Preparation method of MCrAlY high temperature protection coating

A protective coating and high temperature technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of low utilization rate, large particles of aggregated arc spot droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The nickel-based superalloy K423A test piece is pre-treated by wet sandblasting. The specific process parameters are: the sandblasting abrasive is white corundum, the abrasive size is 180 mesh, and the sandblasting pressure is 0.2MPa.

[0025] Table 1 NiCoCrAlYTa coating process flow chart

[0026]

[0027] The NiCoCrAlYTa alloy target is used, the working gas is 99.999% argon, the K423A test piece is suspended in the vacuum chamber hanger, and a NiCoCrAlYTa layer of about 45 μm is deposited. After coating, the surface of the coated coating on the two base materials is flat and smooth, the roughness is Ra2.07μm, the color of the coating is uniform, and the bending test results show no peeling. Anti-oxidation test results show that the average oxidation rate is 0.033g / m 2 h, the amount of scale shedding is 1.53g / m 2 , the coating meets the oxidation resistance level. Gas hot corrosion test results show that the average corrosion rate is 0.01g / m 2 , the surface sta...

Embodiment 2

[0029] The nickel-based superalloy DZ22B test piece is pre-treated by wet sandblasting. The specific process parameters: the sandblasting abrasive is white corundum, the abrasive size is 200 mesh, and the sandblasting pressure is 0.3MPa.

[0030] Table 2 NiCoCrAlYTa coating process flow chart

[0031]

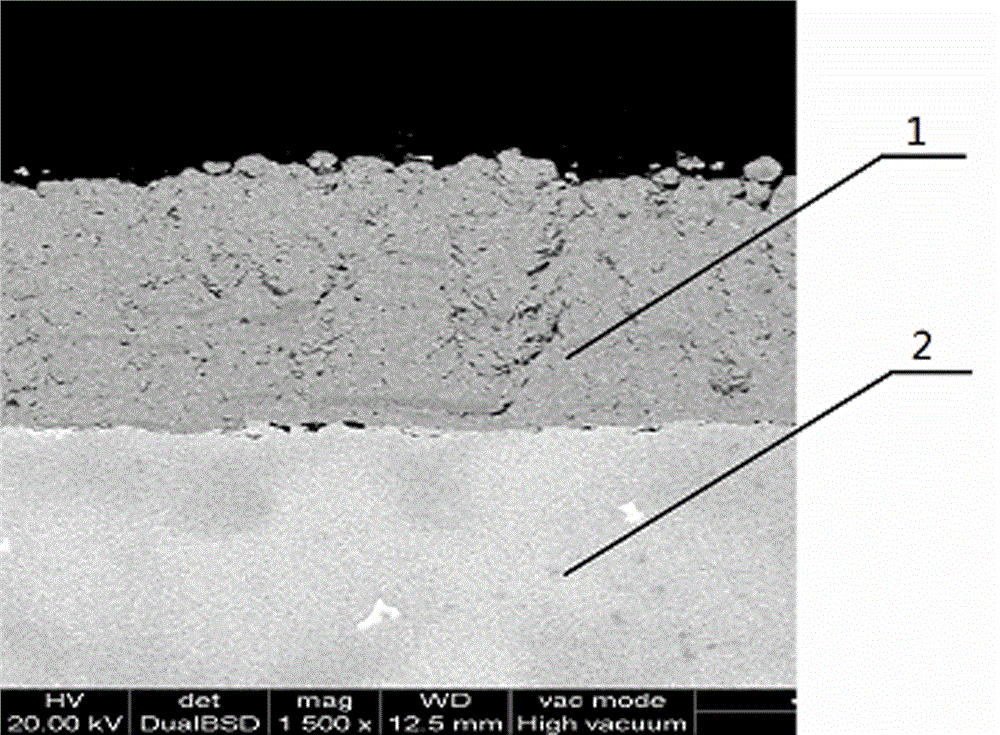

[0032] NiCoCrAlYTa alloy target is used, the working gas is 99.999% argon, the DZ22B test piece is suspended in the vacuum chamber hanger, and a NiCoCrAlYTa layer of about 58 μm is deposited (see image 3 , 1 in the figure is the coating, 2 is the substrate). After coating, the surface of the coated coating on the two base materials is flat and smooth, the roughness is Ra3.02μm, the color of the coating is uniform, and the bending test results show no peeling. Static oxidation test results show that the average oxidation rate is 0.058g / m 2 h, the amount of scale shedding is 1.94g / m 2 , the coating meets the oxidation resistance level. Gas hot corrosion test results show ...

Embodiment 3

[0034] The nickel-based superalloy K403 workpiece is pre-treated by wet sandblasting. The specific process parameters: the abrasive for sandblasting is white corundum, the size of the abrasive is 100 mesh, and the blasting pressure is 0.1MPa.

[0035] Table 3 NiCrAlY coating process flow chart

[0036]

[0037] The NiCrAlY alloy target is used, the working gas is 99.999% argon, the K403 test piece is suspended in the vacuum chamber hanger, and a NiCrAlY layer of about 25 μm is deposited. After coating, the surface of the coated coating on the two substrates is flat and smooth, the roughness is Ra1.75μm, the color of the coating is uniform, and the bending test results show no peeling. Static oxidation test results show that the average oxidation rate is 0.033g / m 2 h, the scale shedding amount is 0.97g / m 2 , the coating meets the complete anti-oxidation level; the gas hot corrosion test results show that the average corrosion rate is 0.04g / m 2 , the surface state of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com