Same-frequency LED lighting source construction method for detecting product surface two-dimensional defects

A technology of LED lighting and construction method, applied in the direction of optical testing flaws/defects, etc., can solve the problems of insufficient bright spots and poor heat dissipation of the lighting source, and achieve the effect of good lighting effect, meeting lighting needs and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

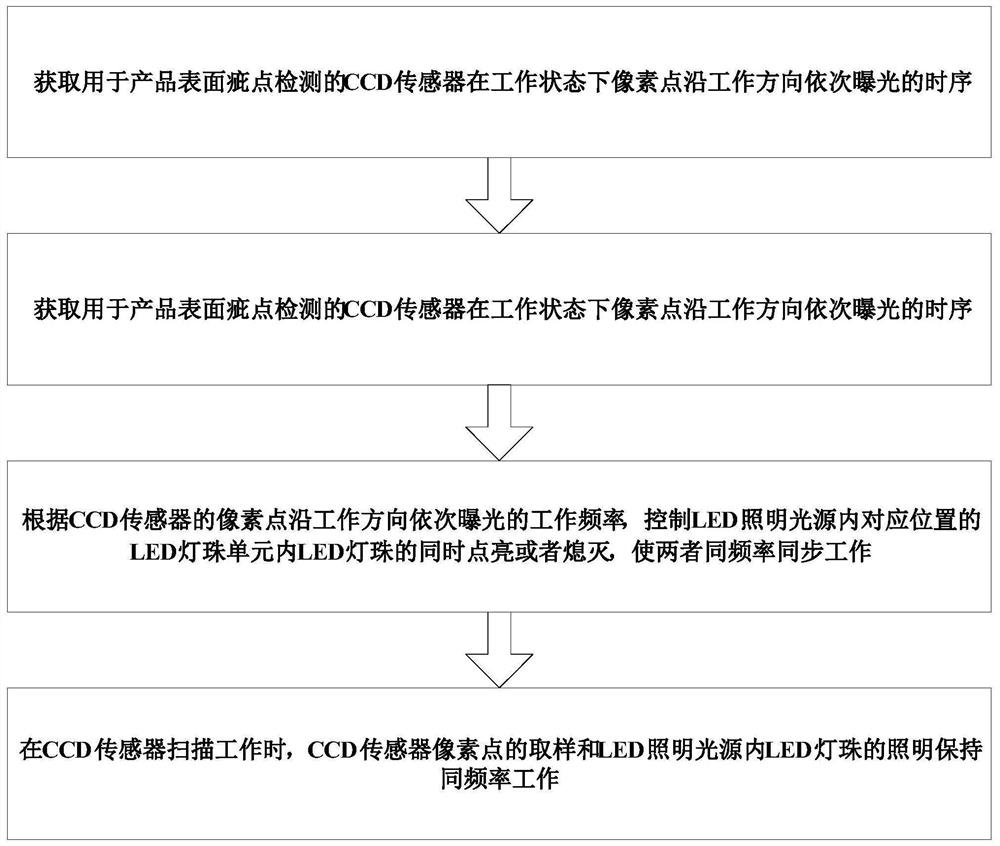

[0035] Such as figure 1 As shown, the construction method of the same-frequency confocal LED lighting source for CCD sensor scanning of the present invention comprises the following steps,

[0036] Step (A), obtaining the time sequence of sequentially exposing pixels along the working direction of the CCD sensor used for product surface defect detection in the working state, includes the following steps,

[0037] (A1), connect the electrical signal test instrument with the CCD sensor, and establish a test environment;

[0038] (A2), provide the required clock signal and power supply to the CCD sensor to make it work normally;

[0039] (A3), sequentially perform instantaneous single-point illumination on each pixel point in the CCD sensor that is working normally, and record the output signal of the pixel point of the CCD sensor through the electrical signal tester, a...

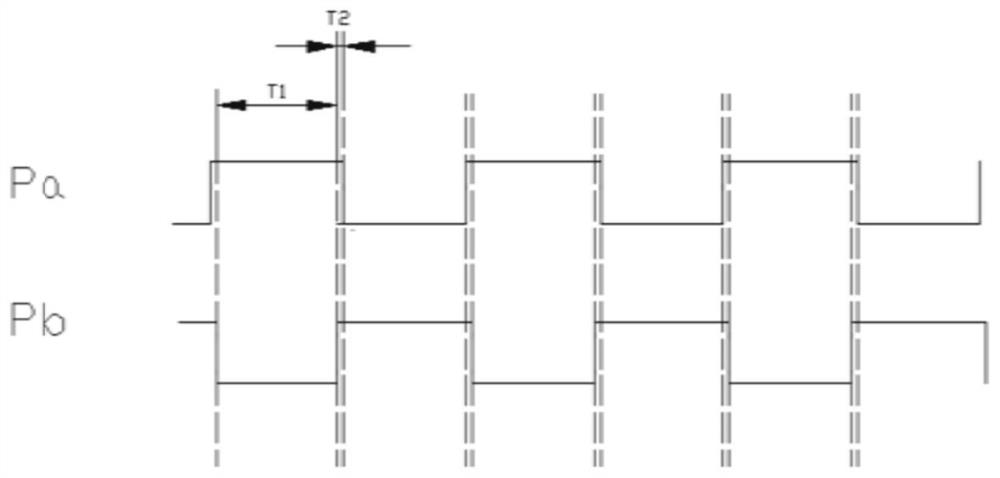

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com