Method for improving microbial corrosion resistance of concrete

An anti-microbial and corrosion-resistant technology, applied in the field of improving the anti-microbial corrosion performance of concrete, can solve the problems of easy leaching and low service life of the coating, and achieve the effect of improving the impermeability, reducing copper ion leaching, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

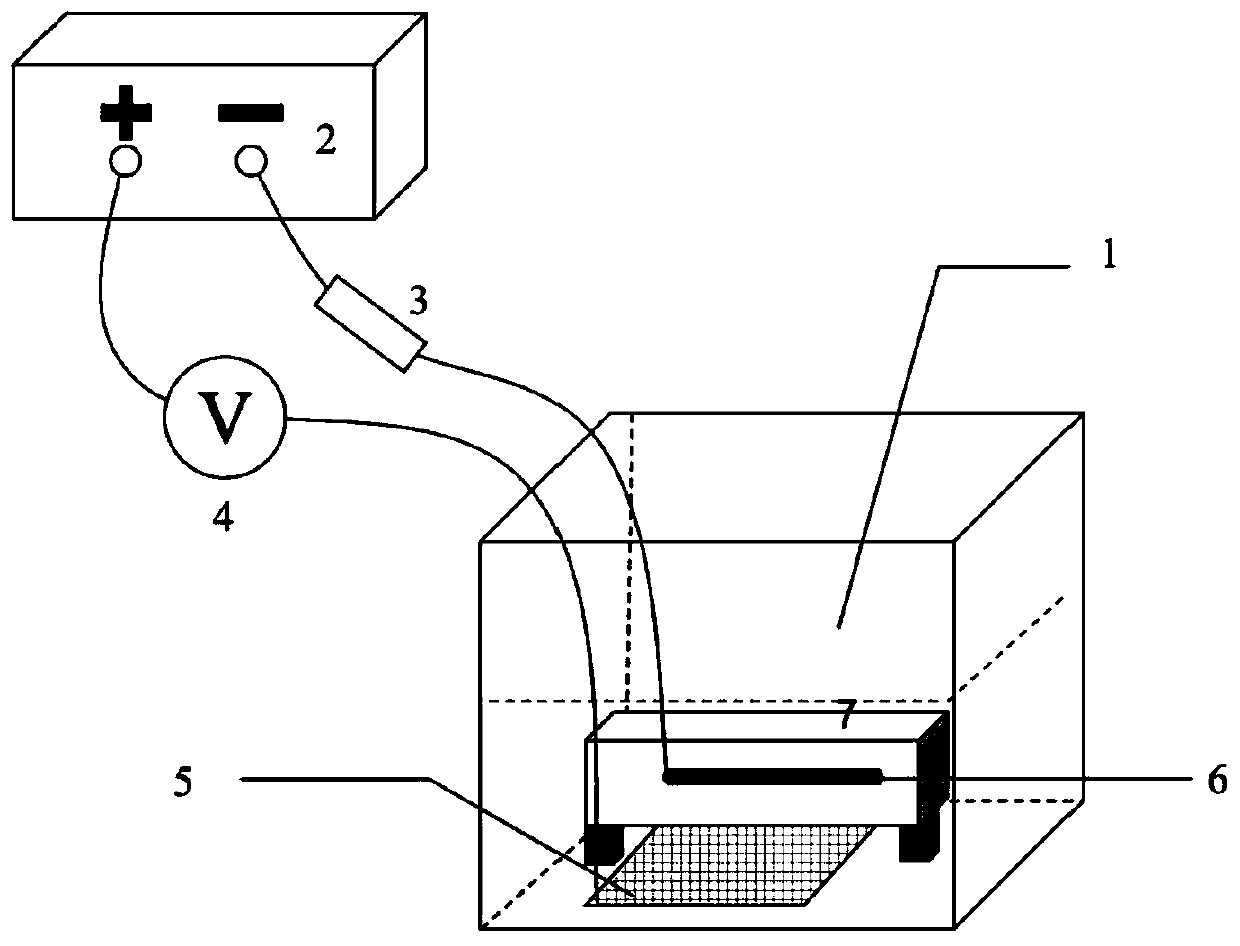

[0055] The concentration of copper nitrate used is 0.6mol / L, the concentration of lactic acid is 3mol / L electrolyte, the pH value of the electrolyte is adjusted to 9 with a concentration of 5mol / L sodium hydroxide solution, and the current density is 2.5A / m 2 , the solution temperature was maintained at 60°C, the electrolyte was replaced every 5 days, and the test piece was taken out after 15 days of power on.

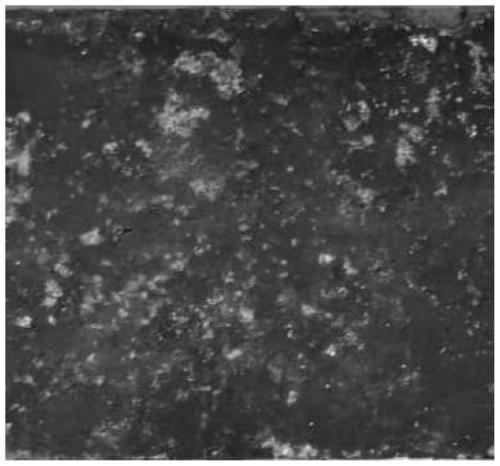

[0056] Observe the surface morphology of the specimen:

[0057] A. If figure 2 As shown, the surface of the specimen was covered with dark brown deposits.

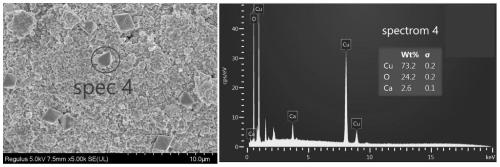

[0058] B. Analyze the surface microstructure of the specimen by scanning electron microscope and energy spectrum (SEM-EDS); image 3 is the SEM image of the surface of the mortar specimen after electrodeposition. According to the energy spectrum, the main elements of the deposited species are Cu (73.2%) and O (24.2%). The SEM image shows that there are obvious copper and copper oxides covering the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com