Elastomer composite with high dielectric constant and low dielectric loss and preparation method thereof

A technology of high dielectric constant and composite materials, applied in the processing of textile materials, filament/thread forming, fiber processing, etc., can solve the problem of incompatibility between high dielectric constant and low dielectric loss, surface modification and coating Problems such as complicated process and limited dielectric loss can be achieved to solve the problems of high dielectric constant and low dielectric loss, increase percolation value, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

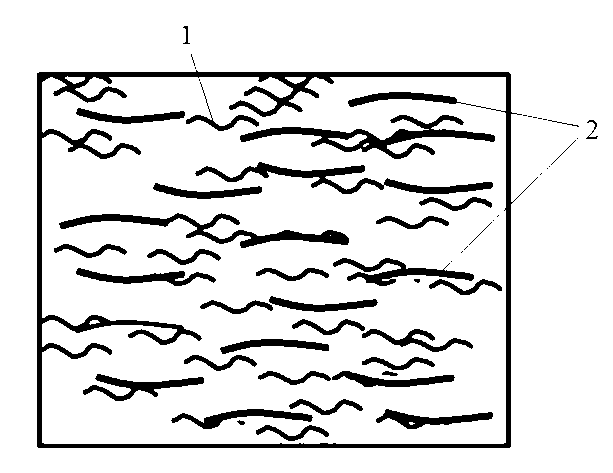

[0034] Example 1: Using thermoplastic polyurethane (TPU) with an amino content of 34% as an elastomer matrix, a carbon nanotube / TPU dielectric composite material with a carbon nanotube content of 0.5% and carbon nanotube orientation was prepared.

[0035] 1) Prepare a TPU / tetrahydrofuran (THF) solution, keep the temperature at 50°C for 2 hours until the TPU is completely dissolved; ultrasonically disperse a certain mass concentration of carboxyl-modified carbon nanotubes in N,N-dimethylformamide (DMF) dispersant 2h; mix the above TPU / THF solution with the carbon nanotube suspension, and stir magnetically to form a carbon nanotube / TPU / THF / DMF suspension in which the carbon nanotubes are uniformly dispersed, wherein the mass ratio of THF to DMF is 7:3. TPU is 5g; carbon nanotube is 0.025g; THF is 31.5g; DMF is 13.5g.

[0036] 2) Put the above solution in a plastic medical syringe, use a flat-ended stainless steel needle, that is, a syringe needle whose needle tip is smoothed wit...

Embodiment 2

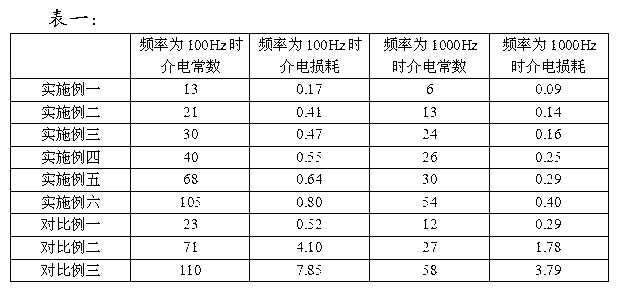

[0039] Embodiment 2: The preparation method and testing method are the same as in Embodiment 1, except that the content of carbon nanotubes is 1.2%. The test results are shown in Table 1.

Embodiment 3

[0040] Embodiment 3: The preparation method and testing method are the same as in Embodiment 1, except that the content of carbon nanotubes is 1.6%. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com