Efficient powder-like material separating device

A separation device, powder technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Conducive to subsequent production, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

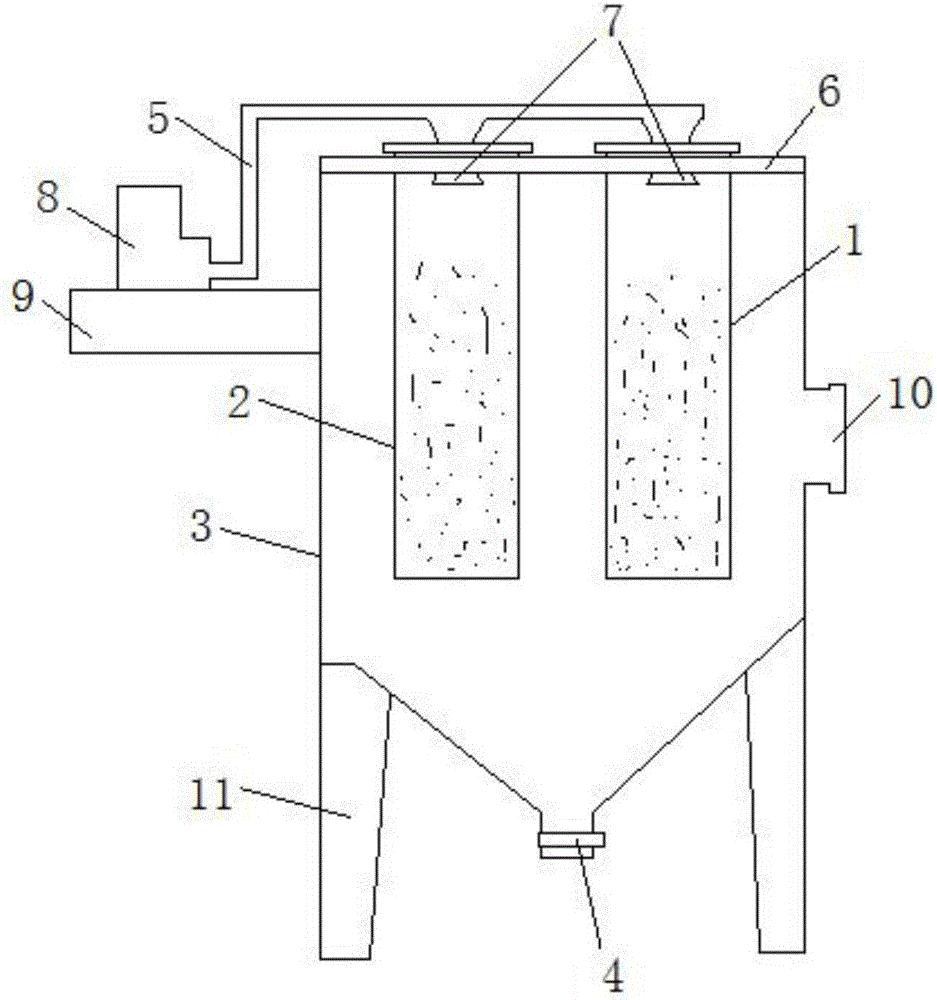

[0009] A high-efficiency separation device for powdery materials, such as figure 1 As shown, it includes a separation cylinder 3 installed on the column 11, the upper end of the separation cylinder 3 is provided with a cover 6, the lower end is provided with a material distribution port 4, the material distribution port 4 is provided with a valve, and the peripheral side wall of the separation cylinder 3 is provided with a glass window 10;

[0010] The cover 6 is provided with not less than two round holes, and the present embodiment is provided with two round holes, and the first filter bag 1 and the second filter bag 2 can be respectively placed in the separation cylinder through the two round holes. The first filter bag 1 and the second filter bag 2 hold different powdery materials to be separated;

[0011] A support plate 9 is welded and fixed on the circumferential side wall of the separation cylinder 3, and a fan 8 is installed on the support plate 9. The air outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com