Patents

Literature

32results about How to "Extend power-on time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

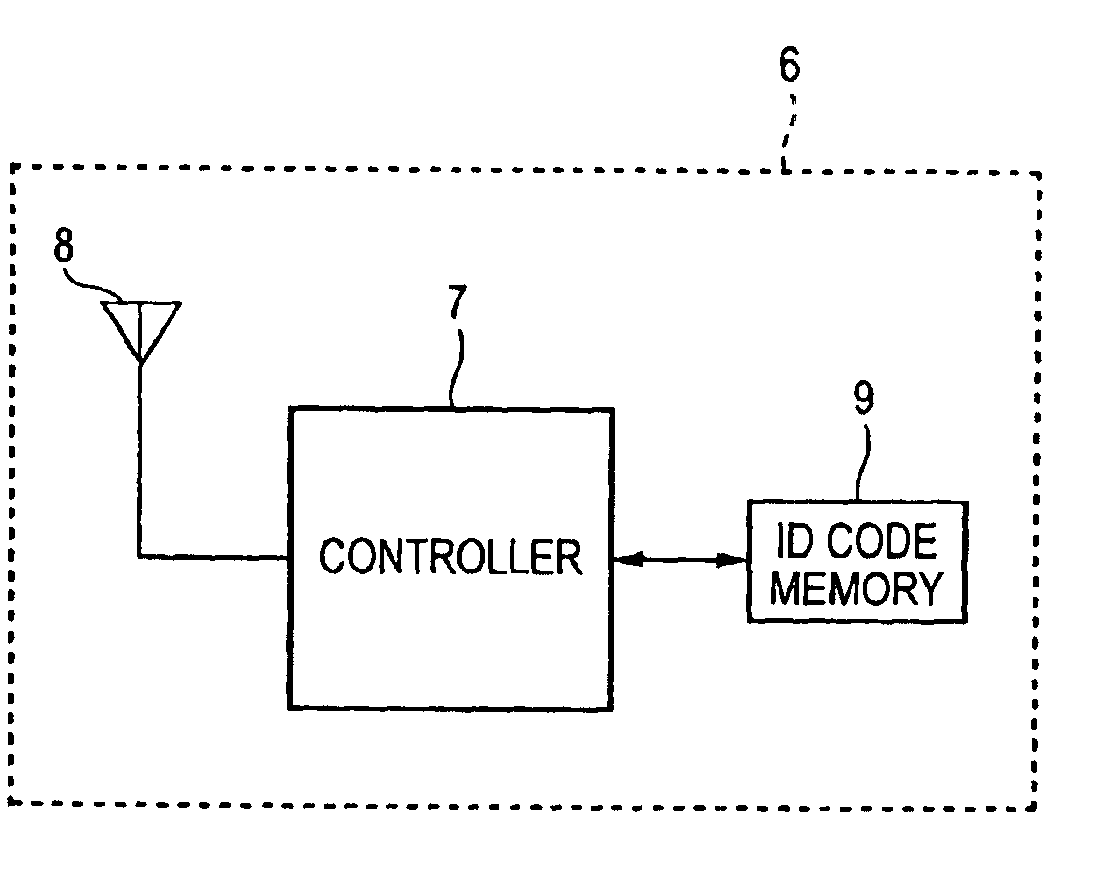

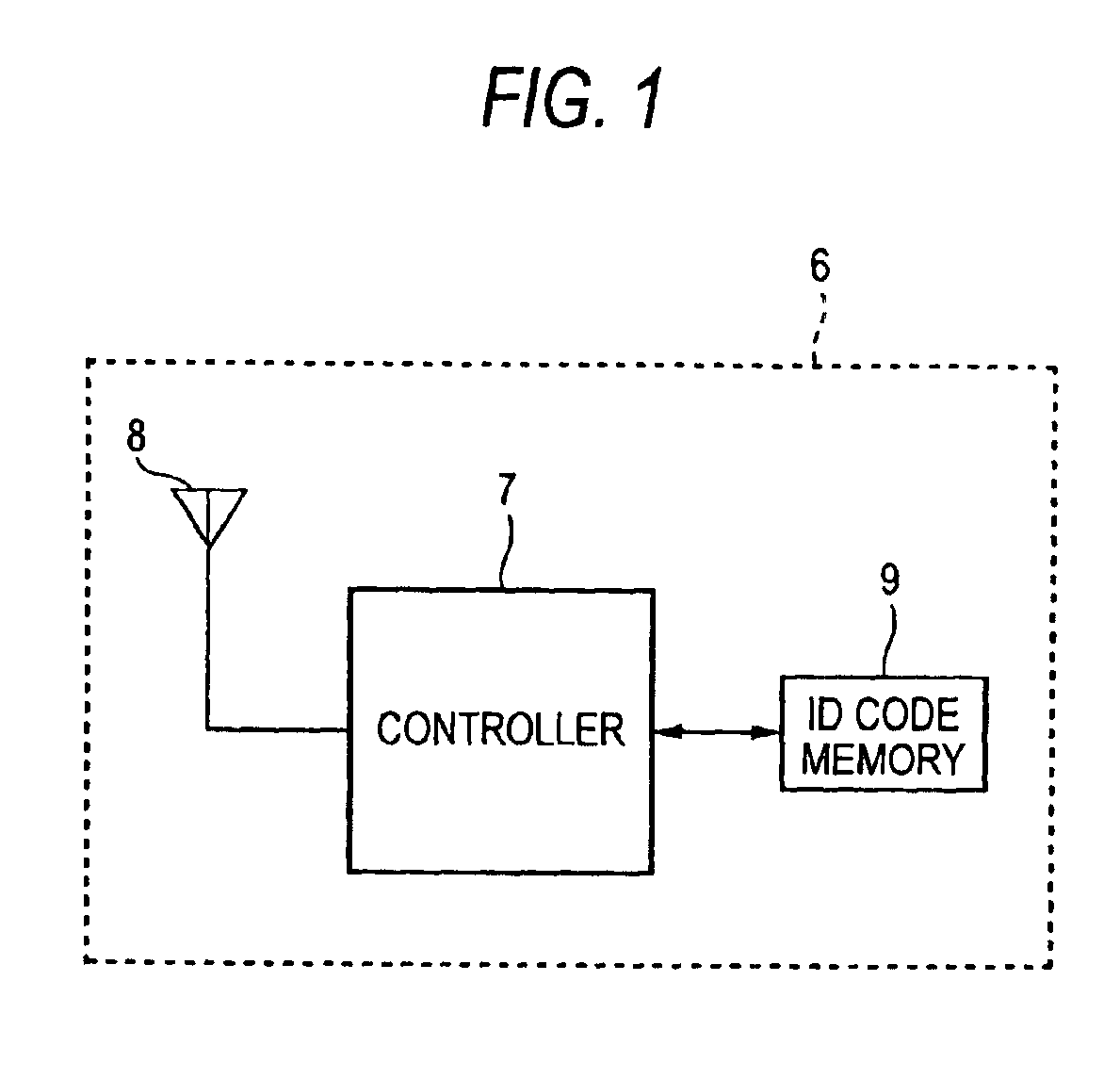

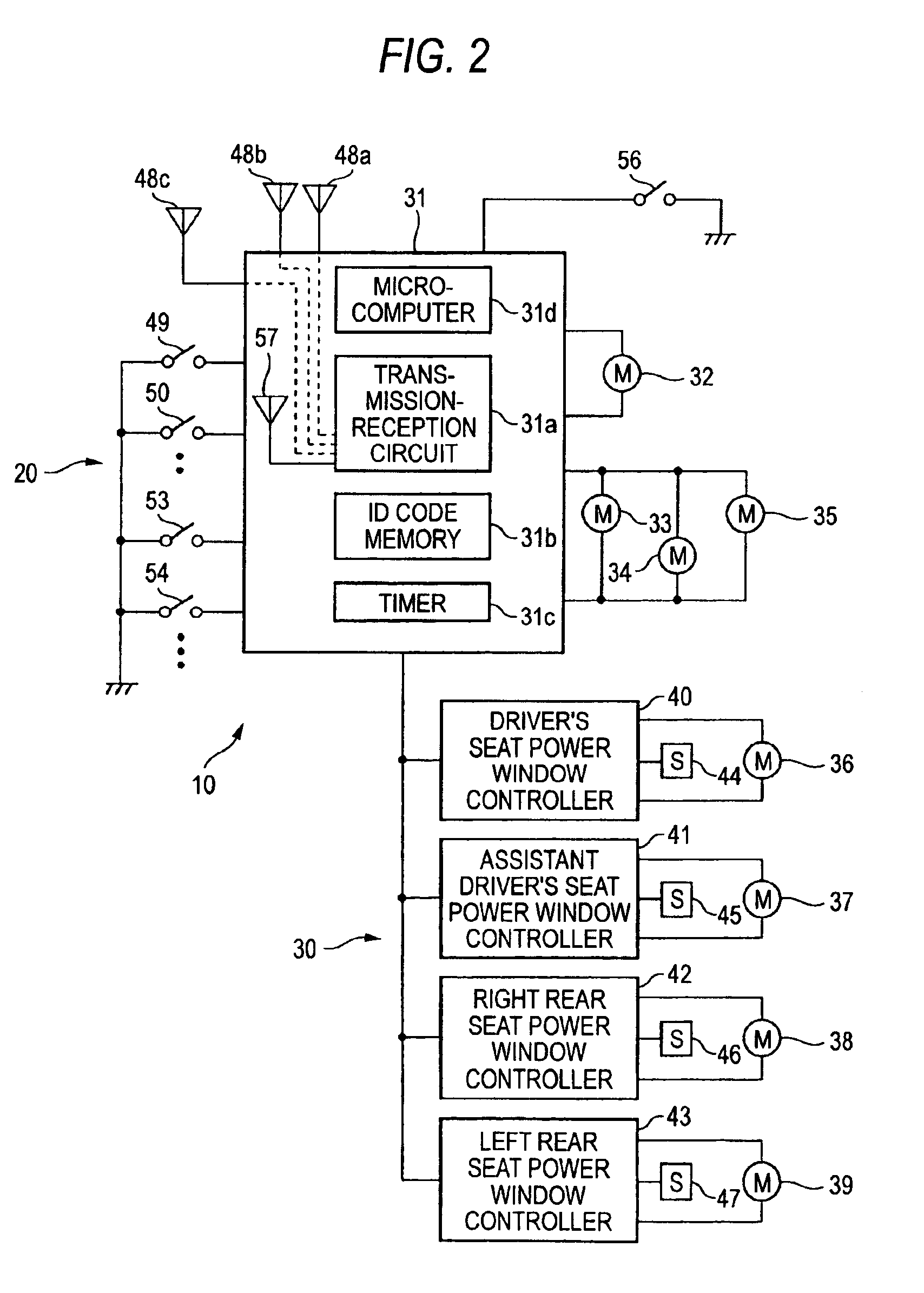

Wireless communication system for vehicle

InactiveUS6944528B2Improve convenienceEasy to useDigital data processing detailsAnti-theft devicesCommunications systemMaster controller

A wireless communication system for a vehicle, including: a portable transmitter-receiver adapted to communicate information wirelessly; a main controller mounted on the vehicle, the main controller adapted to communicate information wirelessly with the portable transmitter-receiver, to determine whether the portable transmitter-receiver is located within a communicatable range, and to output an enable signal when the portable transmitter-receiver is located within the communicatable range; a sub-controller mounted on the vehicle and connected to the main controller, the sub-controller adapted to enable-control of a vehicle mounted electronic device when the enable signal is input from the main controller.

Owner:CALSONIC KANSEI CORP

Preparing method of waterproof electric-breakdown-resisting coating

ActiveCN107058979AExtend power-on timeImprove electrical breakdown resistancePrinted circuit manufactureSpecial surfacesCross-linkHigh energy

The invention discloses a preparing method of a waterproof electric-breakdown-resisting coating, and belongs to the technical field of plasma chemical vapor phase deposition. According to the method, a base material is placed in a reaction cavity, continuous vacuum pumping is carried out, and inert gases or nitrogen is led in; monomer steam is led to start plasma discharge, the waterproof electric-breakdown-resisting coating is prepared on the surface of the base material; the monomer steam is a mixture of at least one kind of single-functional unsaturated fluorocarbon resin and at least one kind of polyfunctionality unsaturated hydrocarbon derivatives, wherein the mass percent of the polyfunctionality unsaturated hydrocarbon derivatives in the monomer steam ranges from 30% to 50%. Extra cross-linked points are led in by introducing of other monomer components with polyfunctional group cross-linked structures to form a cross-linked structure; plasma is broken by active base groups with high energy in the monomer components to form active points, the introduced extra active points are subject to cross-linking polymerization under the plasma environment to form a compact net-shaped structure, hydrophobicity of a thin film is ensured, and the property of corrosion resistance and underwater powering resistance of an electronic product is improved.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

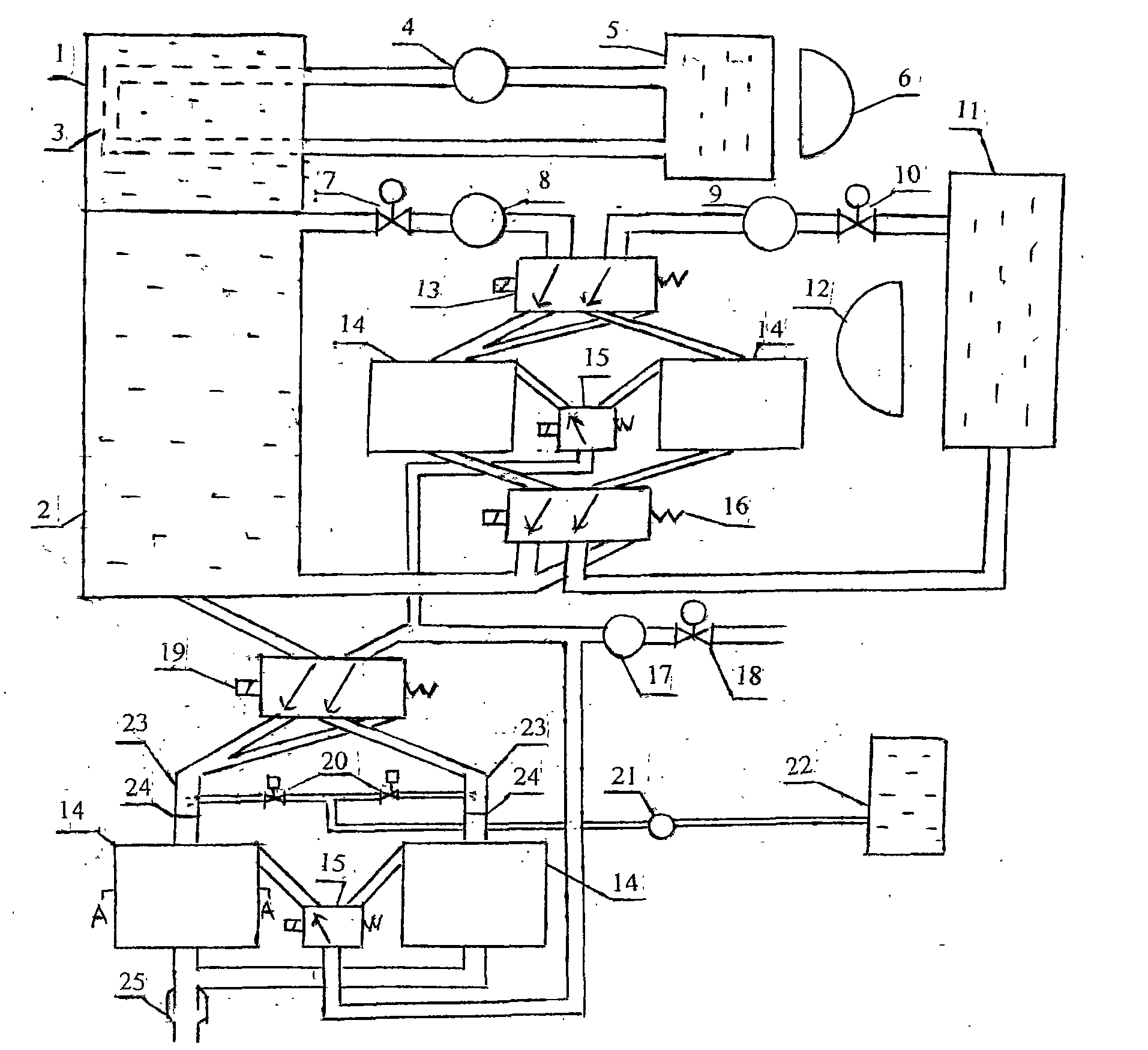

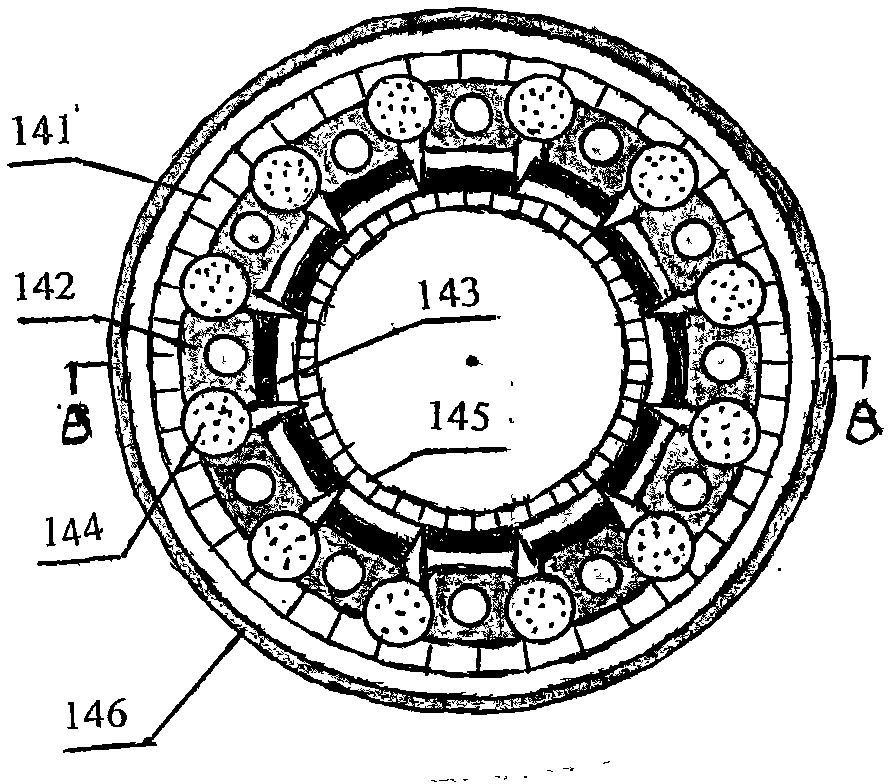

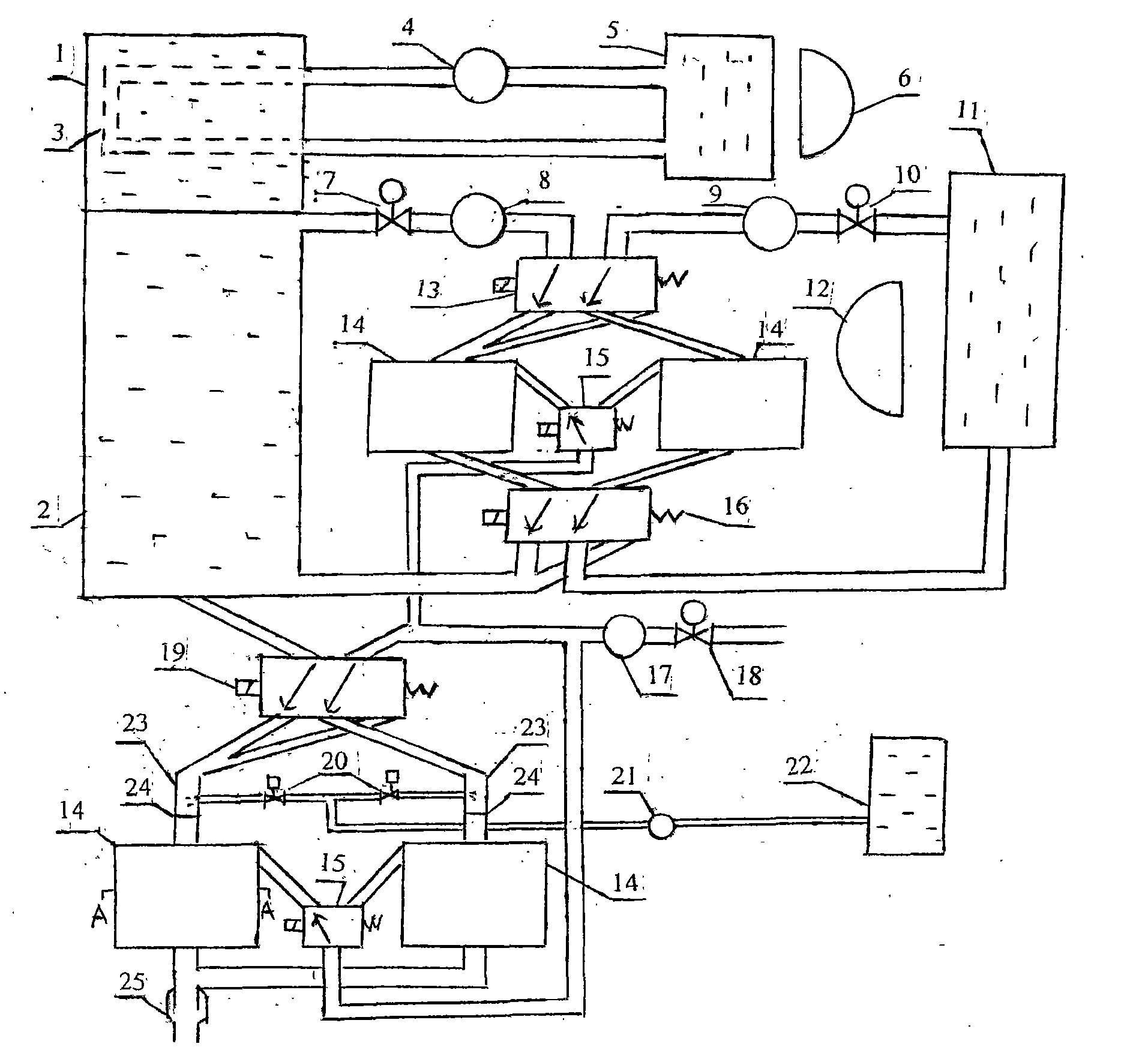

Power generating device by waste heat of automobiles

ActiveCN102510243AImprove pressure resistanceAccelerated corrosionInternal combustion piston enginesEngine componentsNon magneticAlternating current

The invention discloses a power generating device by waste heat of automobiles. A plurality of novel alloy bars are attached to the inner side of a circular iron hose of a power generator, coils are mounted between adjacent novel alloy bars and arranged in coil slots formed by adjacent novel alloy bars in a surrounded manner, heat and cold exchange holes are arranged on the novel alloy bars, an elongated rare earth magnet is attached on an outer face side of each alloy bar, magnetic polarities of the rare earth magnets on the face sides of the adjacent novel alloy bars are opposite, the other magnetic polarity surfaces of the rare earth magnets are wrapped on steel pipes, and the power generator is provided with an outer casing. The novel alloy bars are non-magnetic substances at a certain low temperature while are magnetic substances at a certain high temperature. When the rare earth magnets are close to the novel magnetic alloy bars, magnetism of the novel magnetic alloy bars is doubled. The novel alloy bars have magnetism after being heated by tail gas or a heat medium liquid in a cylinder liner of an automobile and have no magnetism after being cooled by cold air with water mist or refrigerant liquid, and high alternating current can be produced in the coils by repeating the above steps and can be used as power force for electric automobiles.

