Microporous polyether urethane elastomer composite material and preparation method thereof

A technology of polyether polyurethane and microcellular elastomer, which is applied in the field of materials, can solve the problem that the elongation at break does not decrease, the elongation at break will not increase, and the comprehensive mechanical properties of polyurethane microcellular elastomer composite materials are not particularly ideal, etc. problems, to achieve the effect of improving the degree of phase separation, excellent mechanical properties, and strengthening the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

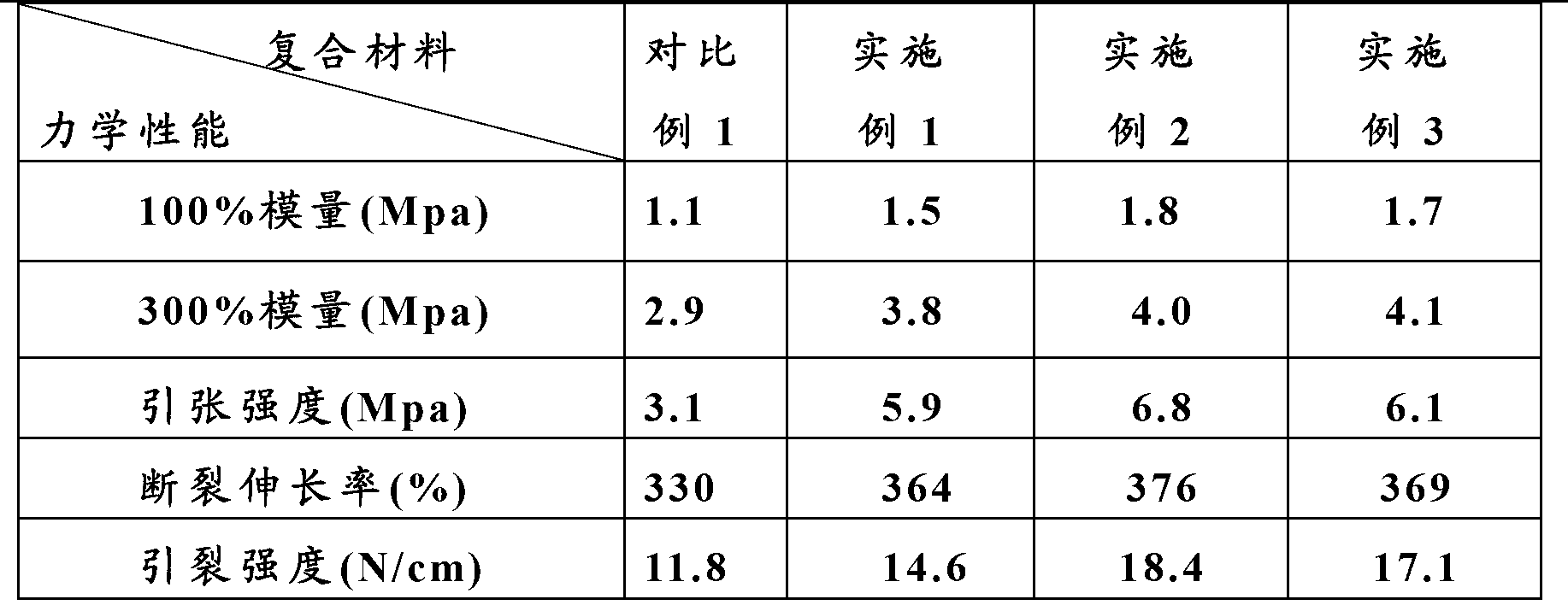

Examples

Embodiment 1

[0035] This example provides a polyether polyurethane microcellular elastomer composite material, the preparation method of which is as follows:

[0036] (1) Preparation of polyol A component: Add 50kg of polyoxypropylene diol (number average molecular weight 8000) and 0.5kg of nano-graphene into the reaction kettle, stir at 90-110°C for 2 hours, and obtain uniformly dispersed nano-graphite ethylene-polyoxypropylene glycol solution, lower the temperature to 90°C, add polytetrahydrofuran polyol (number-average molecular weight 3000-3500, functionality 2.3-2.8) 30kg, polyether polyol III 20kg, ethylene glycol 3.5kg, 1 , 4-butanediol 7kg, H 2 0.4kg, 0.5kg of silicone oil and 2.5kg of organic amine catalysts are fully stirred and discharged, sealed and preserved for subsequent use;

[0037] (2) Preparation of prepolymer component B: 40kg of MDI, 10kg of liquefied MDI-100LL (purchased from Ningbo Wanhua) and 32.24kg of polyoxypropylene glycol (number average molecular weight 3000)...

Embodiment 2

[0040] This example provides a polyether polyurethane microcellular elastomer composite material, the preparation method of which is as follows:

[0041] (1) Preparation of polyol A component: Add 55kg of polyoxypropylene diol (number average molecular weight 6000) and 1.2kg of nano-graphene into the reaction kettle, stir at 90-110°C for 2 hours, and obtain uniformly dispersed nano-graphite Alkene-polyoxypropylene glycol solution, cooling. Add 15kg polytetrahydrofuran polyol (number-average molecular weight 4000, functionality 2.3-2.8), 30kg polymer polyether polyol III, ethylene glycol 4kg, 1,4-butanediol 8kg, H 2 O0.4kg, HCFC-141b0.8kg, 0.5kg of silicone oil and 3kg of amine catalysts, fully stirred evenly and discharged, sealed and stored for later use;

[0042] (2) Preparation of prepolymer component B: 40kg of MDI, 10kg of liquefied MDI-100LL (purchased from Ningbo Wanhua) and 40.24kg of polyoxypropylene glycol (number average molecular weight 4000) were placed in a reac...

Embodiment 3

[0045] This example provides a polyether polyurethane microcellular elastomer composite material, the preparation method of which is as follows:

[0046] (1) Preparation of polyol A component: Add 60kg of polyoxypropylene diol (number-average molecular weight 4000) and 1.9kg of nano-graphene into the reaction kettle, stir at 90-110°C for 2 hours, and obtain uniformly dispersed nano-graphite Alkene-polyoxypropylene glycol solution, cooling. Add 15kg of polyoxypropylene oxide ethylene copolyether polyol (number-average molecular weight 4000, functionality 2-3), polyether polyol III 25kg, ethylene glycol 1.5kg, 1,4-butanediol 10kg, H 2 O0.4kg, HCFC-141b1.6kg, 0.5kg of silicone oil, 2.8kg of amine catalyst, 0.8kg of organic tin catalyst, fully stirred and evenly discharged, sealed and stored for later use;

[0047] (2) Preparation of component B of the prepolymer: 35kg of MDI, 15kg of liquefied MDI-100LL (purchased from Ningbo Wanhua) and 23.51kg of polyoxypropylene glycol (numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com