Method for preparing two-dimensional montmorillonite/cellulose composite filter membrane

A cellulose filter membrane and composite filtration technology is applied in the field of preparing two-dimensional montmorillonite/cellulose composite filter membrane, which can solve the influence of filtrate components, weaken the adsorption performance of the composite porous adsorption membrane, and cannot effectively remove heavy metal ions and dyes and other problems, to achieve the effect of easy industrial production and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

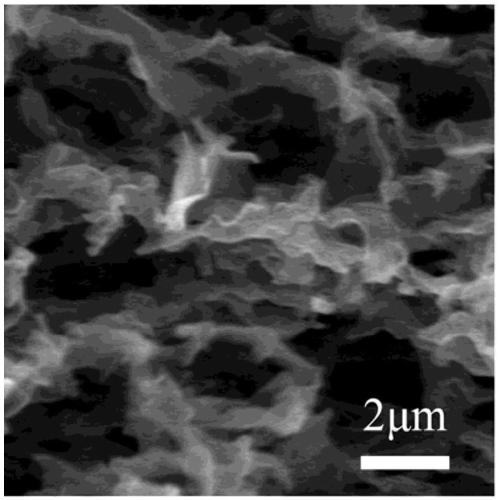

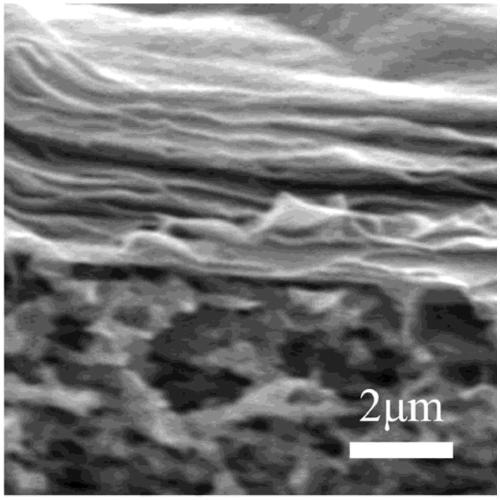

[0047] Using solid montmorillonite and pure water as a solvent, a two-dimensional montmorillonite solution with a solid-to-liquid ratio of 10 g / L was prepared, and ultrasonicated in a 90W probe ultrasonic breaker for 10 minutes with an ultrasonic interval of 5 seconds and 5 seconds. The montmorillonite solution after ultrasonication was centrifuged at 8000 rpm for 5 minutes, and the supernatant was taken to obtain a two-dimensional montmorillonite solution with a concentration of 3.35 mg / ml.

[0048] Place the mixed cellulose filter membrane with a pore size of 0.22 microns on the vacuum filter bottle, add 3 ml of two-dimensional montmorillonite solution to the Buchner funnel, turn on the circulating water vacuum pump, and filter out the two-dimensional montmorillonite solution. Water makes the two-dimensional montmorillonite tightly stacked on the surface of the cellulose microporous membrane. After air-drying at room temperature, a two-dimensional montmorillonite / cellulose c...

Embodiment 2

[0054] Choose pure water as a solvent, disperse the freeze-dried solid two-dimensional montmorillonite in an aqueous solution, prepare a 5 mg / ml two-dimensional montmorillonite solution, and ultrasonicate the two-dimensional montmorillonite solution at a power of 100W for 0.5 hours , fully dispersed to form a uniform two-dimensional montmorillonite solution.

[0055] Place the mixed cellulose filter membrane with a pore size of 0.22 microns on the vacuum filter bottle, add 2 ml of two-dimensional montmorillonite solution to the Buchner funnel, turn on the circulating water vacuum pump, and filter out the two-dimensional montmorillonite solution. Water makes the two-dimensional montmorillonite tightly stacked on the surface of the cellulose microporous membrane. After air-drying at room temperature, a two-dimensional montmorillonite / cellulose composite filter membrane was obtained.

[0056] The two-dimensional montmorillonite / cellulose composite filter membrane that this embod...

Embodiment 3

[0058] Using solid montmorillonite and pure water as a solvent, a montmorillonite solution with a solid-to-liquid ratio of 10 g / L was prepared, and the montmorillonite solution was stirred at 500 rpm for 3 days. The stirred montmorillonite solution was centrifuged at 8000 rpm for 5 minutes, and the supernatant was taken to obtain a two-dimensional montmorillonite solution with a concentration of 1 mg / ml.

[0059] Spray the two-dimensional montmorillonite solution evenly on the 0.22 micron cellulose filter membrane, after natural air-drying, spray evenly again, air-dry naturally, repeat the above steps 5 times, and obtain the two-dimensional montmorillonite / cellulose composite accumulated many times filter membrane.

[0060] The two-dimensional montmorillonite / cellulose composite filter membrane that this embodiment prepares filters the Pb of 20 milliliters 50mg / L 2+ Solution, the concentration after filtration is 1mg / L. It shows that the composite membrane has good performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com