Sealing microcrystalline glass, and sealing method and application thereof

A technology of glass-ceramics and glass, which is applied in the field of sealing metal shells of electronic components and sealing glass-ceramics, can solve problems such as less research or technology, and achieve simple process, excellent sealing performance, and dielectric loss electric shock The effect of high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

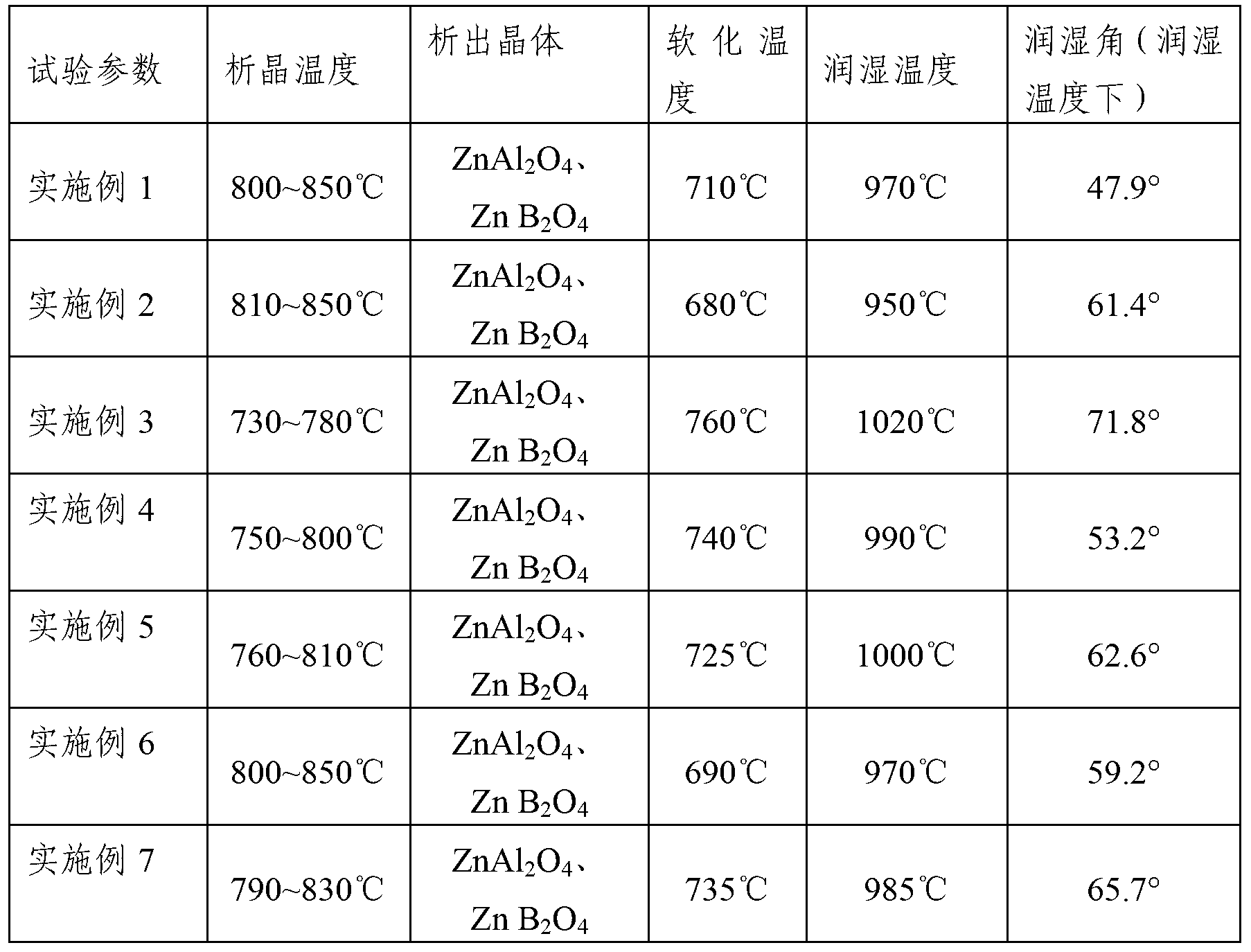

Examples

Embodiment 1

[0050] The sealing process of embodiment 1 glass-ceramic is as follows:

[0051] (1) Mix the raw materials for sealing the glass-ceramics described in Example 1 in Table 1, add absolute ethanol, and ball mill until the raw material components are evenly mixed.

[0052] (2) Heat the material obtained in step (1) to about 1500°C and keep it warm for about 4 hours, then rapidly cool the obtained molten glass through a rolling mill (cooling rate is about 1200°C / s) and roll it to obtain a flake, The resulting flakes are then ground into glass powder with a particle size of 2-10 microns.

