Process for preparing metal-organic complex electric bistable film

An organic complex, bistable technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of thick film, rough surface of film, difficult to prepare film and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

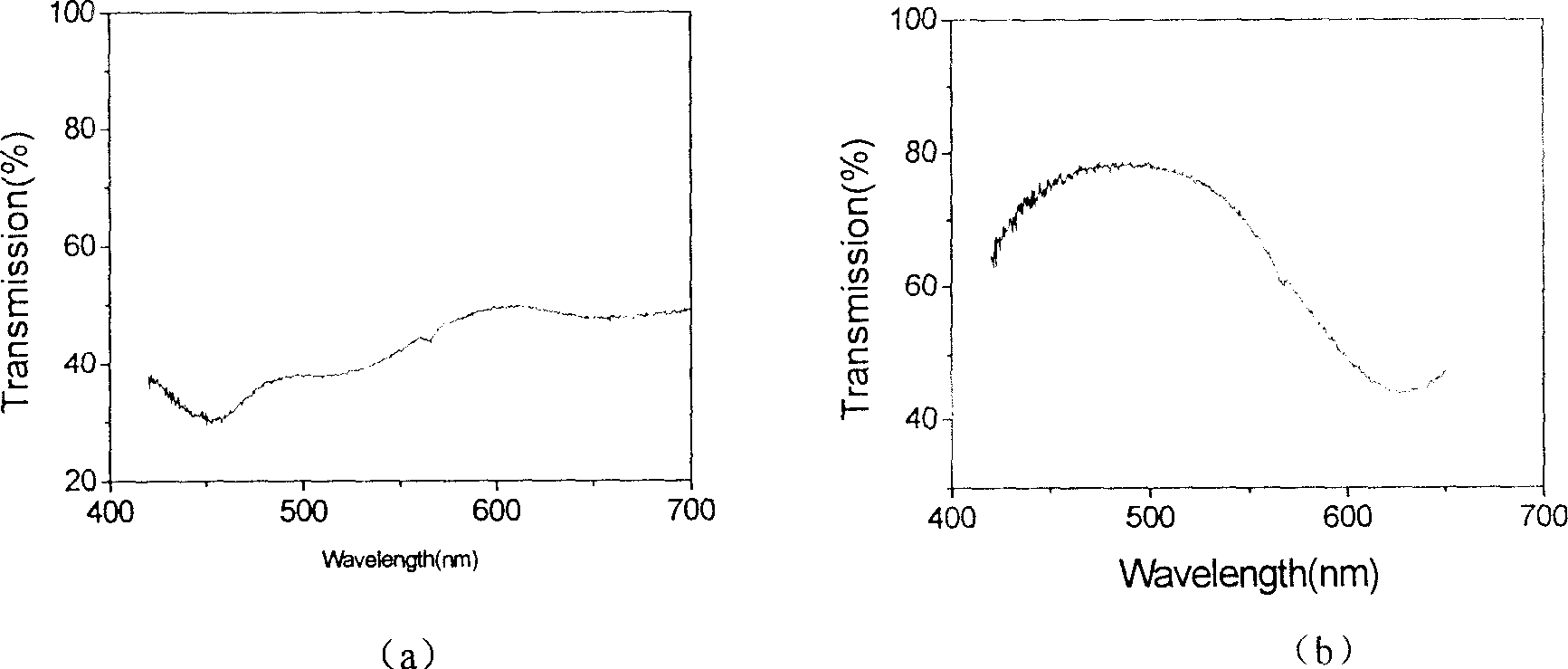

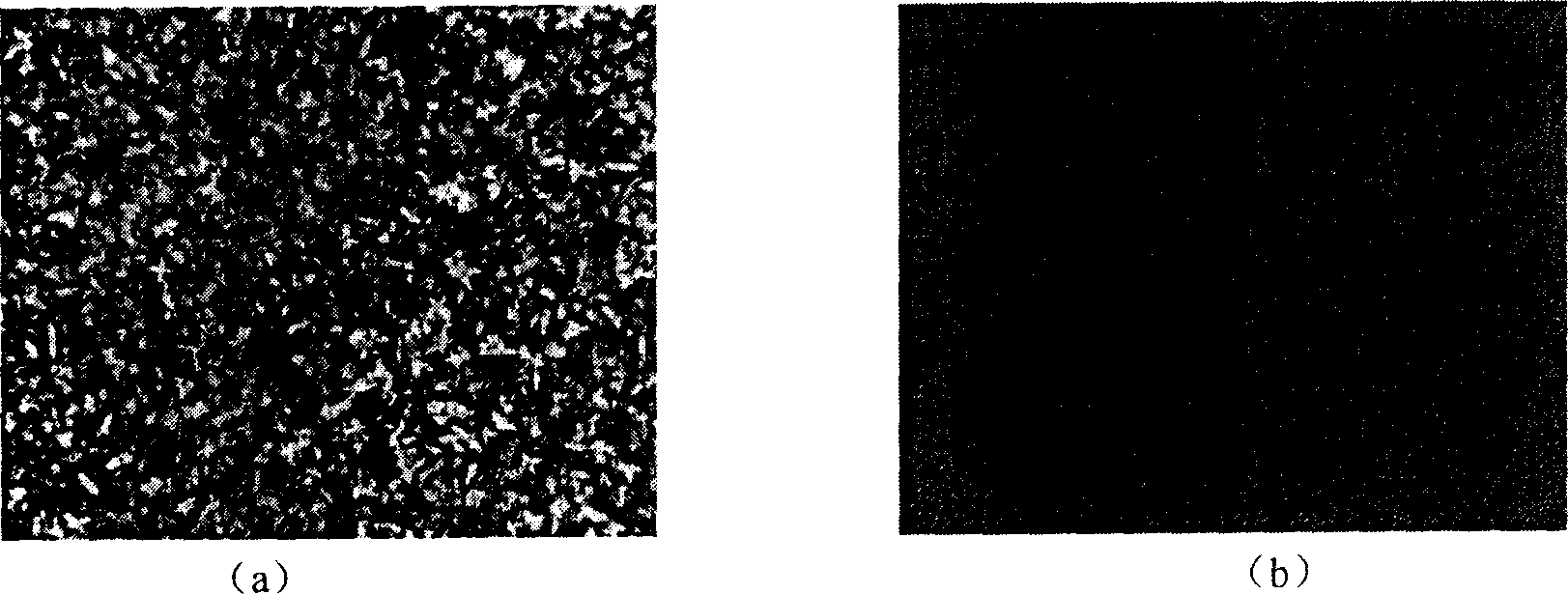

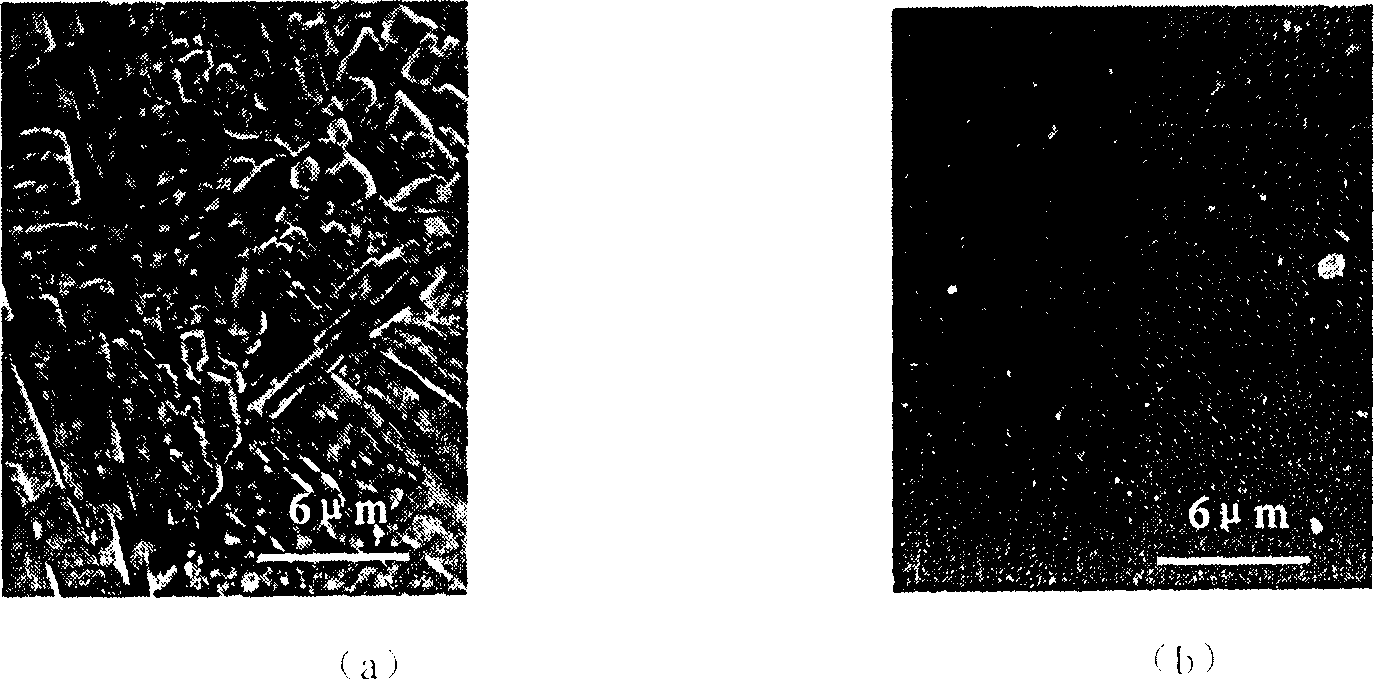

[0018] Example 1 Preparation of AgTCNQ electrically bistable thin film (thinner)

[0019] Put the glass substrate into the vacuum coating machine, the vacuum degree is 1×10 -3 Pa, under room temperature conditions, first evaporate a layer of Ag film with a thickness of 10nm, and then evaporate a layer of TCNQ film with a thickness of 20nm; take out the mixed film and put it in an environment with a humidity