Preparation method for active metal micro-projectile loading high explosive

A technology of active metal and high-energy explosives, applied in the fields of energetic materials, damage and ammunition engineering, can solve the problems of high pressure of ballistic calculation, low probability of successful interception, and difficulty in tracking, etc. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

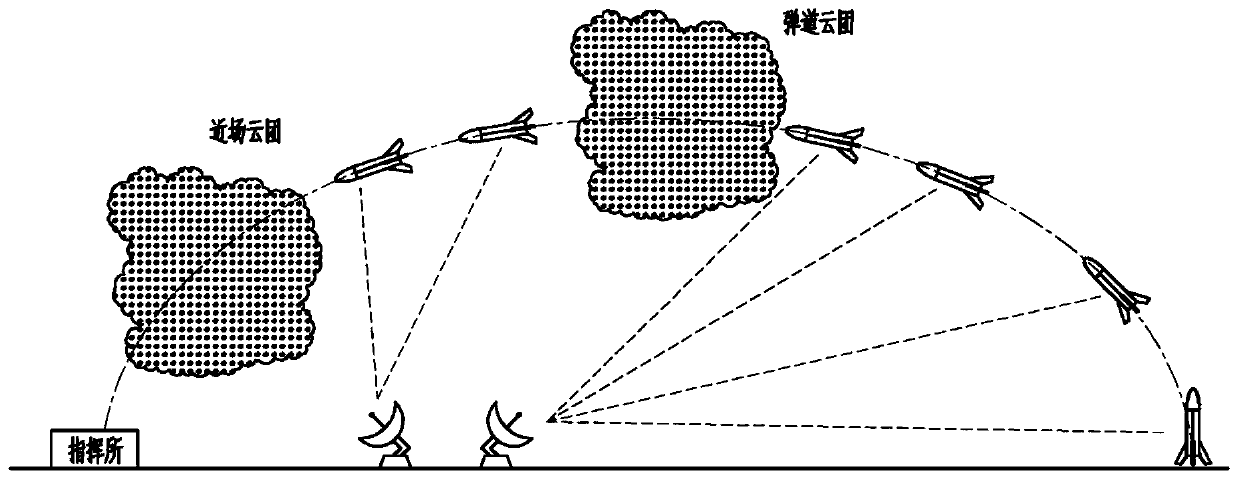

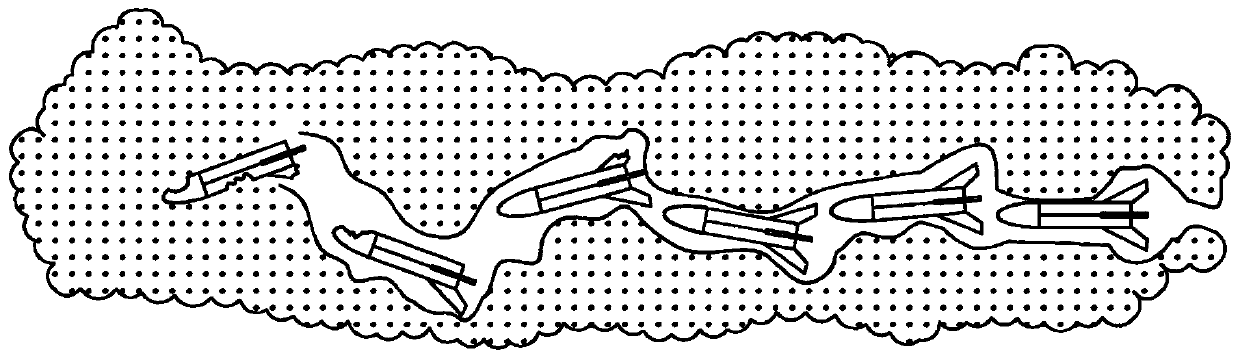

Problems solved by technology

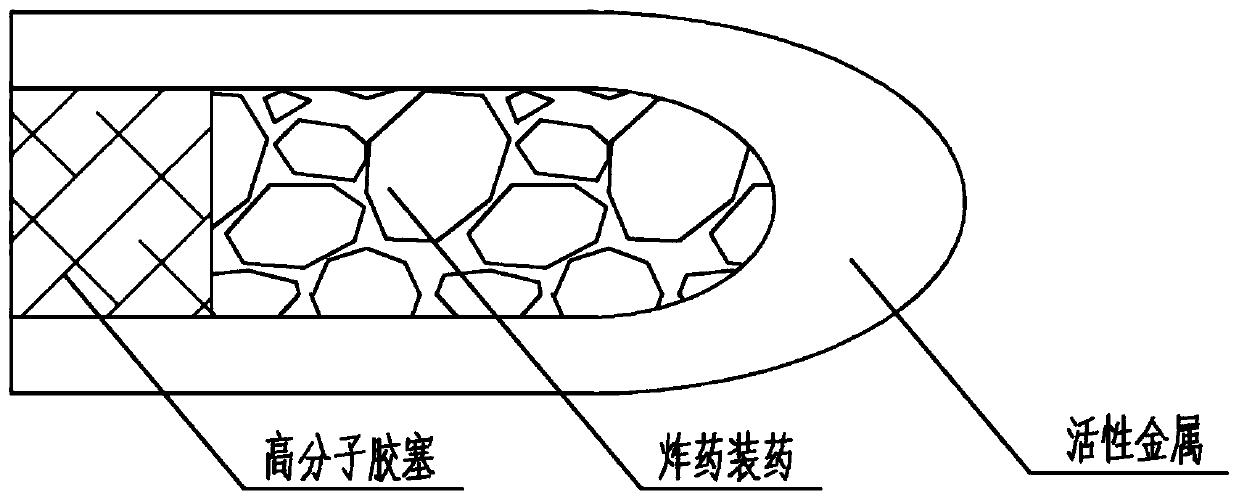

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of active metal micro-projectiles loaded with high-energy explosives, the specific steps are as follows:

[0028] (1) Weighing and powder mixing: the mass ratio of each component is: active metal / heavy metal / fluoropolymer = magnesium aluminum alloy / tungsten / polytetrafluoroethylene = 30 / 15 / 55, that is, weigh 15g of magnesium aluminum alloy powder , tungsten powder 7.5g, polytetrafluoroethylene powder 27.5g, placed in a planetary mixer and mixed for 20min, and mixed;

[0029] (2) Molding: put the above-mentioned uniformly mixed powder in a mold for compression, the pressure is 50MPa, the pressurization rate is 30N / s, the pressure holding time is 5min, the pressure release rate is 30N / s, and the mold is demoulded after the pressure release to obtain the molded part A;

[0030] (3) Sintering: Put the above-mentioned molded part A after demoulding in a sintering furnace for sintering. During the sintering process, an argon atmosphere is used. The...

Embodiment 2

[0035] A preparation method of active metal micro-projectiles loaded with high-energy explosives, the specific steps are as follows:

[0036] (1) Weighing and powder mixing: 50g per sample, the mass ratio of each component is: active metal / heavy metal / fluoropolymer=aluminum / tungsten-zirconium alloy / polytetrafluoroethylene=25 / 20 / 55, namely Take 12.5g of aluminum powder, 10g of tungsten-zirconium alloy powder, and 27.5g of polytetrafluoroethylene powder, mix them in a planetary mixer for 20 minutes, and mix well;

[0037] (2) Molding: put the above-mentioned uniformly mixed powder in a mold for compression, the pressure is 50MPa, the pressurization rate is 30N / s, the pressure holding time is 5min, the pressure release rate is 30N / s, and the mold is demoulded after the pressure release to obtain the molded part A;

[0038] (3) Sintering: Put the above-mentioned molded part A after demoulding in a sintering furnace for sintering. During the sintering process, an argon atmosphere i...

Embodiment 3

[0043] A preparation method of active metal micro-projectiles loaded with high-energy explosives, the specific steps are as follows:

[0044] (1) Weighing and powder mixing: 50g per sample each time, the mass ratio of each component is: active metal / heavy metal / fluoropolymer=magnesium / tungsten / fluororubber=25 / 15 / 60, that is, weigh 12.5 grams of magnesium powder g, 7.5g of tungsten powder, 30g of fluororubber powder, mixed in a planetary mixer for 30min, and mixed evenly;

[0045](2) Molding: put the above-mentioned uniformly mixed powder in a mold for compression, the pressure is 40MPa, the pressurization rate is 30N / s, the pressure holding time is 5min, the pressure release rate is 30N / s, and the mold is demoulded after the pressure release to obtain the molded part A;

[0046] (3) Sintering: Place the above-mentioned molded part A after demoulding in a sintering furnace for sintering. During the sintering process, an argon atmosphere is used. The sintering temperature is 360...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Packing density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com