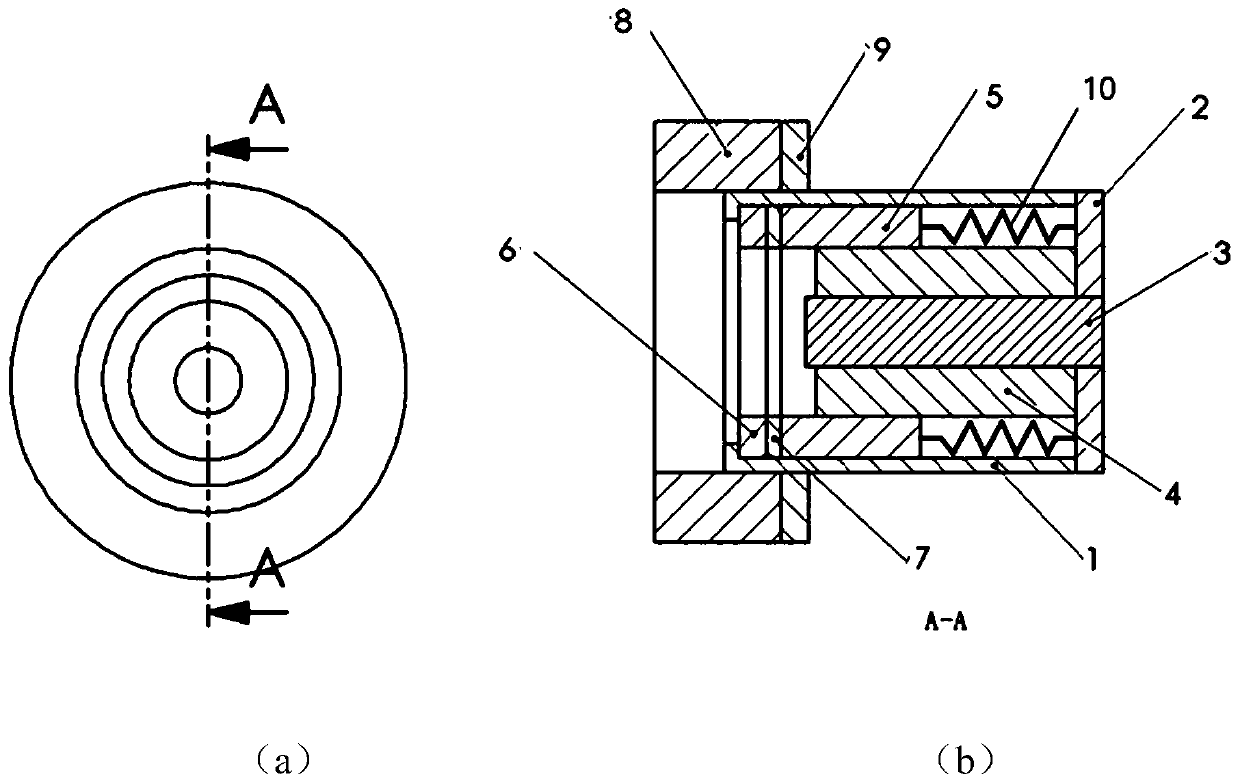

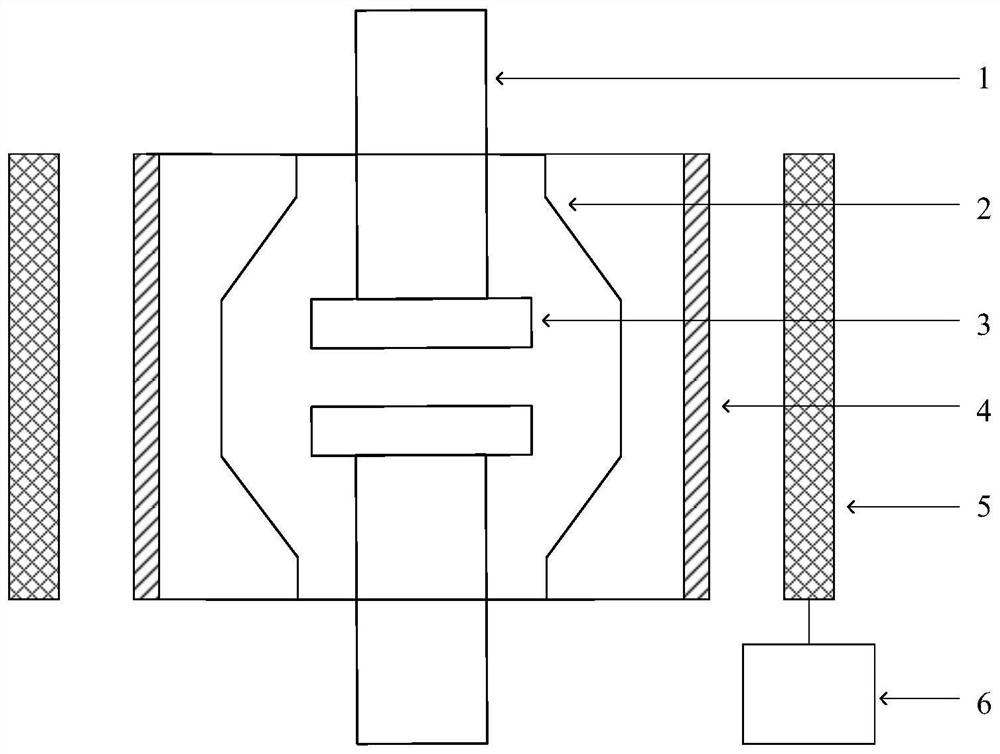

Bipolar multi-mode micro-cathode arc thruster

ActiveCN110594114AImprove efficiencySolution to short lifeMachines/enginesUsing plasmaCathode rayOperating life

The invention discloses a bipolar multi-mode micro-cathode arc thruster. The bipolar multi-mode micro-cathode arc thruster is characterized by comprising an insulating cylindrical shell (1), an insulating plate (2), a coaxial anode (3), a hollow coaxial insulating member (4), an annular cathode (5), an annular anode (6), an annular insulating member (7), an electromagnetic coil (8) and a permanentmagnet (9). The double-anode structure of the bipolar multi-mode micro-cathode arc thruster has two anode structures with different configurations, namely the coaxial anode and the annular anode, andthe coaxial anode and the annular anode can be switched to run along with the change of the operating life of the thruster, so that the working states of the two modes in the life period of the thruster are achieved.

