Accurately controllable nano-hole manufacturing method

A manufacturing method and precise control technology, applied in nanotechnology and other directions, can solve the problems of uncertainty of use parameters, difficult to control electron beam and ion beam nanohole, etc., to achieve simple and efficient manufacturing method, wide application range, and application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

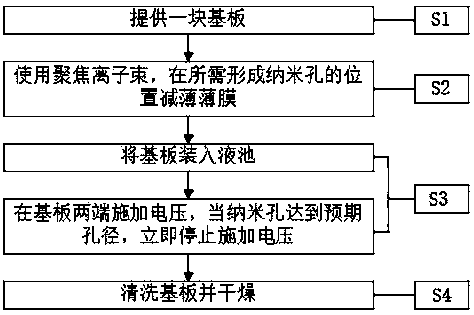

[0037] Such as figure 1 Shown is a flow chart of the precisely controlled nanopore 20 manufacturing method of the present invention, comprising the following steps:

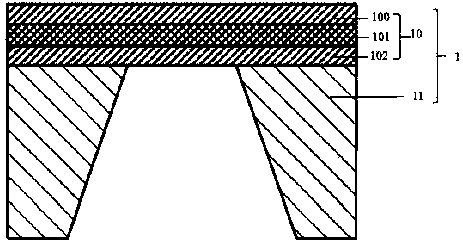

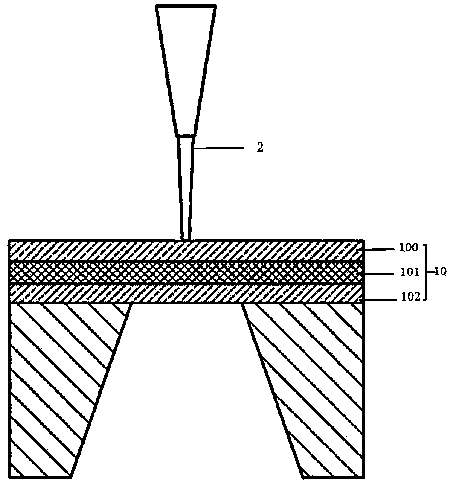

[0038] S1. Provide a substrate such as figure 2 As shown, the substrate includes a composite film 10 made of a P-type silicon chip 11 and several layers of single-layer films, and the composite film 10 is grown on one side of the P-type silicon chip 11; wherein, the back side of the P-type silicon chip 11 is photoetched and Wet etching forms an inverted cone-shaped structure, grows a 20nm silicon nitride film 102 by low-stress chemical vapor deposition on the front of the P-type silicon wafer 1111, and then grows a 20nm silicon oxide film by low-stress chemical vapor deposition 101101, and then grow a 20nm silicon nitride film 100 by low-stress chemical vapor deposition, and the back of the silicon wafer is etched into an inverted cone structure through photolithography and wet etching, exposing a 6um*6um film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Minimum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com