Electrospark deposition-based preparation method of diamond abrasive particle layer

A technology of electric discharge deposition and diamond, which is applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems that the electric spark deposition of metal materials and non-metal materials cannot be realized, and solve the problem of green recycling and reuse , the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

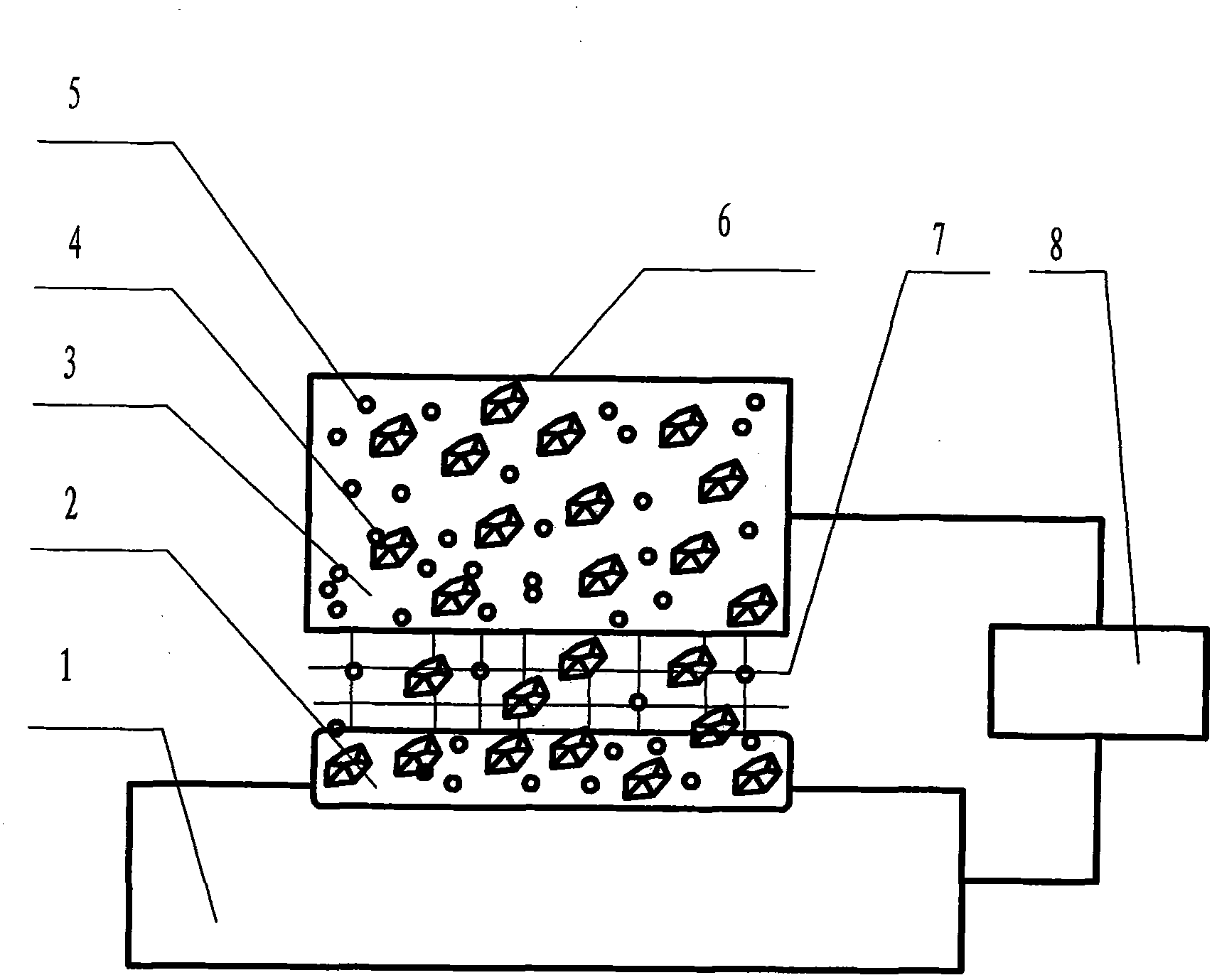

[0028] A kind of electric discharge deposition preparation method of diamond abrasive grain layer, adopts electric discharge machine tool to prepare diamond abrasive grain layer, such as figure 1 As shown, an electrode 6 is provided on one side of the workpiece 1, the workpiece 1 is connected to the positive pole of a pulse power supply 8 capable of generating discharge pulses, the electrode 6 is connected to the negative pole of the pulse power supply 8, and the working fluid 7 is injected during deposition. The gap between the workpiece 1 and the electrode 6, the electrode 6 is a compressed powder electrode formed by pressing and sintering the diamond abrasive grains 4 and the metal powder; the steps of the method are:

[0029] Turn on the pulse power supply 8, keep the discharge voltage at 70V-90V, the discharge current at 1.5A-9A, the discharge pulse width at 20μs-60μs, and the discharge pulse gap at 25μs-90μs; spray working fluid into the gap, and the pulse power supply 8 ...

Embodiment 2

[0087] The metal powder in the compressed powder electrode is silver powder and cobalt powder 5, which is pressed together with diamond abrasive grains and sintered in an inert gas to make a compressed powder, and the silver powder in the compressed powder electrode: diamond grinding Particles: The mass percentage of cobalt powder is (55~65):(20~25):(15~20), the particle size of cobalt powder is 3~5μm, the particle size of silver powder is 50~100μm, and the particle size of diamond abrasive is 80μm ~150μm, pressing pressure is 75MPa~90MPa, sintering temperature of compressed powder electrode is 650℃~750℃, electrode density after sintering is 6.82~7.15g / cm 3 .

[0088] The specific preparation method and other process conditions are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0090] The metal powder in the compressed powder electrode is copper powder 3 and nickel powder, which are pressed together with diamond abrasive grains and sintered in an inert gas to form a compressed powder, and the copper powder in the compressed powder electrode: Diamond abrasive grains: The mass percentage of nickel powder is (60~68):(18~22):(12~20), the particle size of nickel powder is 5~8μm, the particle size of copper powder is 120~180μm, the diamond abrasive grain The diameter is 80μm~150μm, the pressing pressure is 80MPa~100MPa, the sintering temperature of the compressed powder electrode is 650℃~800℃, and the electrode density after sintering is 6.75~7.18g / cm 3 .

[0091] The specific preparation method and other process conditions are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com