Highly-stretchable 3D printed graphene-based flexible sensor with high sensitivity and preparation method of graphene-based flexible sensor

An alkenyl-based flexible, 3D printing technology, which is used in electric/magnetic solid deformation measurement, electromagnetic measurement devices, additive processing, etc., can solve the problem that flexible sensors cannot obtain high sensitivity coefficient and high strain sensing range at the same time. Sensitivity, excellent comprehensive performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

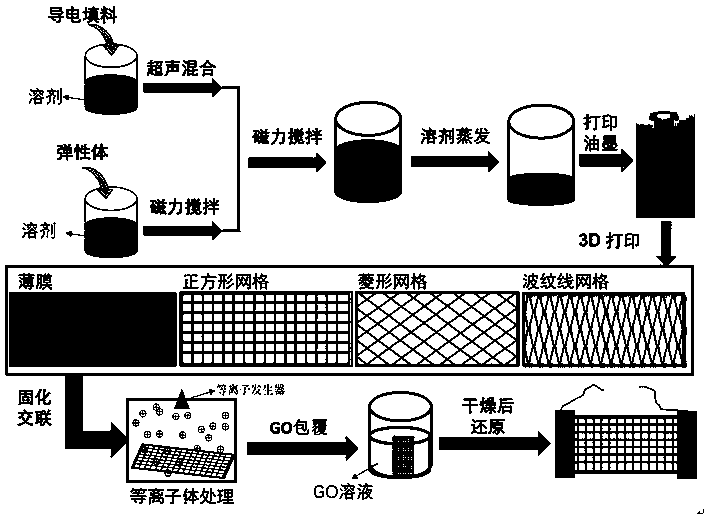

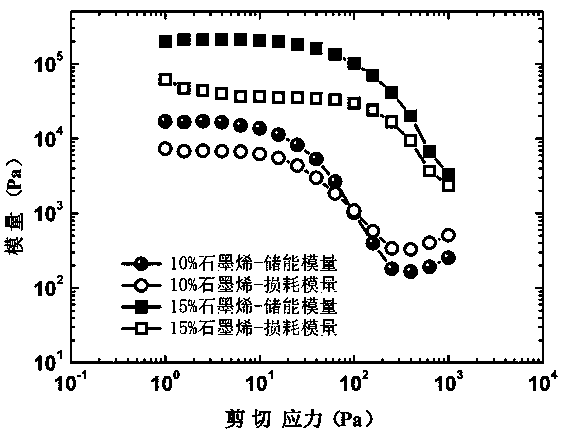

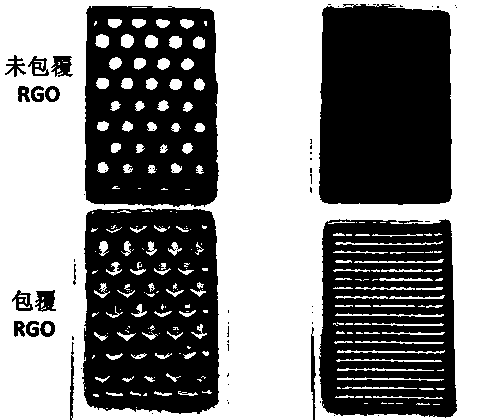

[0029] Mix 100 parts (the said parts are parts by mass) of the main agent of PDMS with different parts of graphene in ethyl acetate solvent, add 10 parts of PDMS curing agent to the system after evaporating the solvent, figure 2 The modulus of the PDMS / graphene 3D printing material with different graphene addition ratios prepared according to the method in Example 1 of the present invention is shown as a function of shear stress; the above mixed material is used for 3D printing to form a corrugated network three-dimensional structure . Place the printed three-dimensional structure in an oven at 80°C to cure for 6 hours, then place the cured three-dimensional structure in oxygen plasma for 2 minutes, and further immerse the material in 2.5 mg / ml PEI solution for 10 minutes, take out After drying, immerse the material in 3 mg / ml GO solution for 10 minutes, take it out for drying and cleaning, place the material in HI acid solution at 60°C for 30 minutes, take it out and clean i...

Embodiment 2

[0031] Mix 100 parts (the parts are parts by mass) of TPU with 10 parts of carbon black and 5 parts of carbon nanotubes in a tetrahydrofuran solvent, and obtain a 3D printed material after evaporating the solvent. Use the above mixed materials for 3D printing to form a corrugated network three-dimensional structure. Place the printed three-dimensional structure in deionized water for 1 hour, then dry it in a 60°C oven for 2 hours, and then place the three-dimensional structure in oxygen plasma for 2 minutes. , further immerse the material in a 3.5 mg / ml PDDA solution for 10 minutes, take it out and dry it, then immerse the material in a 3 mg / ml GO solution for 10 minutes, take it out, dry it and wash it, then place the material in a HI acid solution at 95°C After reducing for 30 minutes, take it out and clean it, connect it to the electrode, and use n-hexane diluted PDMS solution to impregnate and encapsulate the above materials to prepare a flexible sensor. The sensitivity fa...

Embodiment 3

[0033] Mix 100 parts (the stated parts are parts by mass) of Agent A of Ecoflex silicone rubber with 20 parts of graphene in xylene solvent, and after evaporating the solvent, add 100 parts of Agent B of Ecoflex silicone rubber to the system and mix Uniform, use the above mixed materials for 3D printing to form a corrugated network three-dimensional structure. Place the printed three-dimensional structure in an oven at 80°C to cure for 6 hours, then place the cured three-dimensional structure in oxygen plasma for 2 minutes, and further immerse the material in a 3 mg / ml PDMA solution for 10 minutes, take out After drying, immerse the material in 3 mg / ml GO solution for 10 minutes, take it out, dry and clean it, place the material in HI acid solution at 95°C for 30 minutes, take it out and clean it, connect it to the electrode, and use n-hexane diluted PDMS solution to impregnate and package The above materials are used to prepare flexible sensors. The 3D printed grid-structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com