Method for preparing p-type copper-sulfur-containing transparent conductor film

A technology of transparent conductive film and copper-sulfur, which is applied in vacuum evaporation plating, coating, sputtering plating, etc., can solve the problems that the research on sulfide film deposition has not been reported.

Active Publication Date: 2010-02-10

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

PLD has high effectiveness and universality, but it is generally only used to deposit oxide films, and the deposition research of sulfide films has not been reported.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

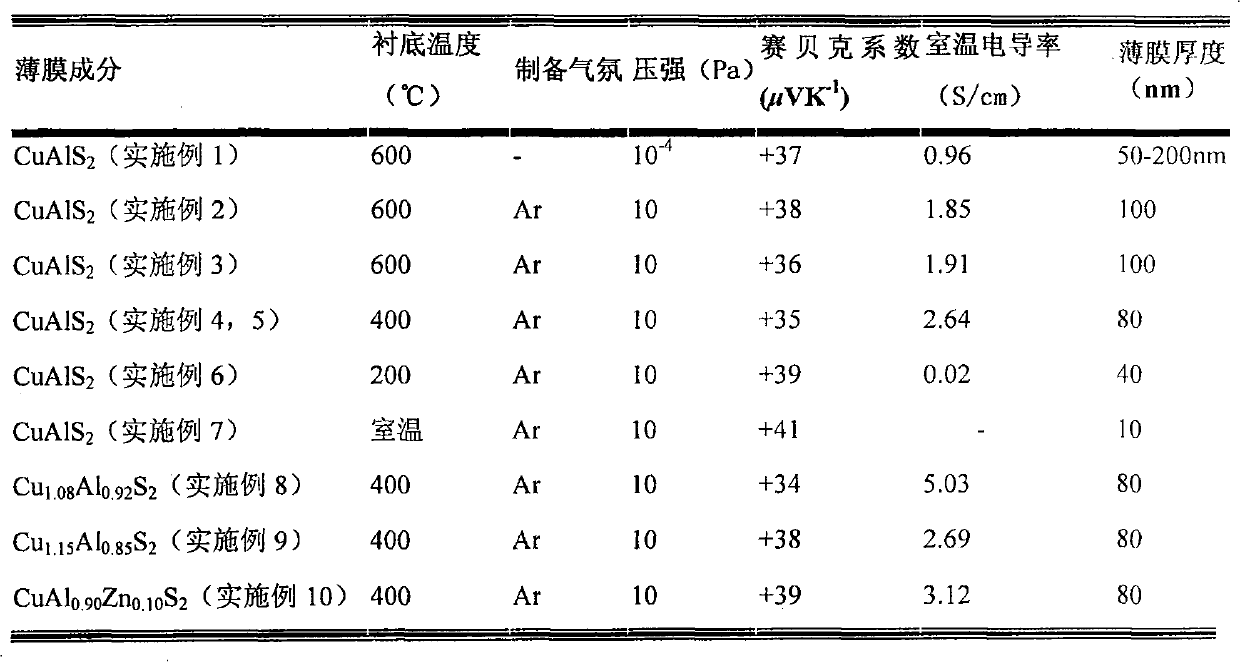

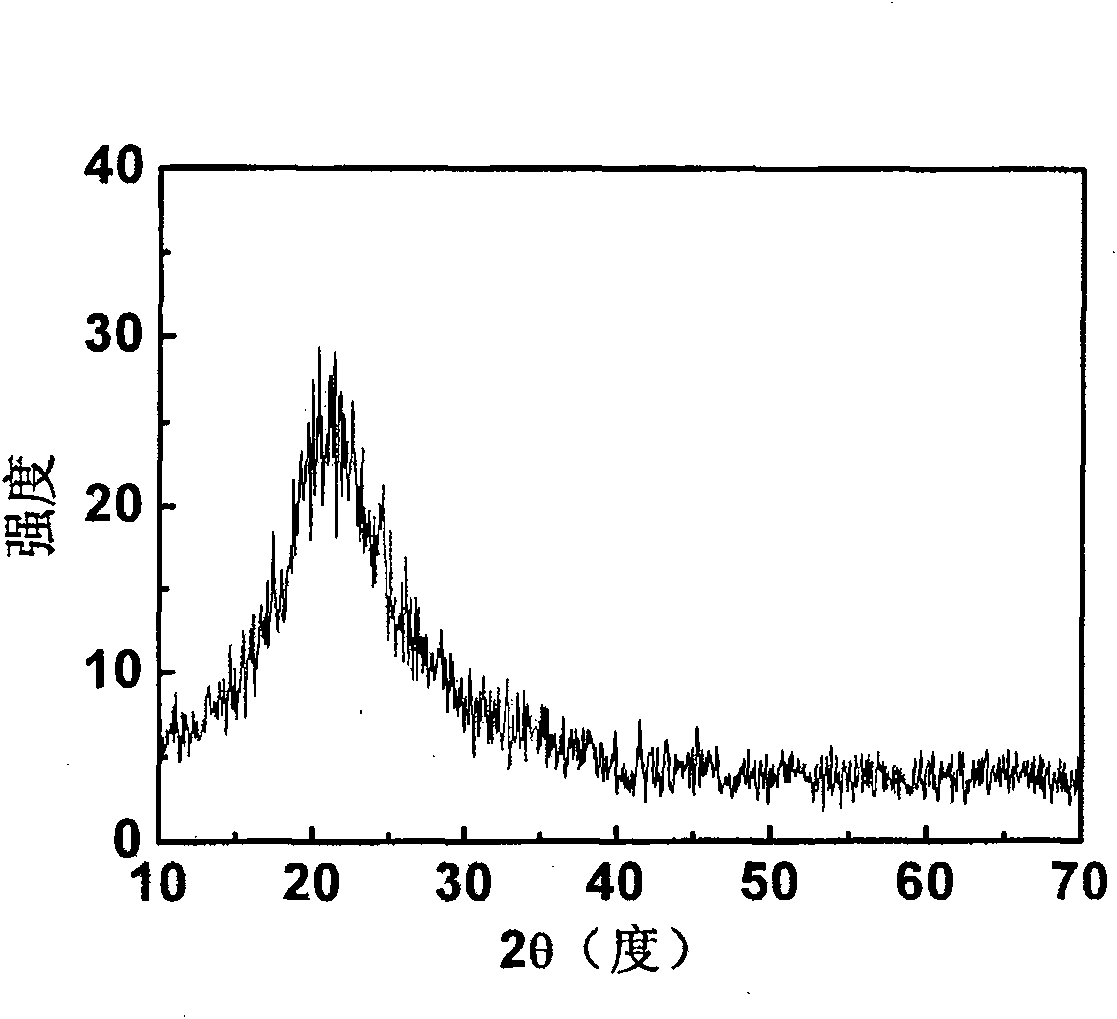

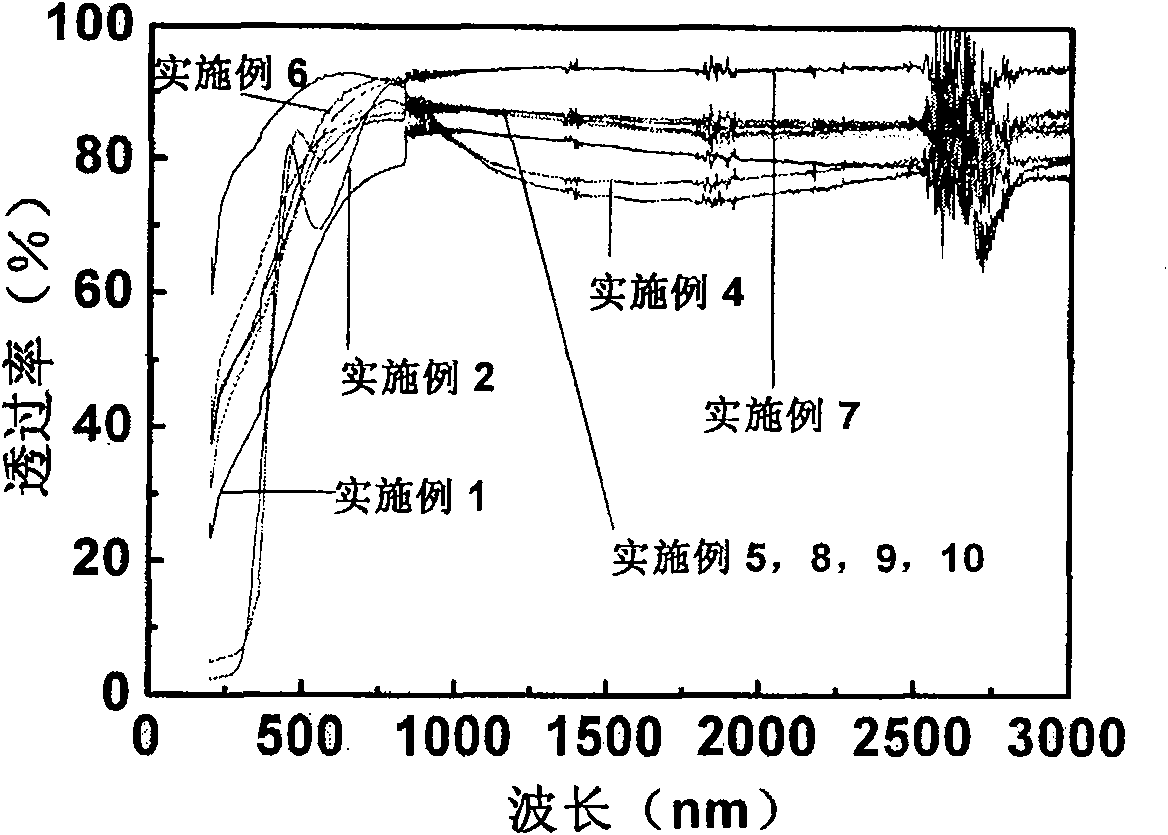

