Mask plate used for evaporation and manufacturing method thereof

A manufacturing method and masking plate technology, which are applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of deviation of evaporation holes, reduction of evaporation effect, deformation of evaporation holes, etc., and achieve improved Accuracy and stability, reduce manufacturing cost, improve the effect of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

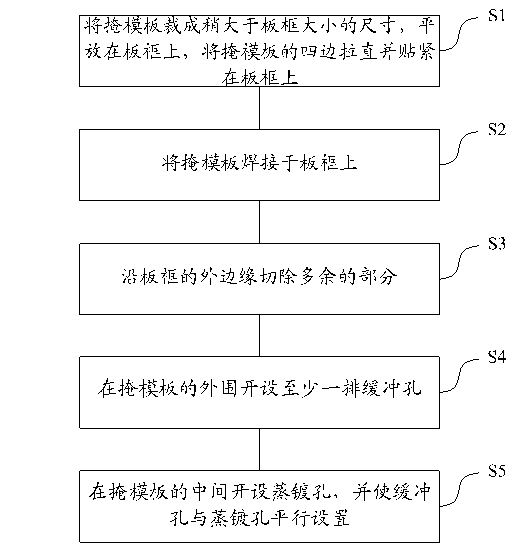

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

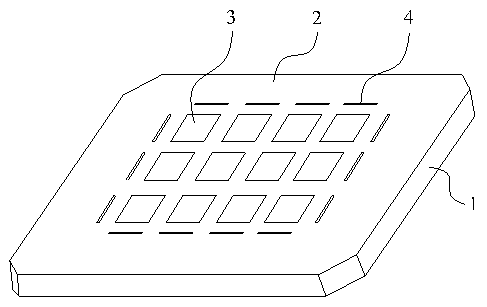

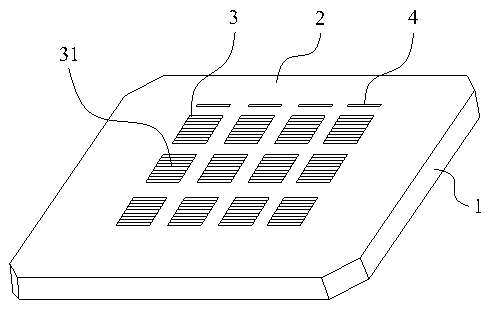

[0031] figure 1 It is a schematic diagram of the structure of the mask plate for evaporation in the embodiment of the present invention Figure 1 ; figure 2 It is a schematic diagram of the structure of the mask plate for evaporation in the embodiment of the present invention Figure II .

[0032] refer to figure 1 As shown, this embodiment provides a mask for evaporation, including a plate frame 1 and a mask plate 2 flattened and fixed on the plate frame. The mask plate 2 is provided with a plurality of evaporation holes 3 arranged regularly. The vapor deposition hole 3 is located at the center of the mask plate 2 and inside the plate frame 1 . A circle of buffer holes 4 is provided around the vapor deposition hole 3 for buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com