Method and device for checking the seal of structural seals

A seal and construction technology, applied in construction, protection devices, infrastructure engineering, etc., can solve the problems of high maintenance cost, leakage, cost consumption, etc., and achieve the effect of preventing current shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

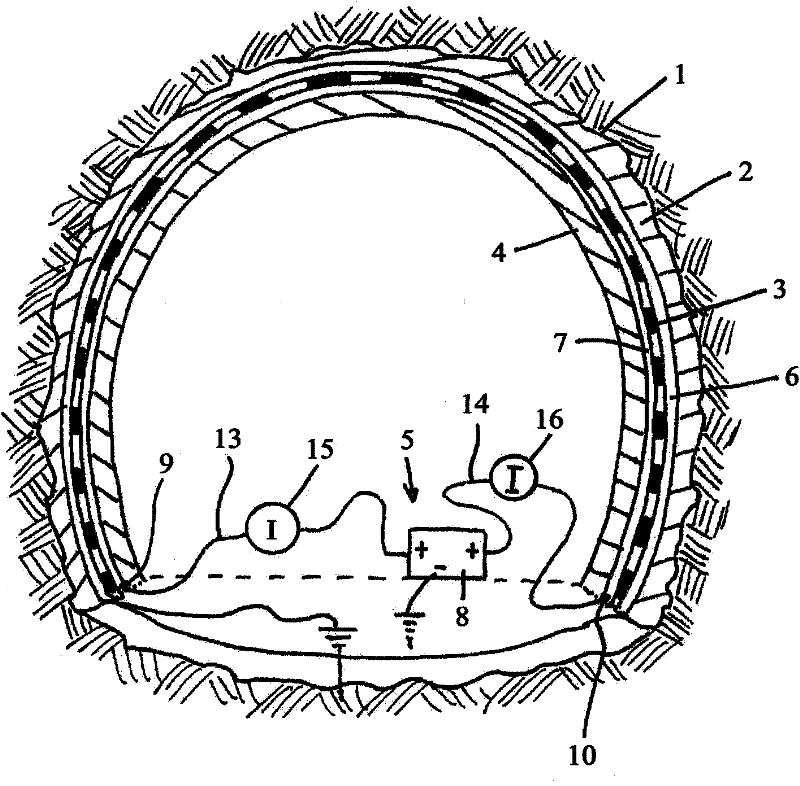

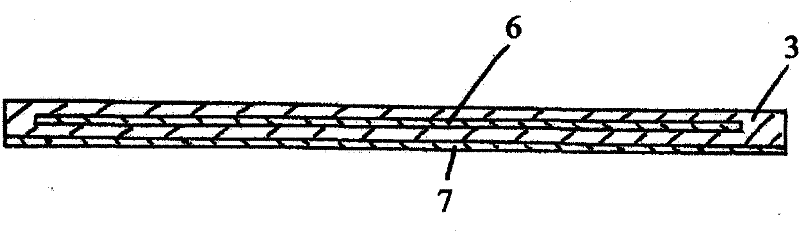

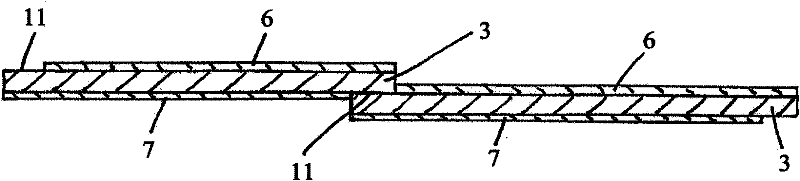

[0036] figure 1 The dome of the shown tunnel is covered with shotcrete 2 and steel lining directly after the construction of the Gebirgsausbruch 1 . The advancement of such tunnels is usually discontinuous over axial local sections. The reinforced concrete shotcrete 2 forms an outer dome whose inner surface is covered by a building seal 3 . The building seal 3 prevents the penetration of water or moisture from the mountain into the region of the outer dome 2 . Immediately on the inner side of the building seal 3 is an inner dome 4 made of concrete, which is also referred to below as an “inner shell”. Before the inner dome or the inner shell 4 is poured with concrete, the sealing performance of the building seal 3 is tested. In this case, the building seal 3 is provided with a detection device 5 for localizing possible damage or defects.

[0037]The building seal 3 to be tested is a seal which has a material-dependent high insulation resistance and a high dielectric strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com