High-density yarn-dyed jacquard fabric with various colors and figures on double faces

A double-sided different color and different pattern technology, which is applied in the direction of fabrics, textiles, multi-strand fabrics, etc., can solve the problems of general shading effect, unclear shed opening, and affecting normal weft insertion, etc., to achieve rich pattern and strong three-dimensional effect , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

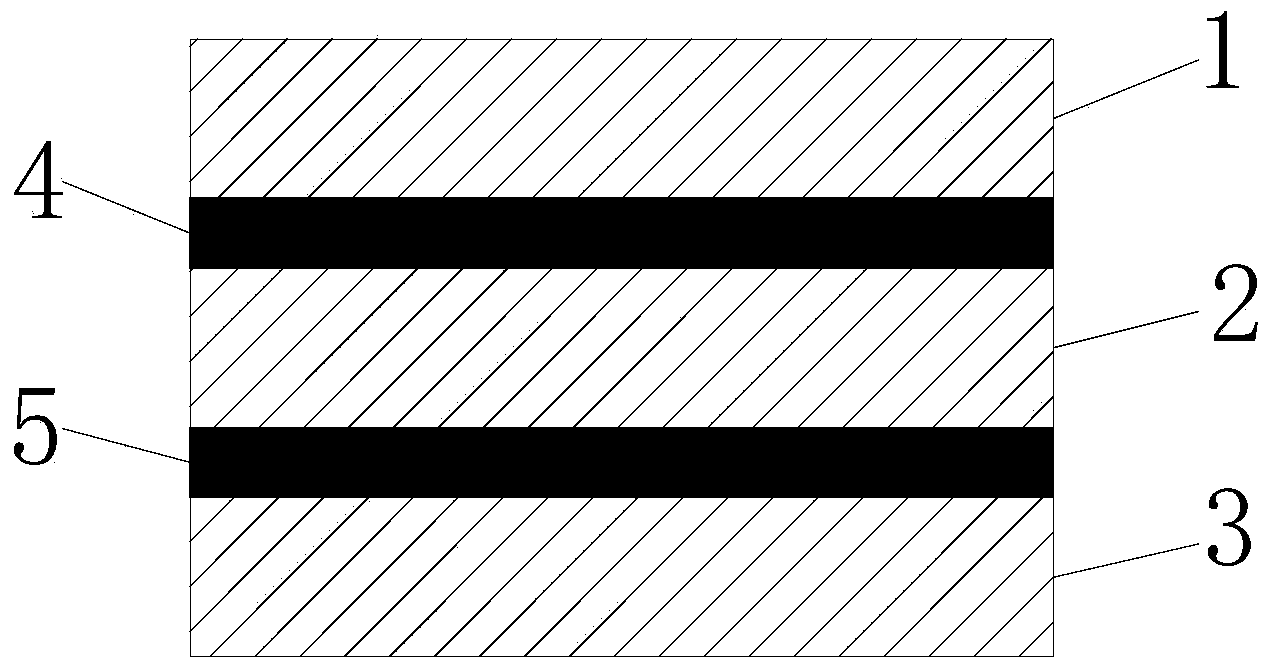

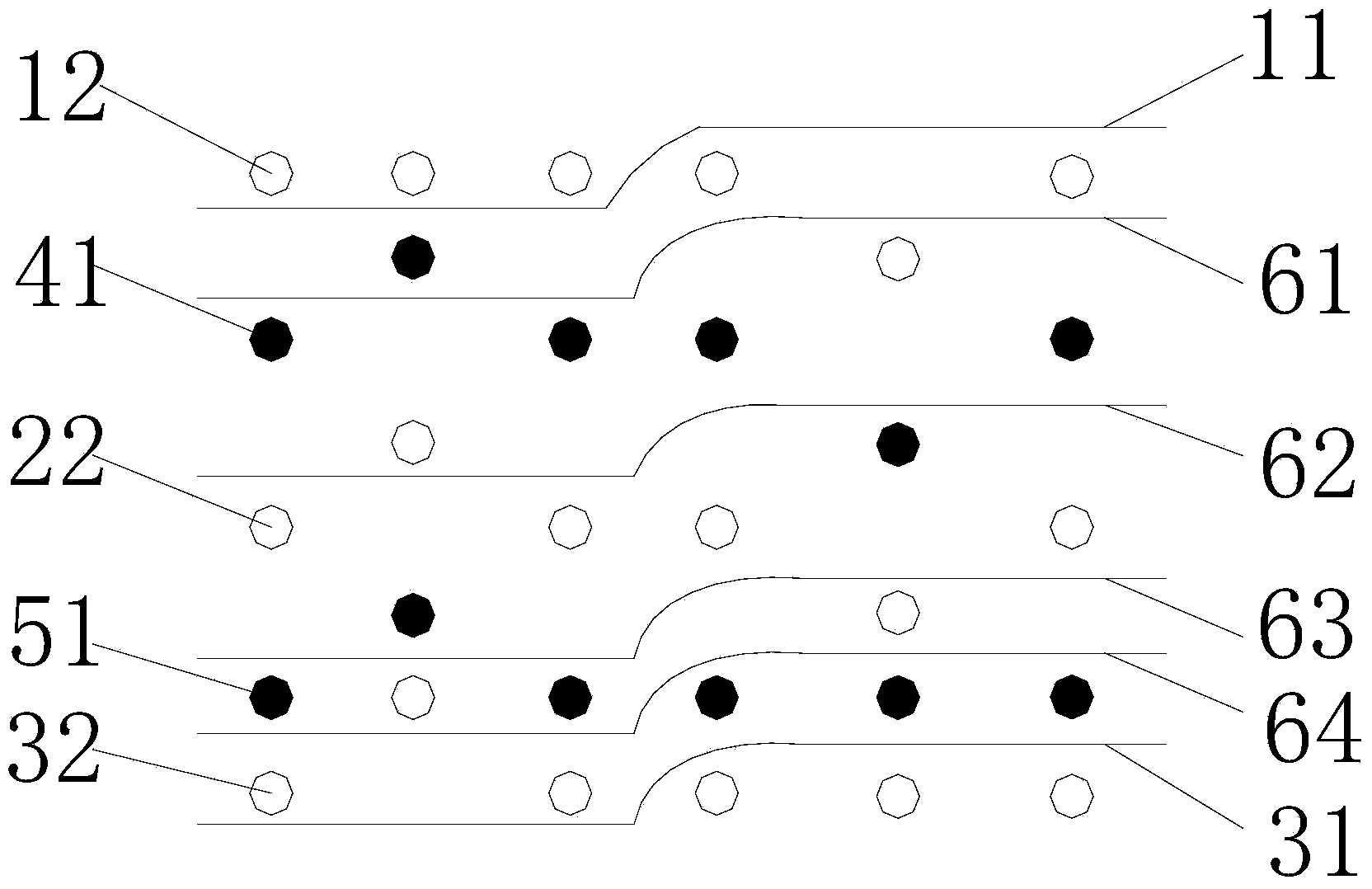

[0016] refer to figure 1 with figure 2 , the present invention is a kind of double-sided heterochromatic different flower high-density yarn-dyed jacquard fabric, comprising a first structural layer 1, a second structural layer 2 and a third structural layer 3, the first structural layer 1 is composed of a first warp yarn 11 and a second structural layer A weft yarn 12 is woven, the first warp yarn 11 and the first weft yarn 12 are interwoven to form a first structure 13, the second structure layer 2 is composed of a number of second weft yarns 22, and the third structure layer 3 is composed of a third warp yarn 31 and a second weft yarn 22. Three weft yarns 32 are woven, the third warp yarn 31 and the third weft yarn 32 are interwoven to form a second weave structure 33, a first black silk layer 4 is arranged between the first structure layer 1 and the second structure layer 2, and the second structure A second black silk layer 5 is provided between the layer 2 and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com