Trickling biofilter

A biological and water inlet pipeline technology, applied in the field of biological dripping bed, can solve the problems of sewage treatment process management and energy consumption, small surface area of the plate body, and the need for backwashing, etc., to simplify the operation process of sewage treatment and simplify the operation. process, the effect of reducing the energy consumption of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

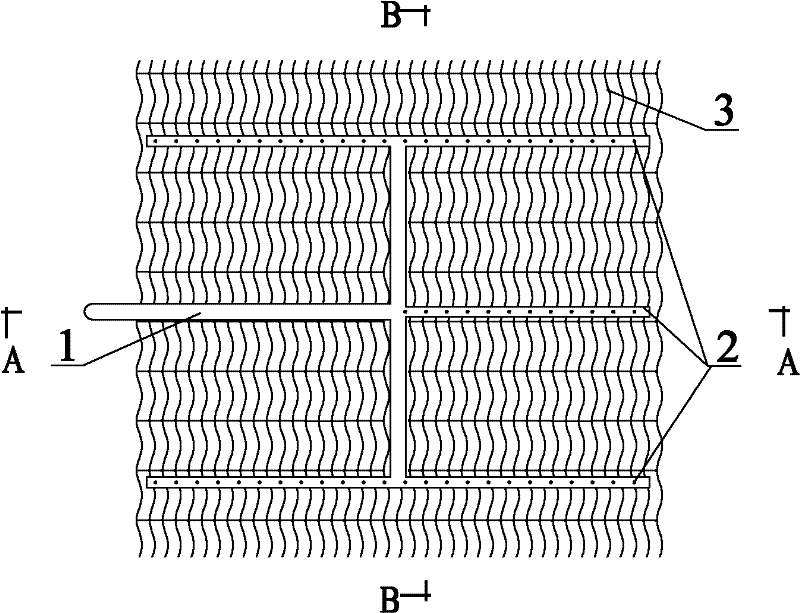

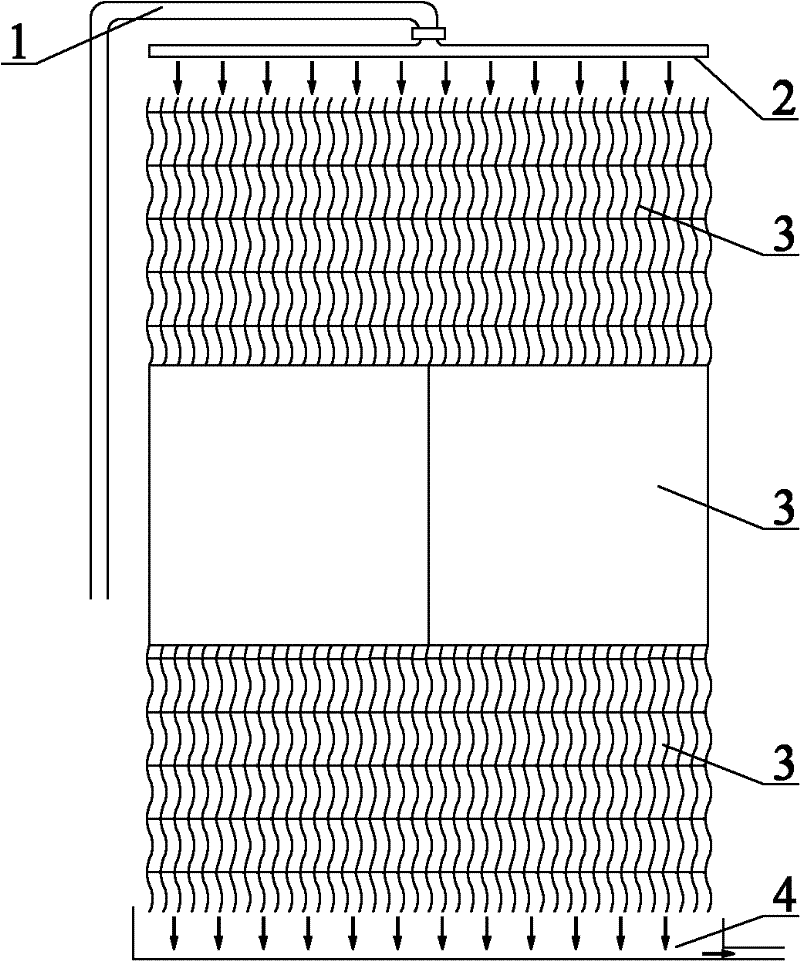

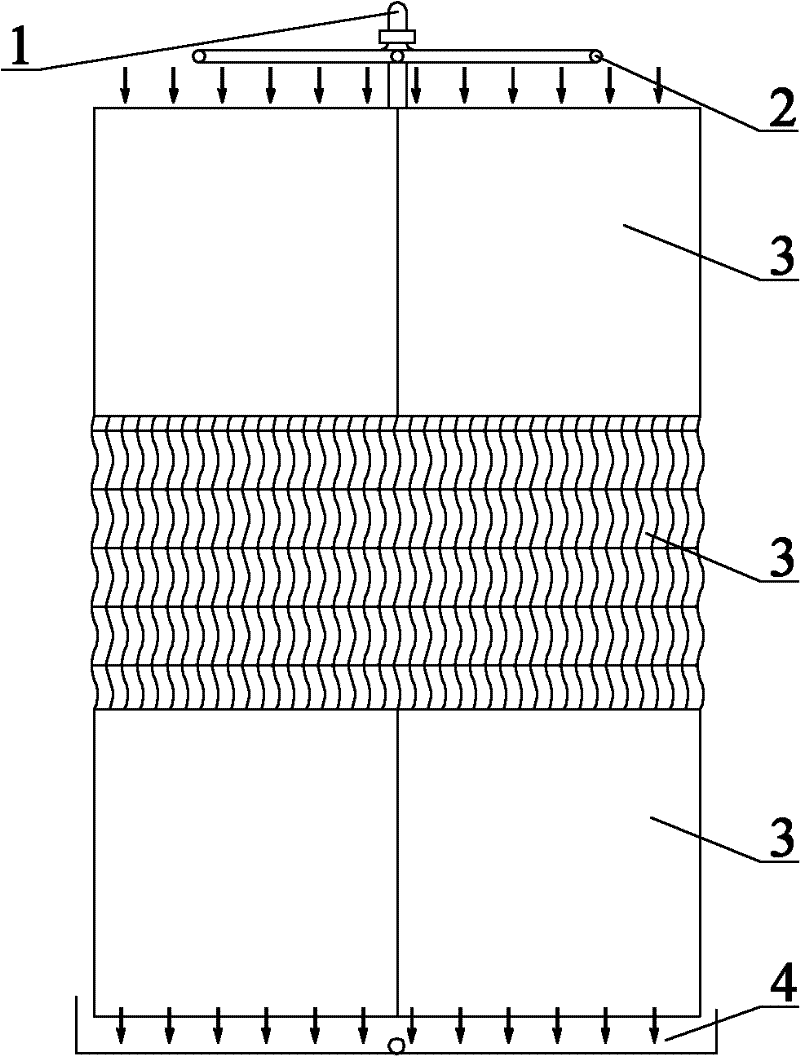

[0025] A kind of biological drip bed, its planar structure is as figure 1 As shown, the biological trickling filter is composed of water inlet pipeline 1, water distribution system 2, packing module 3 and water outlet system 4. The water inlet pipeline 1 and water distribution system 2 mainly play the role of evenly distributing the inlet water to the packing module 3 , so that all the fillers can be in contact with the sewage. According to the amount of water inflow and the quantity of the water distribution system 2, a hole with a diameter of 6mm is opened on the water inlet pipe 1, so that the influent water is first evenly distributed to the water distribution system 2 through the pipe holes, and then Relying on the overflow weir designed by the water distribution system 2 for secondary distribution, the influent water is evenly distributed to the packing module 3; the packing module 3 is made of PVC material, and its structure is as follows figure 2 and image 3 As show...

Embodiment 2

[0028] A biological trickle bed. The biological trickle filter is composed of water inlet pipeline, water distribution system, packing module and water outlet system. It can be in contact with sewage. According to the amount of water inflow and the number of water distribution systems, a hole with a diameter of 15mm is opened on the water inlet pipe, so that the influent water can be evenly distributed to the water distribution system through the pipe holes first, and then rely on the overflow designed by the water distribution system. The weir performs secondary distribution, and the influent water is evenly distributed to the packing module; the packing module is made of polyvinyl chloride material. In order to increase the path of water flowing through the packing module, the packing module is designed to be wave-shaped along the vertical direction, and the vertical path of water flow is increased. At the same time, the water flow is repeatedly distributed under the drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com