Owner:张英华

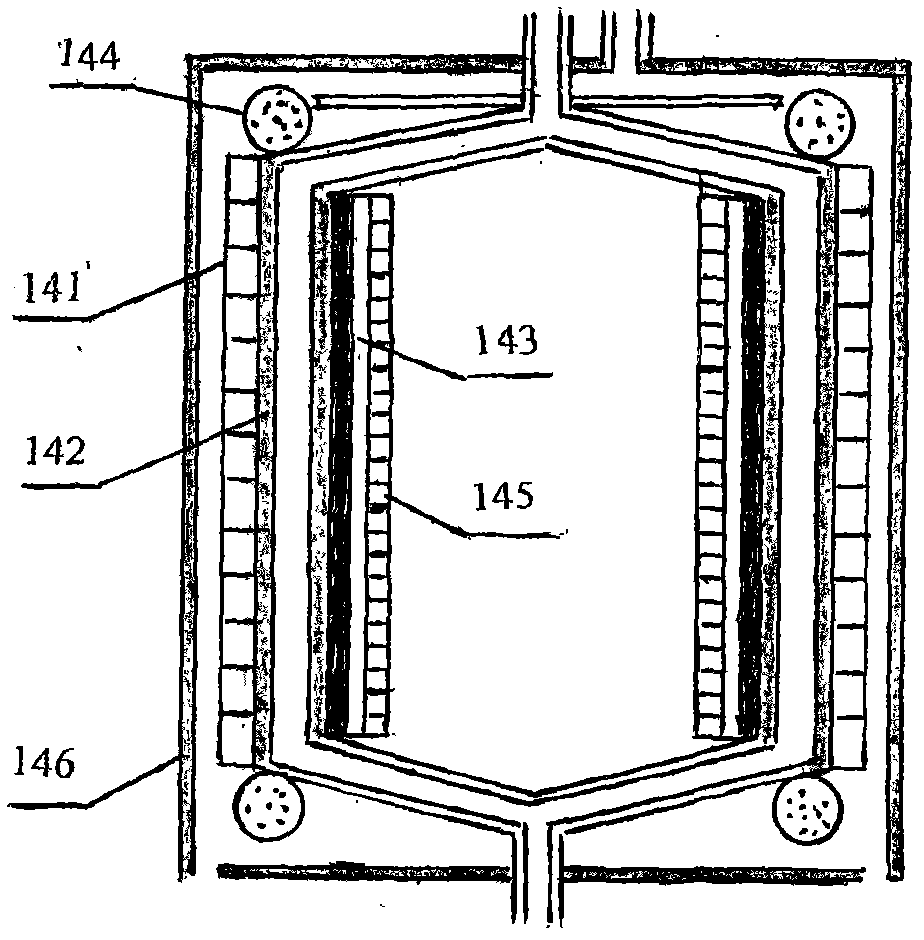

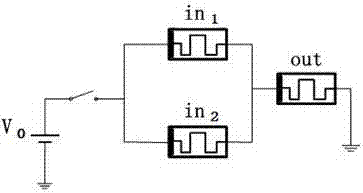

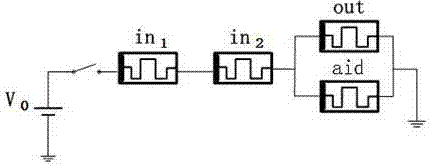

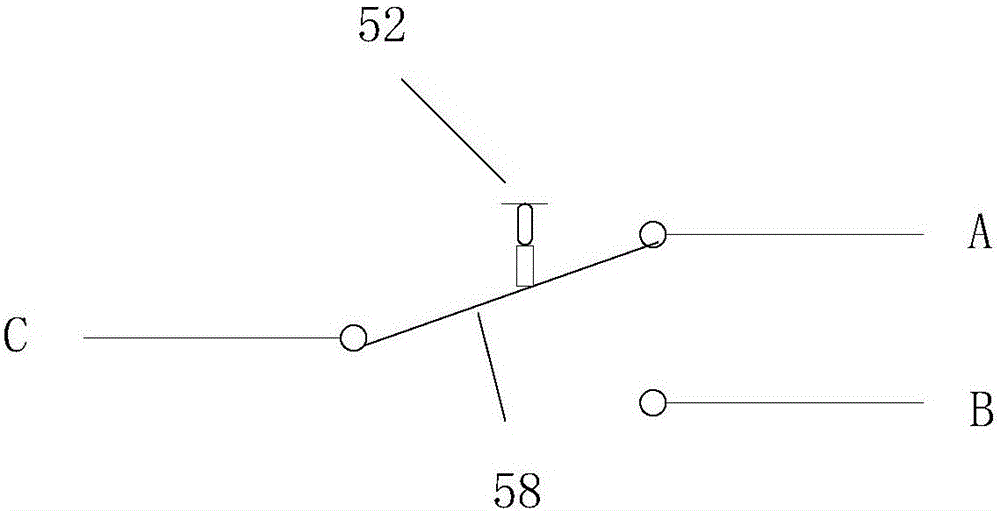

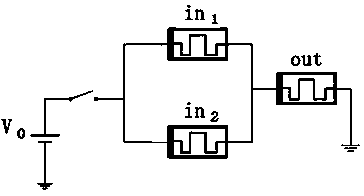

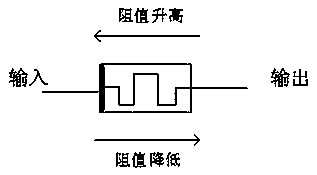

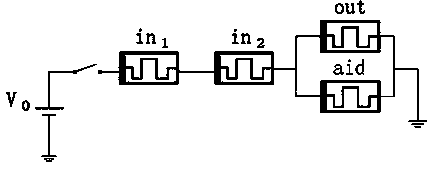

Memristor-based XOR gate circuit and designing and manufacturing method thereof

ActiveCN106941350AImplement logical operationsSmall sizeExclusive-OR circuitsCAD circuit designExertionEngineering

The invention discloses a memristor-based XOR gate circuit and a designing and manufacturing method thereof, which aims to solving the problem that a currently available memristor-based auxiliary logic MACIG gate set is incomplete. Therefore, the invention provides a new type of memristor-based XOR gate circuit designing method. The XOR gate of the invention is improved on the basis of the MAGIC OR gate. According to the invention, the two ends of the output memristor of the OR gate circuit are connected with memristors in parallel and the improved gate circuit is capable of obtaining correct XOR gate logic operation result. The XOR gate adopts fewer components with only four memristors and the excitation voltage sequence is simple, requiring only one stable and unchanging externally added excitation source. In addition, the energy comsumption of the XOR gate is low. Only with the exertion of short-term voltage, it is possible to realize the logic operations to the XOR gate. Beyond that, the XOR gate circuit has a simple structure and a small size.

Owner:SOUTHEAST UNIV

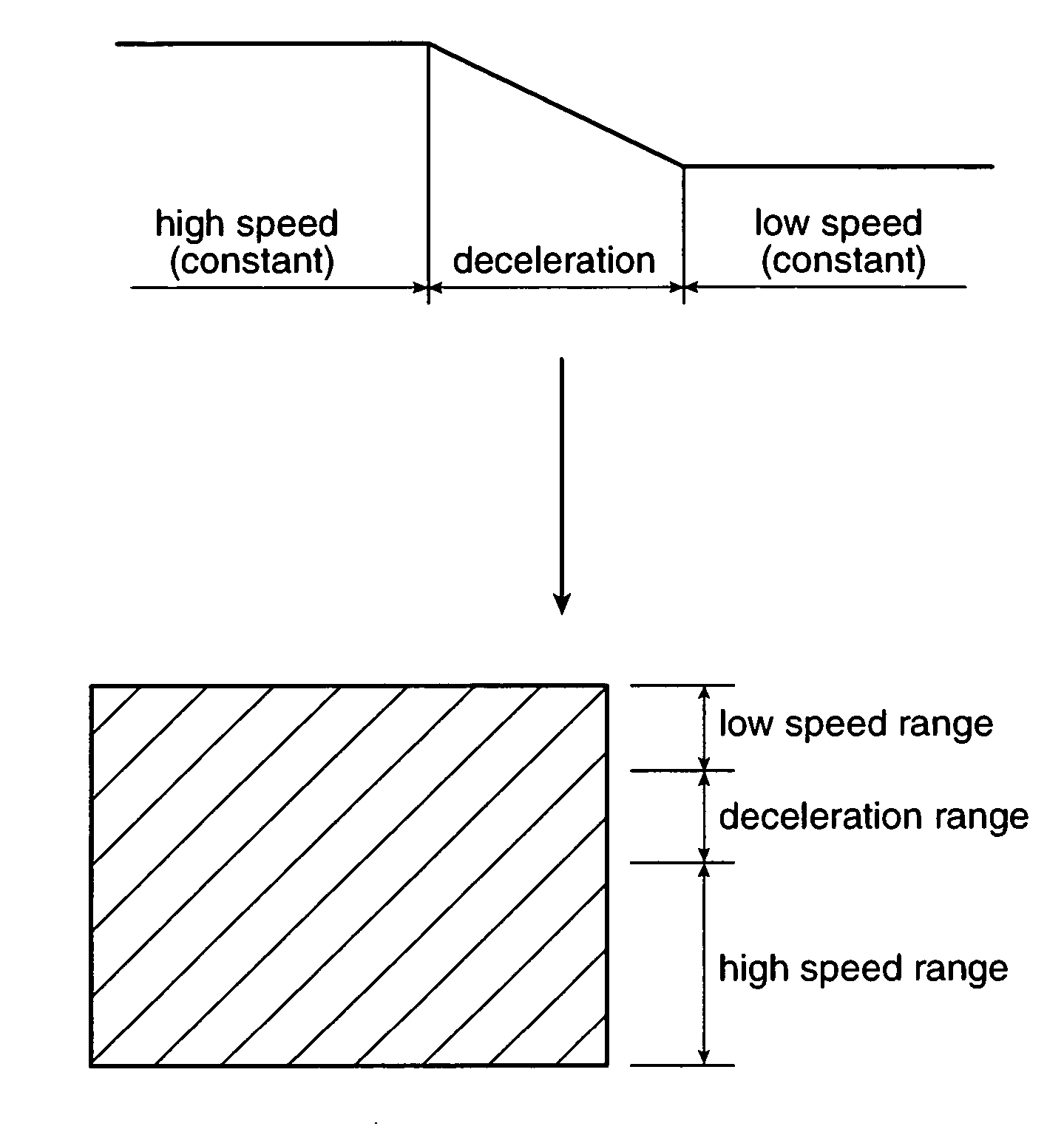

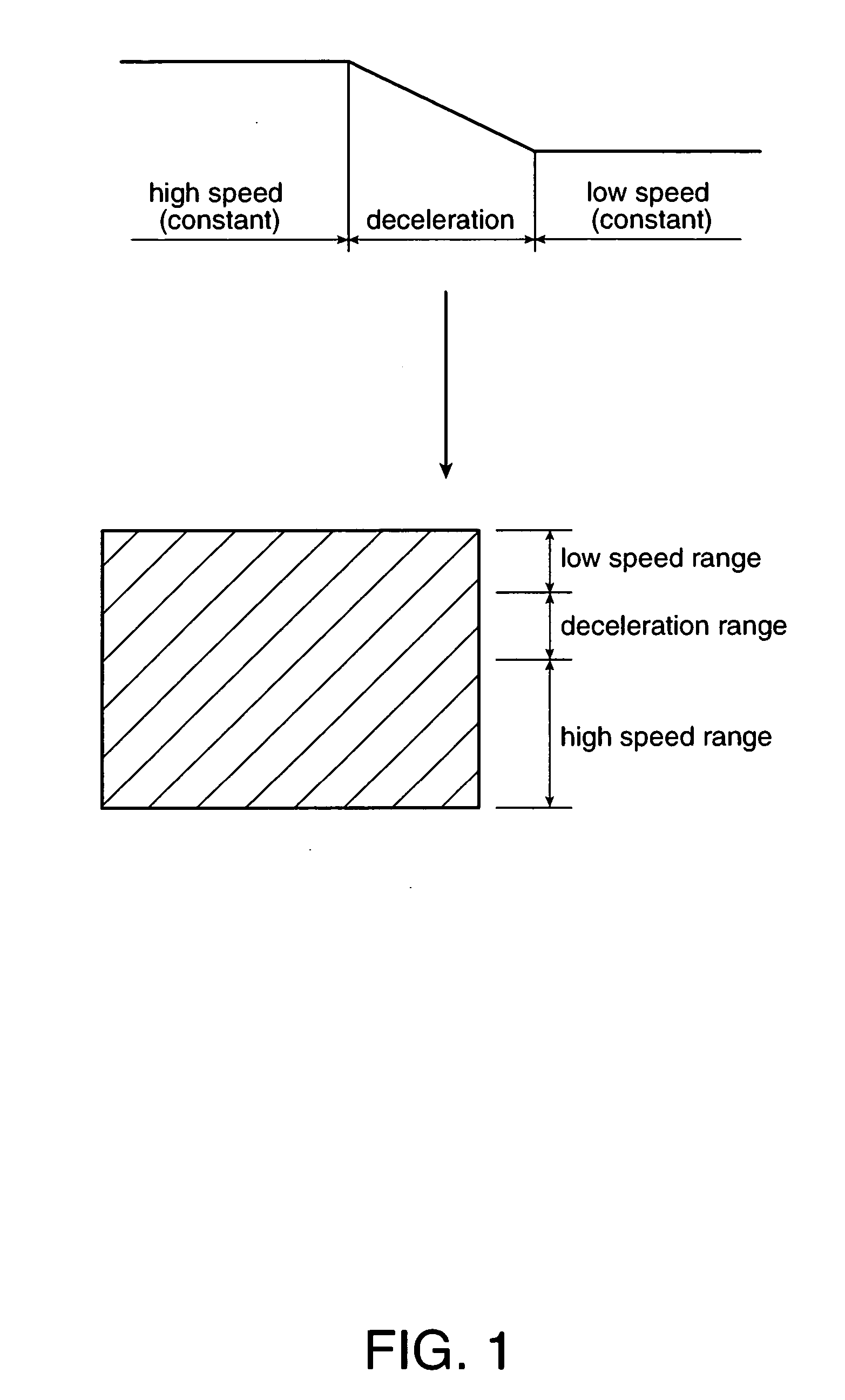

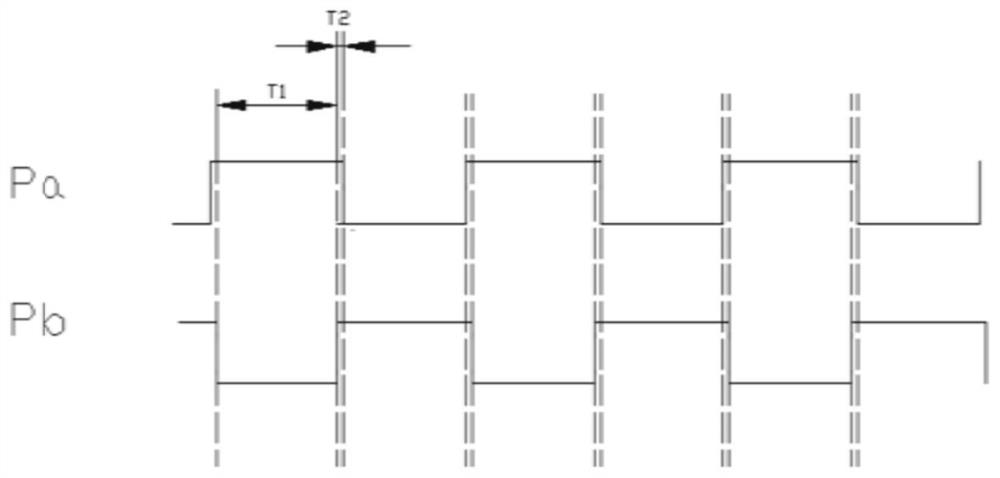

Thermal printer and thermal printer control method

ActiveUS20070019062A1Improve the overall coefficientReduce driving timePrintingHysteresisEngineering