Owner:BEIHANG UNIV

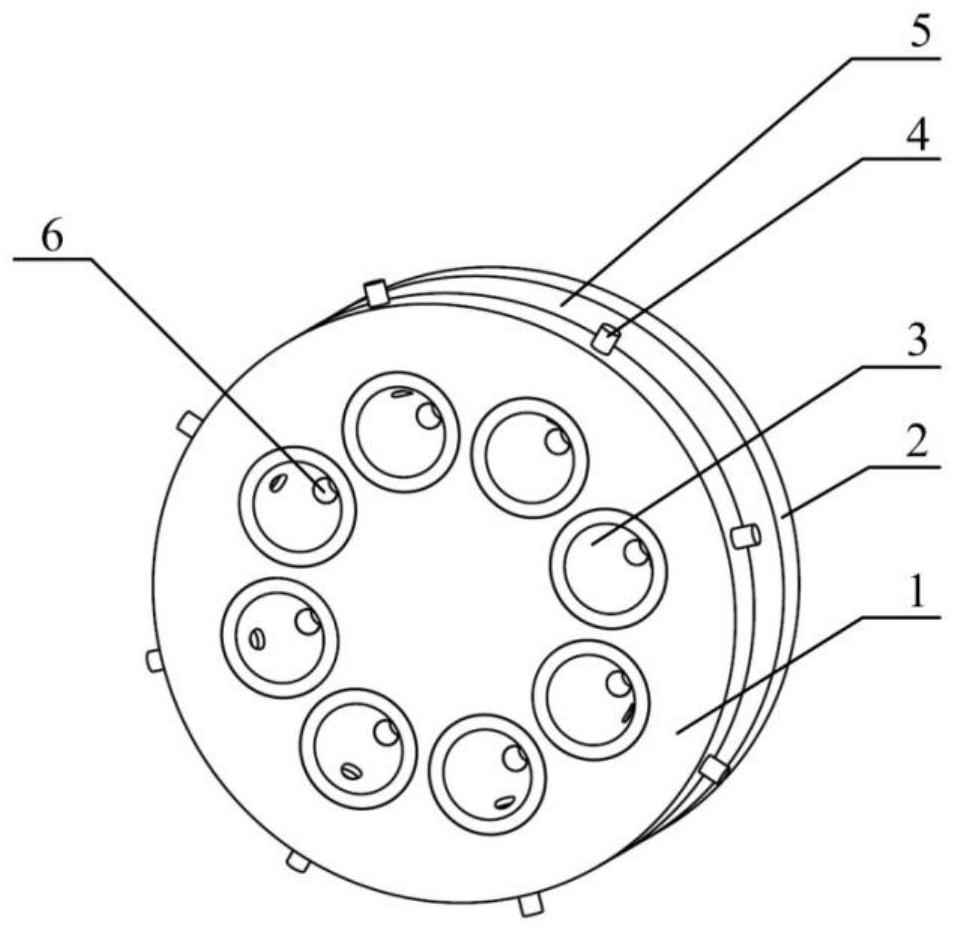

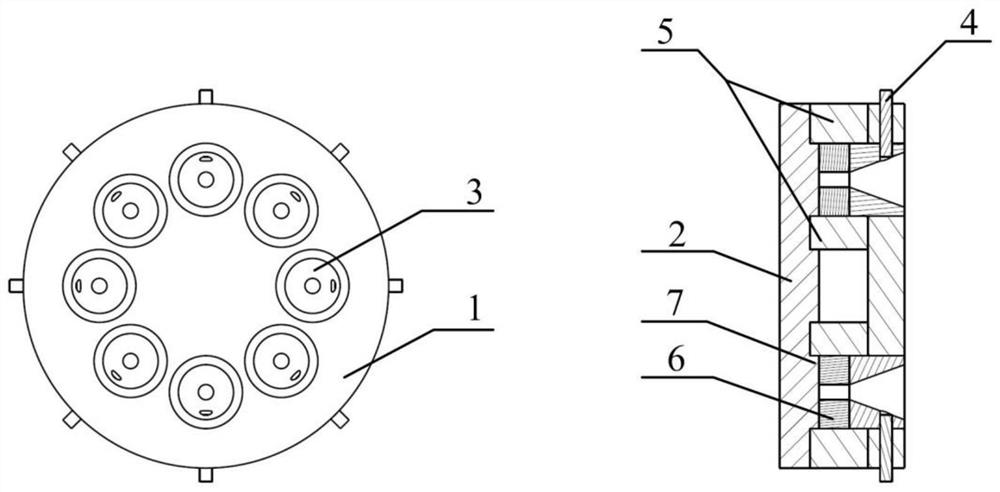

An Array Type Electrothermal Plasma Accelerator

ActiveCN112392675BEnhanced flushingThe number is adjustableMachines/enginesUsing plasmaEngineeringPhysics

An array-type electrothermal plasma accelerator belongs to the field of space electric propulsion technology, which overcomes the problems of uncontrollable ablation, difficult to accurately control the thrust, and low total impulse in the existing technology. The body unit is controlled to achieve the effect of controlling the amount of ablation and adjusting the thrust under the condition of maintaining the advantages of the structure and reliability of the acceleration device, and the discharge cavity group is formed by the array propellant arrangement to increase the total impact of the acceleration device. It can meet the requirements of diverse space propulsion missions and expand the field of application.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

A Surface Breakdown Type Two Pairs of Rod Structure Triggered Vacuum Switch

ActiveCN104617491BIncrease insulation distanceImprove the withstand voltage levelElectrical apparatusVacuum switchMetal

The invention discloses a triggering vacuum switch with two pairs of rod pole structures along the surface breakdown; the triggering vacuum switch adopts a three-stage structure, including an upper corrugated ceramic shell, a lower corrugated ceramic shell, and a middle metal shield, which are arranged on the metal shield The upper and lower electrodes in the cover, the trigger electrode, the upper electrode metal connecting rod, the upper electrode flange, the lower electrode metal connecting rod and the lower electrode flange; the upper electrode flange is connected with the upper corrugated ceramic shell, and the lower The electrode flange is connected to the lower corrugated ceramic shell, and then together with the metal shield to form a closed shell; the upper electrode flange is connected through the upper corrugated ceramic shell, and the lower electrode flange is connected through the lower corrugated ceramic shell. Effectively improve the creepage distance between the upper electrode flange and the lower electrode flange. The invention has high working voltage, large arc burning area, high transfer coulomb quantity in conduction process, long working life under high current, uniform electrode ablation degree, and high power frequency withstand voltage level after arc extinguishing.

