Optical sheet for controlling the direction of ray of light

An optical sheet and light technology, applied in optical elements, nonlinear optics, optics, etc., can solve the problem of ineffective viewing angle control, and achieve the effects of brightness viewing angle adjustment, brightness improvement, and uniform diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

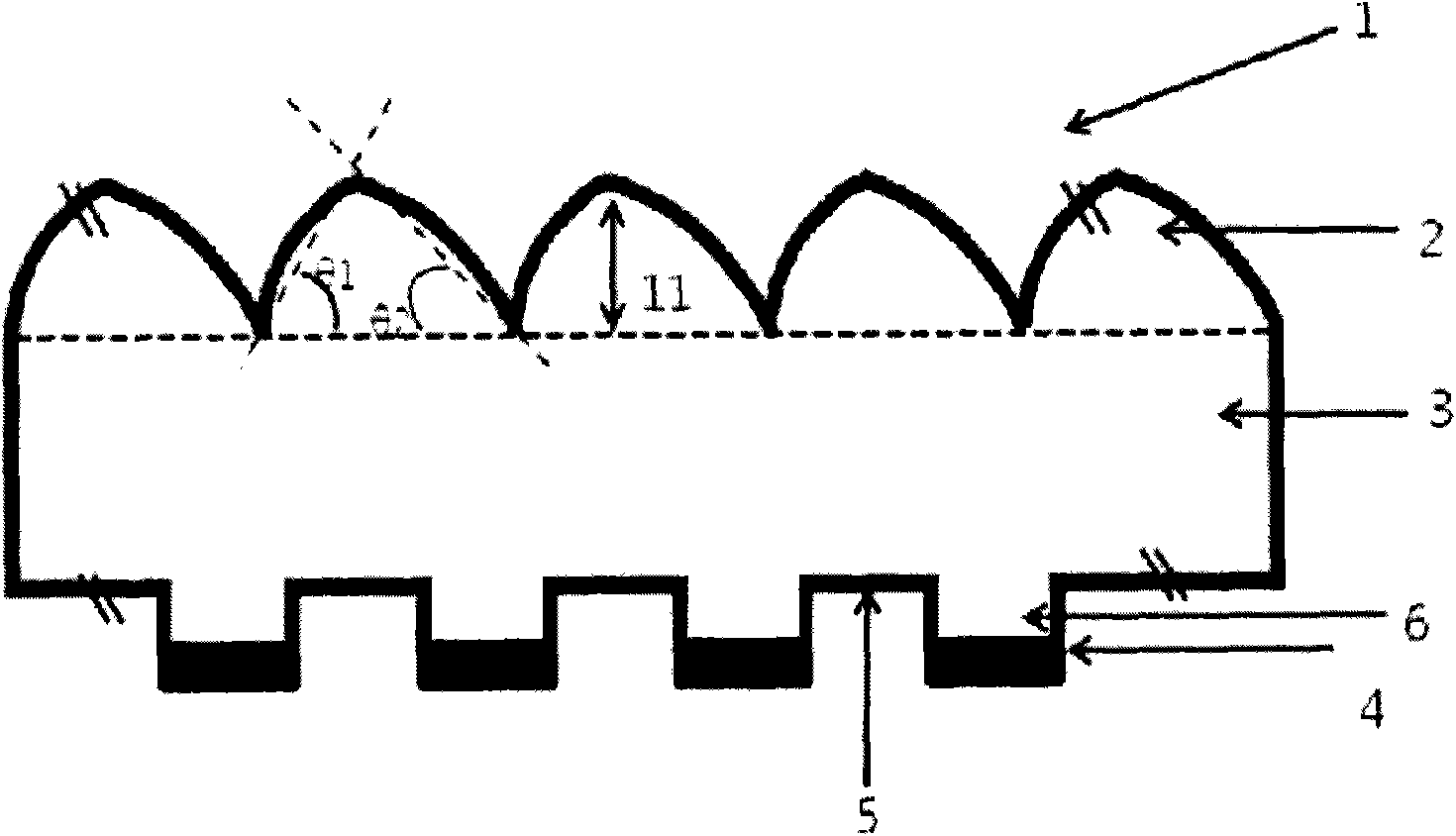

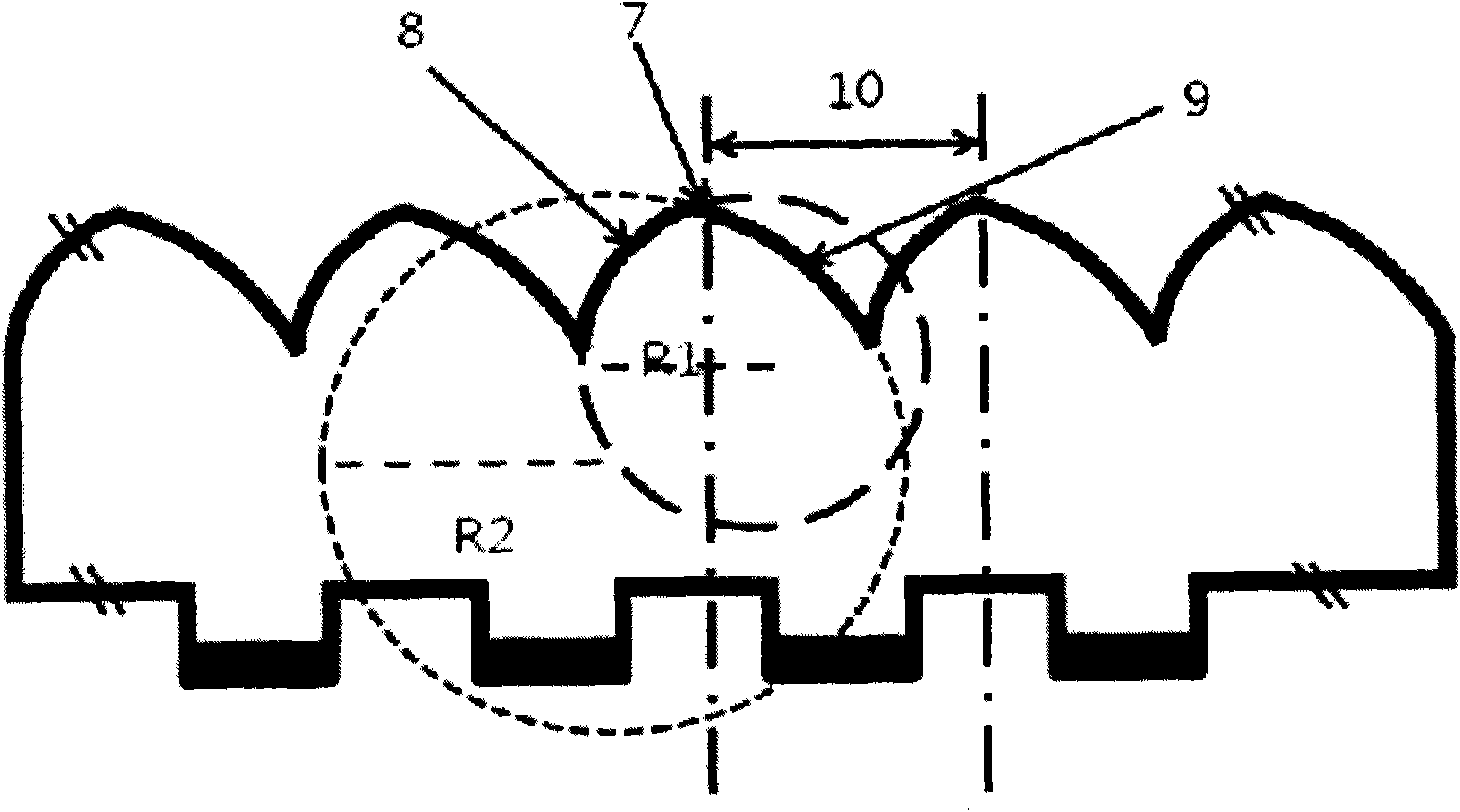

[0059] (1) Manufacture of microlens

[0060] A metal mold having a pitch of 200 μm as a period was prepared using diamond bites having a curvature radius R1 of 100 μm and a curvature radius R2 of 185 μm, and the mold was filled with an ultraviolet curable resin (acrylic resin) having a refractive index of 1.54 . Next, a polyester film having a thickness of 188 μm was placed on the ultraviolet curable resin filled in the mold, and then ultraviolet rays were irradiated thereon to be cured. Afterwards, the mold is removed to obtain microlens groups.

[0061] (2) Manufacture of bumps and reflective layers

[0062] On the opposite side of the microlens group obtained in the microlens manufacturing process, a photosensitive resin was applied so that the resin thickness after drying was 40 μm. A photocuring reaction was performed using a photomask designed to form a convex pattern such that the center of each convex 6 of the reflective layer having a width of 40 μm was located at ...

