LED lamp tube power-on detection device and detection method

A technology of LED lamp tube and detection device, applied in the direction of measurement device, measurement device shell, lamp testing, etc., can solve the problems of incomplete detection, underutilization, waste of time, etc., and achieve convenient removal, loading, installation, and power-on time. Long and good detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

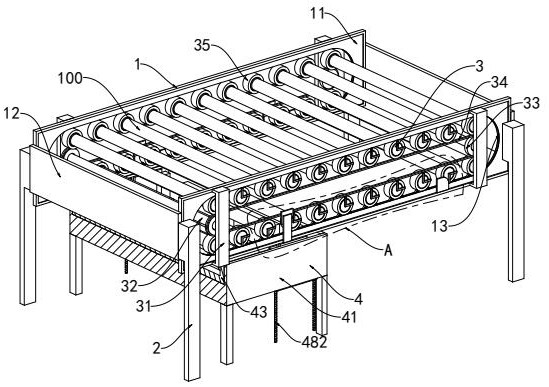

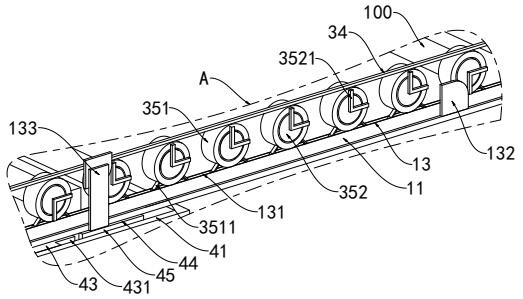

[0041] see figure 1 , an LED lamp power-on detection device disclosed in this embodiment includes a detection frame 1 and a support leg 2 for supporting and fixing the detection frame 1. The detection frame 1 includes two front and rear guide rail frames 11, two The two ends of the guide rail frame 11 are connected and fixed by two connecting plates 12 respectively. The guide rail frame 11 is provided with a running track 13 , and the running track 13 is provided with a running detection mechanism 3 .

[0042] The operation detection mechanism 3 includes mounting brackets 31 installed on both ends of the guide rail frame 11 , a rotating shaft 32 is installed between the two symmetrical mounting brackets 31 through bearings, and both ends of the rotating shaft 32 are installed through bearings. Linkage sprocket 33, the two linkage sprockets 33 located on the same guide rail frame 11 are connected by a transmission chain 34, and a plurality of clamping energization units are con...

Embodiment 2

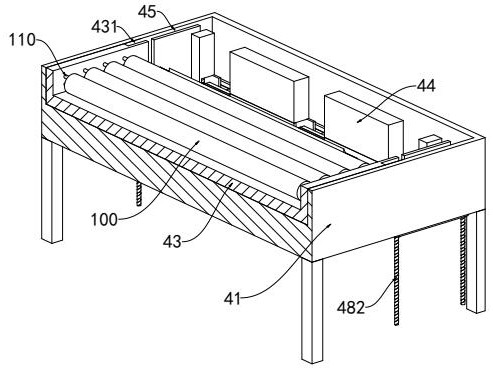

[0053] see image 3 , Figure 4 , Figure 5 , Figure 7 and Figure 8 , on the basis of the first embodiment, in order to ensure that the lamp 100 can be automatically loaded without manual clamping, installation and power-on detection of the lamp 100, an automatic feeding mechanism 4 is arranged under the detection frame 1, so The automatic feeding mechanism 4 includes a feeding bottom frame 41 installed with support bars, a feeding slot 42 is opened on the right side of the bottom of the feeding bottom frame 41, and a transportation platform 43 is provided on the left side of the bottom of the feeding bottom frame 41. , and the right end of the transport platform 43 is located above the feeding chute 42. The feeding chute 42 is provided with a rectangular pre-clamping frame 44 with an open upper end, and the rectangular pre-clamping frame 44 is distributed on the front and rear sides of the feeding chute. 42 There are gap areas 45 on both the front and rear sides, cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com