Owner:HUAZHONG UNIV OF SCI & TECH

Arc ion plating method combined with multi-stage magnetic field straight tube magnetic filtering and pulse bias

ActiveCN103276362BIncrease the areaImprove mechanical propertiesVacuum evaporation coatingSputtering coatingSingle stageStraight tube

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

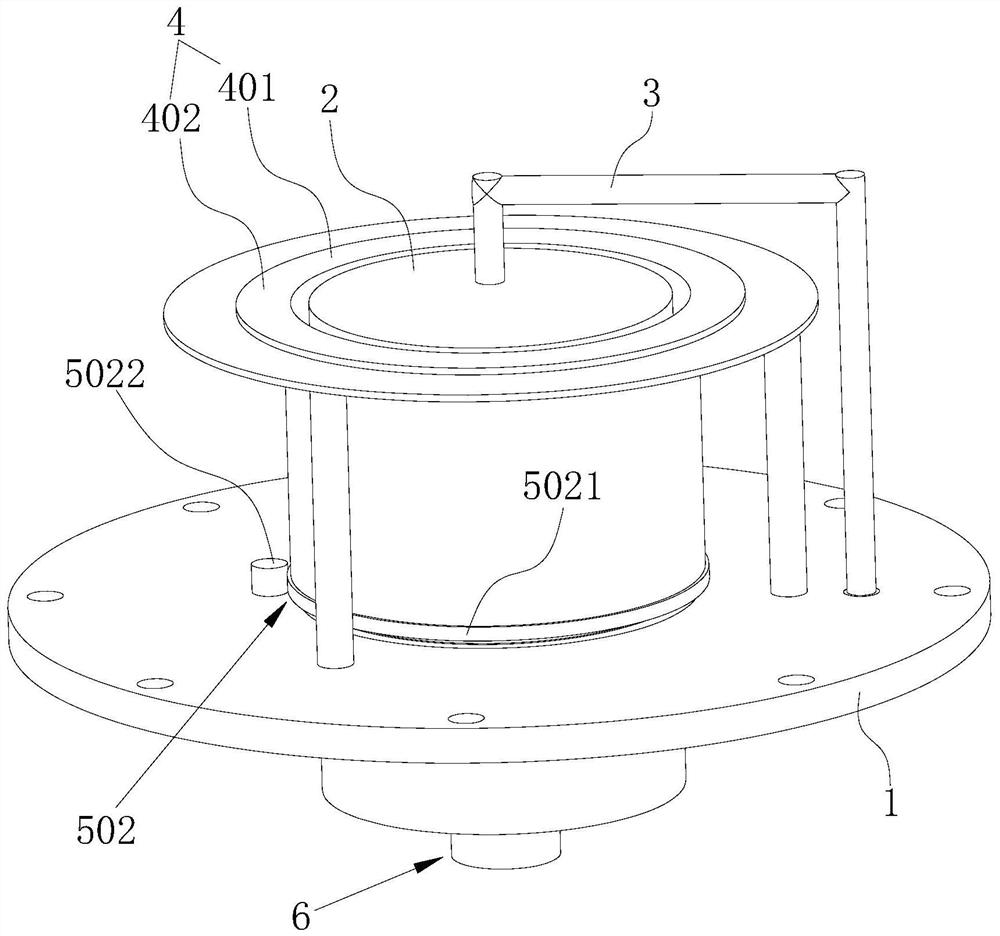