Embodiment 2

[0064] (1) Manufacture of microlens

[0065] A metal mold having a pitch of 200 μm as a period was prepared using diamond teeth having a curvature radius R1 of 100 μm and a curvature radius R2 of 175 μm, and the mold was filled with an ultraviolet curable resin (acrylic resin) having a refractive index of 1.54. Next, a polyester film having a thickness of 188 μm was placed on the ultraviolet curable resin filled in the mold, and then ultraviolet rays were irradiated thereon to be cured. Afterwards, the mold is removed to obtain microlens groups.

[0066] (2) Manufacture of bumps and reflective layers

[0067] The same procedure as in Example 1 was used.

Embodiment 3

[0069] (1) Manufacture of microlens

[0070] A metal mold having a pitch of 200 μm as a period was prepared using diamond teeth having a curvature radius R1 of 100 μm and a curvature radius R2 of 165 μm, and the mold was filled with an ultraviolet curable resin (acrylic resin) having a refractive index of 1.54. Next, a polyester film having a thickness of 188 μm was placed on the ultraviolet curable resin filled in the mold, and then ultraviolet rays were irradiated thereon to be cured. Afterwards, the mold is removed to obtain microlens groups.

[0071] (2) Manufacture of bumps and reflective layers

[0072] The same procedure as in Example 1 was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com