Graphene-based dielectric elastomer composite material and preparing method thereof

A dielectric elastomer and graphene-based dielectric technology, which is applied in the field of graphene-based dielectric elastomer composite materials and their preparation, can solve the problem of high dielectric loss, low electrical breakdown strength, and influence on percolation. Threshold and other issues, to achieve the effect of reducing dielectric loss, high breakdown strength, and improving electrical breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) 100 mg of graphite oxide synthesized by the Hummers method was dissolved in 200 mL of deionized water, and 1000 W ultrasonic dispersion was performed for 1 h. The graphite oxide was exfoliated into flake graphene oxide with a thickness of about 1 nm, and a stable suspension of graphene oxide was obtained. aqueous solution;

[0040] (2) Adjust the pH of the graphene oxide aqueous solution prepared in step (1) to 8.5 with 0.24 g of tris hydroxymethylaminomethane solid, add 50 mg of dopamine, and react with mechanical stirring at 60 °C for 6 h. After the reaction, use a microporous membrane to vacuum filter, deionize and wash, and vacuum dry to obtain a dopamine-modified graphene oxide solid;

[0041] (3) Graphene oxide modified by step (2) is ultrasonically dispersed in deionized water, and then with 10 g of carboxylated nitrile latex (the brand produced by Zeon Company is the carboxylated nitrile latex of Nipol 5171H, Wherein the solid content is 40 wt.%, acrylonitr...

Embodiment 2

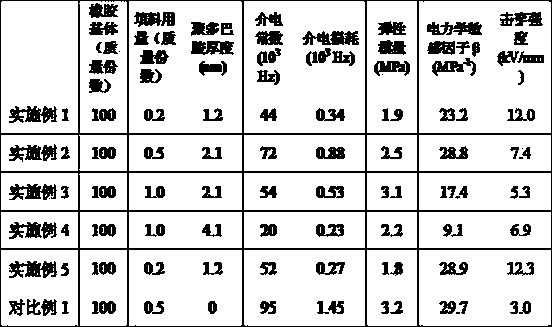

[0046] The preparation method is the same as in Example 1, except that the ultrasonic conditions in step (1) are: 300 W, 6 h; the amount of dopamine used in step (2) is 100 mg; the amount of dopamine-modified graphene oxide in step (3) The dosage is 20 mg. The composition of the graphene-based dielectric elastomer composite obtained in this example is 4 g of carboxylated nitrile rubber, 20 mg of dopamine-modified graphene oxide, and the thickness of the polydopamine organic layer is 2.1 nm. The test results are shown in Table 1.

Embodiment 3

[0048] The preparation method is the same as in Example 1, except that the consumption of graphite oxide in step (1) is 200 mg, and the consumption of deionized water is 400 mL; The usage amount is 200 mg; the usage amount of dopamine-modified graphene oxide in step (3) is 40 mg. The composition of the graphene-based dielectric elastomer composite obtained in this example is 4 g of carboxylated nitrile rubber, 40 mg of dopamine-modified graphene oxide, and the thickness of the polydopamine organic layer is 2.1 nm. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com