Membrane treatment technique of low-concentration heavy metal wastewater

A low-concentration heavy metal and membrane treatment technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low system energy consumption, low interception efficiency, and slow processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

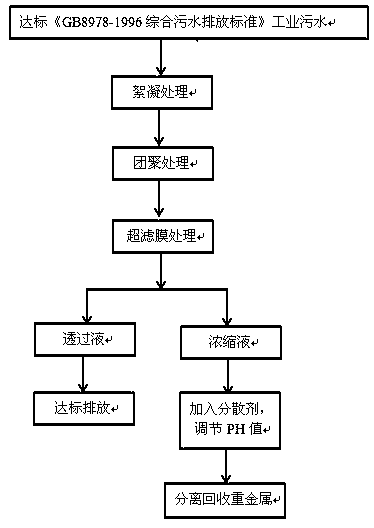

Image

Examples

Embodiment 1

[0022] Up to the standard "GB8978-1996 Comprehensive Wastewater Discharge Standard" Industrial sewage (Ni 0.98mg / L, Cd 0.11mg / L, Pb1.01mg / L, Sb 0.51mg / L) 1000ml, add 20mg / L flocculant, after solid-liquid separation , add agglomerating agent in filtrate, agglomerating agent comprises sodium dodecylbenzene sulfonate (C1 2 h 25 -C 6 h 4 -SO 3 Na) 5g, polyaluminum chloride [Al 2 (OH) n Cl 6-n ·xH 2 O] m , (m≦10, 3~5, Al 2 o 3 ≧28.0%) 30g, dimethyldiallyl sodium chloride 5g, diatomaceous earth 10g, stir with a stirrer at normal temperature and pressure, the speed of the stirrer is 60r / min, the stirring time is 60min, and the standing time is 8h. Pumped into the ultrafiltration membrane separator for filtration, permeate sampling analysis, Ni 0.29mg / L, Cd 0.03mg / L, Pb 0.26mg / L, Sb 0.02mg / L, up to standard discharge, sampling analysis in the concentrated solution, Ni 0.29g / L, Cd 0.03g / L, Pb 0.26g / L, Sb 0.02g / L, add a dispersant to the concentrated solution, adjust the pH v...

Embodiment 2

[0026] Up to the standard "GB8978-1996 Comprehensive Wastewater Discharge Standard" Industrial sewage (Ni 0.98mg / L, Cd 0.11mg / L, Pb1.01mg / L, Sb 0.51mg / L) 1000ml, add 15mg / L flocculant, after solid-liquid separation , add agglomerating agent in filtrate, agglomerating agent comprises sodium dodecylbenzene sulfonate (C1 2 h 25 -C 6 h 4 -SO 3 Na) 5g, polyaluminum chloride [Al 2 (OH) n Cl 6-n ·xH 2 O] m , (m≦10, 3~5, Al 2 o 3 ≧28.0%) 55g, dimethyldiallyl sodium chloride 5g, diatomaceous earth 25g, stir with a stirrer at normal temperature and pressure, the speed of the stirrer is 60r / min, the stirring time is 60min, and the standing time is 8h. Pumped into the ultrafiltration membrane separator for filtration, permeate sampling analysis, Ni 0.11mg / L, Cd 0.01mg / L, Pb 0.12mg / L, Sb 0.01mg / L, up to standard discharge, sampling analysis in the concentrated solution, Ni 0.39g / L, Cd 0.13g / L, Pb 0.46g / L, Sb 0.05g / L, add a dispersant to the concentrated solution, adjust the pH v...

Embodiment 3

[0028] Up to standard "GB8978-1996 Comprehensive Sewage Discharge Standard" Industrial sewage (Ni 0.98mg / L, Cd 0.11mg / L, Pb1.01mg / L, Sb 0.51mg / L) 1000ml, add 10mg / L flocculant, after solid-liquid separation , add agglomerating agent in filtrate, agglomerating agent comprises sodium dodecylbenzene sulfonate (C1 2 h 25 -C 6 h 4 -SO 3 Na) 5g, polyaluminum chloride [Al 2 (OH) n Cl 6-n ·xH 2 O] m , (m≦10, 3~5, Al 2 o 3≧28.0%) 25g, dimethyldiallyl sodium chloride 5g, diatomaceous earth 10g, stir with a mixer at normal temperature and pressure, the speed of the mixer is 60r / min, the stirring time is 60min, and the standing time is 8h. Pumped into the ultrafiltration membrane separator for filtration, permeate sampling analysis, Ni 0.22mg / L, Cd 0.03mg / L, Pb 0.23mg / L, Sb 0.02mg / L, up to standard discharge, sampling analysis in the concentrate, Ni 0.31g / L, Cd 0.03g / L, Pb 0.29g / L, Sb 0.02g / L, add a dispersant to the concentrated solution, adjust the pH value to 9-11, and use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com