[0053] (3) Add about 5% by mass of PVA binder to the glass powder obtained in step (2) for granulation, and then make a glass green body.

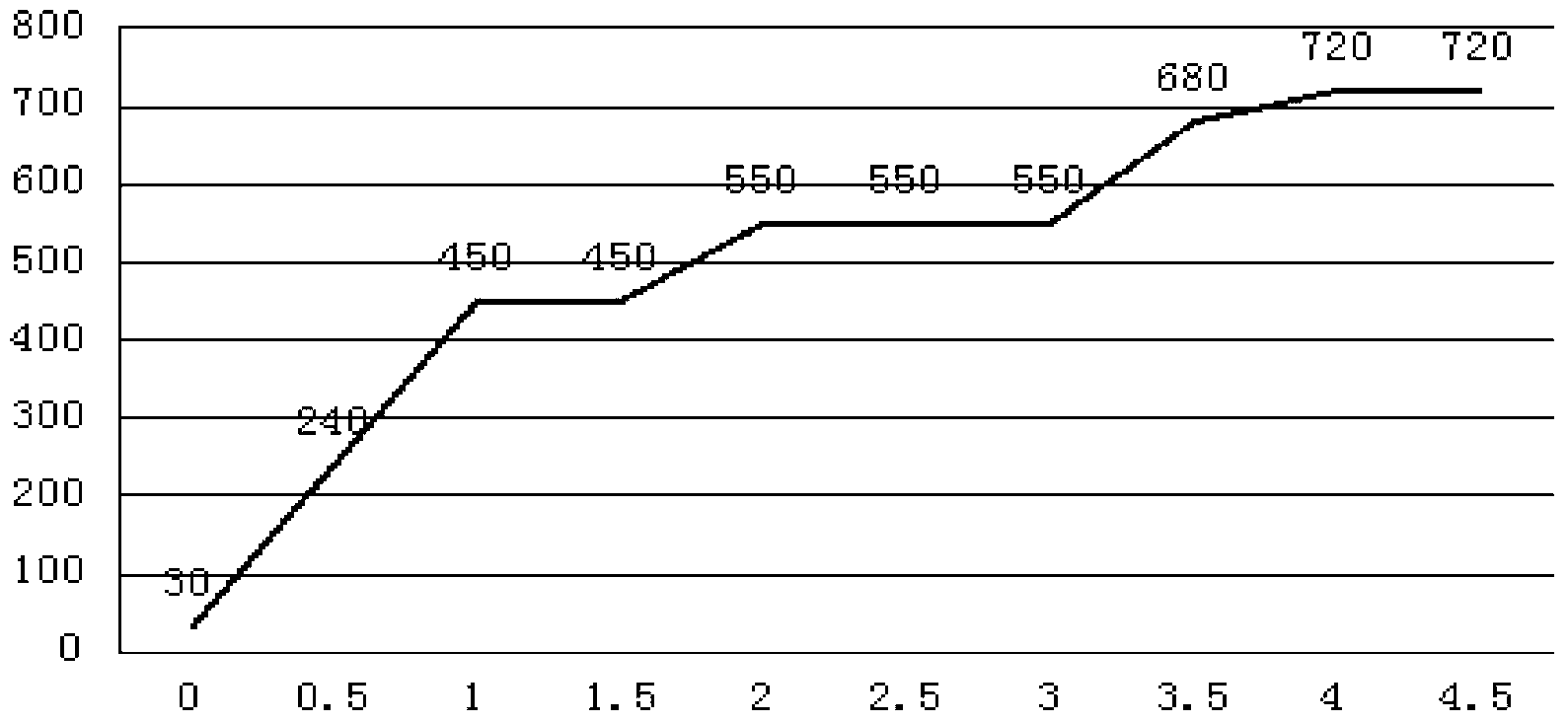

[0054] (4) the glass green body obtained in step (3) according to figure 1 The dewaxing regime is shown for dewaxing.