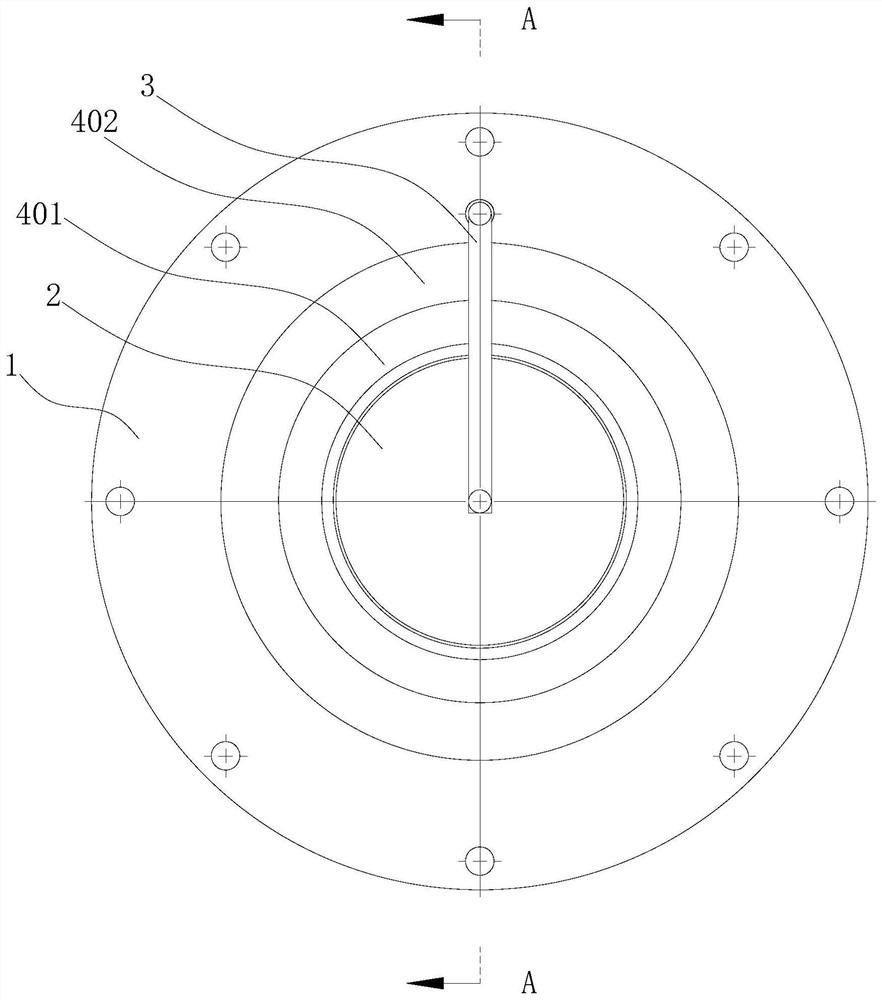

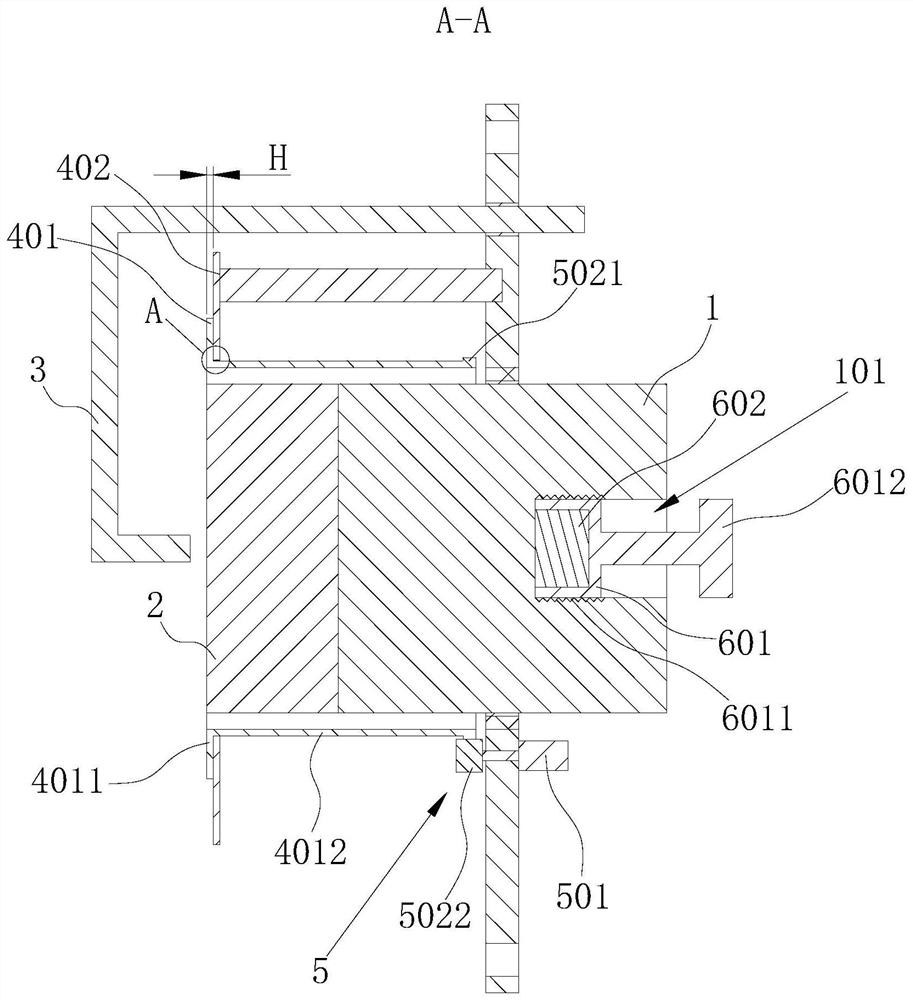

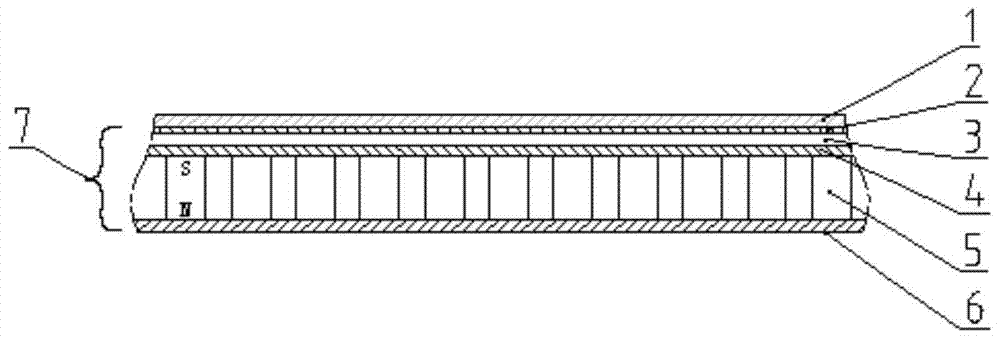

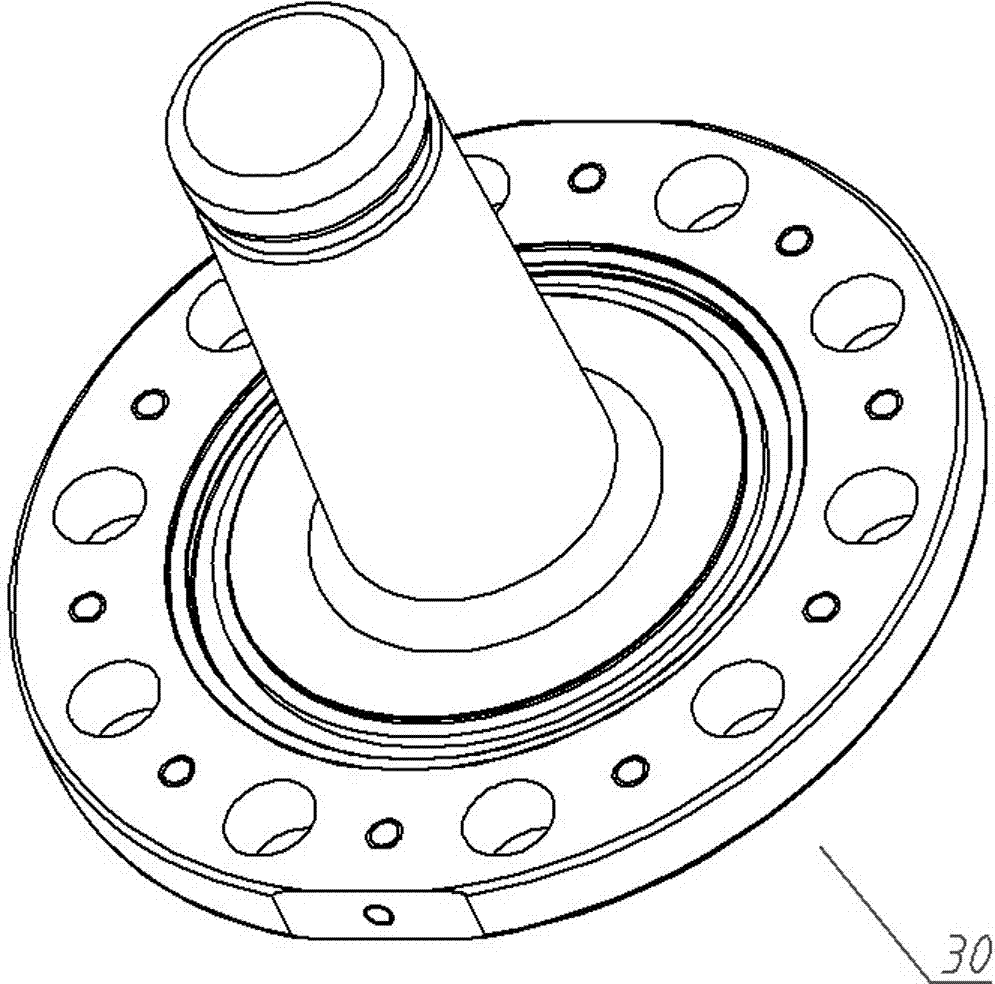

Cathode arc head with double-layer shielding cover

InactiveCN112501572AIncrease profitReduce replacement frequencyVacuum evaporation coatingSputtering coatingIon beamConductive materials