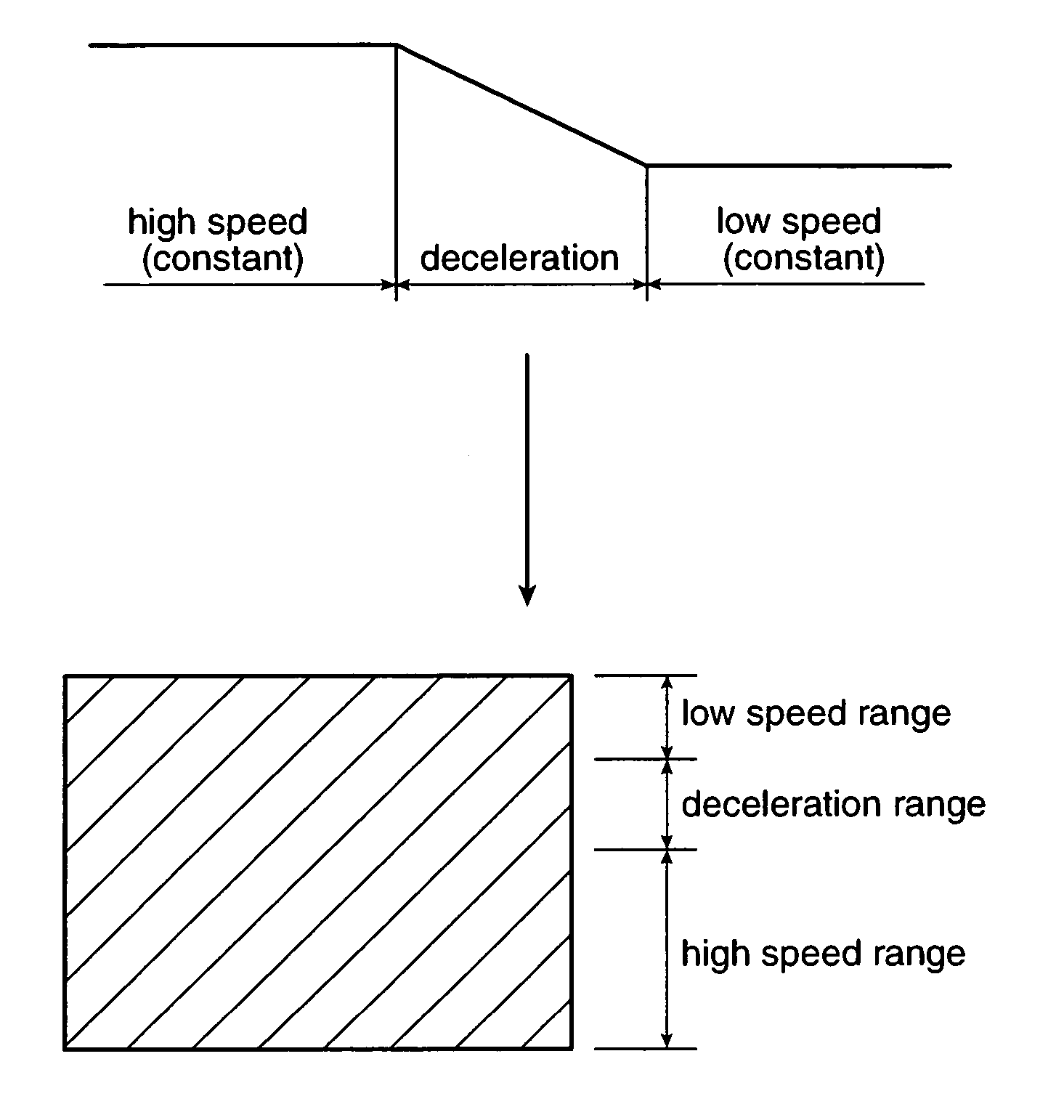

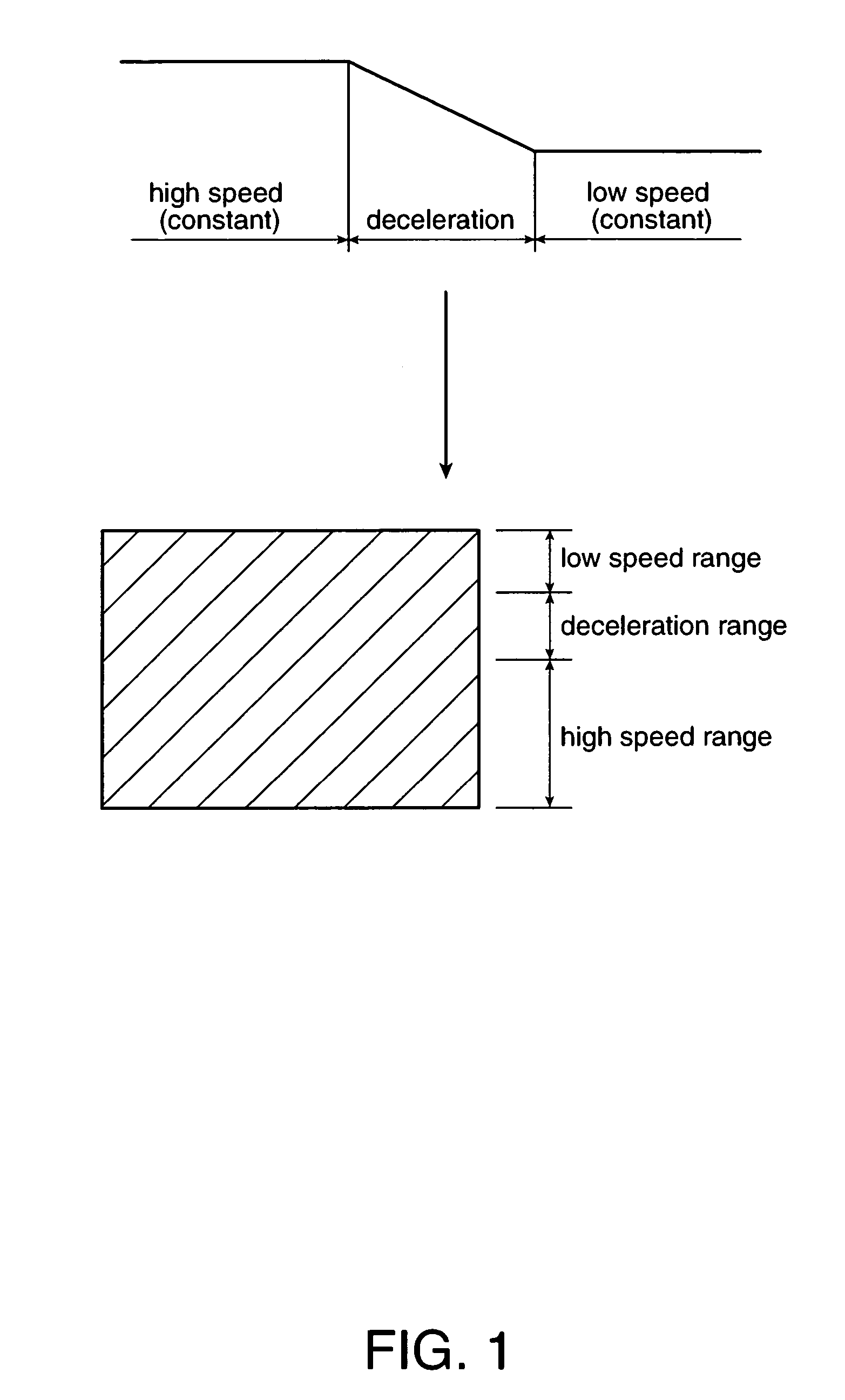

High print quality from a thermal printer is maintained while the print speed is decreasing without producing white streaks or uneven print density by controlling the hysteresis coefficient of the thermal print head 35 based on the energizing history of the thermal print head 35 and print speed control factors used for determining print speed,which is the speed at which the paper is advanced while printing. The thermal printer, comprises a hysteresis coefficient setting unit 2 for setting a hysteresis coefficient for the print head based on the energizing history of the thermal print head 35; an energizing time calculation unit 3 for calculating the energizing time during which drive signals are to be applied to the thermal print head 35 for printing based upon the hysteresis coefficient set by the hysteresis coefficient setting unit; a printing control device 4 for generating the drive signals to be applied to the print head in response to the energizing time calculated by the energizing time calculation unit 3; a print speed determination unit 5 for determining the change in the print speed and when the print speed is decreasing; and a coefficient changing unit 6 for changing the hysteresis coefficient when a change in print speed occurs causing the print speed to decrease. Preferably the coefficient changing unit changes the hysteresis coefficient to a value greater than the hysteresis coefficient value used immediately before deceleration.

Owner:SEIKO EPSON CORP

Method for improving microbial corrosion resistance of concrete

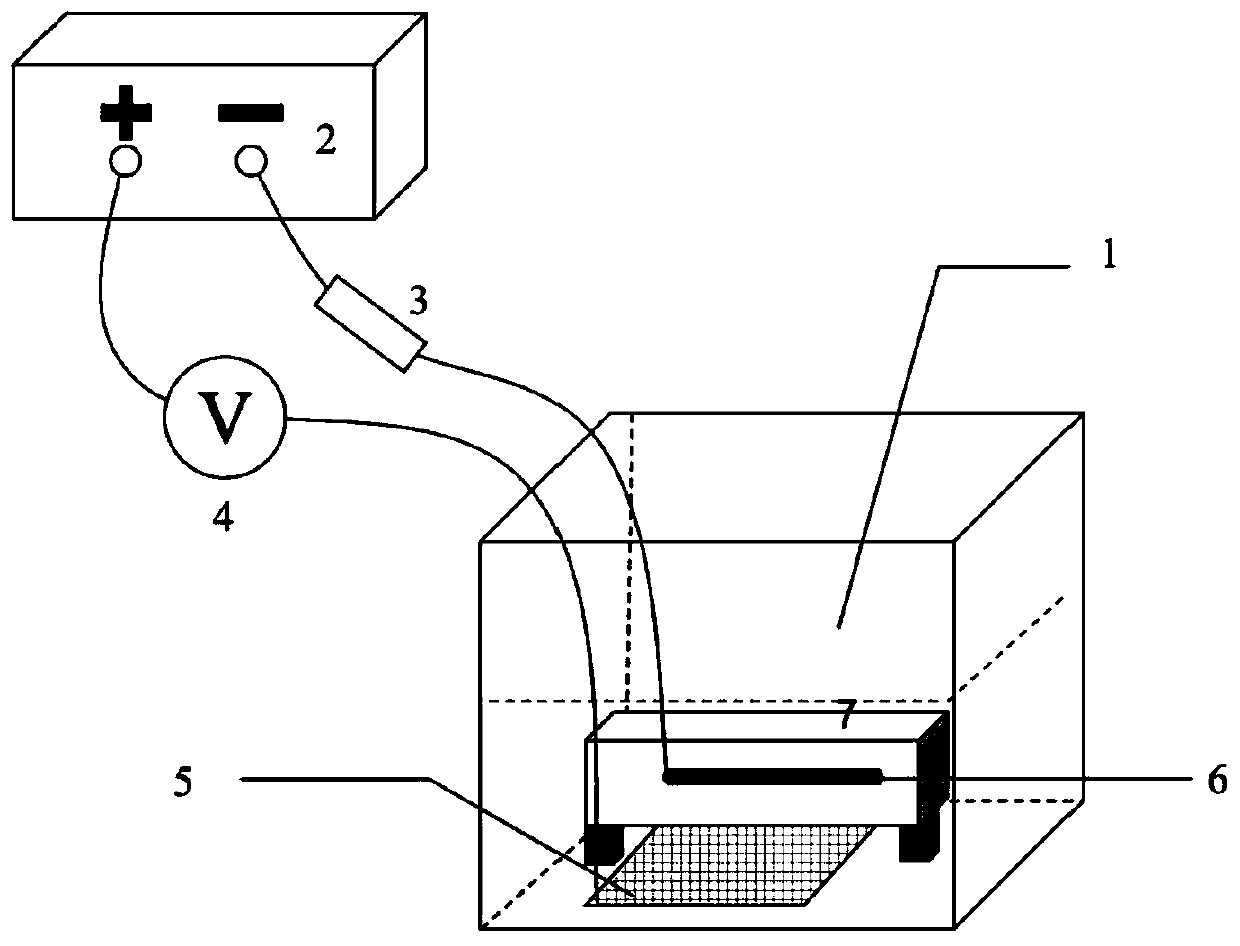

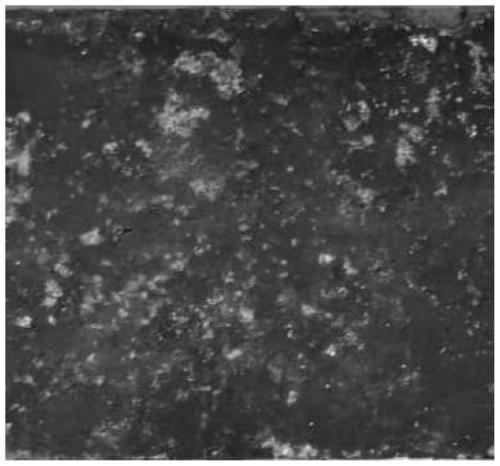

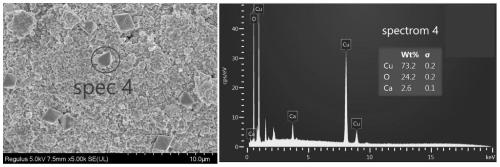

InactiveCN111424300AOverall goodImprove adhesionElectrolytic inorganic material coatingSuperimposed coating processElectrolytic agentSulfate radicals

The invention discloses a method for improving microbial corrosion resistance of concrete. The method comprises the following steps: immersing concrete with built-in steel bars in a copper lactate electrolyte of a direct-current electrolysis device, and performing direct-current electrolysis by taking the steel bars in the concrete as a cathode; and cleaning and blow-drying the electrolyzed concrete, soaking the concrete in a dopamine solution and a 1-dodecanethiol solution for coating sequentially, and taking the concrete out for cleaning and blow drying. The microbial corrosion resistance ofthe concrete is improved by depositing copper and copper oxide on the surface of concrete; by addition of a composite coating to the surface of deposit, hydrophobicity of the test piece surface is improved, leaching of copper ions is reduced, and the service life of the deposit is prolonged. The electrolyte prepared from copper nitrate instead of copper sulfate prevents the influence of sulfate ions on performance of the concrete during electrodeposition. The concrete electrodeposition method and device have the advantages of simple structure, simple and convenient operation, good anticorrosion effect, high practicability and wide applicability.

Owner:HOHAI UNIV

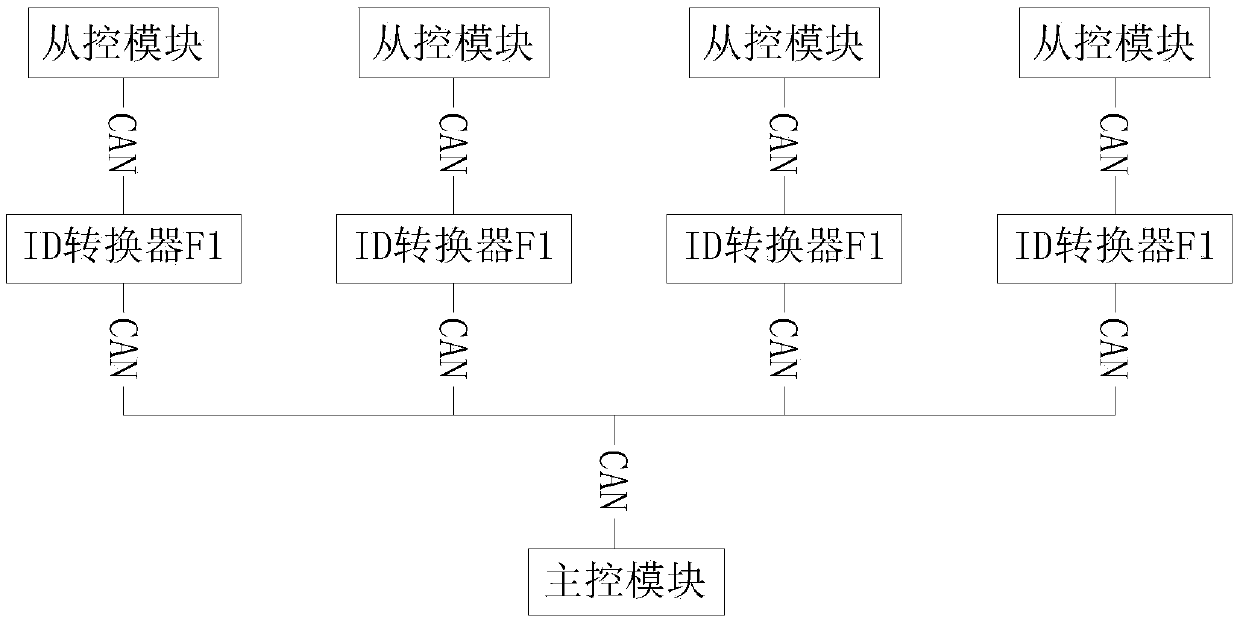

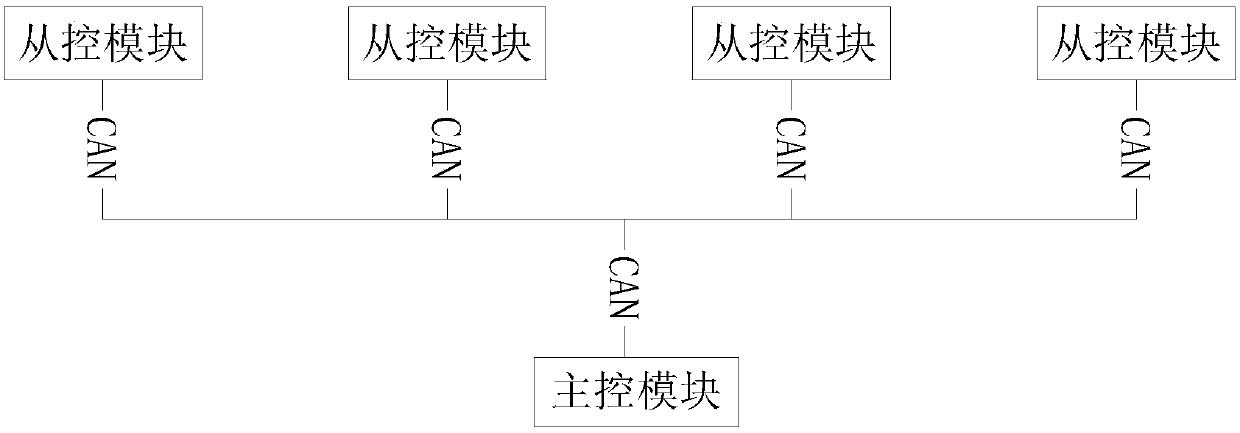

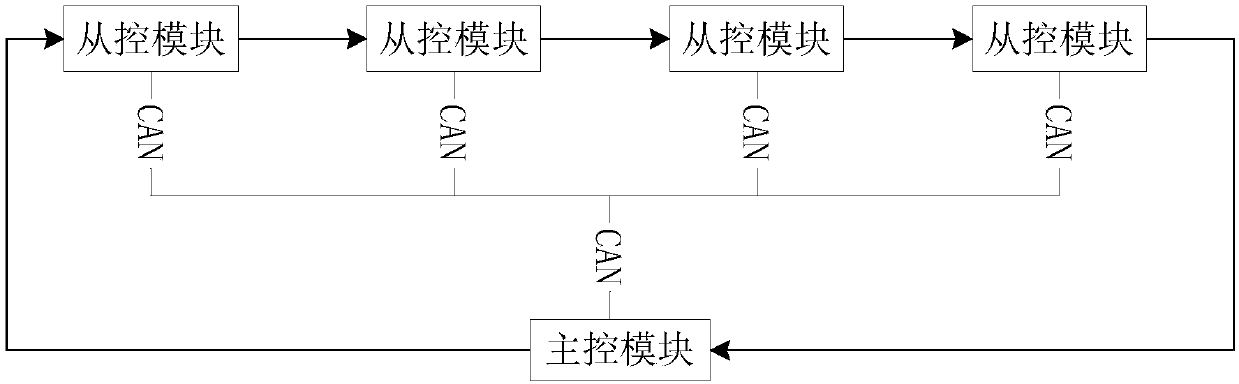

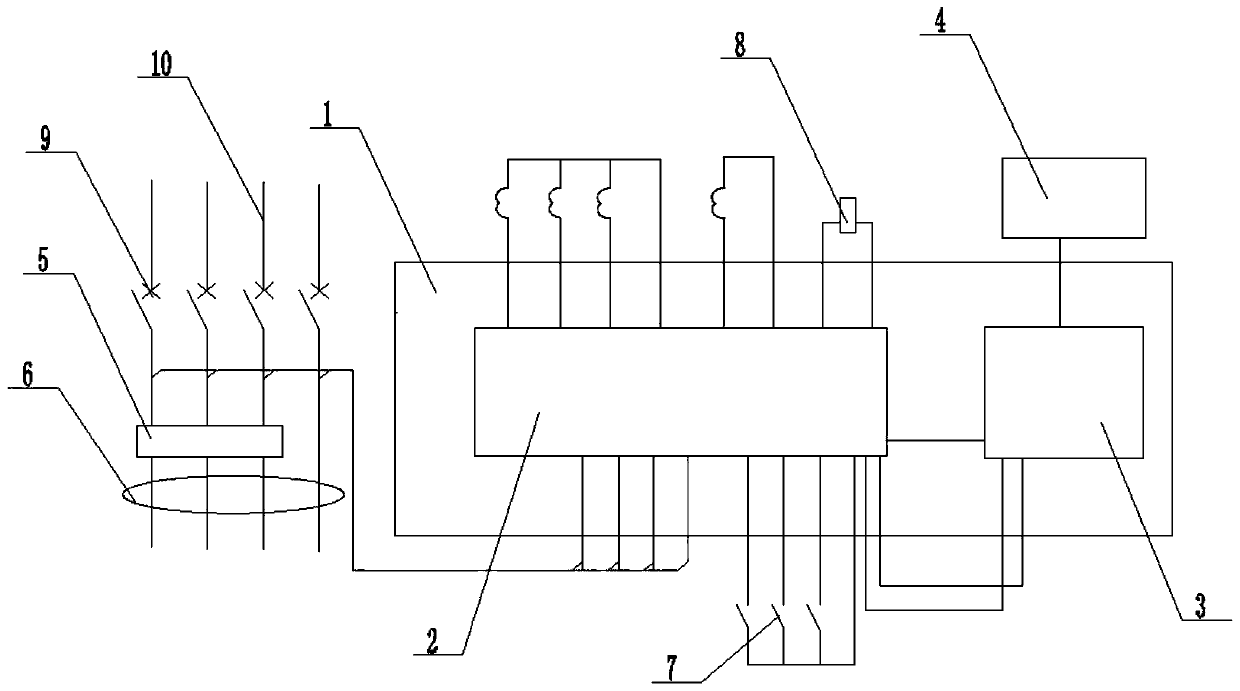

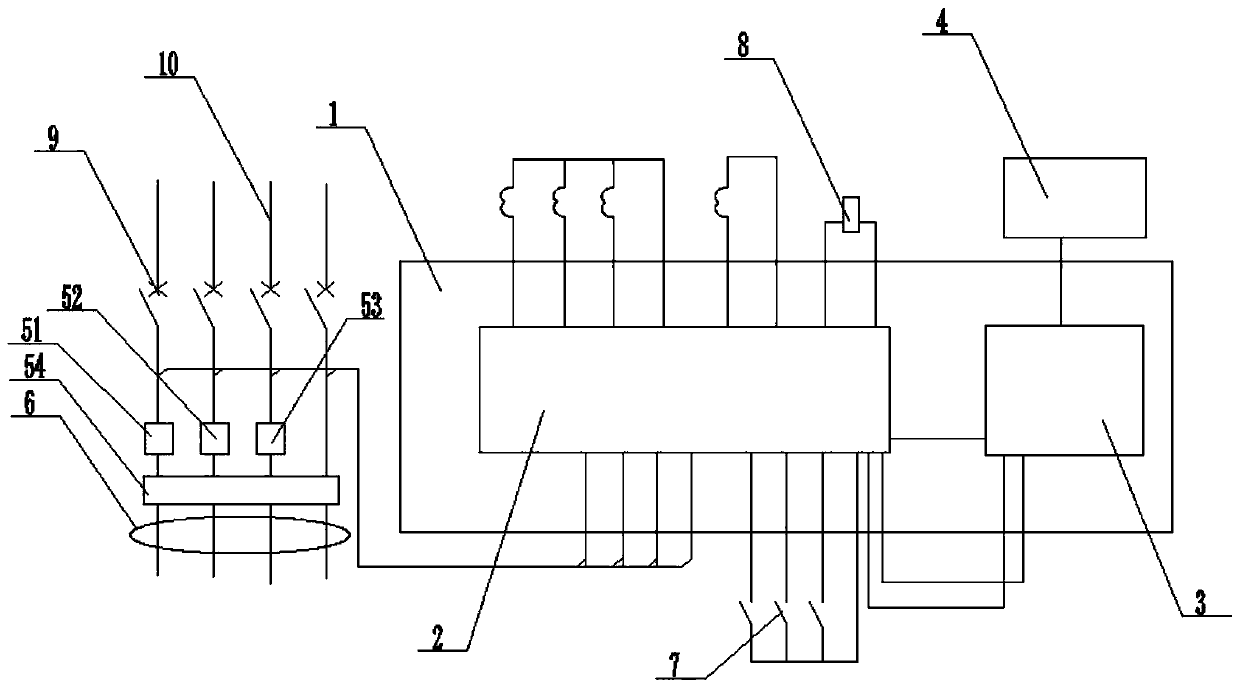

System for distributing BMS addresses on electric cars

PendingCN107766271ALow costExtend power-on timeElectric digital data processingElectricityPhysical address

The invention discloses a system for distributing BMS addresses on electric cars. The system comprises a primary control module and a plurality of secondary control modules; different pieces of identification information are written in the secondary control modules; a CAN bus is connected among the secondary control modules in series; when each secondary control module is electrified, the identification information is sent through the CAN bus and any secondary control module receives the identification information of the other secondary control modules; after receiving the identification information of all the other secondary control modules on the CAN bus, each secondary control module adds the own identification information, and carries out sorting according to the identification information so as to generate address information which is used for determining a physical address of the secondary control module; after determining new address information, the secondary control modules communicate the main control module via the new address information; and time limiting devices are arranged in the secondary control modules. According to the system disclosed by the invention, BMS systems on electric cars completely carry out address distribution through software logic, so that the cost is saved.

