Soft mineral fireproof cable

A fireproof cable and mineral technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of high temperature resistance and poor fire resistance, and achieve the effect of improving toughness, simple process and improving power-on time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

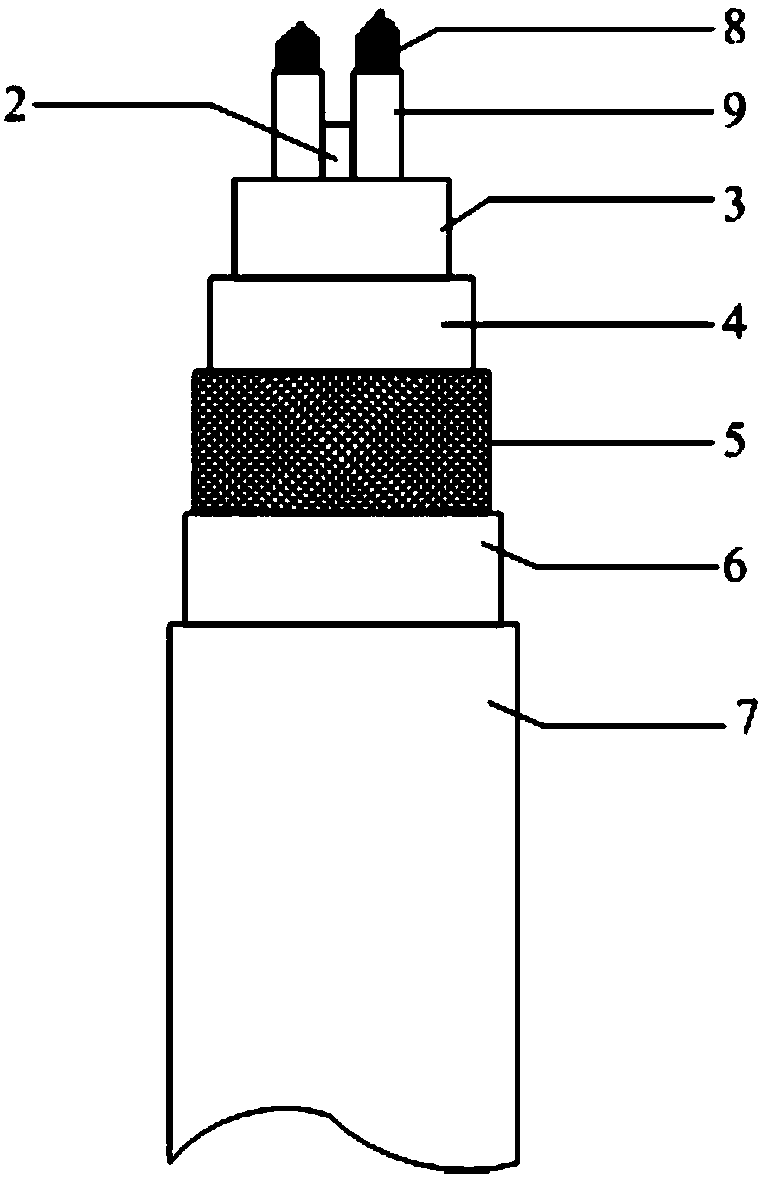

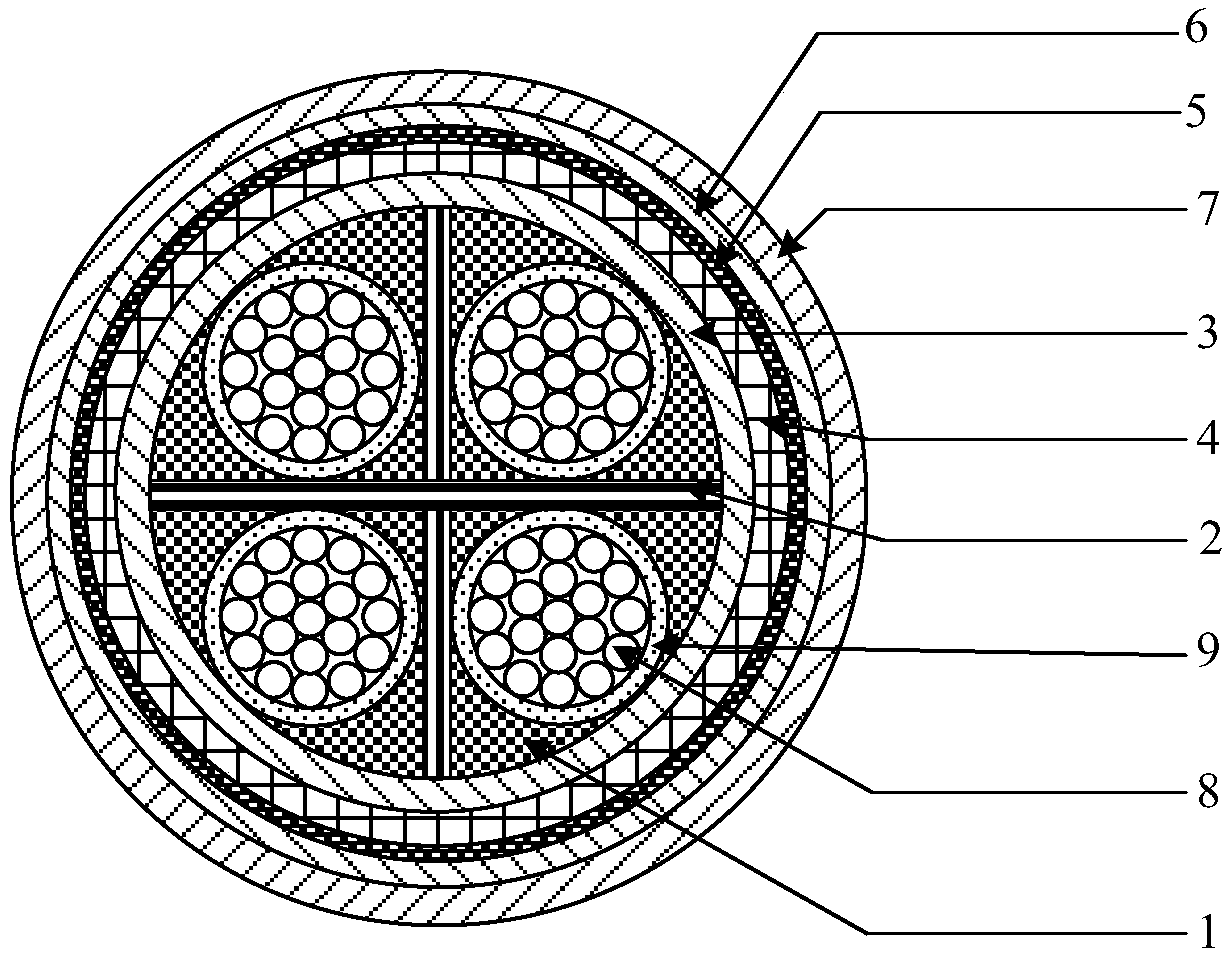

[0023] Such as figure 1 and figure 2 As shown, a soft mineral fireproof cable of this embodiment includes a filling layer 1, a grid 2, a cable core, a flexible protective layer 3, a second fireproof layer 4, a first fireproof layer 5, and a heat insulation layer 6, and sheath 7. Among them, such as figure 2 As shown, the cable core includes a plurality of flexible conductors 8 and an insulating layer 9 extruded on the flexible conductors 8 .

[0024] During implementation, the filling layer 1 is preferably composed of volcanic ash, phthalate ester and acrylic resin. When the filling layer 1 is made, the weight ratio of volcanic ash, phthalate ester and acrylic resin is 4:1.5:1. The volcanic ash and the phthalate are stirred and mixed at a temperature of 140°C for 10 minutes, and then cooled to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com