Preparation method of transmission electron microscope sample

A transmission electron microscope sample and sample technology, which is applied in the field of integrated circuit manufacturing, can solve problems such as sample damage and electrical breakdown, and achieve the effect of avoiding accumulation and breakdown of the insulating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below Figure 3-6 , the specific embodiment of the present invention will be further described in detail.

[0034] It should be noted that, in the following embodiments, the target structure in the form of trenches is taken as an example for illustration.

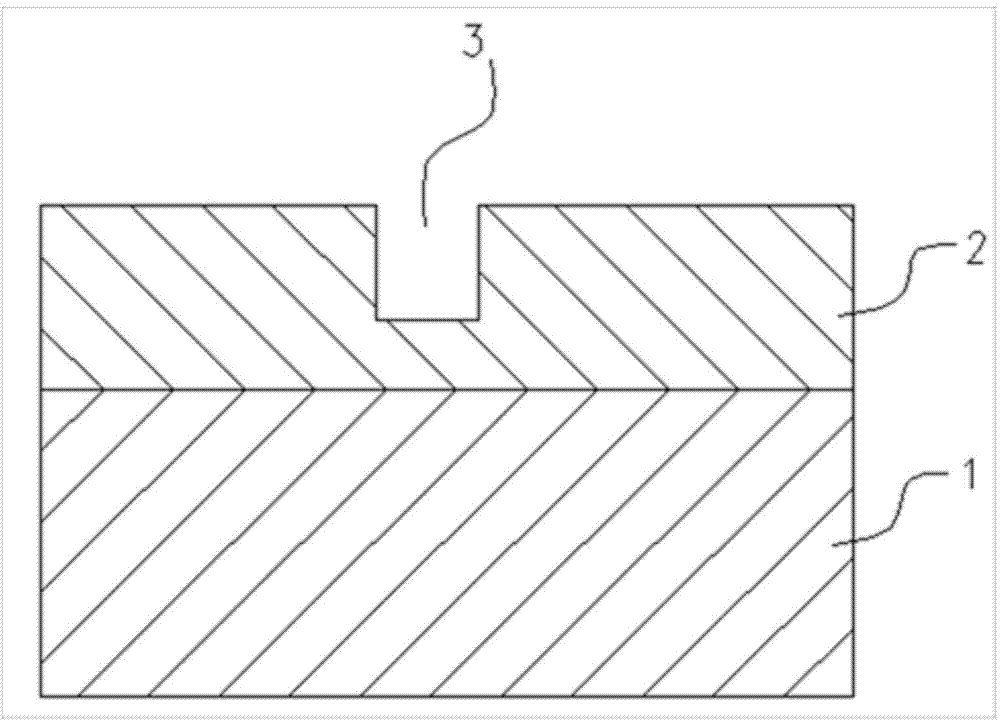

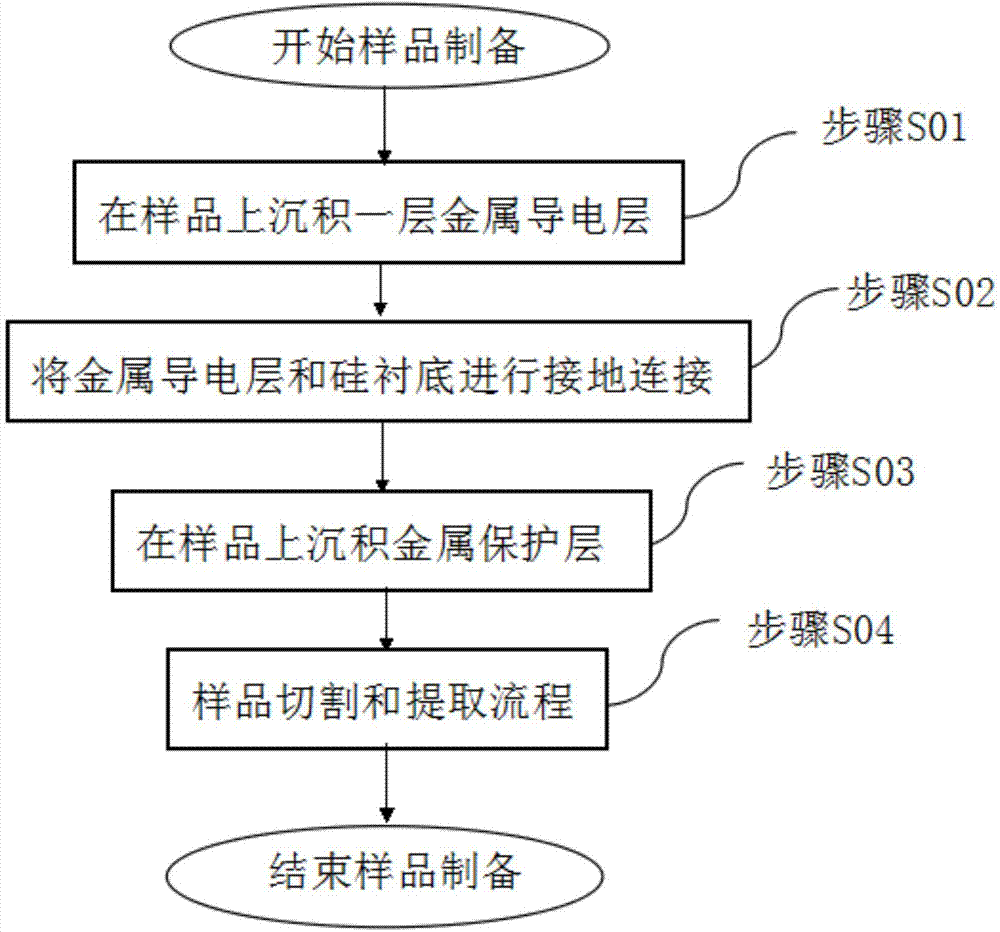

