Knitting mechanism of embossed grain electronic jacquard warp knitting machine

An electronic jacquard and jacquard knitting technology, which is applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of unclear embossed pattern, increased fabric weight, and low recognition, so as to avoid the obstruction of yarn routing, Effect of reducing weight and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

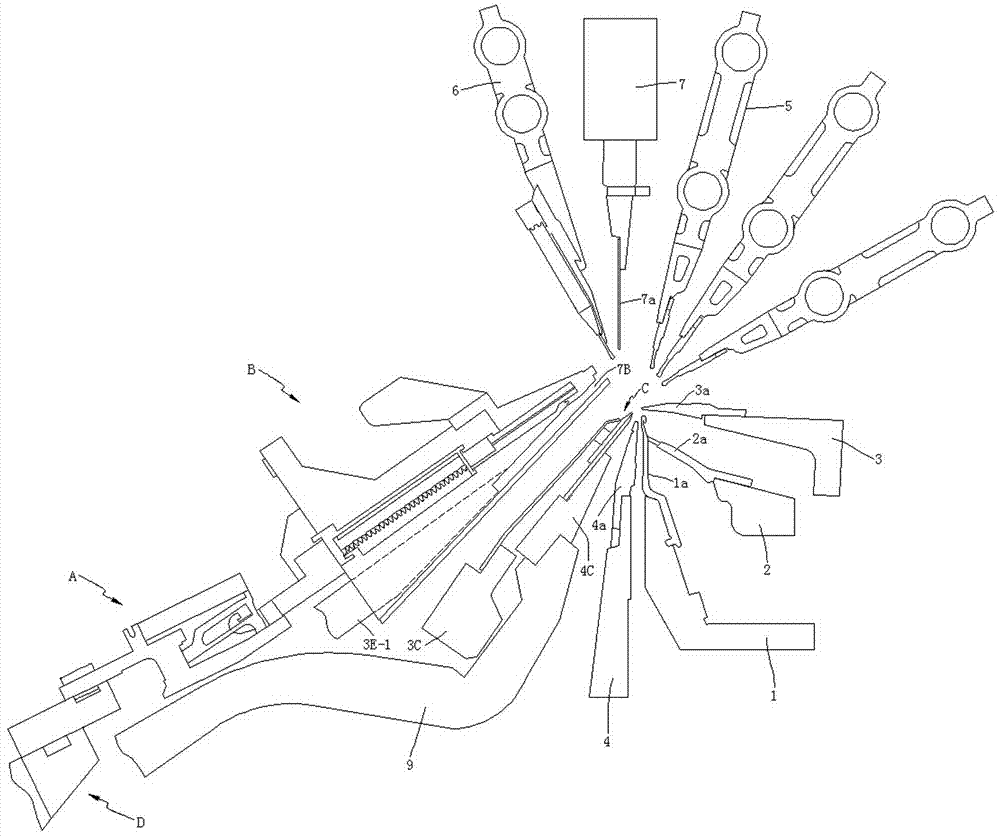

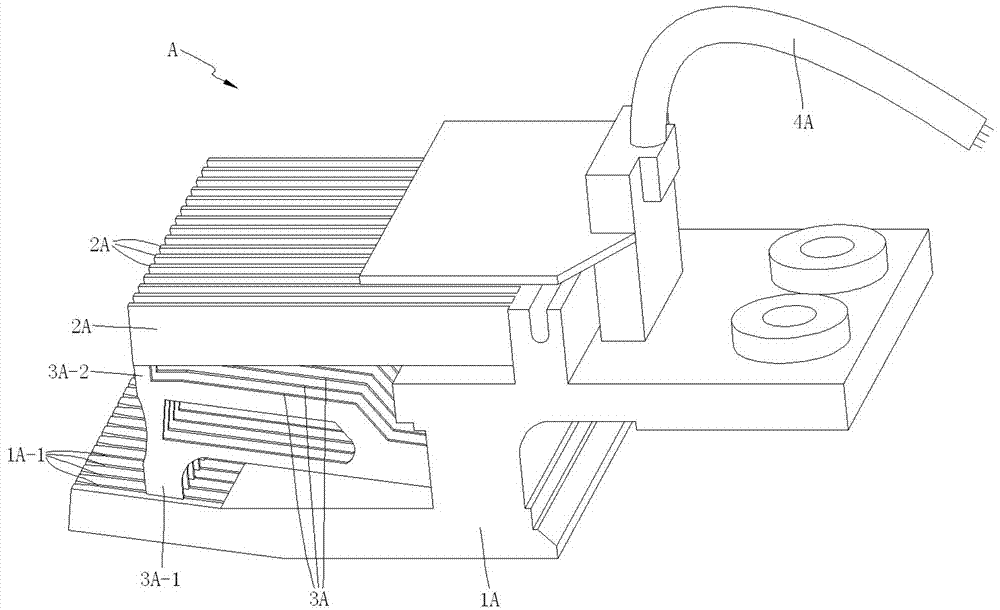

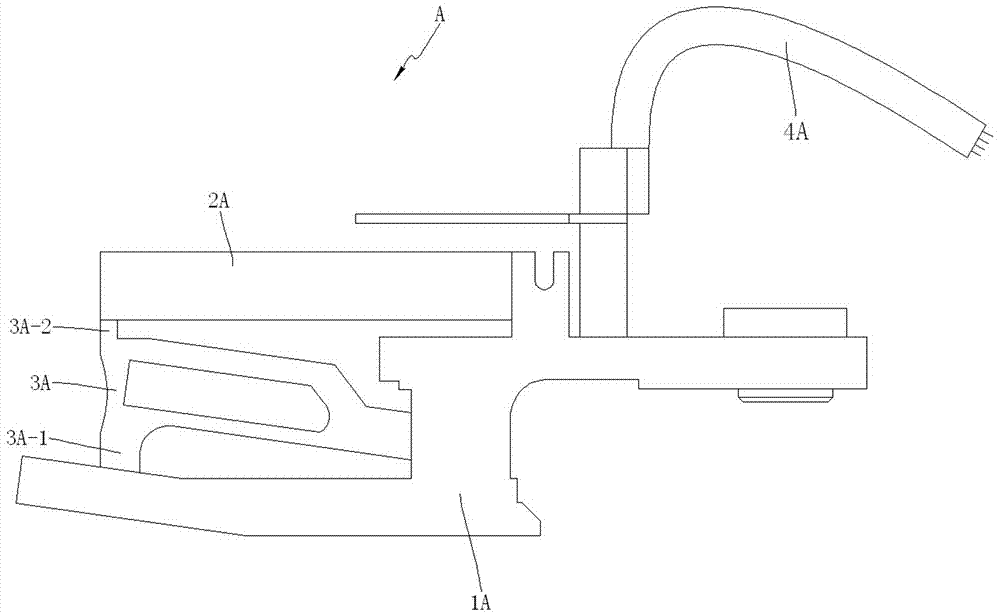

[0050] see Figure 1 to Figure 27 The knitting mechanism of a kind of relief electronic jacquard warp knitting machine shown includes the grooved needle 1a installed on the grooved needle bed 1, the needle core 2a installed on the needle core bed 2, and the sinker installed on the sinker bed 3 3a, and the knocker needle 4a installed on the knocker needle bed 4, and the bar mechanism with at least one ground bar 5, at least one jacquard bar 6 and one pressing bar 7, the The lower end of the yarn-pressing bar 7 is equipped with a yarn-pressing plate 7a; during work, the yarn-pressing plate 7a of the yarn-pressing bar 7 will participate and not participate in the yarns of the jacquard weaving on the jacquard bar 6 downward. Press into the grooved needle 1a, and cooperate with the needle core 2a, sinker 3a, tripping needle 4a and ground bar 5 to carry out jacquard knitting. A yarn cutting device that participates in jacquard knitting yarn cutting, and a broken yarn cleaning devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com