The invention discloses a cathode arc head with a double-layer shielding cover, and relates to the field of ion beam generation devices. According to the scheme, a fixed flange plate, a cathode targetmaterial, a trigger electrode, a shielding system and an auxiliary anode plate are included, the shielding system comprises a first shielding cover and a second shielding cover, the first shielding cover and the second shielding cover are both coaxial with the cathode target material, both sleeve the cathode target material and are kept to be spaced from the cathode target material, the first shielding cover is made of a magnetic conductive material, and the second shielding cover is made of a non-magnetic conductive material. The double-layer shielding cover is arranged, so that arc spots onthe cathode target material are better restrained, the surface of the cathode target material is uniformly ablated, the utilization rate of the cathode target material is improved, the replacement frequency of the cathode target material is reduced, and the influence on production is reduced.

Owner:廖斌 +1

A Vacuum Cathode Arc Source with Discharge Arc Spots Covering the Target Surface

ActiveCN105039915BLarge discharge areaIncrease deposition rateVacuum evaporation coatingSputtering coatingHeat conductingMagnetic poles

Owner:DONGGUAN HUICHENG VACUUM TECH

Two-electrode gas switch

ActiveCN105405729BReduce withstand voltageAvoid pollutionSolid cathode detailsCold-cathode tubesHoopingEngineering

The invention relates to a two-electrode gas switch. The two-electrode gas switch comprises a first electrode base, a second electrode base, and two electrodes which are used for forming electrode gaps. The first electrode base is tubular. The electrode gaps are arranged in the internal cavity of the first electrode base. The radial side wall of the first electrode base is provided with a conductive connection structure which is used for enabling the first electrode base to be conductively connected with an external object. The conductive connection structure is arranged at one side, which is close to the second electrode base, of the electrode gaps in the axial direction of the first electrode base. The direction of current flowing through the radial side wall of the first electrode base is opposite to the direction of current flowing through the electrode gaps when current flows. The electromagnetic force generated by current flowing through the radial side wall of the first electrode base affects on the discharge arcs of the two electrode gaps to generate hooping constraint force on the discharge arcs of the two electrode gaps so that heat, the arcs and graphite particles are enabled to be concentrated, more graphite particles are enabled to be oxidized into gas, pollution of the graphite particles to insulating cylinders can be reduced and the service life of the switch can be prolonged.

Owner:XJ POWER CO LTD +3

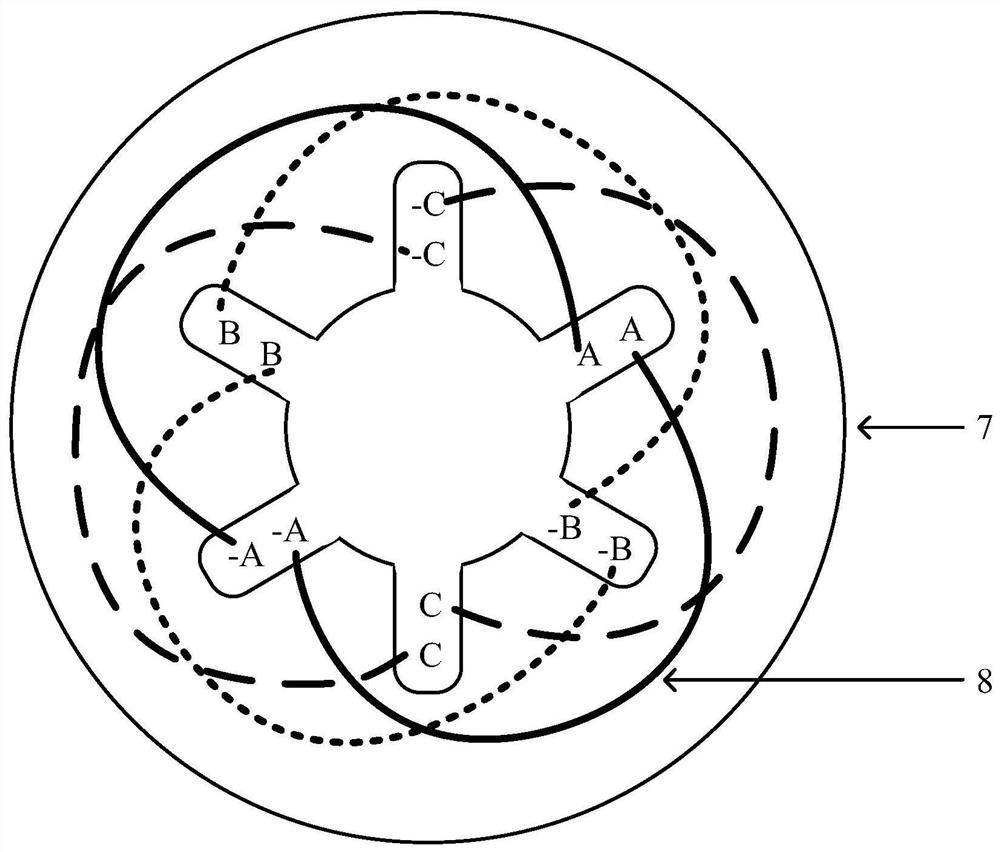

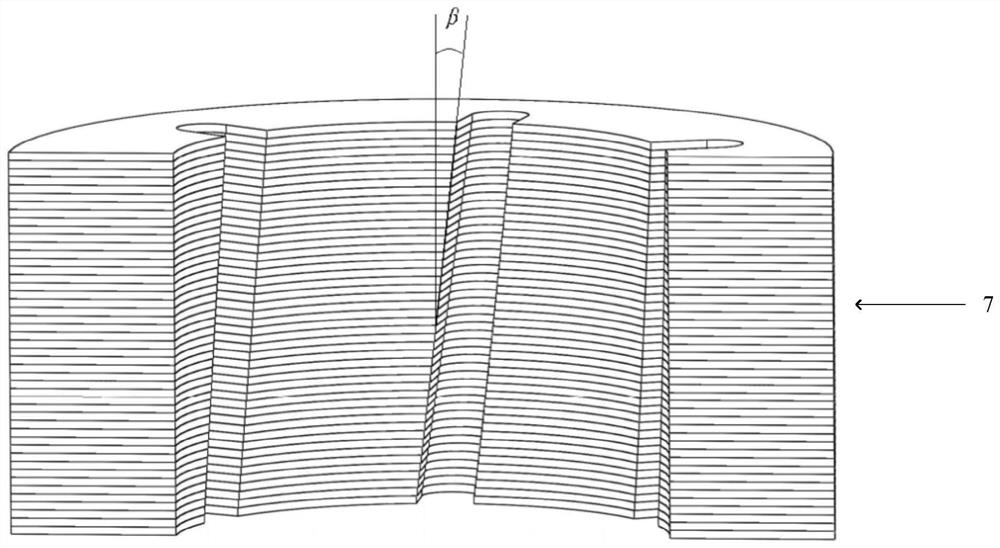

An adjustable rotating magnetic field vacuum interrupter

ActiveCN107342186BEasily brokenInhibit gas productionHigh-tension/heavy-dress switchesAir-break switchesCircular discTransverse magnetic field

