Silicon rubber based porous dielectric elastomer composite material and preparation method thereof

A technology of dielectric elastomer and composite material, applied in the field of silicone rubber-based porous dielectric elastomer composite material and its preparation, can solve the problems of increasing dielectric constant modulus, decreasing material breakdown voltage, and high local electric field, and achieving Effects of low Young's modulus, high dielectric constant, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the above-mentioned silicone rubber-based dielectric elastomer composite material, comprising the following steps:

[0034] 1) Add the conductive filler to deionized water and stir, then ultrasonically obtain the initial suspension, then add polyethylene glycol to the initial suspension, perform ultrasonication in a water bath after stirring, and obtain the polyethylene glycol / conductive filler suspension;

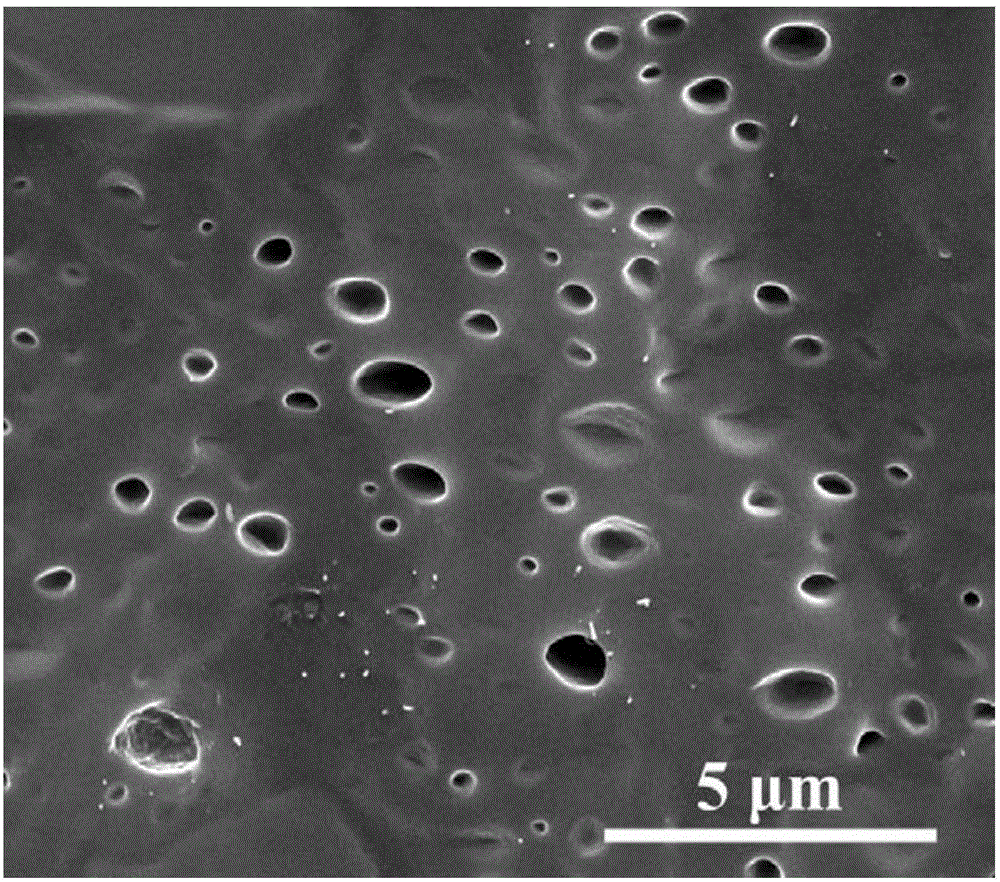

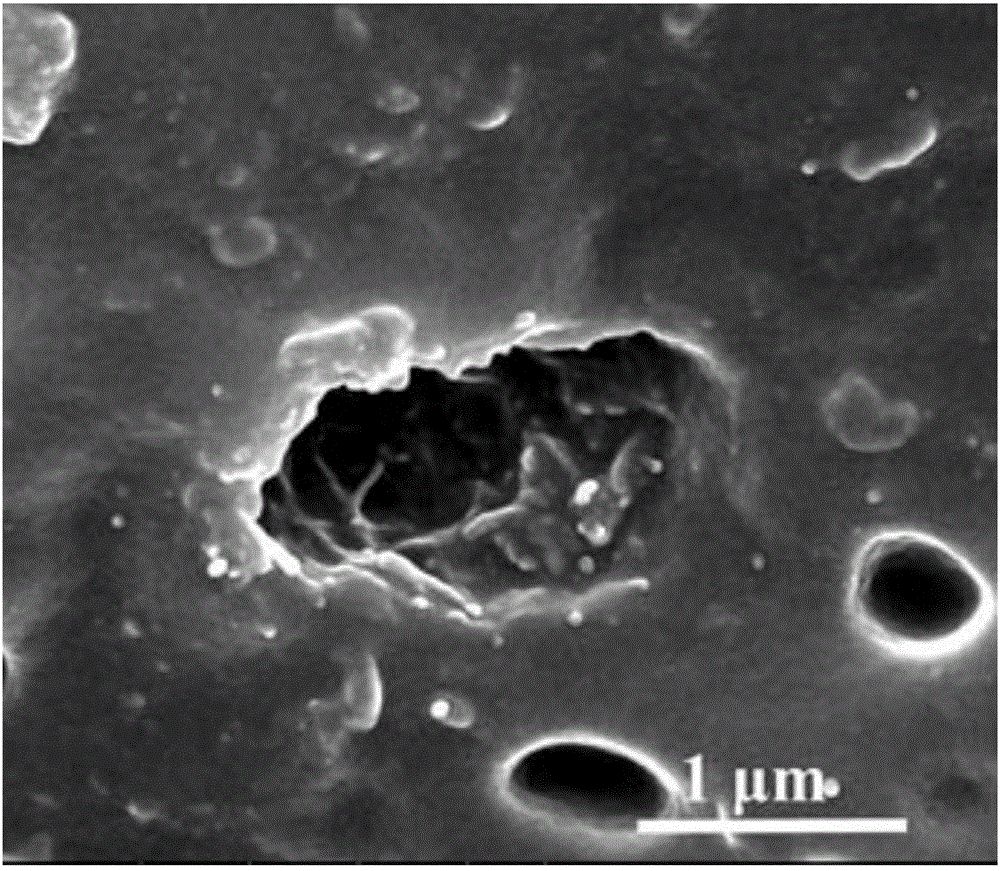

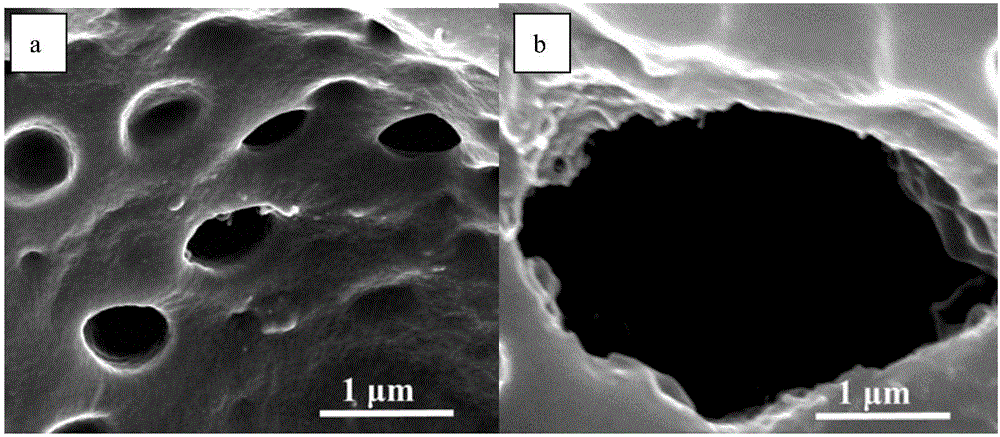

[0035]2) Mix the polyethylene glycol / conductive filler suspension obtained in step 1) into the polydimethylsiloxane that has been added with curing agent, stir and mix well to obtain polyethylene glycol / polydimethylsiloxane / cured Agent / conductive