The present invention is pulse laser deposition (PLD) process for preparing p-type compound CuAlS2 in chalcopyrite structure and transparent doped conducting film. The PLD process prepares p-type compound CuAlS2 or doped film on the substrate of quartz glass, common glass or Si chip by using the compound block obtained through solid phase reaction and SPS sintering or no-pressure sintering as thetarget and under proper conditions of atmospheric pressure, substrate temperature, and laser strength and frequency. The prepared CuAlS2 film has p-type conductivity, high conductivity, high visible light transparency and other excellent optoelectronic performance, and may find its broad application foreground in electronics and optoelectronics.

Description

technical field The invention relates to a chalcopyrite structure compound CuAlS which can be used for p-type transparent conductors 2 The method of film preparation. The invention belongs to the technical field of transparent conductive material (TCM) film. Background technique A transparent conductor is a material that is highly transparent in the visible region and has good electrical conductivity. In 1907, Badeker first reported the translucent conductive CdO material [K.Badeker, Ann.Phys.Leipzig1907, 22, 749], which attracted people's attention. Until World War II, due to military needs, transparent conductors were widely valued and applied. Transparent conductors are basically oxides, also known as transparent conducting oxides (TCO). TCO can be divided into n-type and p-type according to the conductivity characteristics. n-type TCO materials such as In 2 o 3 :Sn(ITO), SnO 2 :F(FTO) and Zn:Al(AZO), as transparent electrodes, have been widely used in flat displa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C14/28C23C14/06B22F3/16C23C14/56

Inventor 黄富强刘敏玲陈立东

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com