Energy-saving non-oriented silicon steel coating liquid, and preparation method and application thereof

An oriented silicon steel, energy-saving technology, applied in the field of energy-saving non-oriented silicon steel coating solution and its preparation, can solve problems such as difficulty in meeting the individual needs of users, reducing the drying temperature of the coating, and easy burning and cracking of refractory bricks. Adhesion, lowering film forming temperature, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

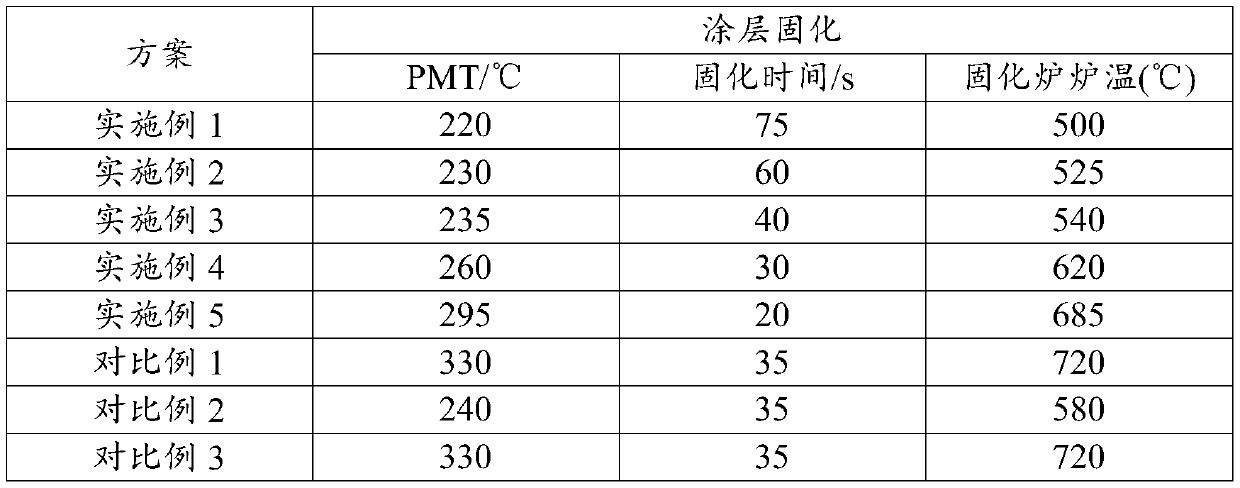

Examples

Embodiment 1~5

[0038] Embodiment 1~5, all adopt following method to prepare

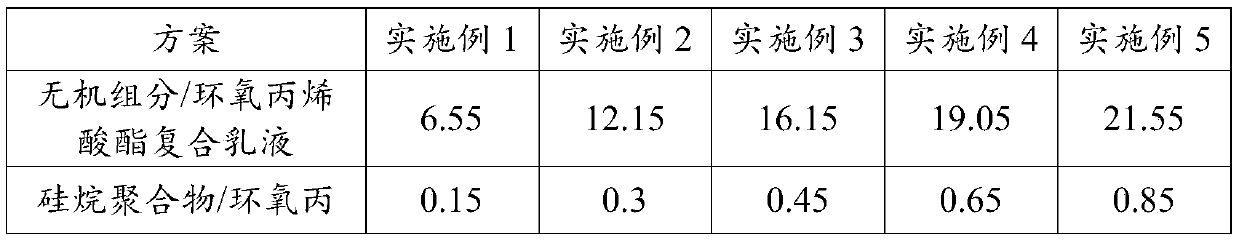

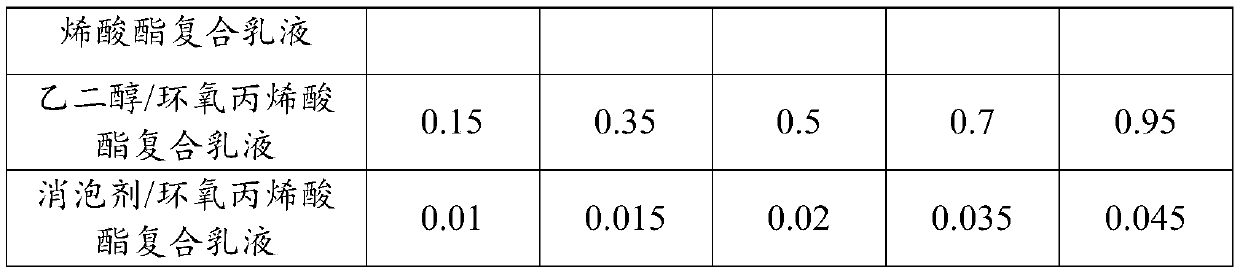

[0039] The non-oriented silicon steel coating solution provided by the present invention is a semi-organic-semi-inorganic silicon steel sheet coating solution, which is composed of inorganic components, epoxy acrylate composite emulsion, silane polymer, ethylene glycol, defoamer polyoxyethylene poly Oxypropanolamine ether is composed of (6-22): 1: (0.1-1.0): (0.1-1.0): (0.01-0.05) by mass ratio; the inorganic components include 15-30 parts by mass of silica sol 14-28 parts of aluminum dihydrogen phosphate, 10-20 parts of chromium dihydrogen phosphate, 0.1-0.8 parts of boric acid and 40-100 parts of water.

[0040] The preparation method of the epoxy acrylate composite emulsion is as follows:

[0041] Add 32 parts of ethyl methacrylate, 25 parts of butyl acrylate, 2 parts of acrylic acid, and 3 parts of hydroxyethylacrylamide into the container, and stir evenly at 25° C. to obtain a mixed monomer solution.

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com