Owner:浙江高泰昊能科技有限公司

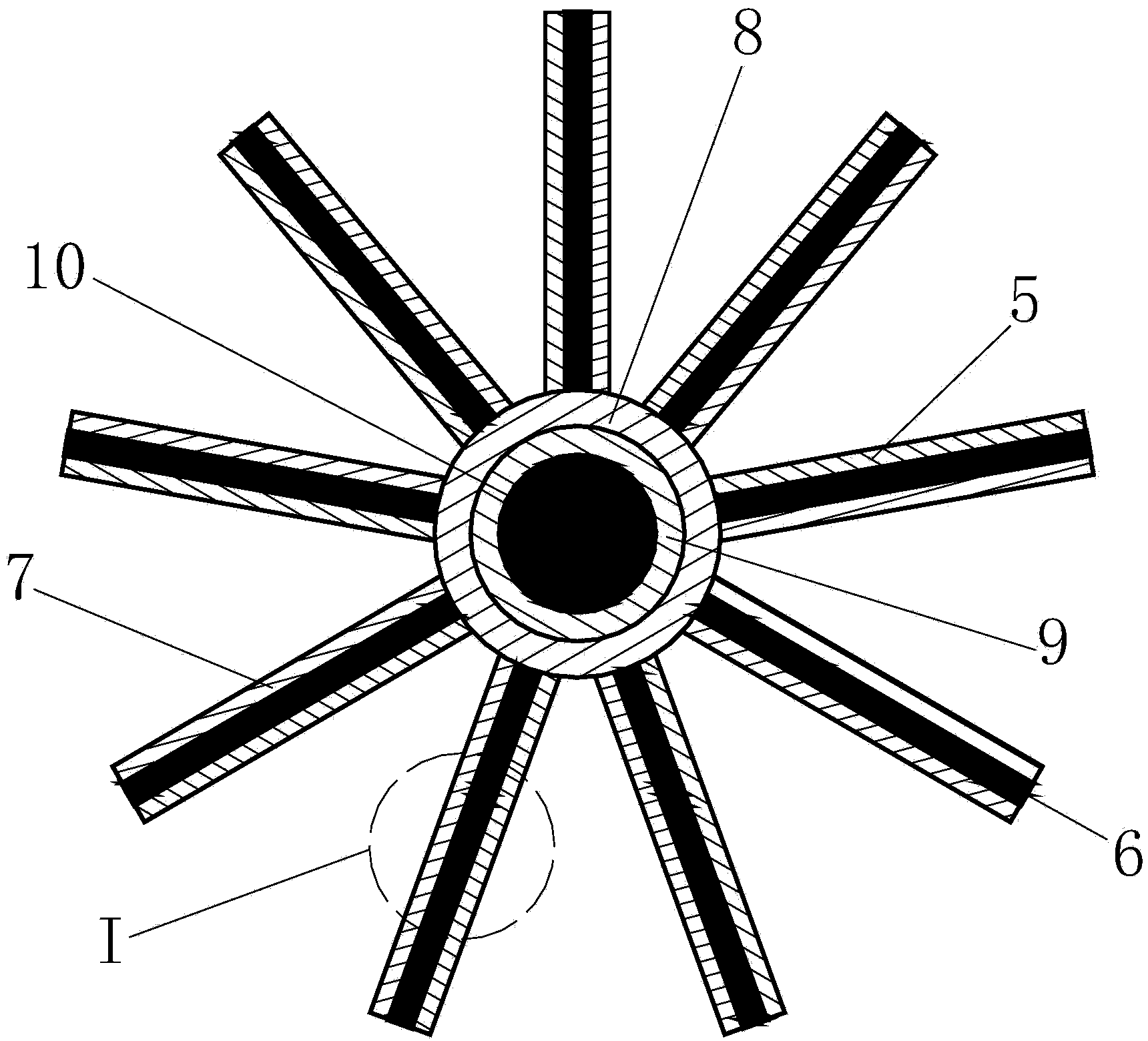

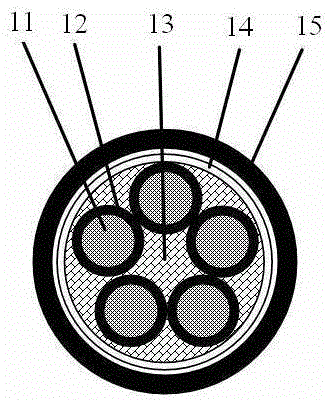

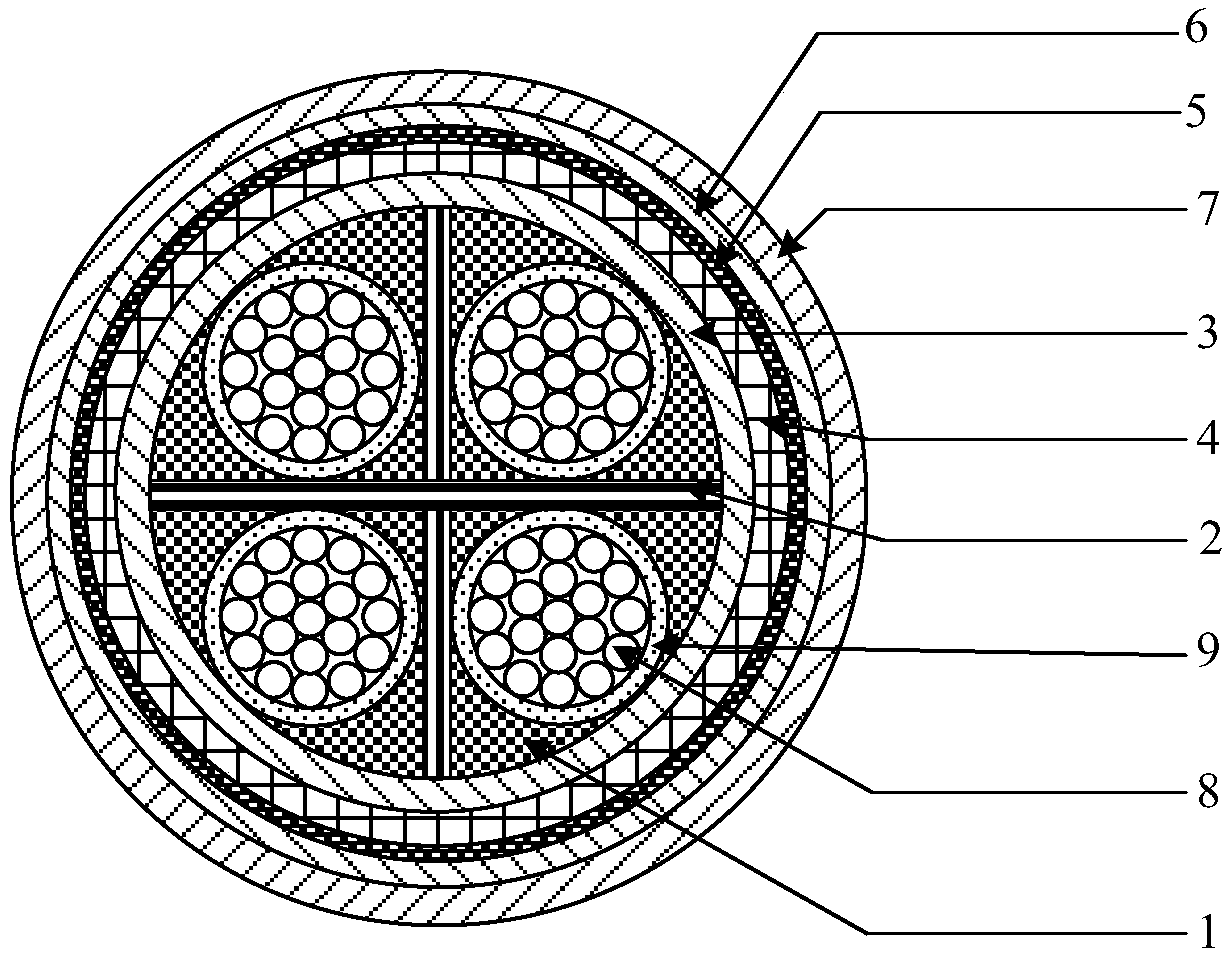

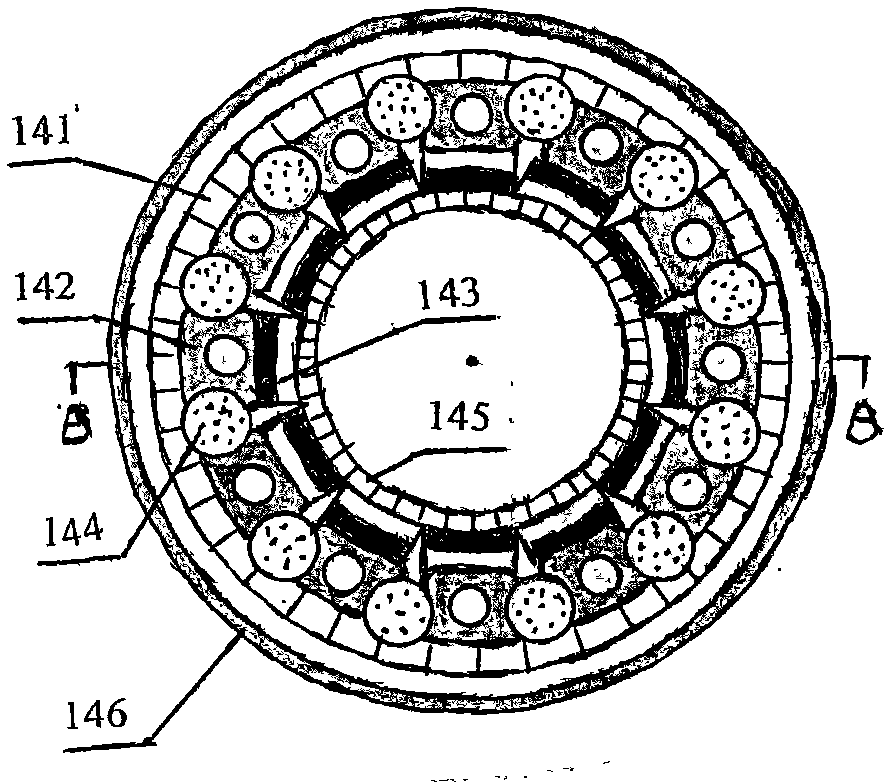

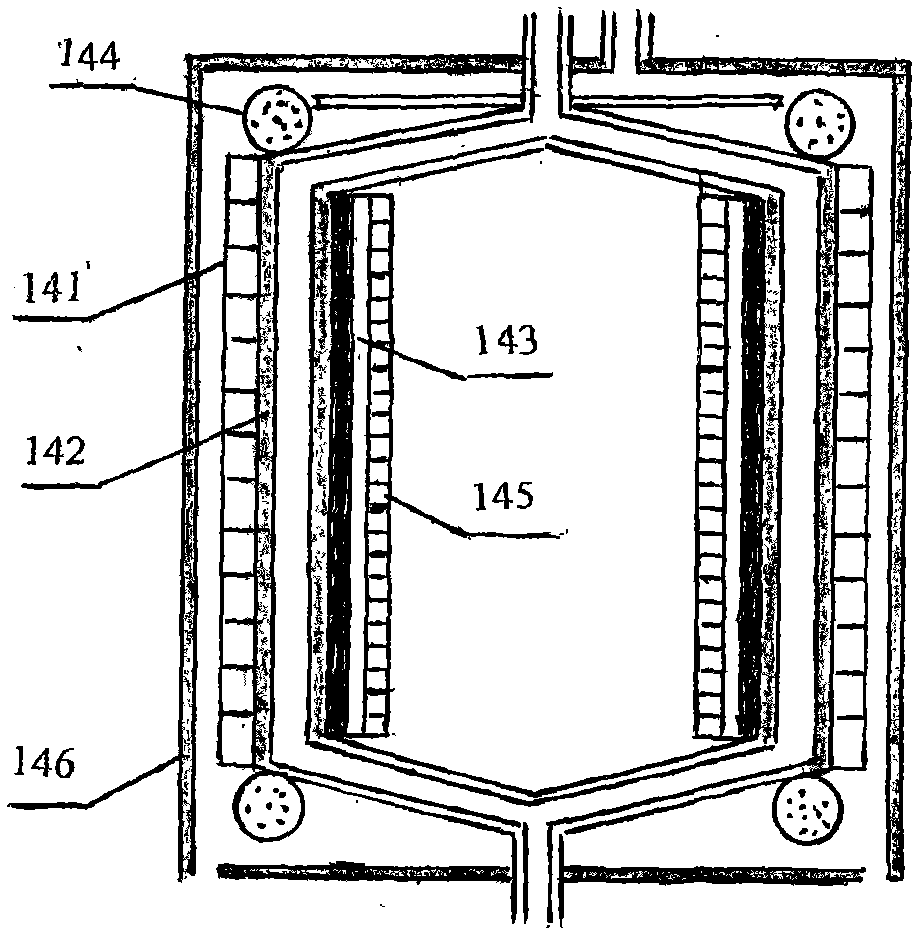

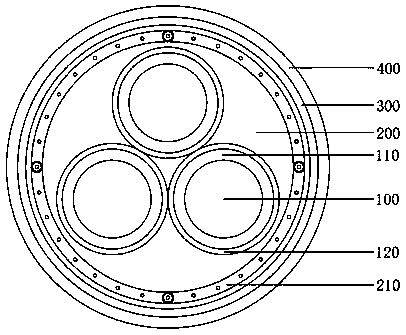

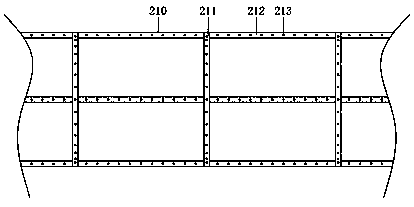

Fireproof control cable

ActiveCN103886988AAvoid skin breakdownImprove toughnessInsulated cablesInsulated conductorsCombustionElectrical conductor

The invention relates to a fireproof control cable which comprises a sheath, an inner protective layer, outer insulating layers, outer conductors, radial interlayers, a main fireproof layer, an inner insulating layer and an inner conductor, wherein the axis of the main fireproof layer coincides with the axis of the sheath, the inner insulating layer is fixed in the main fireproof layer, the radial interlayers are evenly and symmetrically installed in an annular space formed by the main fireproof layer and the inner protective layer, and the outer insulating layers are evenly and symmetrically distributed in the fan-shaped space formed by the radial partition interlayers, the inner protective layer and the main fireproof layer. The fireproof control cable has the advantages of being reasonable in structural design, convenient to machine and high in durability. According to the fireproof control cable, mutual combustion is avoided, electrifying time can be guaranteed and prolonged when the cable burns in a high-temperature and flame environment, and therefore, control requirements in an emergency are met, the tenacity of the cable is improved, cable surface breakage or internal conductor breakage is avoided when the cable is bent or pulled, and the service life of the cable is prolonged.

Owner:ANHUI YIHE CABLE

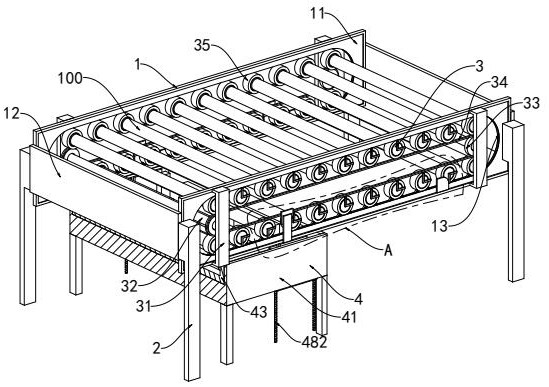

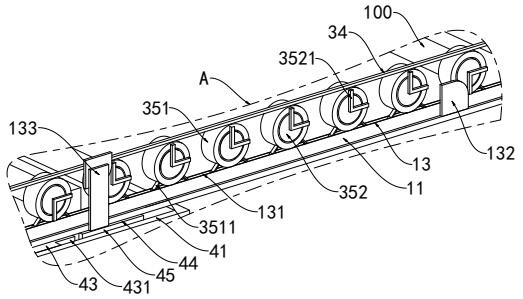

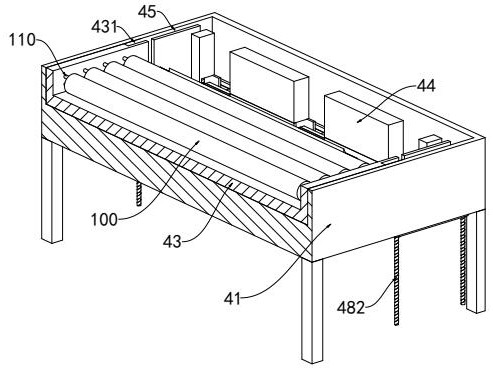

LED lamp tube power-on detection device and detection method

ActiveCN114755601AExtend power-on timeEasy to detectEnergy saving control techniquesMeasurement instrument housingComputer hardwareEngineering

The invention relates to the technical field of LED lamp tube power-on detection, in particular to an LED lamp tube power-on detection device and method.The LED lamp tube power-on detection device comprises a detection frame and supporting legs used for supporting and fixing the detection frame, the detection frame comprises two guide rail frames distributed front and back, and the two ends of the two guide rail frames are connected and fixed through two connecting plates; a running track is arranged on the guide rail frame, a running detection mechanism is arranged in the running track, and an automatic feeding mechanism is arranged below the detection frame. According to the invention, the plurality of clamping electrifying units can be driven to move in the operation track through the transmission chain, so that electrifying detection can be carried out on a plurality of to-be-detected lamp tubes at the same time, the electrifying time of the lamp tubes can be ensured to be long enough, and a better detection effect is achieved; according to the automatic feeding and electrifying device for the lamp tube, the lamp tube to be detected can be automatically corrected, clamped and pushed into the detection frame, manual feeding and electrifying of the lamp tube are not needed, and the automatic feeding function and the automatic electrifying function of the lamp tube are achieved.

Owner:JIAGNSU PUYA LIGHTING TECH PUBLIC CO LTD

Thermal printer and thermal printer control method

ActiveUS7542060B2Improve the overall coefficientReduce driving timePrintingHysteresisVolumetric Mass Density

High print quality from a thermal printer is maintained while the print speed is decreasing without producing white streaks or uneven print density by controlling the hysteresis coefficient of the thermal print head 35 based on the energizing history of the thermal print head 35 and print speed control factors used for determining print speed, which is the speed at which the paper is advanced while printing. The thermal printer, comprises a hysteresis coefficient setting unit 2 for setting a hysteresis coefficient for the print head based on the energizing history of the thermal print head 35; an energizing time calculation unit 3 for calculating the energizing time during which drive signals are to be applied to the thermal print head 35 for printing based upon the hysteresis coefficient set by the hysteresis coefficient setting unit; a printing control device 4 for generating the drive signals to be applied to the print head in response to the energizing time calculated by the energizing time calculation unit 3; a print speed determination unit 5 for determining the change in the print speed and when the print speed is decreasing; and a coefficient changing unit 6 for changing the hysteresis coefficient when a change in print speed occurs causing the print speed to decrease. Preferably the coefficient changing unit changes the hysteresis coefficient to a value greater than the hysteresis coefficient value used immediately before deceleration.

