Ignition device having power compensation function

An ignition device and power compensation technology, applied in jet propulsion device, gas turbine device, machine/engine, etc., can solve the problems of ignition device spark frequency reduction, electric energy conversion power reduction, inability to ignite oil-gas mixture steam, etc., and achieve constant spark frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

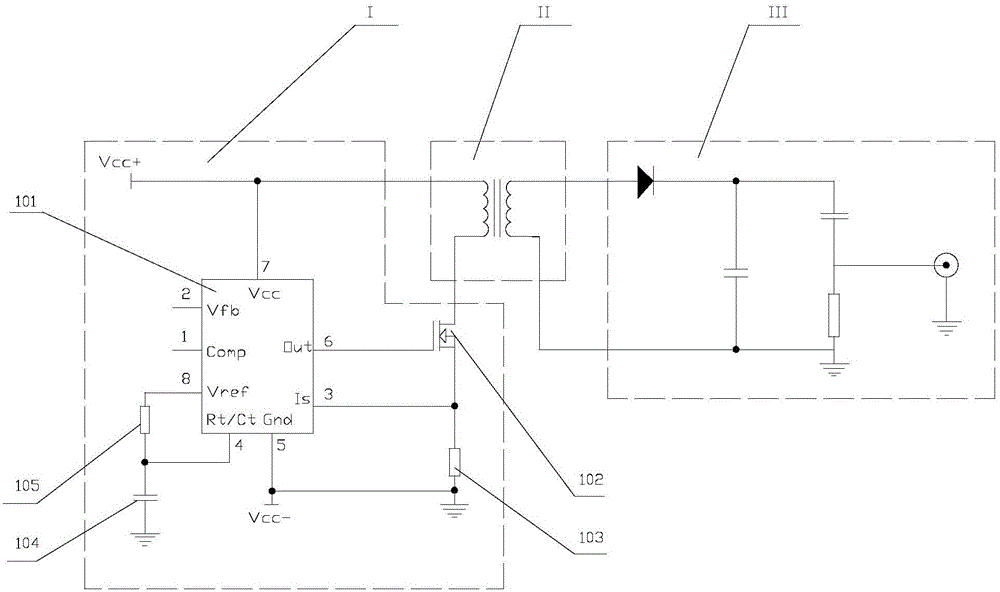

[0013] As shown in the figure, the ignition device with power compensation function includes: energy conversion circuit I, transformer II and energy storage discharge circuit III, and the power compensation function is realized by the energy conversion circuit, specifically including pulse width modulator 101, MOS tube 102, sampling resistor 103, frequency modulation capacitor 104 and frequency modulation resistor 105, pin 7 of the pulse width modulator 101 is connected to the positive pole of the power supply and one end of the primary coil of the transformer, the other end of the primary coil of the transformer is connected to the drain of the MOS tube 102, and the MOS The gate of the tube 102 is connected to pin 6 of the pulse width modulator 101, the source of the MOS tube 102 is connected to the sampling resistor 103 and grounded, and the pin 3 of the pulse width modulator 101 is connected between the source of the MOS tube 102 and the sampling resistor 103, Pin 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com