Laminate with fill layer

A filler layer and plastic technology, applied in layered products, thin material processing, metal layered products, etc., can solve problems such as unevenness of laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

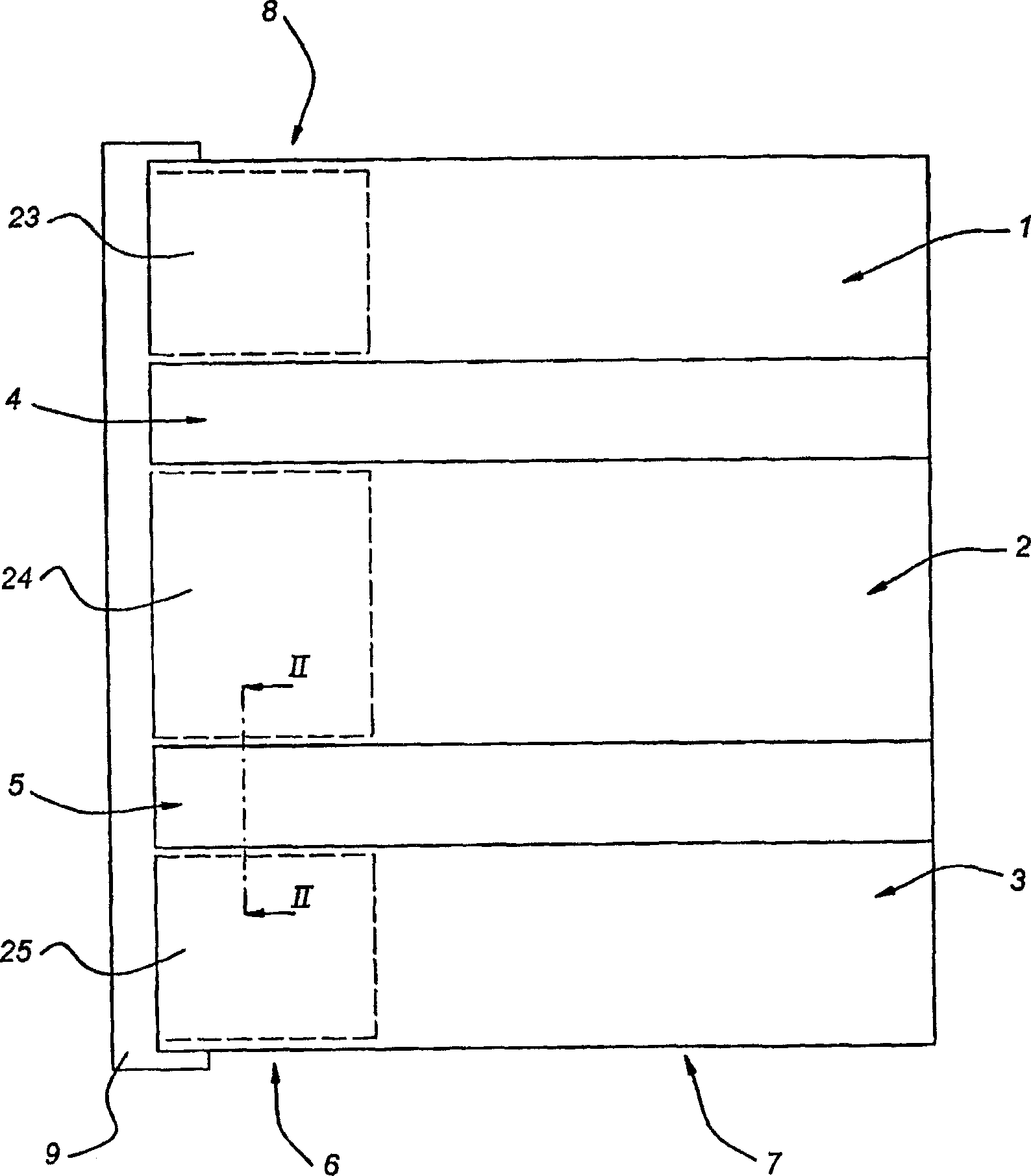

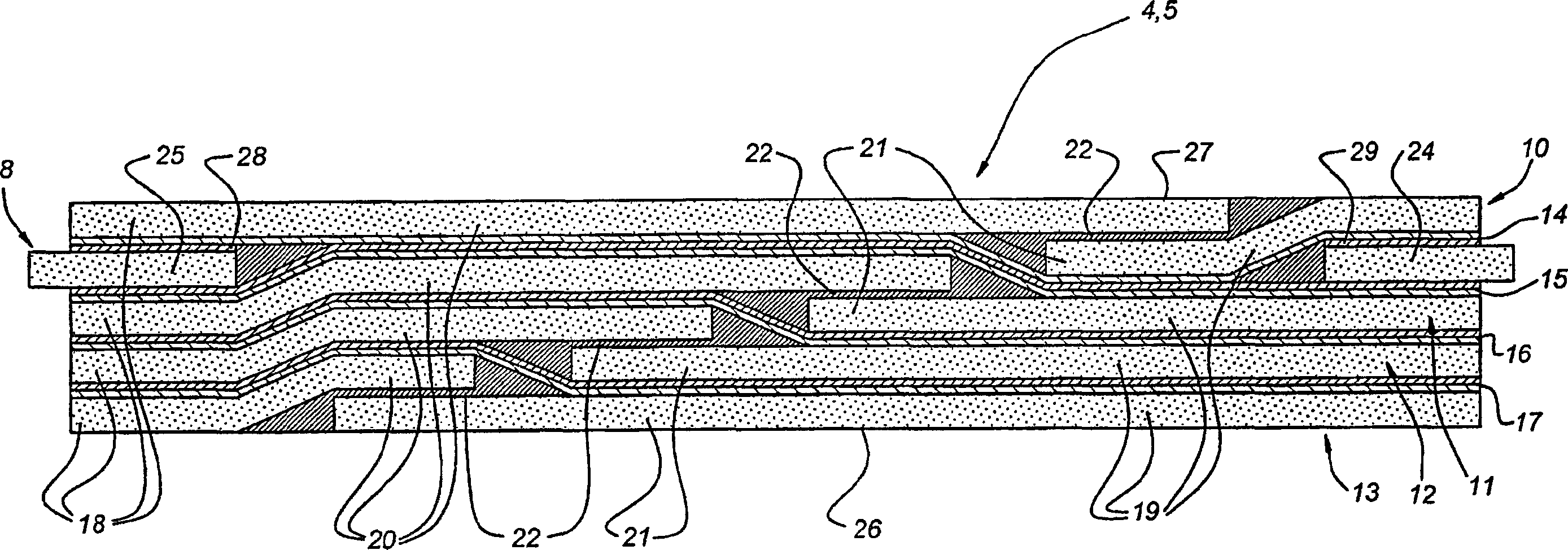

[0010] figure 1 The laminate shown in comprises three laminate parts 1 , 2 and 3 which are fastened to each other by means of joints 4 , 5 . In addition, two distinct regions can be distinguished in the laminate, namely the region 6 provided with a fill, generally indicated by reference numeral 8, between the layers of the laminate, and the region without a fill , in other words the standard laminate 7. At the location of the area 6 the ply can be secured to another ply by means of strip frames 9 .

[0011] It is known that at the position of the combination 4 , 5 the thickness of the standard laminates is somewhat greater since the edges of the laminates overlap one another here. This means that at least one side of the laminate is not flat but somewhat stepped. In some applications, this is not ideal. For example, in the case of aircraft skins, it is preferred that the sides of the laminate be completely flat. The frame 9 can be connected to one side, the inner side, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com