Owner:SEIKO EPSON CORP

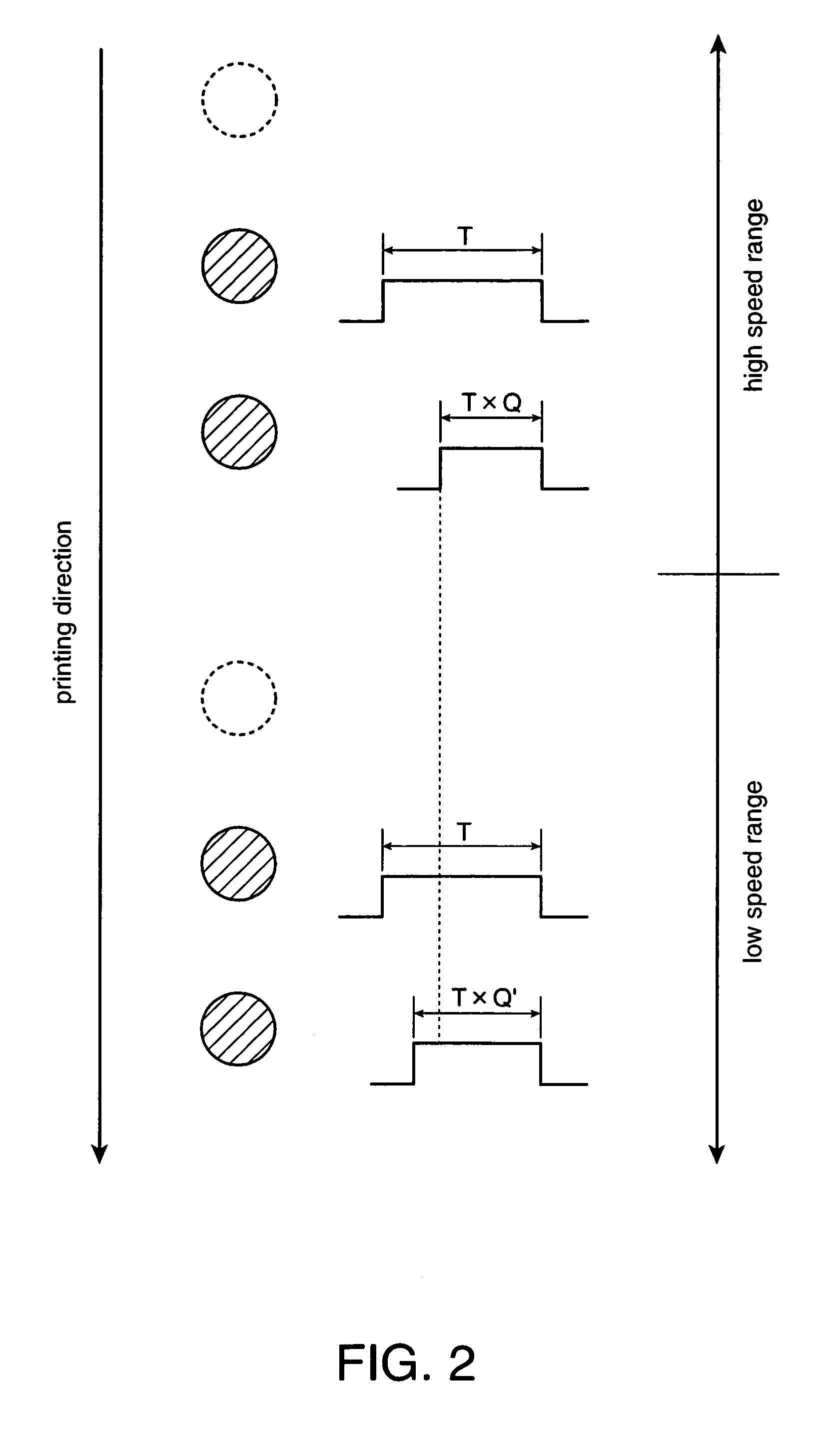

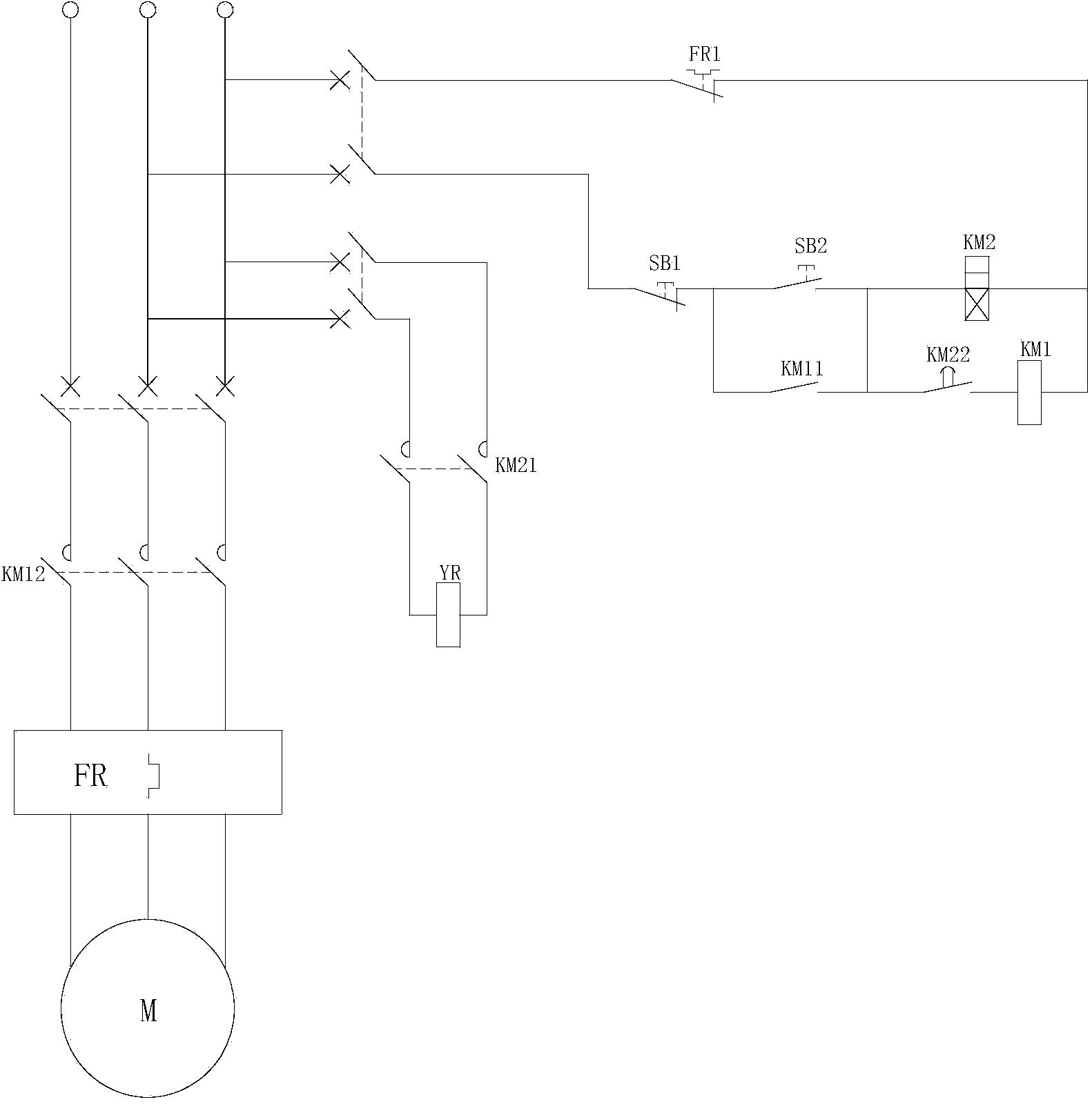

Braking circuit of electromagnetic brake

InactiveCN104378021AExtend power-on timeMotor/generator/converter stoppersDynamo-electric converter controlEngineeringAlternating current

The invention discloses a braking circuit of an electromagnetic brake. One end of a stop button is connected with the positive electrode of a power supply, the other end of the stop button is connected with the negative electrode of the power supply through a start button and a coil of a second alternating current contactor in sequence, a third normally open contact of the second alternating current contactor is connected to the two ends of the start button in parallel, and a coil of an intermediate relay is connected to the two ends of the coil of the second alternating current contactor in parallel; one end of a normally open contact of the intermediate relay is connected with the positive electrode of the power supply, the other end of the normally open contact of the intermediate relay is connected with the negative electrode of the power supply through a coil of a first alternating current contactor, and a normally open contact of the first alternating current contactor is connected between the power supply and a motor; one end of a first normally open contact of the second alternating current contactor is connected with the power supply, and the other end of the first normally open contact of the second alternating current contactor is connected with a coil of the electromagnetic brake. According to the braking circuit, after a brake shoe of the brake is released, the motor can run again, so that safe start is guaranteed.

Owner:CHANGZHOU FEIYU CHEM

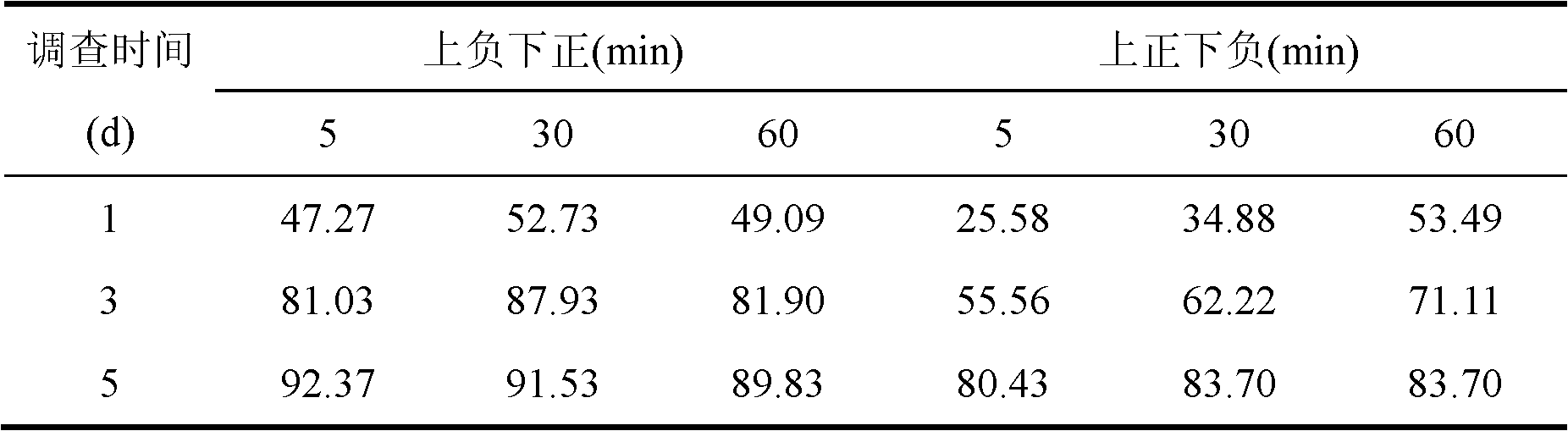

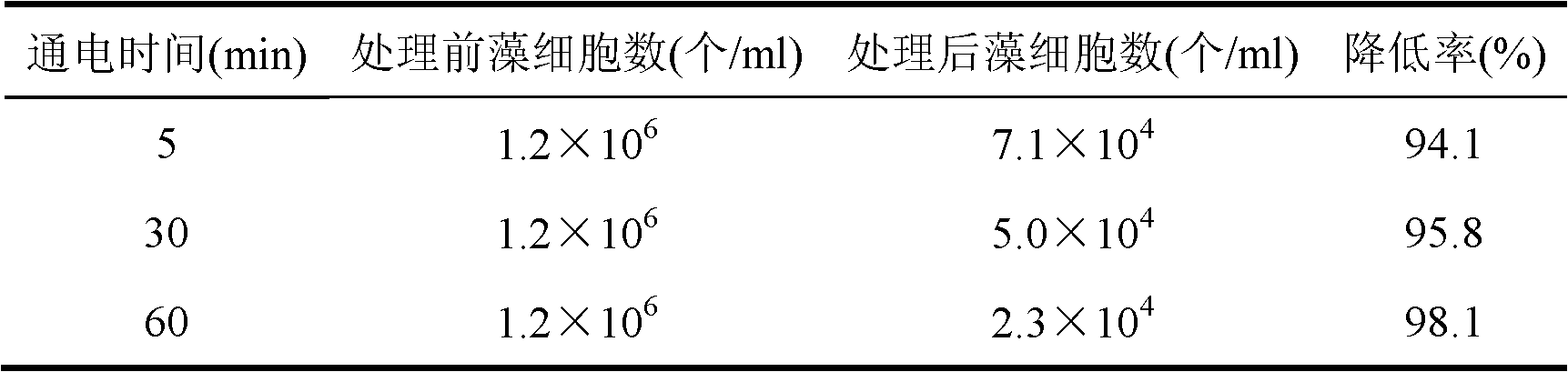

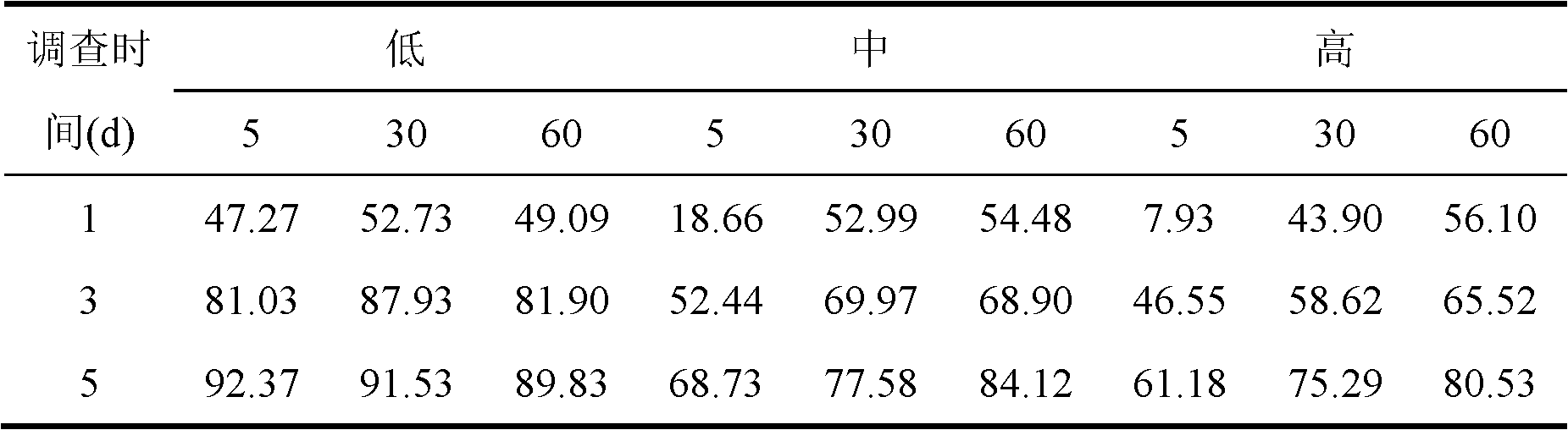

Method for purifying water by killing algae by using micro-current and application thereof

InactiveCN102557206AAchieve purificationReach current densityWater/sewage treatment by magnetic/electric fieldsQuadrigulaAnabaena

The invention belongs to the technical field of water pollution control and particularly relates to a method for purifying water by killing algae by using micro-current and the application of the method. The method is characterized in that two electrodes are put in water with algae and connected with a direct-current motor so that the upper electrode and the lower electrode have a certain current density, and the alga cells are killed after a certain period of time and sunken to the bottom of the water so that the water is purified. The micro-current has the significant function of killing a variety of algae including microcystis, aphanizomenon, anabaena, quadrigula chodatii and scenedesmus and is suitable for lakes, ponds and other water environment.

Owner:NANJING UNIV

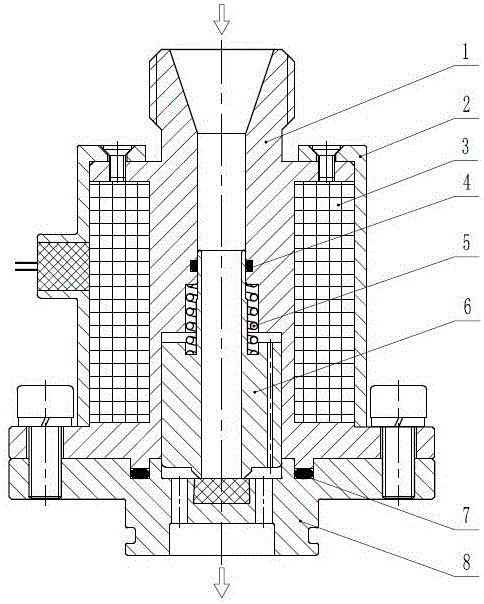

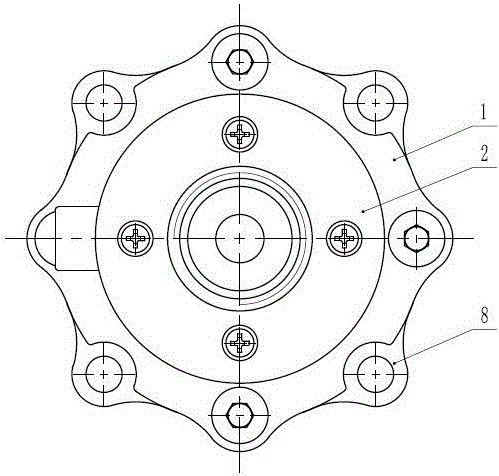

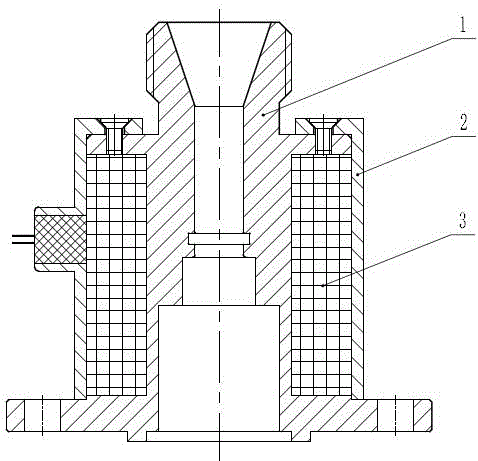

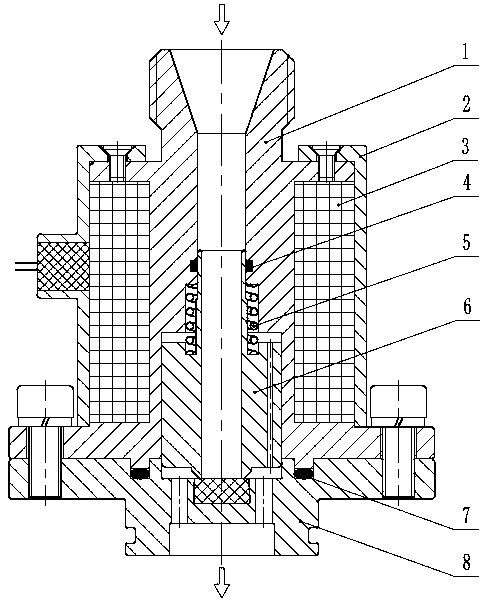

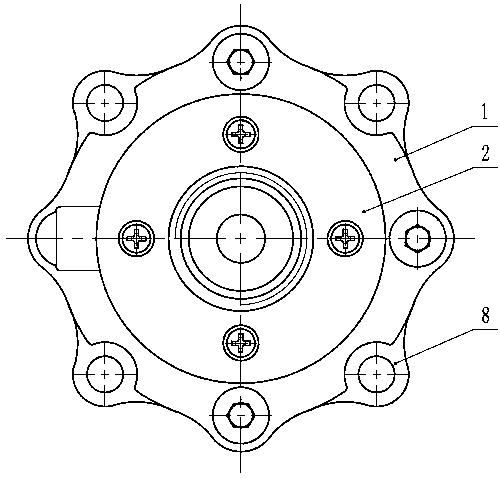

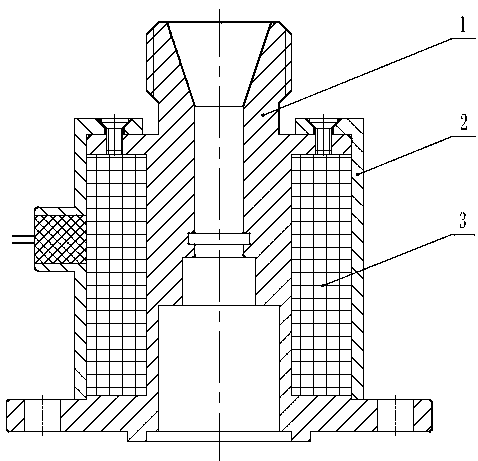

Large-diameter direct-acting type high-pressure solenoid valve

ActiveCN106090398ALarge diameterQuick responseOperating means/releasing devices for valvesLift valveWorking pressureSolenoid valve

The invention relates to a large-diameter direct-acting type high-pressure solenoid valve. The large-diameter direct-acting type high-pressure solenoid valve which is of a coaxial integral structure comprises a valve body, a coil housing, a coil, a spring, a valve core, a valve seat and an O ring, wherein the valve body is arranged on the upper part of the solenoid valve, medium inlet connecting threads are formed on the upper end of the valve body, a solenoid coil is wound on the circumference of the middle part of the valve body, and the coil housing is arranged on the outer side of the solenoid coil. According to a control method, a two-position two-way direct-acting type structure is adopted, the solenoid valve is opened after energization and is closed after deenergization, and a fluid medium flows into from the upper part of the valve body and flows out from the lower part of the valve seat. Compared with the prior art, the large-diameter direct-acting type high-pressure solenoid valve has the obvious advantages that (1) the diameter is large, the working pressure is high, the sustainable conduction time is long, and therefore, large-flow media can be continuously and stably supplied; (2) the action response speed is high (less than or equal to 10 ms), the solenoid coil of the solenoid valve is large, the sectional area of the valve core is large, so that large electromagnetic force can be generated, and therefore, the response speed is high.