The invention provides an adjustable rotating magnetic field vacuum interrupter, comprising: a pair of conductive rods, a shield cover, a pair of disc-shaped contacts, an insulating shell, a rotating magnetic field generating device and an amplitude-frequency adjusting device; the insulating shell It is arranged on the outside of the shield; the rotating magnetic field generating device is fixed on the outside of the insulating shell and placed coaxially with the disc-shaped contact; the amplitude-frequency adjusting device is connected to the rotating magnetic field generating device to adjust The magnetic field generated by the rotating magnetic field generating device; the conductive rod is connected with the disc-shaped contacts; the pair of disc-shaped contacts are arranged coaxially and oppositely in the shielding case. In the technical solution provided by the present invention, the rotating magnetic field generators are all placed outside the insulating shell of the arc extinguishing chamber, avoiding the possibility of gas production, and the generated transverse magnetic field is more concentrated between the contacts, that is, at the arc, which is more conducive to contact disconnection.

Owner:CHINA ELECTRIC POWER RES INST +3

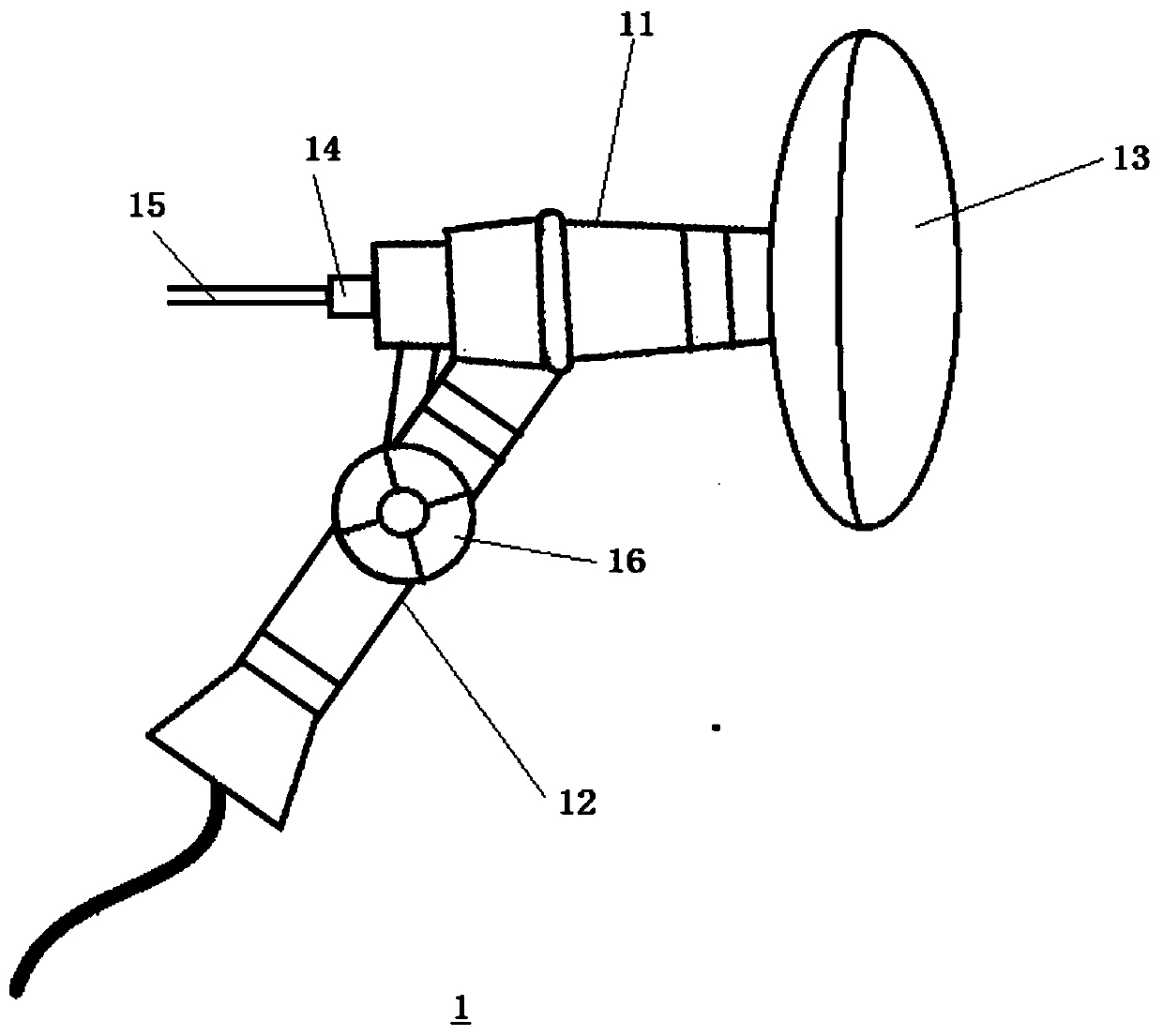

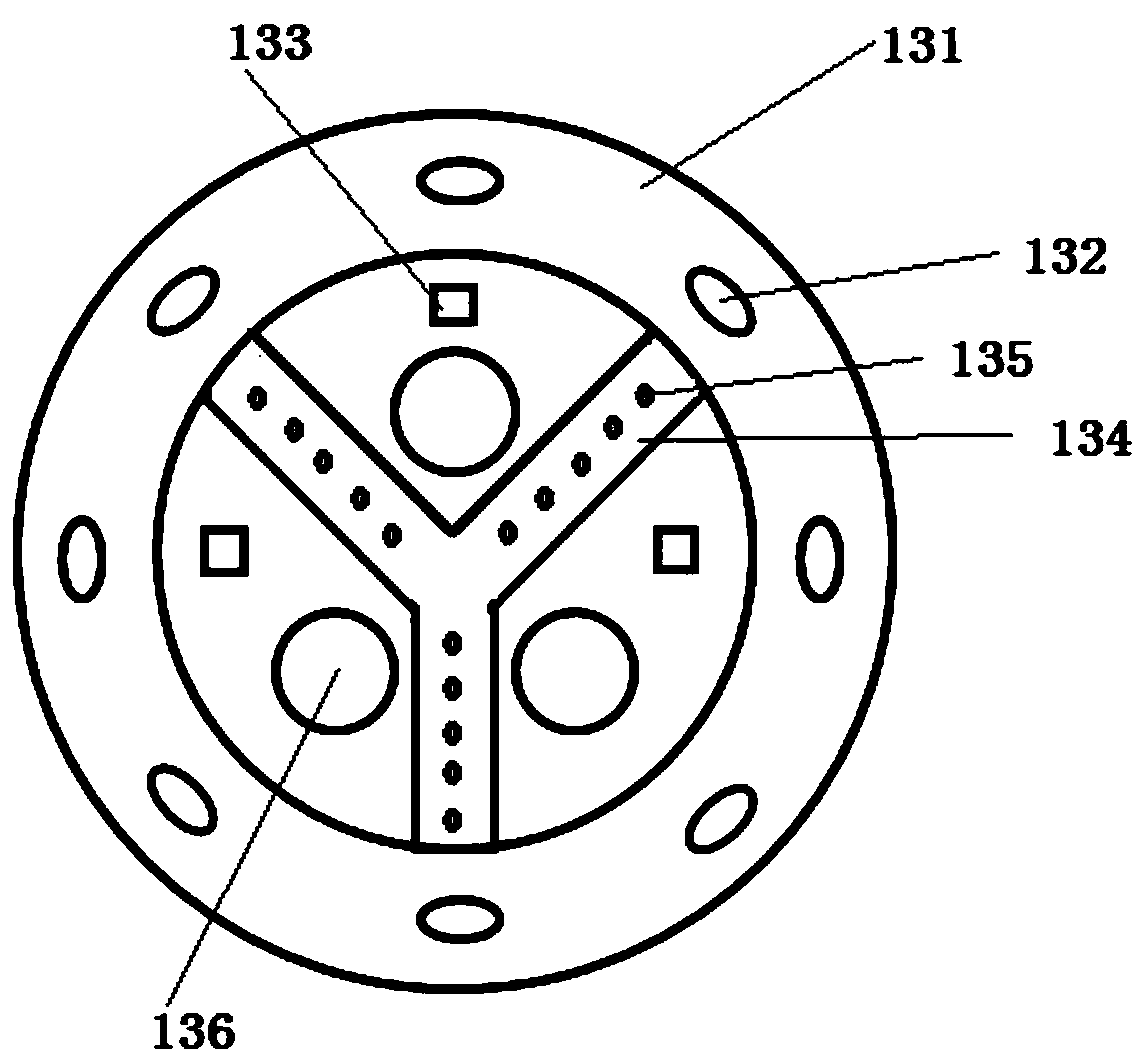

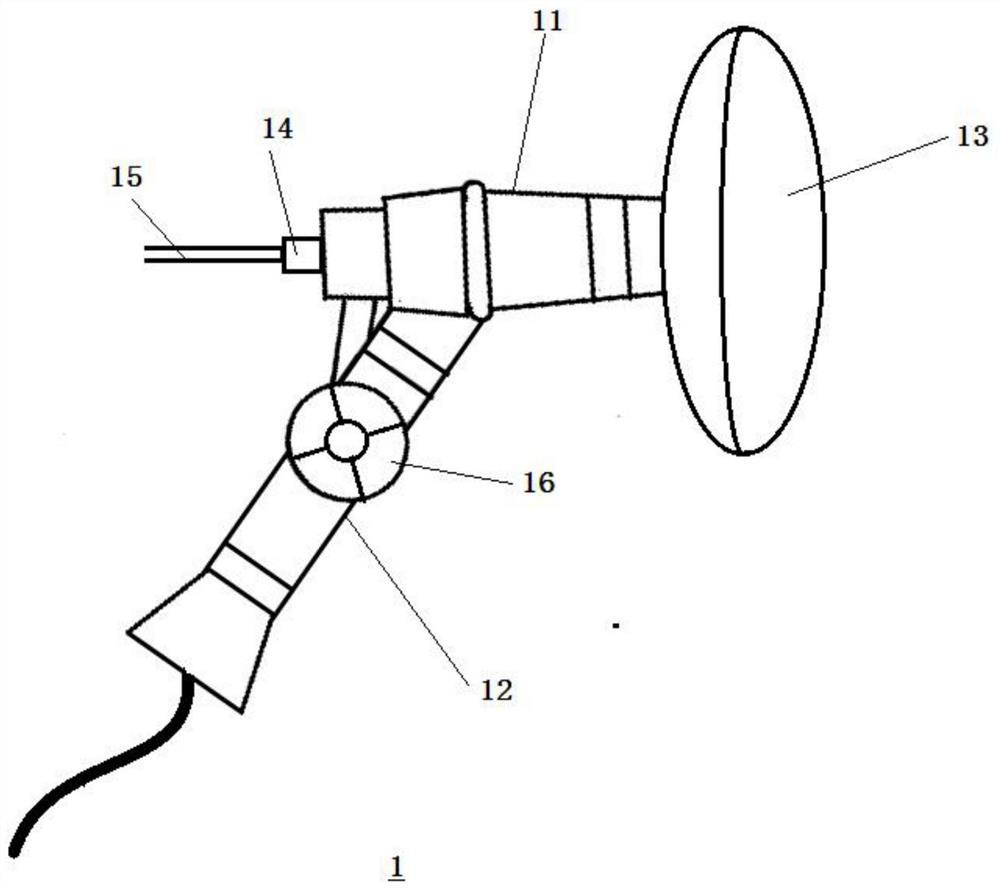

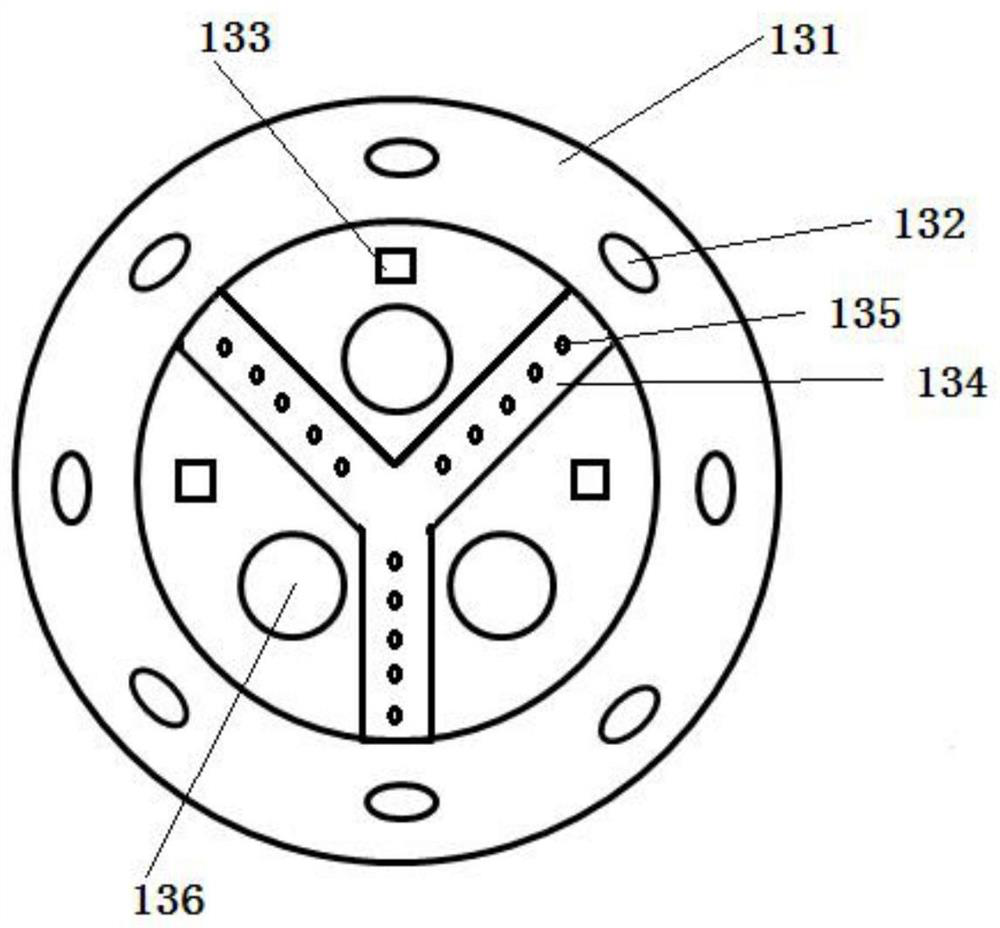

Device for removing bulging fat around the eyes

InactiveCN110559559BUniform ablationReduced responseSurgical instrument detailsRadiation therapyFluid controlControl engineering

The invention discloses a device for removing bulging fat in eyes, which comprises a central controller (6), a cooling fluid control part (3), a heating control part (4), a radio frequency control part (5) and a radio frequency handle (1 ); wherein, the central controller (6) is respectively connected to the cooling fluid control part (3), the heating control part (4), the radio frequency handle (1), and the radio frequency control part (5), for receiving the reservation program and the radio frequency handle (1 ) the temperature feedback signal of the temperature sensor (133); and according to the