Moulded-formative label structure

An in-mold forming and labeling technology, applied in the field of labels, can solve the problem of inability to produce decorative three-dimensional aesthetics, and achieve the effect of enhancing value and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

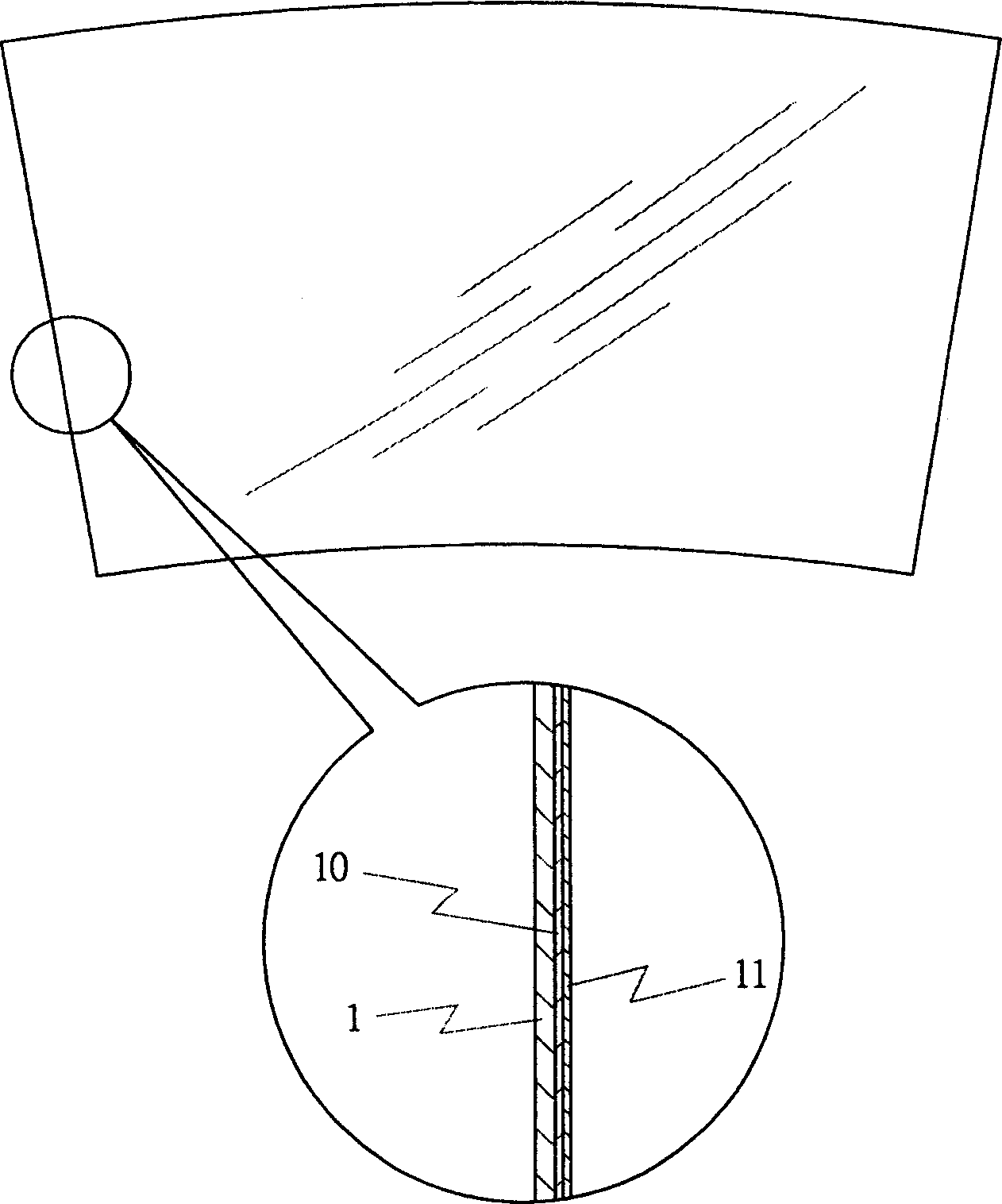

[0032] In this way, in order to further fully understand the present invention, it is explained as follows according to the accompanying drawings:

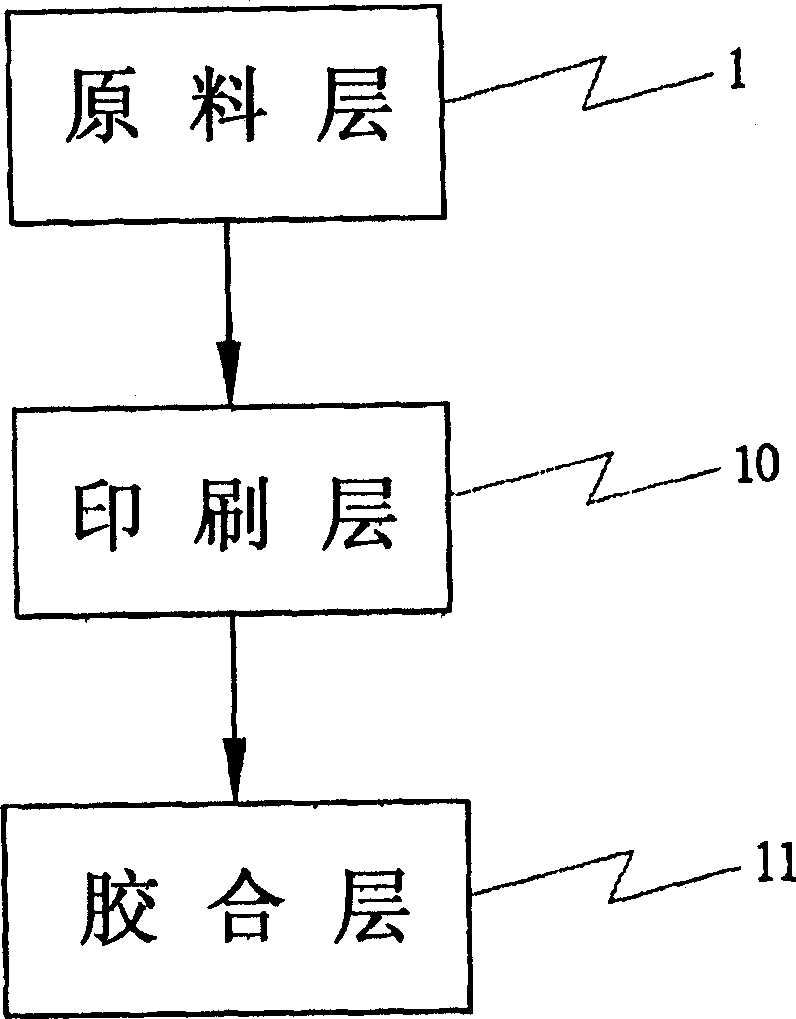

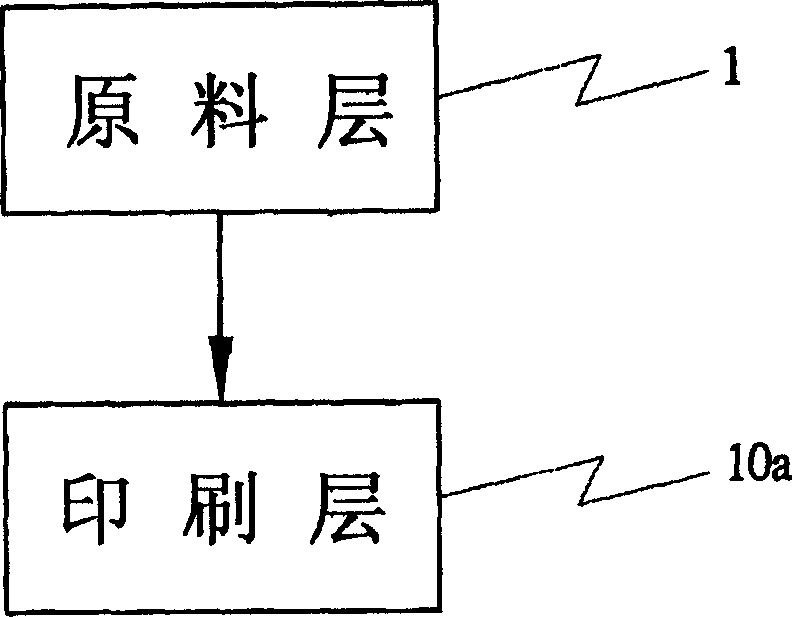

[0033] like Figure 4 and Figure 5 Shown is embodiment (one) of the present invention, shown in the figure, the label of present embodiment (one) comprises:

[0034] Raw material layer 2, raw material layer can be by paper material; Or synthetic material; Or plastic material; or gluing) combined with the raw material layer 2, and then use laser (laser) embossing technology on the outside of the hardened layer 20 to produce an embossed layer 21 on the hardened layer 20, using the embossed layer 21 to produce a more ideal three-dimensional effect, and the pattern of the embossed layer 21 can be uniform or non-uniformly distributed, and a glued layer 22 that can be combined with printing ink is set on the outside of the aforementioned embossed layer, and the glued layer 22 and the aforementioned embossed layer The combination met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com