of 100%, and the electrochemical reaction occurs rapidly to obtain The blue AgTCNQ thin film was tested for electrical bistable properties, and similar attached Figure 5 The curve shown shows that the film has good electrical bistability.

Embodiment 2

[0020] Example 2 Preparation of AgTCNQ electrically bistable thin film (thicker)

[0021] Put the glass substrate into the vacuum coating machine, the vacuum degree is 1×10 -3 Pa, under room temperature conditions, first evaporate a layer of Ag film with a thickness of 40nm, and then evaporate a layer of TCNQ film with a thickness of 80nm; take out the mixed film and put it in an environment with a humidity of 100%, and the electrochemical reaction occurs rapidly to obtain blue The color AgTCNQ thin film was tested for electrical bistability, and similar attached Figure 5 The curve shown shows that the film has good electrical bistability.

Embodiment 3

[0022] Example 3 CuTCNQ electrical bistable thin film preparation

[0023] Put the substrate into the vacuum coating machine, the vacuum is 1×10 -3 Pa, at room temperature, first evaporate a layer of Cu film with a thickness of 20nm, and then evaporate a layer of TCNQ film with a thickness of 65nm; take out the mixed film and place it in an environment with a humidity of 100%, and an electrochemical reaction occurs rapidly to obtain a green color. The CuTCNQ film was tested for electrical bistability, and similar attached Figure 5 The curve shown (the transition voltage is slightly higher, about 7V), shows that the film has good electrical bistability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com