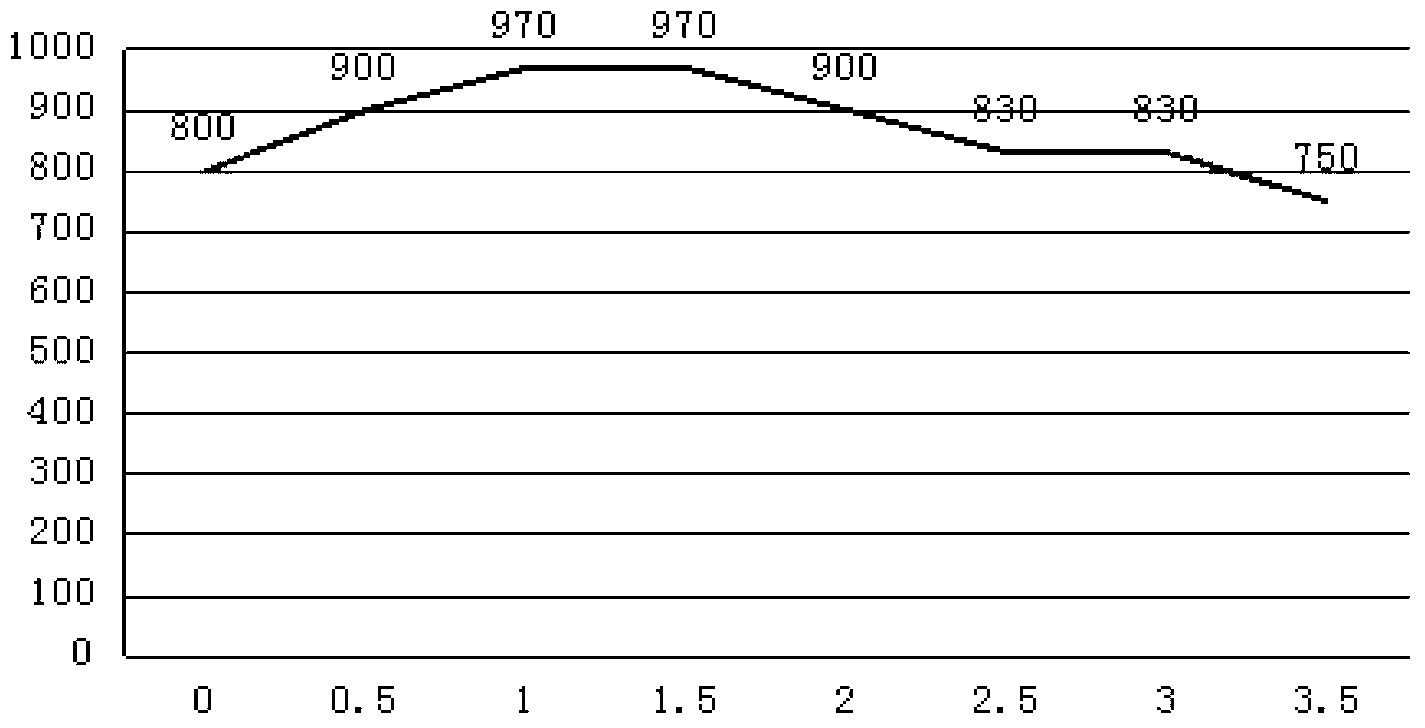

[0055] (5) Put the dewaxed glass green body under the atmosphere of nitrogen protection according to figure 2 Sealing was performed usi...

Embodiment 2

[0057] The sealing process of embodiment 2 glass-ceramics is as follows:

[0058] (1) Mix the raw materials for sealing the glass-ceramics described in Example 2 in Table 1, add absolute ethanol, and ball mill until the raw material components are evenly mixed.

[0059] (2) Heat the material obtained in step (1) to about 1450°C and keep it warm for about 5 hours, then rapidly cool the obtained molten glass through a rolling mill (cooling rate is about 1150°C / s) and roll it to obtain a flake, The resulting flakes are then ground into glass powder with a particle size of 2-10 microns.

[0060] (3) Add about 5% by mass of PVA binder to the glass powder obtained in step (2) for granulation, and then make a glass green body.

[0061] (4) the glass green body obtained in step (3) according to figure 1 The dewaxing regime is shown for dewaxing.

[0062] (5) Put the dewaxed glass green body under the atmosphere of nitrogen protection according to figure 2 Sealing was performed us...

Embodiment 3

[0064] The sealing process of embodiment 3 glass-ceramics is as follows:

[0065] (1) Mix the raw materials for sealing the glass-ceramics described in Example 3 in Table 1, add absolute ethanol, and ball mill until the raw material components are evenly mixed.

[0066] (2) Heat the material obtained in step (1) to about 1550°C and keep it warm for about 3 hours, then rapidly cool the obtained molten glass through a rolling mill (cooling rate is about 1400°C / s) and roll to obtain flakes, The resulting flakes are then ground into glass powder with a particle size of 2-10 microns.

[0067] (3) Add about 5% by mass PEG binder to the glass powder obtained in step (2) for granulation, and then make a glass green body.

[0068] (4) the glass green body obtained in step (3) according to figure 1 The dewaxing regime is shown for dewaxing.

[0069] (5) Put the dewaxed glass green body under the atmosphere of nitrogen protection according to figure 2 Sealing was performed using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com