[0035] see image 3 , image 3 Make flow block diagram for sample of the present invention; It has illustrated a kind of preparation method of TEM sample, and described TEM sample comprises silicon substrate 1 and insulating layer 2, and described insulating layer 2 has target structure 3, and described target structure 3 is a through hole or a groove, and further includes the following steps:

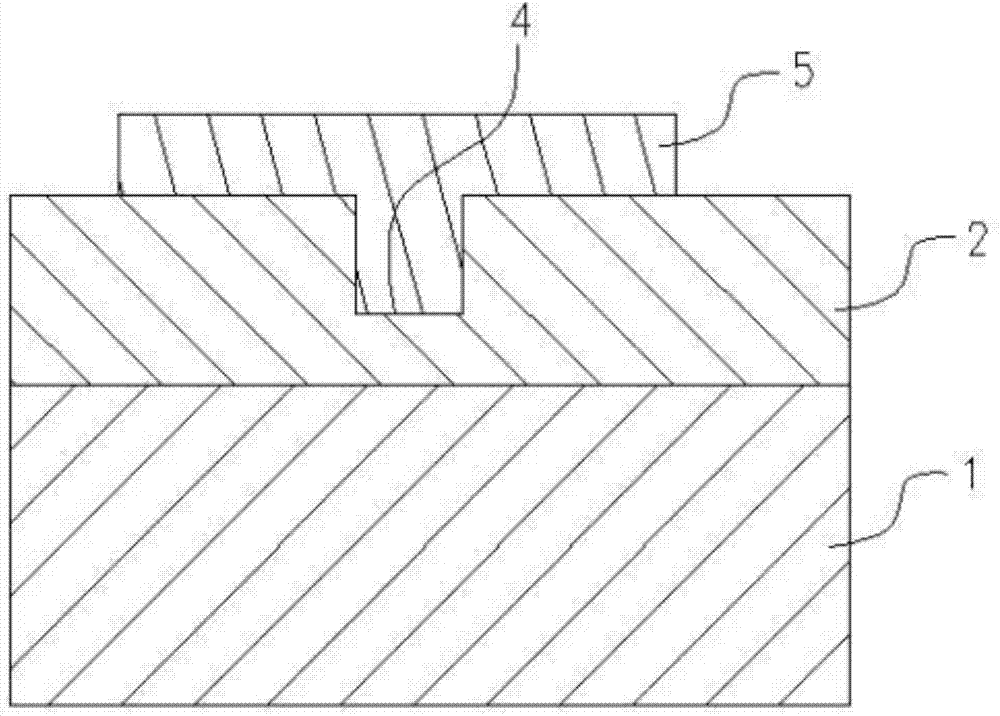

[0036] Step S01: depositing a metal conductive layer 6 on the surface of the sample and the inner wall of the target structure 3;

[0037] see Figure 4 , Figure 4 It is a structural schematic diagram of depositing a layer of metal conductive layer on the sample in the present invention. The deposition method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com