filler blend; Among them, polydimethylsiloxane is the continuous phase, and the conductive filler is gradually dispersed in polydimethylsiloxane with polyethylene glycol aqueous solution, and finally distributed in polydimethylsiloxane At the junction of alkanes an...

Embodiment

[0053] Raw materials and their proportions:

[0054] The mass ratio of deionized water to polyethylene glycol (PEG, molecular weight 10000g / mol, Aladdin) is 7:3, polydimethylsiloxane (PDMS, Sylgard184, Dow Corning) and tetraethylorthosilicate (TEOS , Dow Corning) with a mass ratio of 10:1, the ratio of the overall mass of polydimethylsiloxane and curing agent mixture to the overall mass of polyethylene glycol and deionized water is 7:3, carbon nanotubes (MYCNTs, Nanocyl S.A.) accounts for the mass percent of all mixtures (polydimethylsiloxane / polyethylene glycol / deionized water containing curing agent) to be respectively 0.1125% (embodiment 1), 0.225% (embodiment 2), 0.45% (Example 3), 0.9% (Example 4) and 1.8% (Example 5).

[0055] Preparation method: Add carbon nanotubes into deionized water and stir, then probe ultrasonically for 30-60 minutes to obtain an initial suspension, then add polyethylene glycol to the suspension, and after stirring, perform water-bath ultrasonica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com