Method for the application of a conformal nanocoating by means of a low pressure plasma process

A low-pressure plasma and plasma technology, applied in the field of plasma technology, can solve problems such as complex production processes and achieve cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

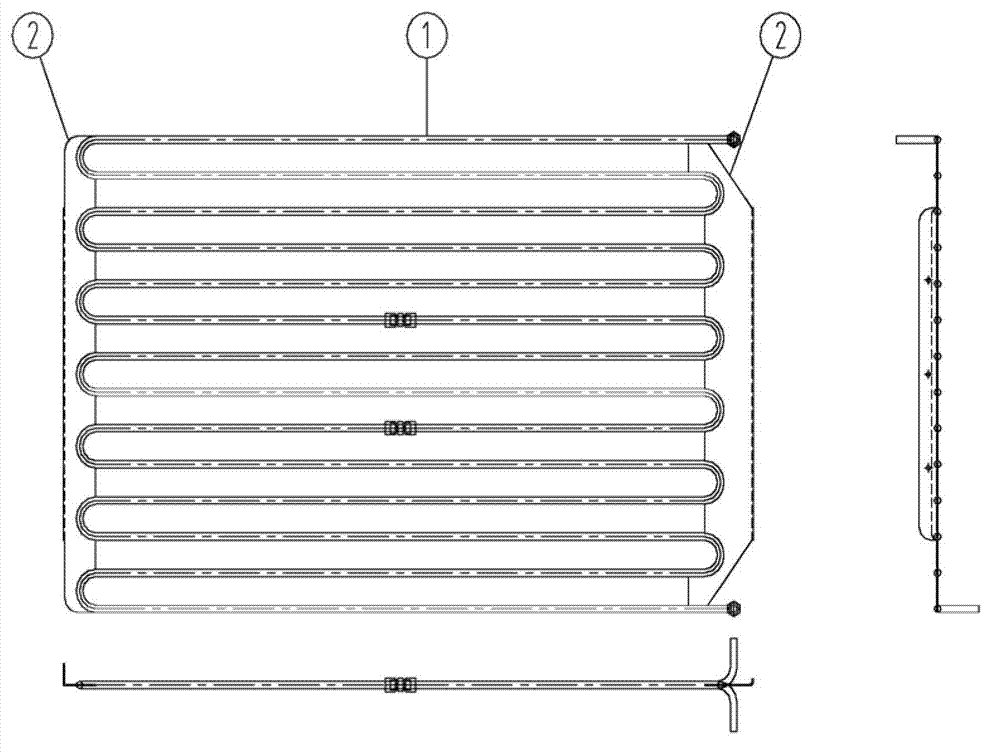

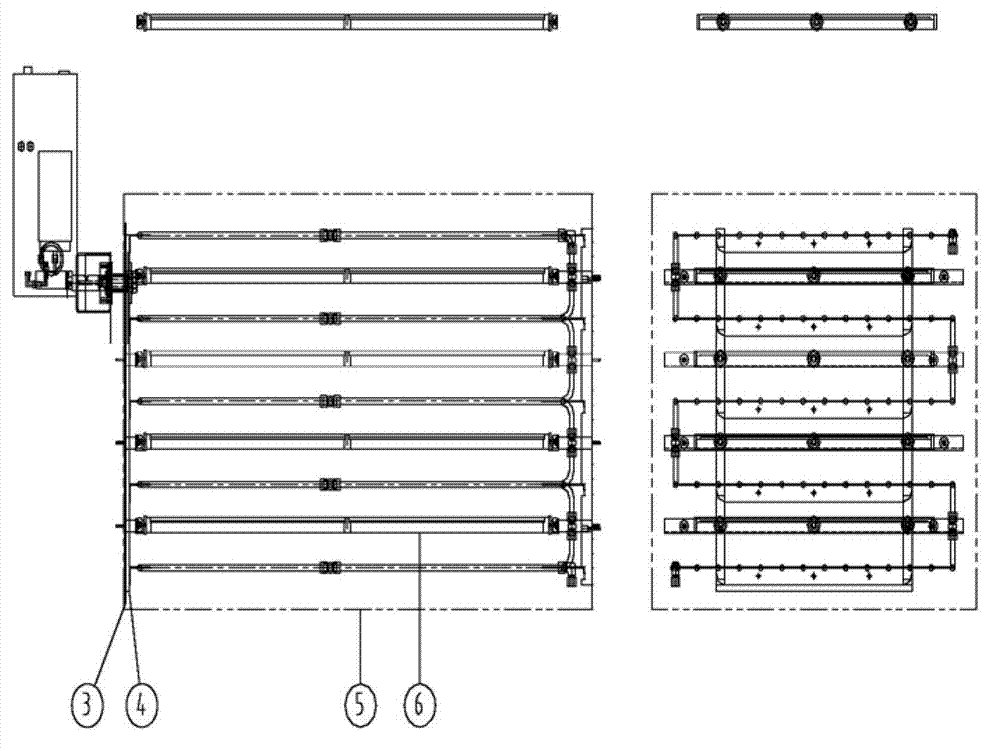

[0049] Example 1: Electrode arrangement in the reaction chamber

[0050] figure 1 with 2 The preferred settings are shown. The electrode set for generating low-pressure plasma includes a set of floating electrodes (1) in a hollow, curved and circular shape and a vacuum chamber (5), and the vacuum chamber (5) is used as the main body. The electrode (1) is provided with a liquid, which can be cooled or heated to perform plasma treatment in a temperature range of 5 to 200°C, and is preferably controlled at a temperature between 20 to 90°C.

[0051] The typical electrode (1) in this setup has a diameter between 5 and 50 mm, a wall thickness of 0.25 to 2.5 mm, and is bent toward the end with a 180° turning circle, and the tube is between before and after bending The distance between is between 1 to 10 times the tube diameter, preferably 5 times.

[0052] Power is applied to the electrode (1) through a connecting plate (2) installed on a clutch plate (4). A thin insulating layer or prot...

example 2

[0056] Example 2: Low-voltage plasma polymerization C3F6 embedded in circuit boards for phones

[0057] The assembled circuit board for the mobile phone was placed in the CD1000 plasma chamber for more than two minutes, as described in Example 1, and was degassed at a pressure between 100 and 1000 mTorr. Then, the board was cleaned and etched with Ar, and plasma polymerization was performed with C3F6 monomer at 50 mTorr and room temperature for 10 minutes. The fluoropolymer conformal coating applied by this process was measured to have a thickness of about 80 nm.

[0058] The board was then exposed to several aging processes, involving extended exposure to moisture, high temperature, and salt fume. It can be seen visually that circuit boards with conformal nano-coatings show significantly lower corrosion than untreated circuit boards. When performing electrical tests, it can also be found that the circuit board assembly with the nano-conformal coating actually shows no electrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com