Manufacturing technology for glass with three-dimensional effect and corresponding production system

A production process and three-dimensional effect technology, applied in the field of production systems, can solve the problems of surface pattern fading, falling off, and the overall thickness of the glass is not strong, and achieve the effect of enhanced refraction and reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1 Manufacturing process of glass with three-dimensional effect

[0059] The invention relates to a manufacturing process of glass with three-dimensional effect, which includes a cleaning process, a front printing process, a reverse multi-layer printing process, and a painting process, which are carried out in sequence.

[0060] The manufacturing process is carried out according to the following sequence of steps:

[0061]A1. Use the edging machine to grind the four sides of the original plate glass to get a1. The standard for edging is 1.5mm evenly edging around the glass and up and down, and the chamfering of the four corners of the glass is 1mm;

[0062] B1. Send a1 into the washing machine, wash it with clean water, and dry it to get b1;

[0063] The above steps A1-B1 complete the cleaning process.

[0064] C1. Use a screen printing machine to print photosensitive ink on the entire front of b1 to obtain c1;

[0065] D1. Paste a UV photosensitive f...

Embodiment 2-6

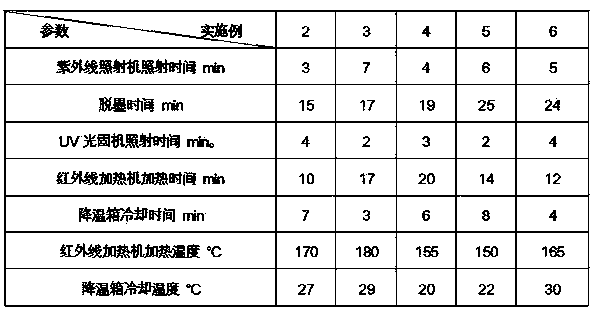

[0087] Embodiment 2-6 Manufacturing process of glass with three-dimensional effect

[0088] Embodiments 2-6 are respectively a manufacturing process of a glass with a three-dimensional effect. The difference between them and Embodiment 1 is that the control parameters in the production process are different, as shown in the following table:

[0089]

[0090] The raw materials of the active ingredients of the soaking solution are made according to the weight ratio shown in the following table:

[0091]

Embodiment 7

[0092] Example 7 Production system for glass with three-dimensional effect

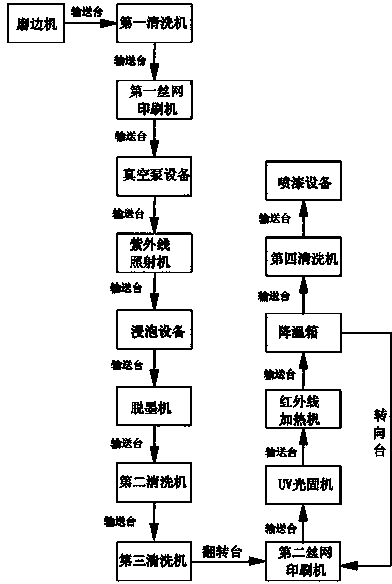

[0093] A production system for glass with three-dimensional effects, the structure of which is as follows figure 1 As shown, the production system is set up based on the manufacturing process of glass with three-dimensional effect in Examples 1-6, and it includes a cleaning system, a front printing system, a reverse multi-layer printing system, and a painting system that are connected in sequence and operate independently.

[0094] The cleaning system includes an edge grinder and a first cleaning machine connected in sequence.

[0095] The front printing system includes a first screen printing machine, a vacuum pump device, an ultraviolet irradiation machine, a soaking device, a deinking machine, a second cleaning machine, and a third cleaning machine connected in sequence.

[0096] The reverse side printing system includes a second screen printing machine, a UV light curing machine, an infrared he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com