Preparation method of large-area high-order porous anodised aluminium film

A highly ordered and porous anode technology, applied in the field of electrochemistry, can solve the problems affecting the uniform growth of oxide film, difficulty, flash fire, etc., and achieve the effect of obvious self-organization effect and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

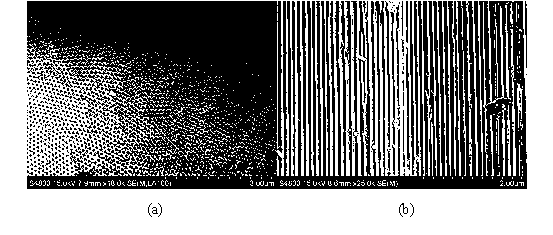

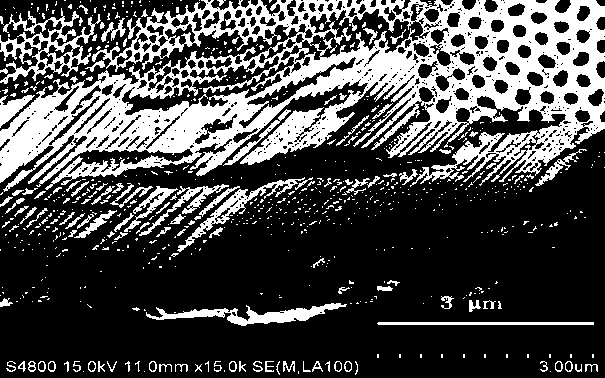

[0020] First, immerse an aluminum foil strip with a purity of 99.99%, a thickness of 200 μm, and a width of 10 mm in a 2 wt % sodium hydroxide solution at a temperature of 70 ° C for 2 minutes to remove the natural oxide film on the aluminum surface. Then rinse it with deionized water, put it into the electrolytic cell as the anode, and use another aluminum foil strip of the same size that has not been treated to remove the natural oxide film as the cathode. With 6M concentrated sulfuric acid aqueous solution as the electrolyte, at 100mA·cm -2 The current density of the constant current anodization is carried out under the condition of vigorously stirring the electrolyte. The temperature of the electrolyte is maintained at about 20°C by a water bath. The oxidation time is determined by the thickness of the PAA template, and the growth rate of the oxide film is about 3 μm min -1 . The morphology of the obtained samples is as figure 1 shown. figure 1 (a) is the SEM image of...

Embodiment 2

[0022] First, immerse an aluminum foil strip with a purity of 99.99%, a thickness of 200 μm, and a width of 10 mm in a 3 wt % sodium hydroxide solution at a temperature of 65 ° C for 3 minutes to remove the natural oxide film on the aluminum surface. Then rinse it with deionized water, put it into the electrolytic cell as the anode, and use another aluminum foil strip of the same size that has not been treated to remove the natural oxide film as the cathode. Using 1M concentrated sulfuric acid aqueous solution as the electrolyte, the constant current anodic oxidation was carried out under the condition of vigorously stirring the electrolyte at a current density of 50mA·cm-2. The temperature of the electrolyte is maintained at about 10°C by a water bath. The oxidation time is determined by the thickness of the PAA template, and the growth rate of the oxide film is about 1 μm·min-1. The average hole spacing of PAA nanoholes is about 45nm.

Embodiment 3

[0024] First, immerse an aluminum foil strip with a purity of 99.99%, a thickness of 200 μm, and a width of 10 mm in a 3 wt % sodium hydroxide solution at a temperature of 75 ° C for 1 minute to remove the natural oxide film on the aluminum surface. Then rinse it with deionized water, put it into the electrolytic cell as the anode, and use another aluminum foil strip of the same size that has not been treated to remove the natural oxide film as the cathode. Using 6M concentrated sulfuric acid aqueous solution as the electrolyte, the constant current anodic oxidation is carried out under the condition of vigorously stirring the electrolyte at a current density of 80mA·cm-2. The temperature of the electrolyte is maintained at about 40°C by a water bath. The oxidation time is determined by the thickness of the PAA template, and the growth rate of the oxide film is about 2 μm·min-1. The average hole spacing of PAA nanoholes is about 55nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com