needs of the predetermined program and the temperature feedback signal, the corresponding control instructions for the cooling fluid, heating components and radio frequency signals are sent to the cooling fluid control part (3), heating The control unit (4) and the radio frequency control unit (5) are used to realize the control of corresponding components.

Owner:徐晓婷

A preparation method of density-controllable profiling rotator

ActiveCN107475899BImprove profile accuracyImprove interlayer cohesionNeedling machinesVolumetric Mass DensityEngineering

The invention discloses a method for preparing a density-controllable profiling rotary body. More than two unit layers are sequentially stacked, followed by profiling acupuncture and stitching to obtain a density-controllable profiling rotary body. The invention can realize the profiling needle-punching forming of a center-symmetrical rotator with controllable density and arbitrary variable cross-section, and can be applied to aerospace ablation-resistant parts and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Narrow cryotherapy system

PendingCN114404019APrevent proliferationReach expansion forceCatheterSurgical instruments for coolingRestenosisCatheter

The invention relates to a narrow cryotherapy system. The narrow cryotherapy system is characterized in that an air outlet of an air source is connected with an air inlet pipeline of a pressure control valve; an air outlet of the pressure control valve is connected with an air inlet pipeline of the low-temperature pipeline and an air inlet pipeline of the normal-temperature pipeline, an air outlet of the low-temperature pipeline is connected with a first air inlet pipeline of the handle, and an air outlet of the normal-temperature pipeline is connected with a first air inlet pipeline of the handle; an air port of the handle is connected with an air port pipeline of the air pump; a first air outlet of the handle is connected with an air inlet pipeline of the equipment air return pipeline valve body; the second air outlet of the handle is in pipeline connection with the air inlet of the catheter; according to the narrow cryotherapy system, the expanded lumen can be torn and