Owner:CHANGDE XIANGYU EQUIP MFG

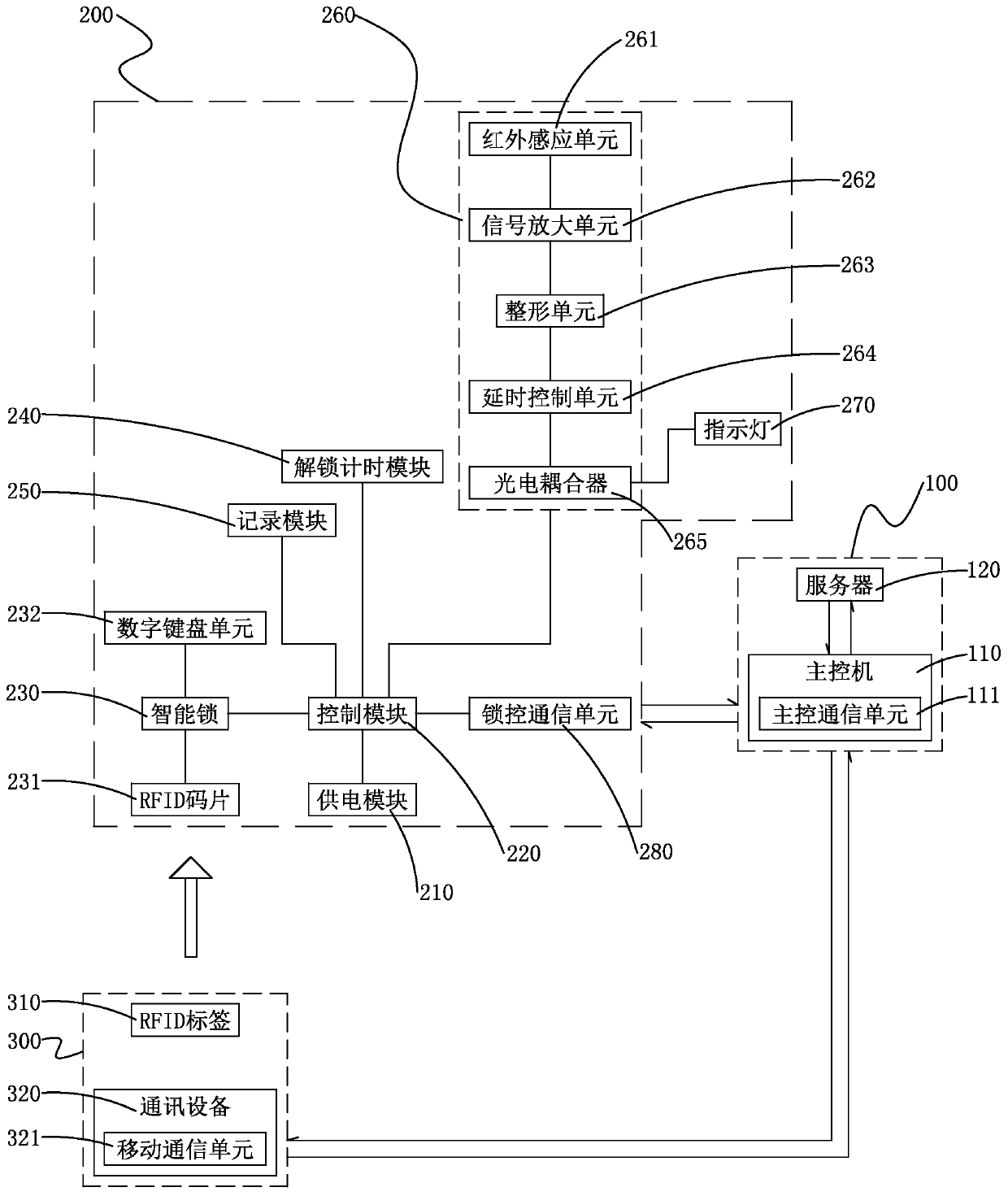

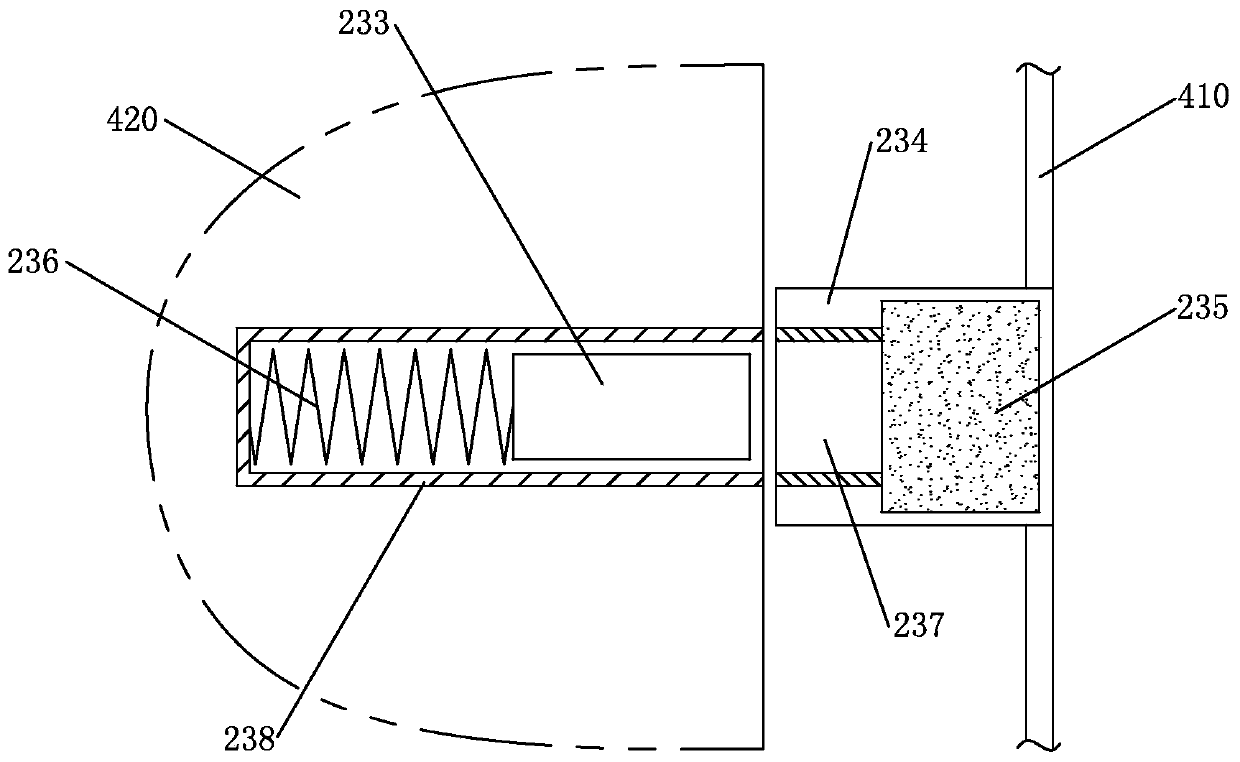

Intelligent lock control system for electric power field and control method

InactiveCN109872420AImprove intelligenceImprove securityIndividual entry/exit registersHigh level techniquesElectricityPassword

The invention discloses an intelligent lock control system for the electric power field and a control method, and belongs to the technical field of electric power field application systems. The intelligent lock control system comprises a main control terminal, a lock control terminal and a mobile terminal, and the lock control terminal and the mobile terminal are both in communication connection with the lock control terminal; the main control terminal is provided with a main control computer; the mobile terminal comprises a RFID label and communication equipment; and the lock control terminalcomprises a power supply module, a control module and an intelligent lock, wherein statistical information is recorded in the control module, the intelligent lock is electrically connected to the control module and is internally provided with a RFID code chip, the RFID code chip reads identification information recorded by the RFID label and sends the identification information to the control module, the control module makes a comparison to judge whether a holder has the unlock permission or not and sends the unlock request to the main control computer when the holder is judged to have the unlock permission, and the main control computer sends dynamic passwords to the communication equipment and the control module at the same time. By adopting a mode of identifying first and then authorizing unlocking to carry out progressive management, the intelligence, the safety and the effectiveness of power security and protection management are improved.

Owner:STATE GRID ZHEJIANG JIANDE POWER SUPPLY +1

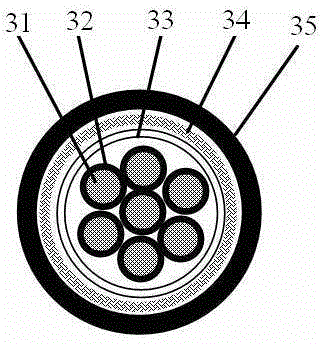

Novel fire-resistant cable

InactiveCN103824621AHigh temperature resistanceIncrease productivityInsulated cablesInsulated conductorsElectrical and Electronics engineeringEngineering

The invention discloses a novel fire-resistant cable comprising a plurality of insulation wire cores. Two layers of porcelain fireproof fire-resistant composite belts are wrapped outside the plurality of insulation wire cores. A shielding layer is arranged outside the porcelain fireproof fire-resistant composite belts. An outer sheath is arranged outside the shielding layer. The porcelain fireproof fire-resistant composite belts are utilized to generate the novel fire-resistant cable, so that the temperature-resistant level of the fire-resistant cable is improved, the normal power on time is prolonged; and meanwhile, the production efficiency of the fire-resistant cable is improved, and the production cost is substantially reduced.

