Method for manufacturing flexible carbon nano-tube transistor

A technology of carbon nanotubes and single-walled carbon nanotubes, applied in transistors, nanotechnology, nanotechnology, etc., to achieve important application value, device performance improvement, and simplified process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

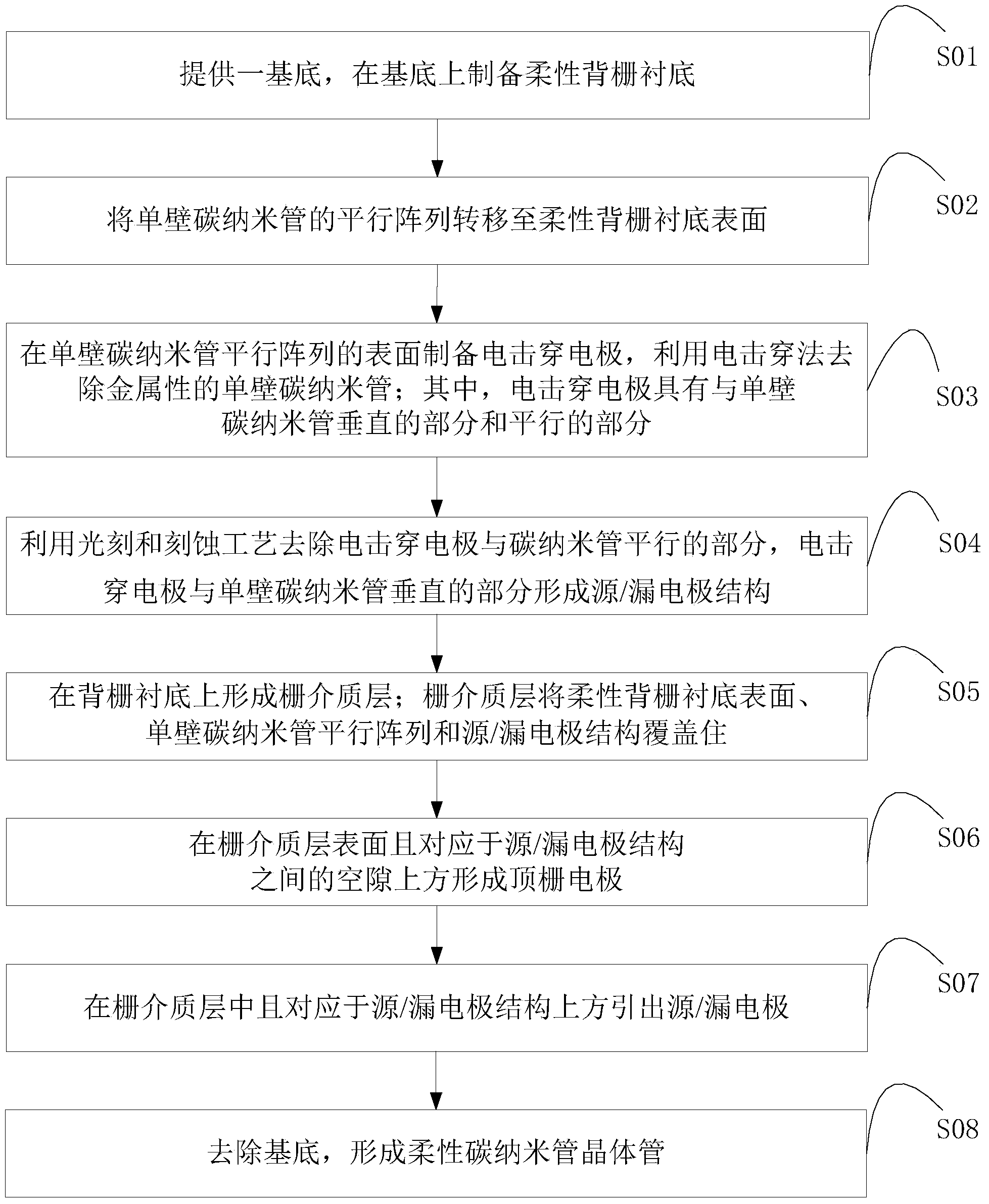

[0060] The preparation method of the flexible carbon nanotube transistor of the present invention comprises:

[0061] A substrate is provided, and a flexible backgate substrate is prepared on the substrate;

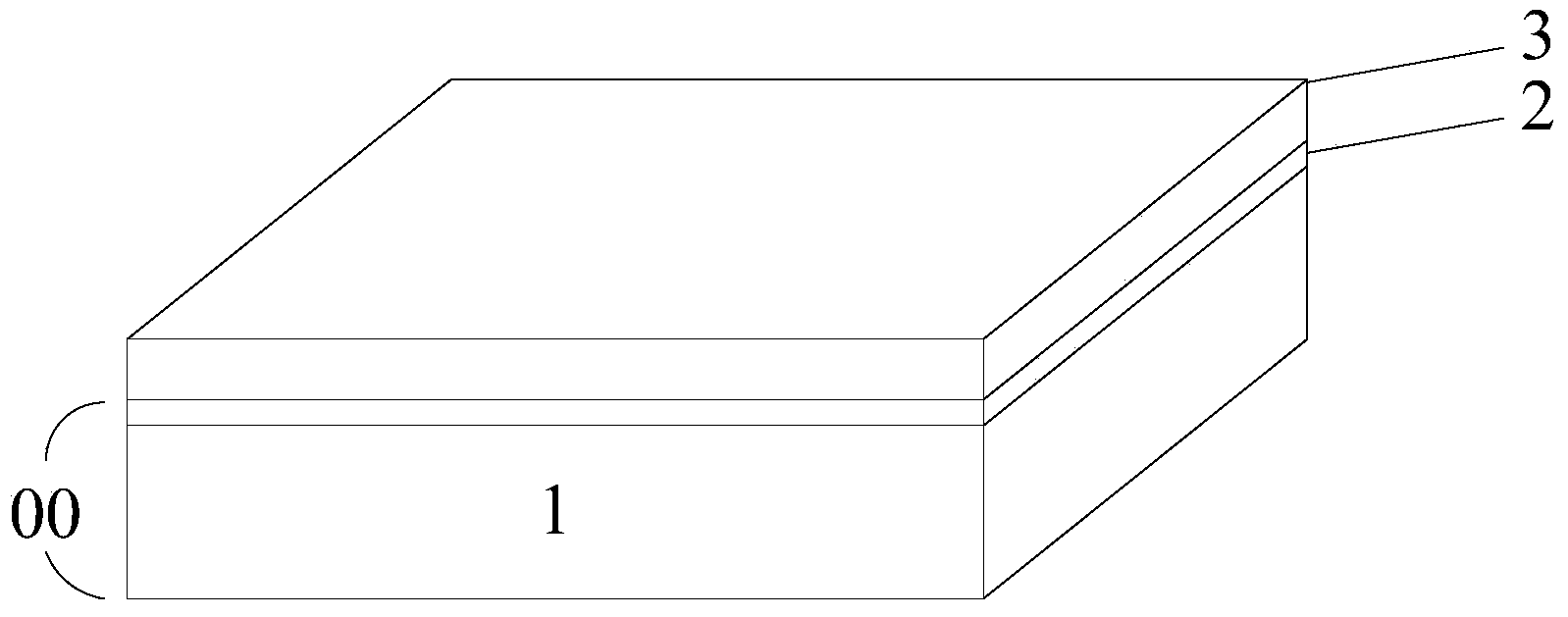

[0062] Transferring parallel arrays of single-walled carbon nanotubes to the surface of a back-gated substrate;

[0063] Prepare an electrical breakdown electrode on the surface of the single-walled carbon nanotube parallel array, and remove the metallic single-walled carbon nanotube by using the electrical breakdown method; wherein, the electrical breakdown electrode has a part parallel to the single-walled carbon nanotube and a vertical part ;

[0064] The part of the electrical breakdown electrode parallel to the single-walled carbon nanotube is removed by photolithography and etching process, and the part of the electrical breakdown electrode perpendicular to the carbon nanotube forms a source / drain electrode structure;

[0065] forming a gate dielectric layer on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com