Thermally conductive pressure-sensitive adhesive composition,thermally conductive pressure-sensitive adhesive sheet,and electronic component

A technology of pressure-sensitive adhesives and thermal conductivity, applied in adhesives, electric solid devices, semiconductor devices, etc., to achieve a well-balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0212] In the reactor, add 100 parts of monomer mixture formed by 94% of 2-ethylhexyl acrylate and 6% of acrylic acid, 0.03 parts of 2,2'-azobisisobutyronitrile and 700 parts of ethyl acetate, uniformly After dissolving and nitrogen substitution, a polymerization reaction was performed at 80° C. for 6 hours. The polymerization conversion rate was 97%. The obtained polymer was dried under reduced pressure, ethyl acetate was evaporated, and a viscous solid (meth)acrylate polymer was obtained. The weight average molecular weight (Mw) of the (meth)acrylate polymer was 270,000, and the weight average molecular weight (Mw) / number average molecular weight (Mn) was 3.1. The weight average molecular weight (Mw) and the number average molecular weight (Mn) were calculated|required by standard polystyrene conversion by gel permeation chromatography using tetrahydrofuran as an eluent.

[0213] Next, 0.9 parts of polyfunctional monomers, 2-ethylhexyl acrylate (hereinafter Abbreviated as...

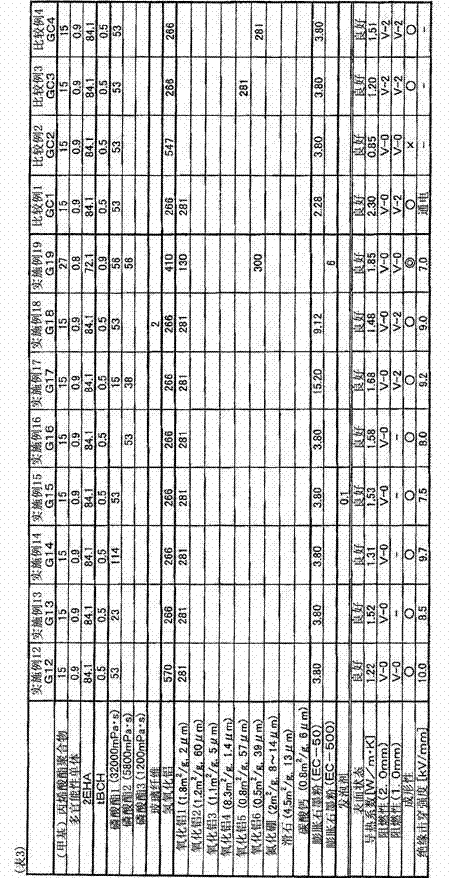

Embodiment 2~18、 comparative example 1~15)

[0218] As shown in Table 2 to Table 4, except for changing each compound and its amount, other experiments were carried out in the same manner as in Example 1 for thermally conductive pressure-sensitive adhesive sheets (G2) to (G19), (GC1) to (GC15) The production of heat-conductive pressure-sensitive adhesive sheets (G2)-(G19), (GC1)-(GC10), (GC13), (GC14) was obtained. For Comparative Example 11, Comparative Example 12, and Comparative Example 15, a heat-conductive pressure-sensitive-adhesive sheet could not be produced.

[0219] About the heat conductive pressure-sensitive-adhesive sheet (G1-G19, GC1), the sheet|seat of thickness 2mm, 1mm, and 0.5mm was produced, respectively, and it evaluated. About the heat conductive pressure-sensitive-adhesive sheet (GC2-GC10, GC13, GC14), the sheet|seat of thickness 2mm and 1mm was produced, respectively, and it evaluated.

[0220] In addition, the complexes not used in Example 1 are as follows.

[0221] ?Expanded graphite powder:

...

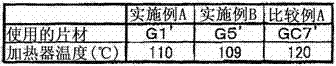

Embodiment A)

[0271] The above measurement was performed using a sheet (G1') having the same composition as the sheet (G1) of Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com