Owner:SHANGHAI CARDIFF CABLE

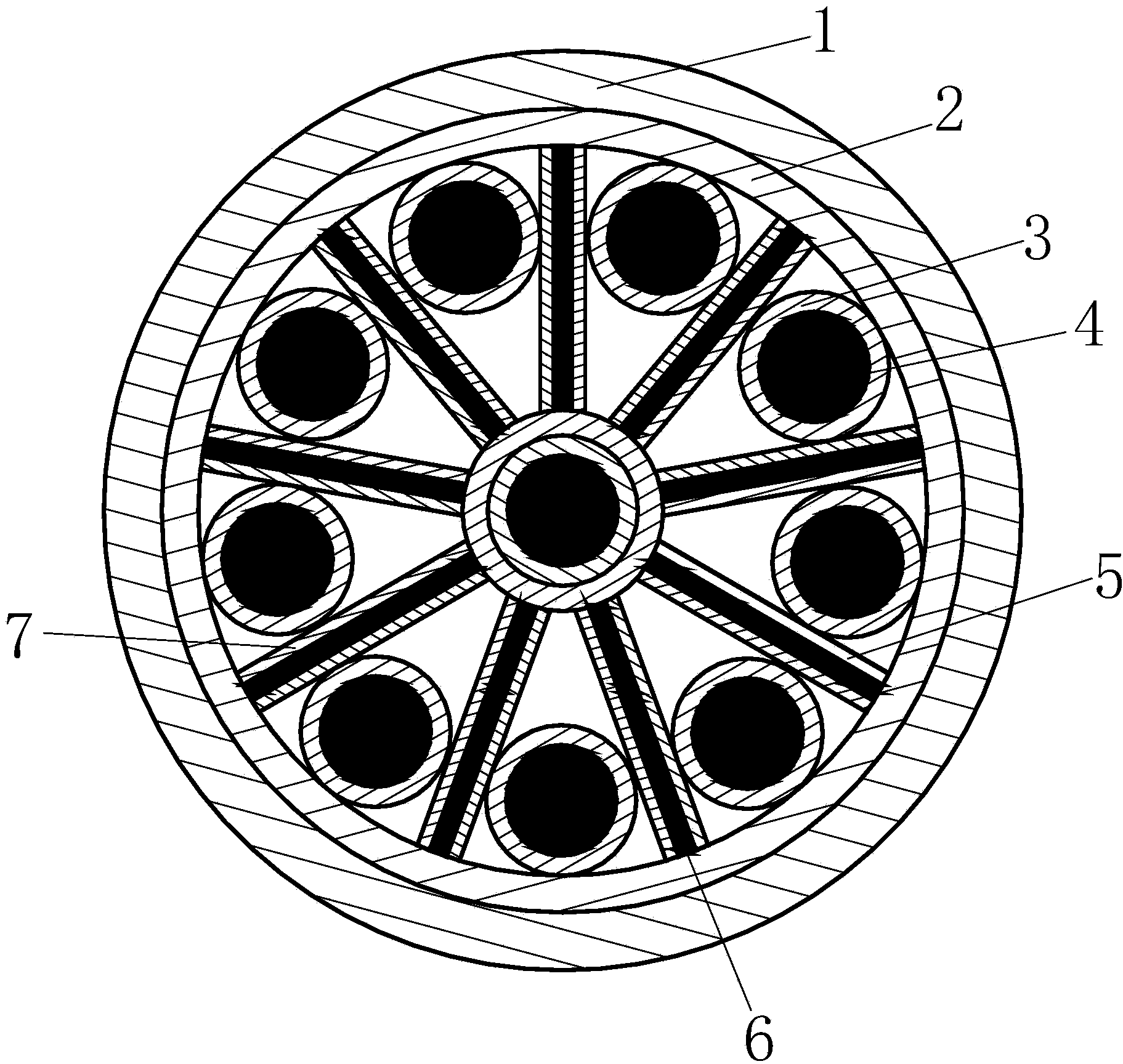

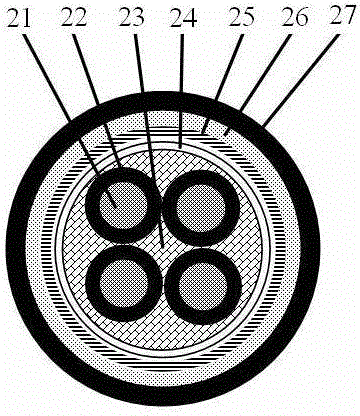

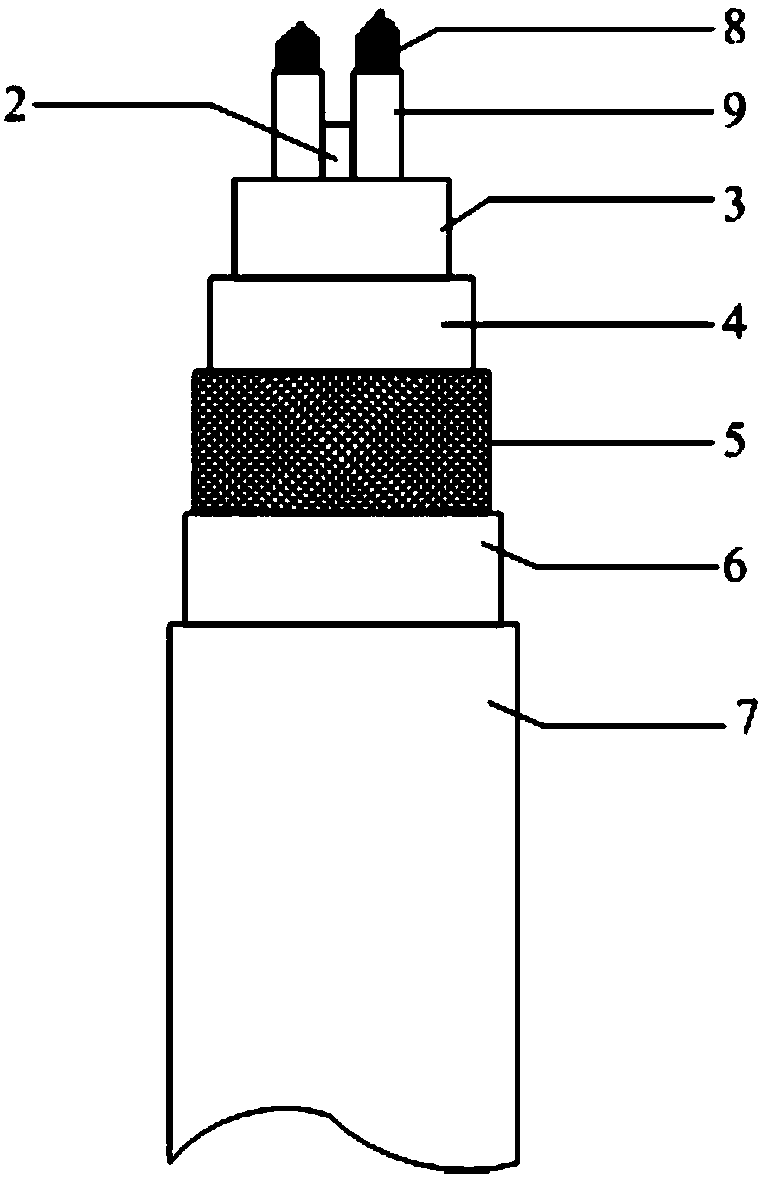

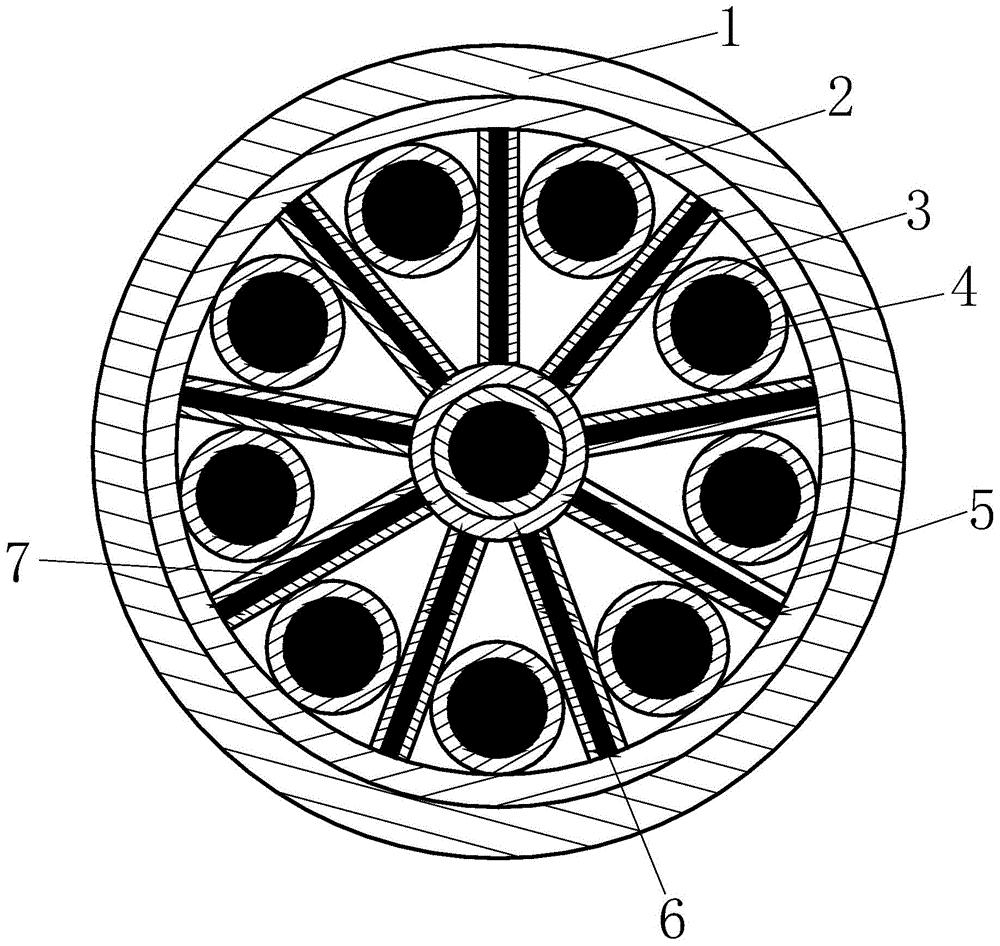

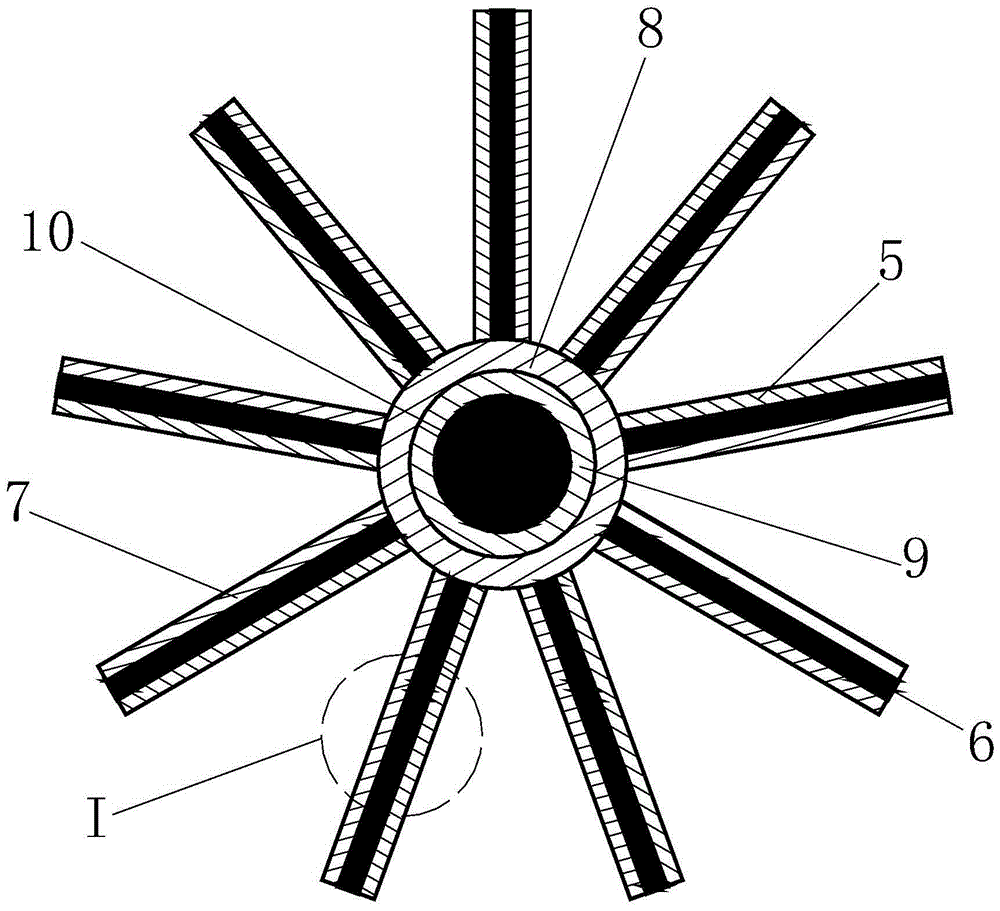

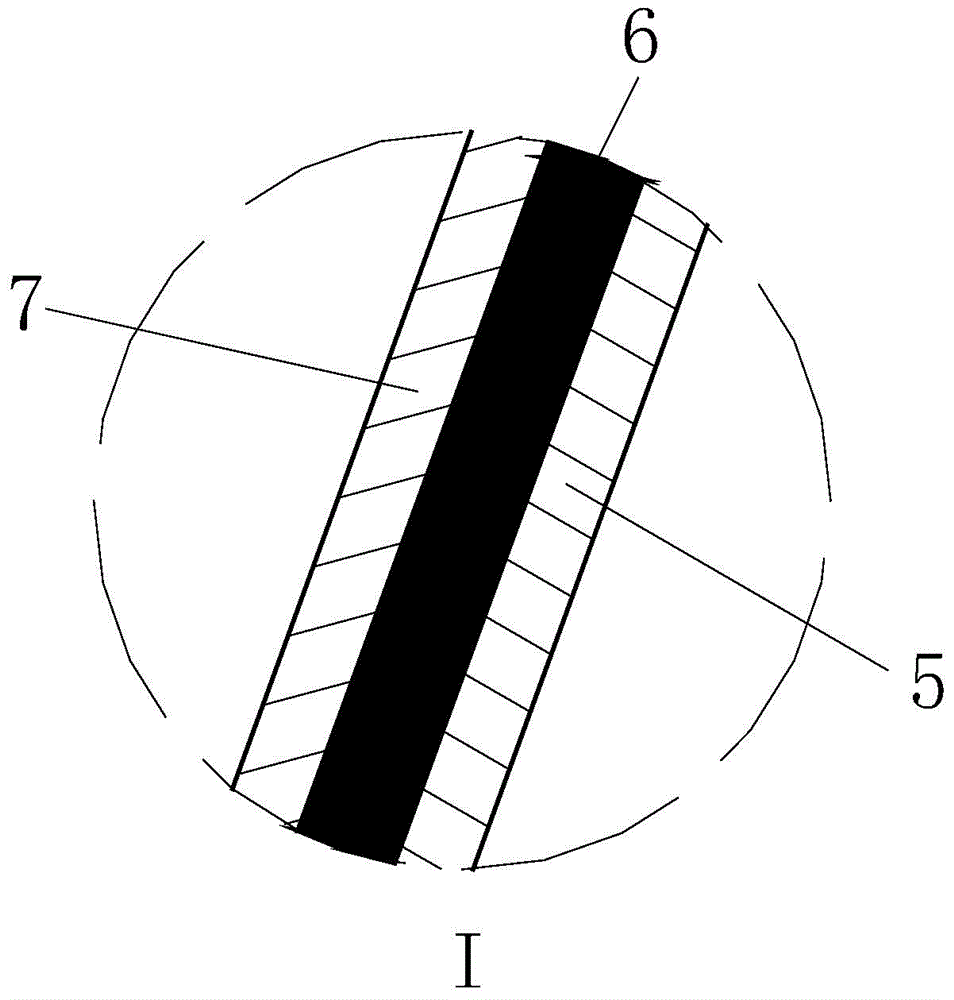

Soft mineral fireproof cable

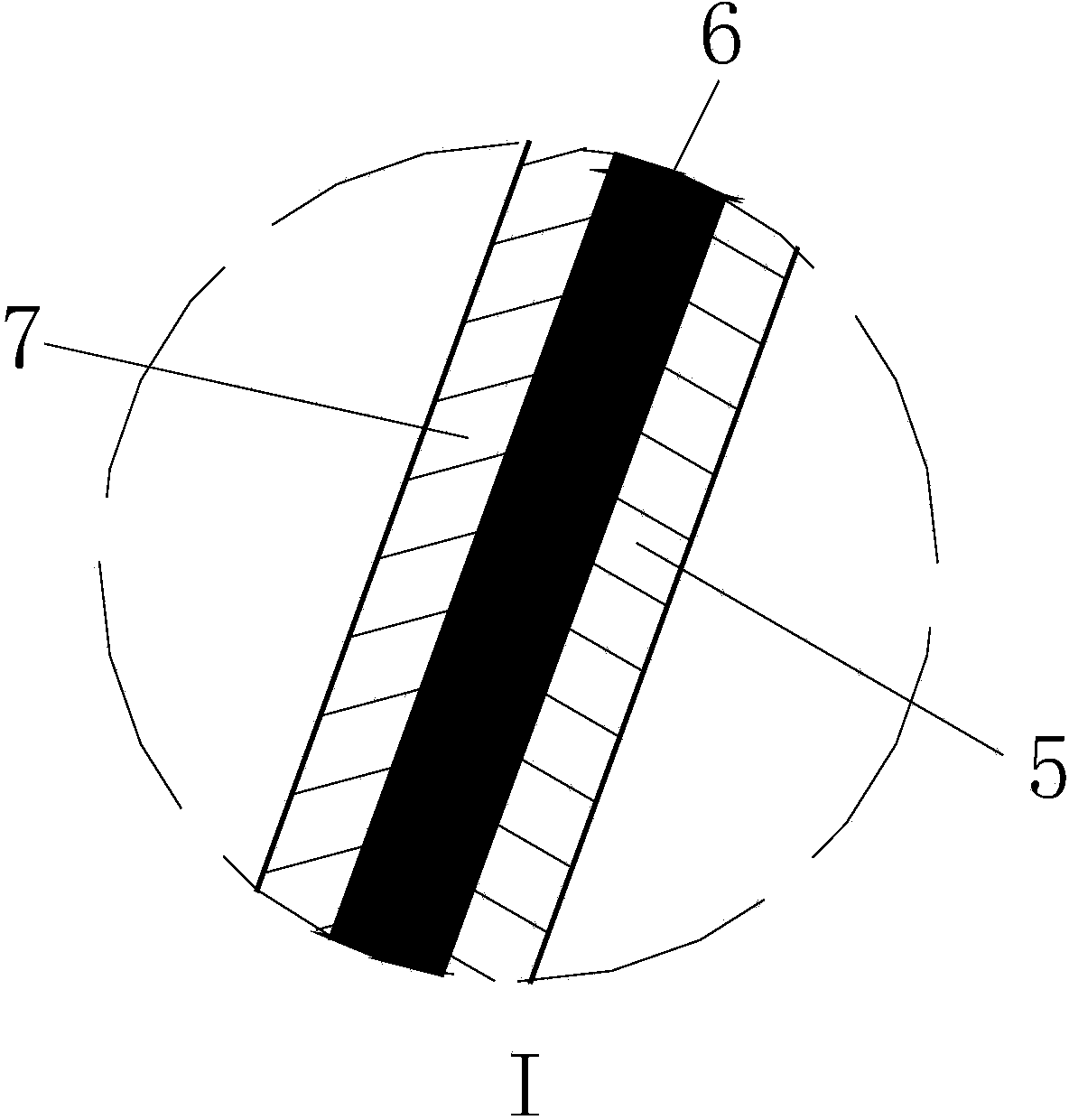

ActiveCN109524157AImprove flexibilityStrong fire resistanceFlexible cablesFlexible conductorsGratingAcrylic resin

The invention discloses a soft mineral fireproof cable comprising a filling layer (1), gratings (2) arranged in the filling layer (1), cable cores arranged in the gratings (2), a flexible protection layer (3) extruding and coating the filling layer (1), a second fireproof layer (4) extruded on the flexible protection layer (3), a first fireproof layer (5) extruded on the second fireproof layer (4), a heat insulating layer (6) extruded on the first fireproof layer (5), and a sheath (7) extruded on the heat insulating layer (6). The process is simple and the production efficiency is high. The obtained high-flexibility fireproof cable has advantages of high flexibility and good fire-resistant performance. The filling layer is made of a material formed by synthesis of volcanic ash, phthalic acid ester and acrylic resin, so that the cable cores are protected from being damaged; and the short-circuit phenomenon among the four cable cores is prevented by the grids at a temperature of 1300 DEGC even when the insulating layers of the cable cores fails to carry out insulation after certain time, so that the cable cores electrified normally.

Owner:四川省川胜电缆有限公司

Improved brake circuit of electromagnetic brake

InactiveCN104378020AExtend power-on timeFast brakingMotor/generator/converter stoppersDynamo-electric converter controlAlternating currentOpen contact

The invention discloses an improved brake circuit of an electromagnetic brake. One end of a stop button is connected with the positive electrode of a power source, and the other end of the stop button is connected with the negative electrode of the power source in sequence through a start button and a coil of a second alternating current contactor. A first normally open contact of a first alternating current contactor is connected with the two ends of the start button in parallel. A branch formed by connecting a power-on delay normally open contact of the second alternating current contactor with a coil of the first alternating current contactor in series is connected with the two ends of the coil of the second alternating current contactor in parallel. A normally open contact of the first alternating current contactor is connected between the power source and a motor. One end of a normally open contact of the second alternating current contactor is connected with the power source. The other end of the normally open contact of the second alternating current contactor is connected with a coil of the electromagnetic brake. By means of the improved brake circuit of the electromagnetic brake, the motor operates after a brake shoe of the brake is loosened, and safe startup is guaranteed.

Owner:CHANGZHOU EAST NOAH PRINTING & DYEING

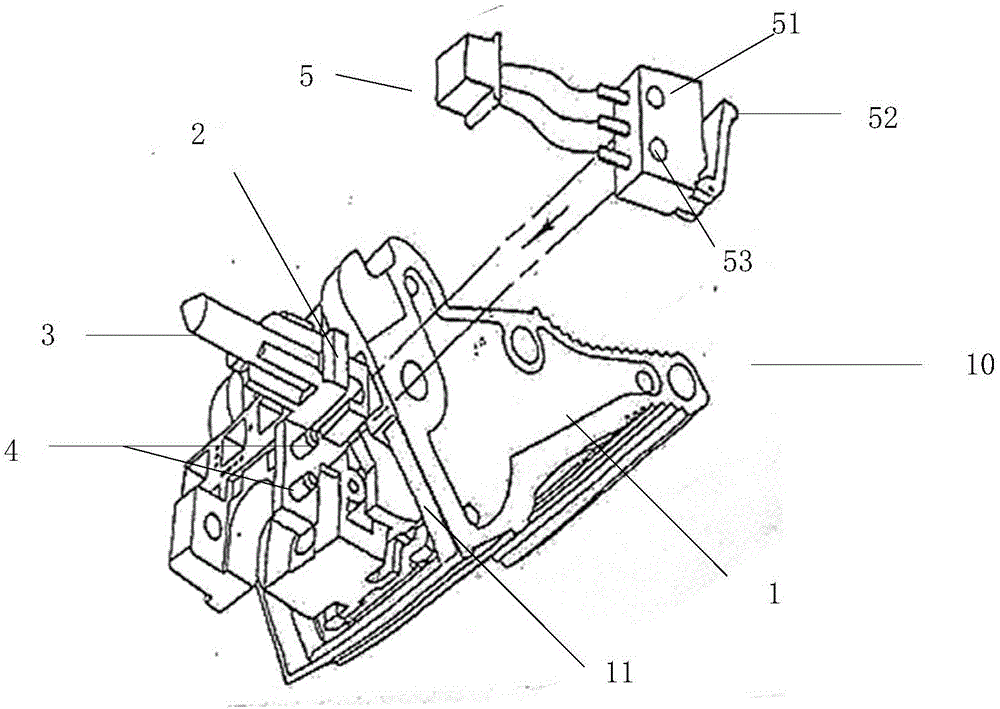

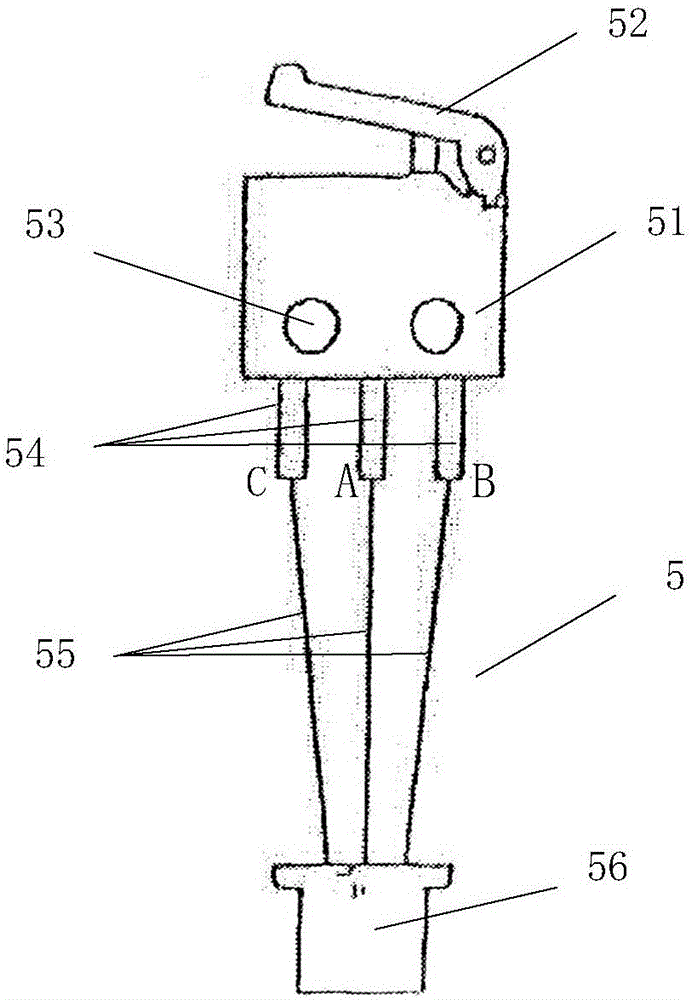

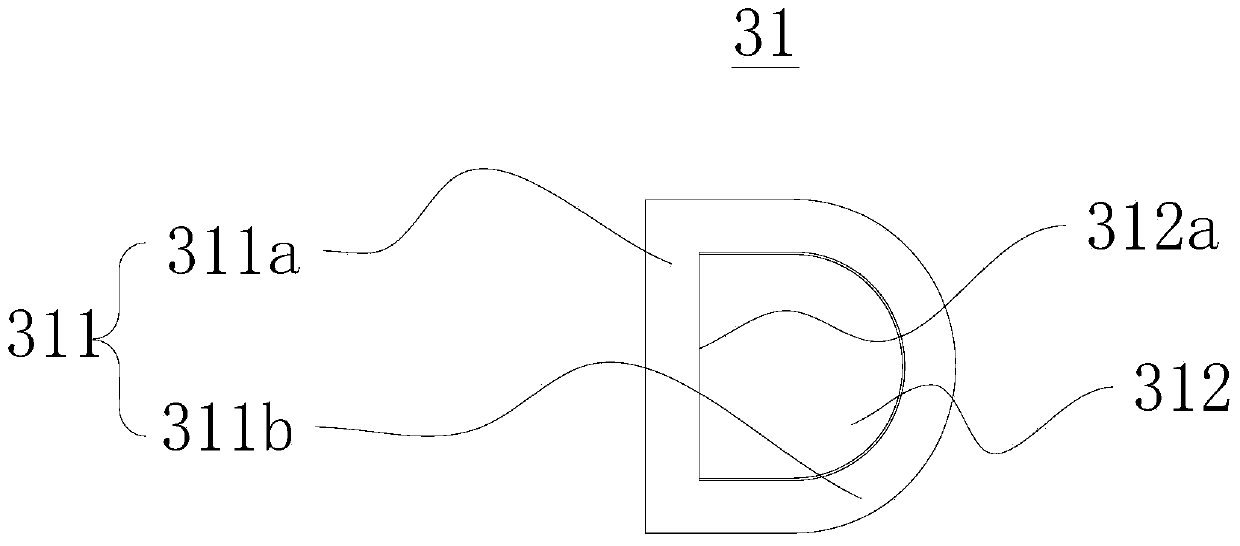

VPX power supply and hot-plugging realizing method thereof

InactiveCN106793657AReduce inrush currentExtend power-on timeContact operating partsClamping/extracting meansElectricityStopped work

The invention discloses a VPX power supply. The VPX power supply comprises a power supply board card and a plugging assistant device fixed at the upper end of the power supply board card, wherein the plugging assistant device comprises a microswitch and controls on-off of the microswitch so as to control working state of the VPX power supply. The invention further discloses a hot-plugging realizing method of the VPX power supply. Surge current produced when the VPX power supply is plugged is reduced, power-on time of the power supply is prolonged, flash spark caused by high impact current when the power supply is plugged is avoided, the VPX power supply stops working immediately when the VPX power supply is pulled out, and the VPX power supply is protected.

Owner:SHENZHEN CONSYS SCI&TECH CO LTD

Paster coating material for rechargeable battery and preparing method

InactiveCN1801522AStir wellExtended service lifeSecondary cells servicing/maintenanceMaterials scienceService time

The invention relates mainly to a companion paster coating material for charged lithium cell or Ni-H cell, which comprises: Al2O3 10-21wt%, SiO2 15-29wt%, Fe 5-10 wt%, Zr 8-30wt%, La 0.2-3.8wt%, Ce 0.1-2.5wt%, and Pr 1.5-3.7wt%. The benefits of this invention include: prolonging service time of charged cell, promoting to form the electrode ion flow, decreasing the reduction of capacity, and need no any modification to prior art.

Owner:潘庆洮

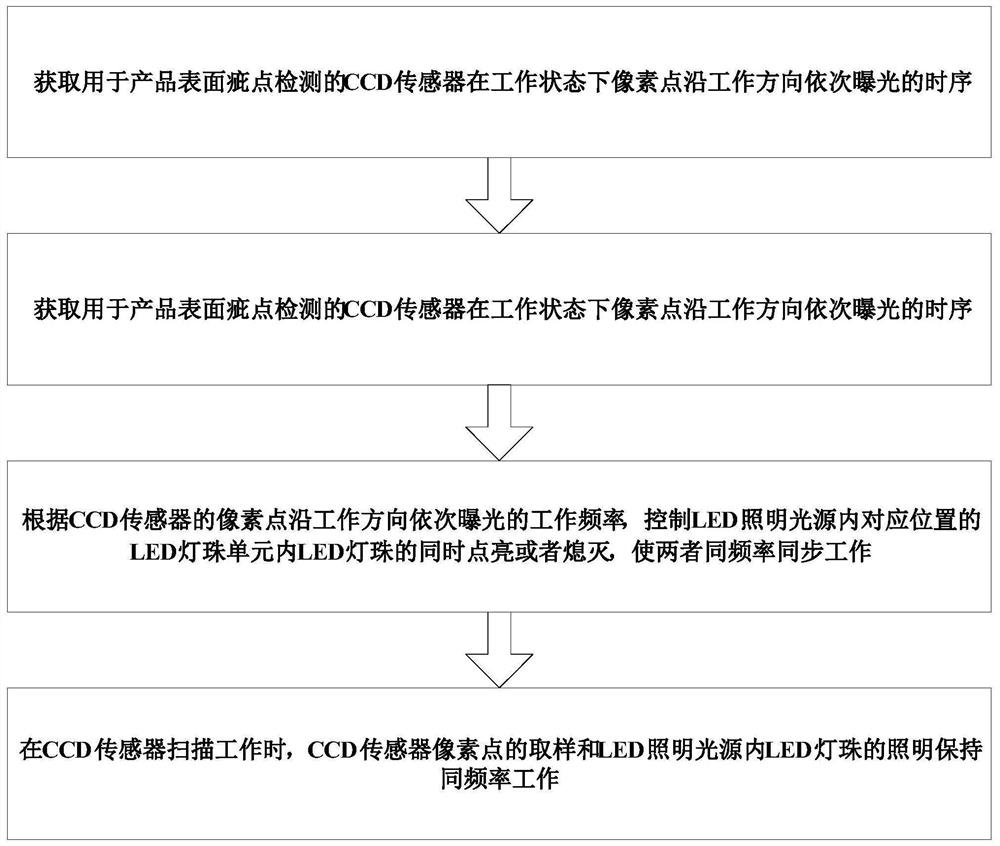

Same-frequency LED lighting source construction method for detecting product surface two-dimensional defects

ActiveCN112326668AEasy to install on siteIncrease brightnessEnergy saving control techniquesOptically investigating flaws/contaminationEngineeringLED lamp

The invention discloses a same-frequency LED lighting source construction method for detecting product surface two-dimensional defects. The same-frequency LED lighting source construction method is characterized by selecting a same-frequency LED lighting source for lighting according to attributive characteristics of the product surface two-dimensional defects, facilitating detection of the two-dimensional defects including different colors, stains and damages, and enabling the LED lighting sources to instantaneously lighten LED lamp beads. According to the working property that the LED lighting sources can be lightened individually, the LED lamp beads at the corresponding positions are lightened in a mapping control mode, overload can be ensured, the brightness is remarkably improved, anddue to the fact that the power-on time is short, the actual power consumption is low, the heating amount is small, an active heat dissipation component is not needed any more, the overall size is small, field installation of product surface detection is facilitated, pixels of a CCD sensor are synchronously lightened in sequence, the service life is prolonged, the illumination effect is good, theheat dissipation efficiency is high, the accuracy of detection and sampling of the product surface two-dimensional defects is greatly improved, and the same-frequency LED lighting source constructionmethod has good application prospect while the illumination requirement is met.

Owner:江苏善果缘智能科技有限公司

Power generating device by waste heat of automobiles

ActiveCN102510243BImprove pressure resistanceAccelerated corrosionInternal combustion piston enginesEngine componentsNon magneticAlternating current

The invention discloses a power generating device by waste heat of automobiles. A plurality of novel alloy bars are attached to the inner side of a circular iron hose of a power generator, coils are mounted between adjacent novel alloy bars and arranged in coil slots formed by adjacent novel alloy bars in a surrounded manner, heat and cold exchange holes are arranged on the novel alloy bars, an elongated rare earth magnet is attached on an outer face side of each alloy bar, magnetic polarities of the rare earth magnets on the face sides of the adjacent novel alloy bars are opposite, the other magnetic polarity surfaces of the rare earth magnets are wrapped on steel pipes, and the power generator is provided with an outer casing. The novel alloy bars are non-magnetic substances at a certain low temperature while are magnetic substances at a certain high temperature. When the rare earth magnets are close to the novel magnetic alloy bars, magnetism of the novel magnetic alloy bars is doubled. The novel alloy bars have magnetism after being heated by tail gas or a heat medium liquid in a cylinder liner of an automobile and have no magnetism after being cooled by cold air with water mist or refrigerant liquid, and high alternating current can be produced in the coils by repeating the above steps and can be used as power force for electric automobiles.

Owner:张英华

A fire-resistant control cable

ActiveCN103886988BAvoid skin breakdownImprove toughnessInsulated cablesInsulated conductorsCombustionElectrical conductor

Owner:ANHUI YIHE CABLE

A large-diameter direct-acting high-pressure solenoid valve

ActiveCN106090398BContinuous and stable supplyLarge diameterOperating means/releasing devices for valvesLift valveSuction forceSolenoid valve

A large-diameter direct-acting high-pressure solenoid valve, including a valve body, a coil cover, a coil, a spring, a valve core, a valve seat and an O-ring, is a coaxial integral structure. The upper part of the solenoid valve is the valve body, and the valve The upper end of the body is a medium inlet connection thread; the middle circle of the valve body is wound with an electromagnetic coil, and the outer side of the electromagnetic coil is a coil cover. Its control method adopts a two-position two-way direct-acting structure, which is opened when the power is turned on and closed when the power is turned off; the fluid medium flows in from the top of the valve body and flows out from the bottom of the valve seat. Compared with the prior art, the present invention has significant advantages: 1. Large diameter, high operating pressure, and long continuous energization time, so it can continuously and stably provide large flow medium; 2. Fast action response speed (≤10ms), The electromagnetic coil of the electromagnetic valve is relatively large, and the cross-sectional area of the valve core is also relatively large, which can generate a large electromagnetic suction force, so the response speed is very fast.