cracked, rapid shaping and expansion can be achieved, cryoablation can be conducted at the same time, the expansion effect can be kept to the maximum extent, meanwhile, inflammation exudation and granulation tissue hyperplasia can be inhibited, mucosa thickening and lumen restenosis can be reduced, and therefore the purpose of treating narrow through replacement is achieved.

Owner:NINGBO SHENGJIEKANG BIOTECH

Four-electrode self-triggering steepening gas switch

ActiveCN113745974AReliable conductionBreakdown promotionSpark gaps with auxillary triggeringEngineeringInductance

The invention discloses a four-electrode self-triggering steepening gas switch which is characterized in that an upper electrode is arranged at the upper part of an insulating sleeve, an upper intermediate electrode sleeves the upper electrode, an upper insulating flange is arranged between the upper electrode and the upper intermediate electrode, and sealing gaskets are respectively arranged between the upper insulating flange and the upper electrode and between the upper insulating flange and the upper intermediate electrode; a lower electrode corresponding to the upper electrode is arranged at the lower part of the insulating sleeve, a lower intermediate electrode sleeves the lower electrode, a lower insulating flange is arranged between the lower electrode and the lower intermediate electrode, and sealing gaskets are respectively arranged between the lower insulating flange and the lower intermediate electrode and between the lower insulating flange and the lower electrode; and an air inlet is formed in one side of the insulating sleeve, and an air outlet is formed in the other side correspondingly. According to the four-electrode self-triggering steepening gas switch, the gap of the two intermediate electrodes is firstly broken down to further assist the breakdown of a main gap, the breakdown between the electrodes does not ablate the internal insulating material, the switch can operate in a repetition frequency mode, the switch is stable in working property and long in service life, the structure is compact, and the conduction inductance is low.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com