Owner:CHANGDE XIANGYU EQUIP MFG

A Memristor-Based XOR Gate Circuit and Its Design and Manufacturing Method

ActiveCN106941350BImplement logical operationsSmall sizeExclusive-OR circuitsCAD circuit designHemt circuitsControl theory

The invention discloses a memristor-based XOR gate circuit and a designing and manufacturing method thereof, which aims to solving the problem that a currently available memristor-based auxiliary logic MACIG gate set is incomplete. Therefore, the invention provides a new type of memristor-based XOR gate circuit designing method. The XOR gate of the invention is improved on the basis of the MAGIC OR gate. According to the invention, the two ends of the output memristor of the OR gate circuit are connected with memristors in parallel and the improved gate circuit is capable of obtaining correct XOR gate logic operation result. The XOR gate adopts fewer components with only four memristors and the excitation voltage sequence is simple, requiring only one stable and unchanging externally added excitation source. In addition, the energy comsumption of the XOR gate is low. Only with the exertion of short-term voltage, it is possible to realize the logic operations to the XOR gate. Beyond that, the XOR gate circuit has a simple structure and a small size.

Owner:SOUTHEAST UNIV

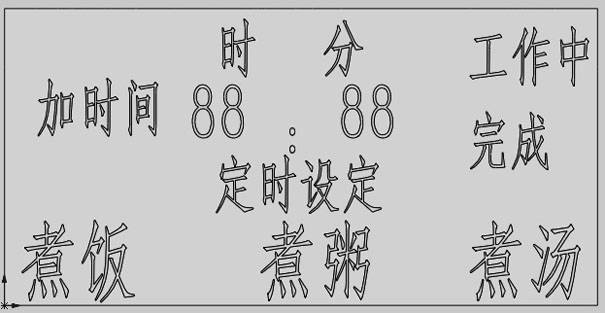

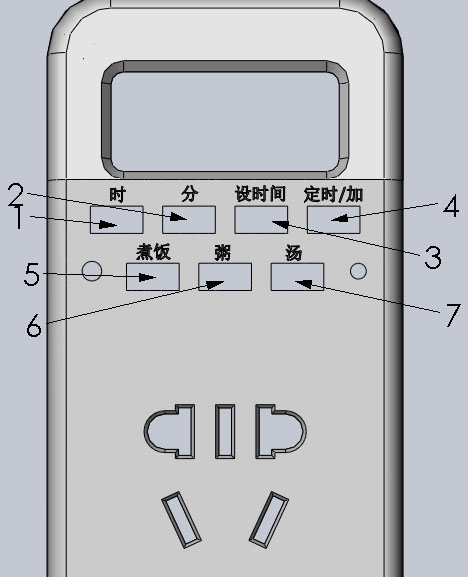

Electric rice cooker timer controller

InactiveCN112006519AExtended working hoursExtend power-on timeWarming devicesVessels with intergral heatingProcess engineeringCooker

The invention relates to a function of controlling a power supply of an electric rice cooker by a timer so as to change the electric rice cooker into an intelligent electric rice cooker, a control method and a display function. According to the invention, the electric rice cooker is changed into an intelligent electric rice cooker, the operation is simple, the functions on a display screen are visual, the program requirements for the porridge cooking and soup cooking functions are reasonable, the porridge cooking and soup cooking time is calculated, the electric rice cooker is controlled by controlling the on-off time, and keys are used in a distributed and combined mode.

Owner:梁玉泉

A cross-linked polyethylene insulated fire-resistant and flame-retardant power cable

ActiveCN110148492BLong flame retardant timeLow oxygenPower cables with screens/conductive layersInsulated cablesCopper conductorPower cable

The invention discloses a crosslinked polyethylene insulating fireproof flame-retardant power cable in the technical field of cables. The cable comprises a copper conductor, and the outer wall of thecopper conductor is sleeved by an insulating layer. The outer wall of the insulating layer is sleeved by a shielding layer. The outer wall of the shielding layer is sleeved by a flame-retardant layer,and a heat conduction frame is arranged in the flame retardant layer. The heat conduction frame comprises ferrules, and the ferrules are uniformly arranged in the flame-retardant layer, wherein a connecting rod is welded between the ferrules. Through holes are formed in the outer walls of the ferrules and the connecting rod, and the outer wall of the flame-retardant layer is sleeved by a mineralinsulating layer, wherein the outer wall of the mineral insulating layer is sleeved by an outer protective sleeve. According to the cable, the heat conduction frame is arranged in the flame retardantlayer; when the cable encounters a fire, the local flame-retardant layer is heated to enable the heat conduction frame to be heated to conduct heat, the flame-retardant layer at the heated heat conduction frame is heated to decompose water vapor, the water vapor moves towards the burning damage position of the cable due to pressure, the flame-retardant time of the flame-retardant layer is effectively prolonged, and the normal power-on time of related alarm and safety indication equipment is effectively prolonged.

Owner:JINYUAN ELECTRIC GRP

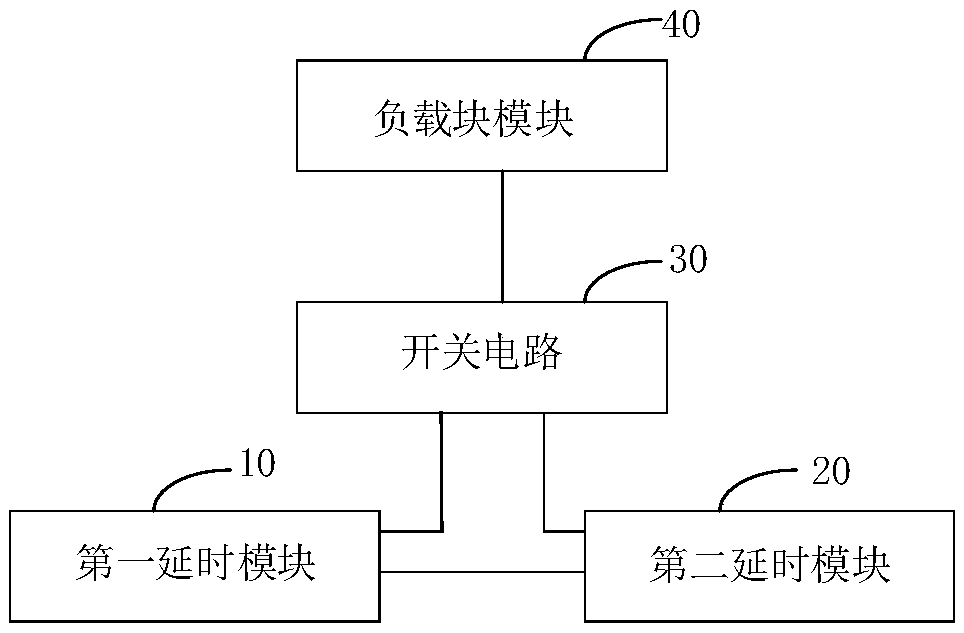

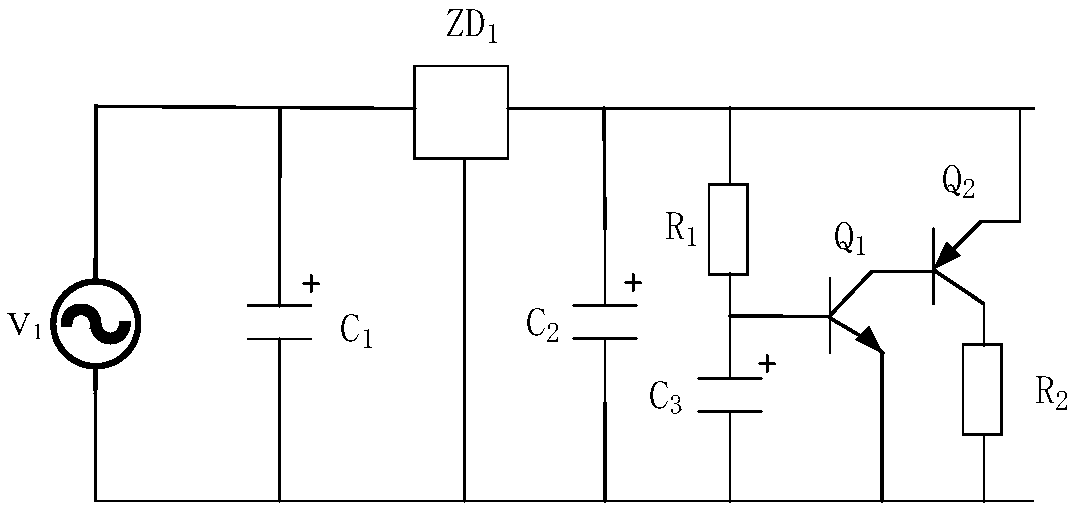

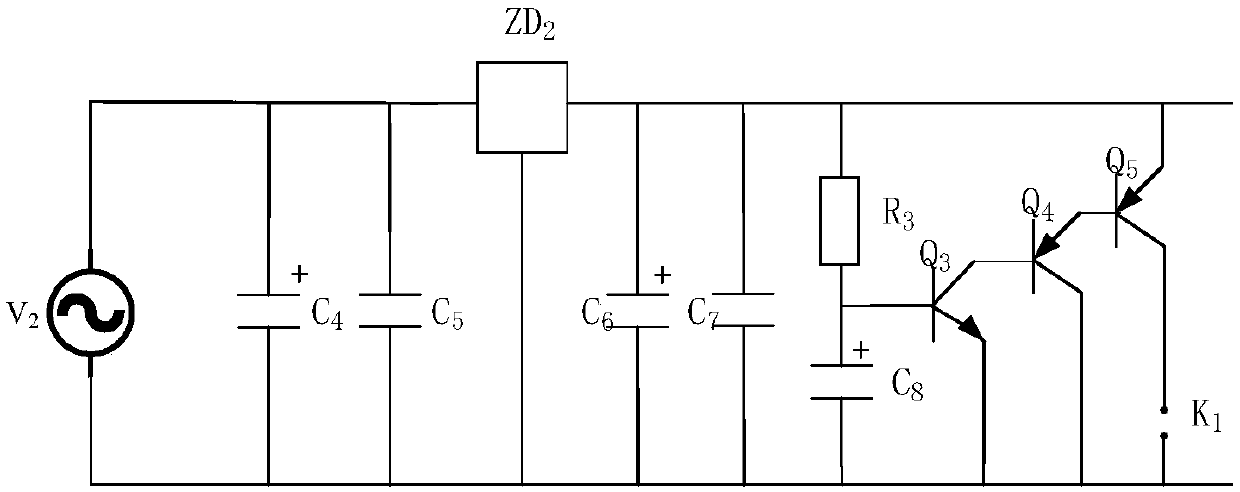

power failure protection circuit

ActiveCN106159874BSo as not to damageExtend power-on timeEmergency protective arrangements for automatic disconnectionTime delaysComputer module

The invention discloses a power outage protection circuit. The power outage protection circuit includes a first time delay module, a second time delay module, a switching circuit and a load block module; the first end of the first time delay module is connected with the first end of the switching circuit; the second end of the switching circuit is connected with the first end of the second time delay module; the third end of the switching circuit is connected with the first end of the load block module; and the second time delay module is connected with the second end of the load block module. According to the power outage protection circuit of the invention, when power supply is turned off after power outage, switching on or switching off is carried out through the switching circuit, so that the first time delay module, the second time delay module and the load block module work together to prolong the power-on time of a load, namely, after current in the circuit is stable, the load is electrified, and therefore, the load can be protected from being damaged due to excessively high current.

Owner:QINHUANGDAO POWER SUPPLY COMPANY OF STATE GRID JIBEI ELECTRIC POWER COMPANY +1

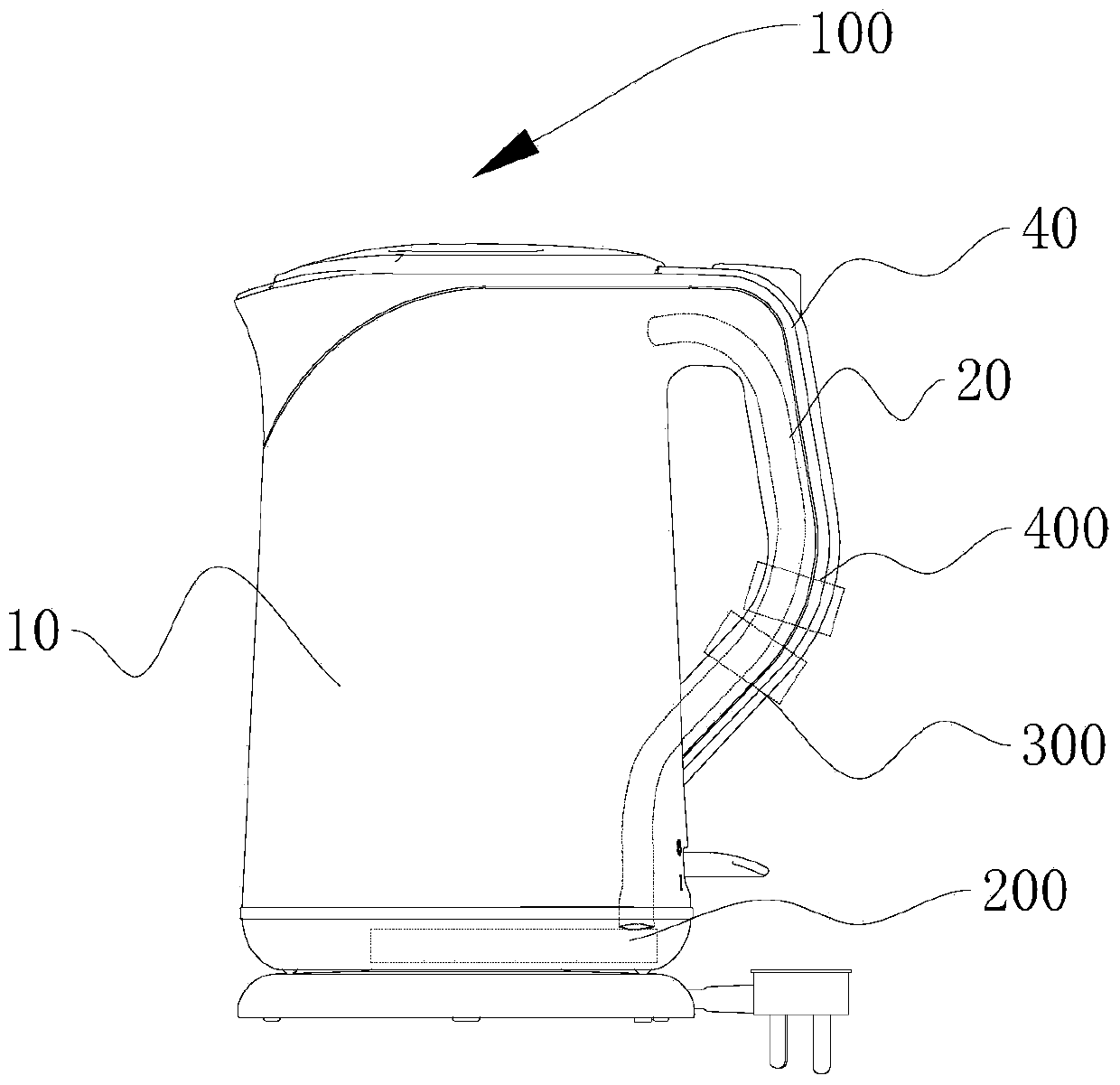

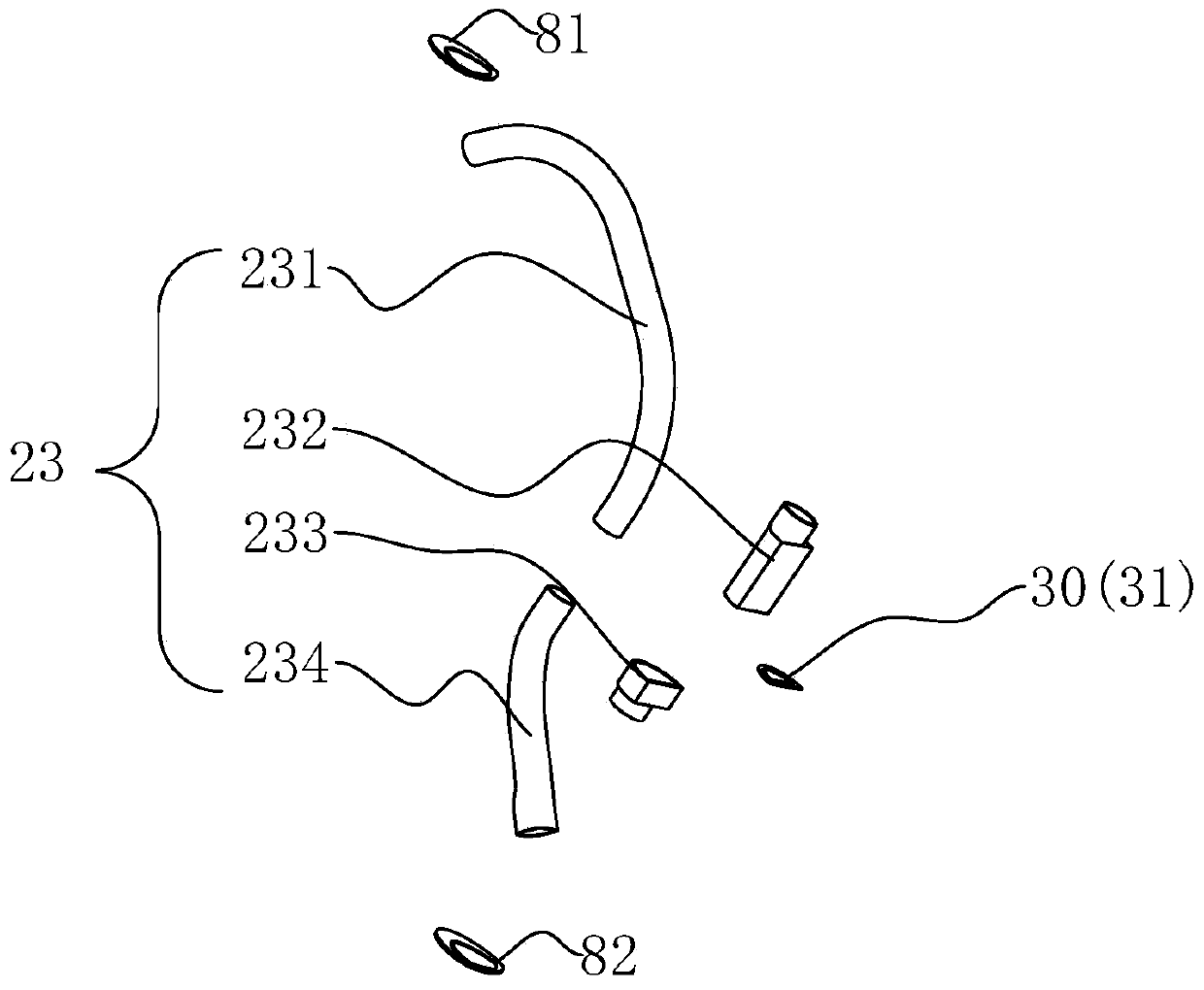

electric kettle

ActiveCN106852644BExtend power-on timeExtended boiling timeWater-boiling vesselsWarming devicesThermodynamicsPotable water

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

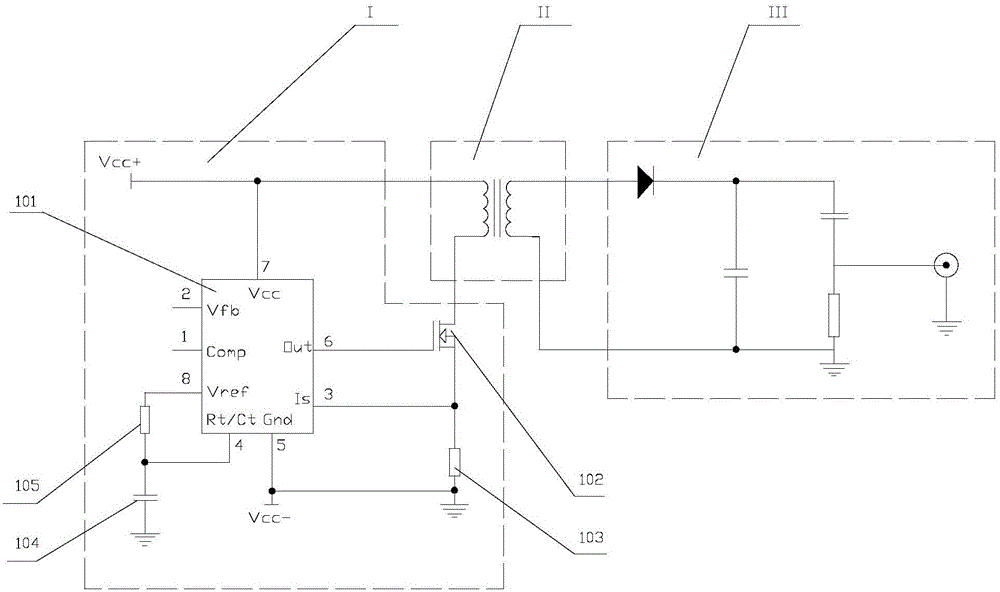

Ignition device having power compensation function

InactiveCN105156215AConstant frequencySame ignition capacityGas turbine plantsJet propulsion plantsCapacitanceTransformer

The invention relates to an ignition device having a power compensation function. The ignition device having the power compensation function comprises an energy conversion circuit, a transformer and an energy storage discharge circuit. The power compensation function is achieved through the energy conversion circuit which specifically comprises a pulse width modulator, an MOS transistor, a sampling resistor, a frequency adjusting capacitor and a frequency adjusting resistor. A pin 7 of the pulse width modulator is connected with the positive electrode of a power source and one end of a primary coil of the transformer. The other end of the primary coil of the transformer is connected with the drain electrode of the MOS transistor. The grid electrode of the MOS transistor is connected with a pin 6 of the pulse width modulator. A pin 3 of the pulse width modulator is connected between the source electrode of the MOS transistor and the sampling resistor. A pin 5 of the pulse width modulator is connected with the negative electrode of the power source. The frequency adjusting resistor is connected between a pin 4 and a pin 8 of the pulse width modulator in series. The frequency adjusting capacitor is connected between the pin 4 of the pulse width modulator and the ground. By the adoption of the ignition device, when the power supply voltage of the power source is reduced, power-on time is prolonged through a field effect transistor till the current reaches a set value so as to compensate for the power lost due to the voltage drop, and the spark frequency output by the ignition device is constant.

Owner:哈尔滨东安高精管轴制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com