Implantation device and implantation method

An implanting device and implanting technology, applied in the field of implanting devices and implants, can solve the problems of great difficulty in grasping and transferring by manipulators, and affect the efficiency, accuracy and efficiency of implantation, so as to avoid improper implantation In place, improve efficiency, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

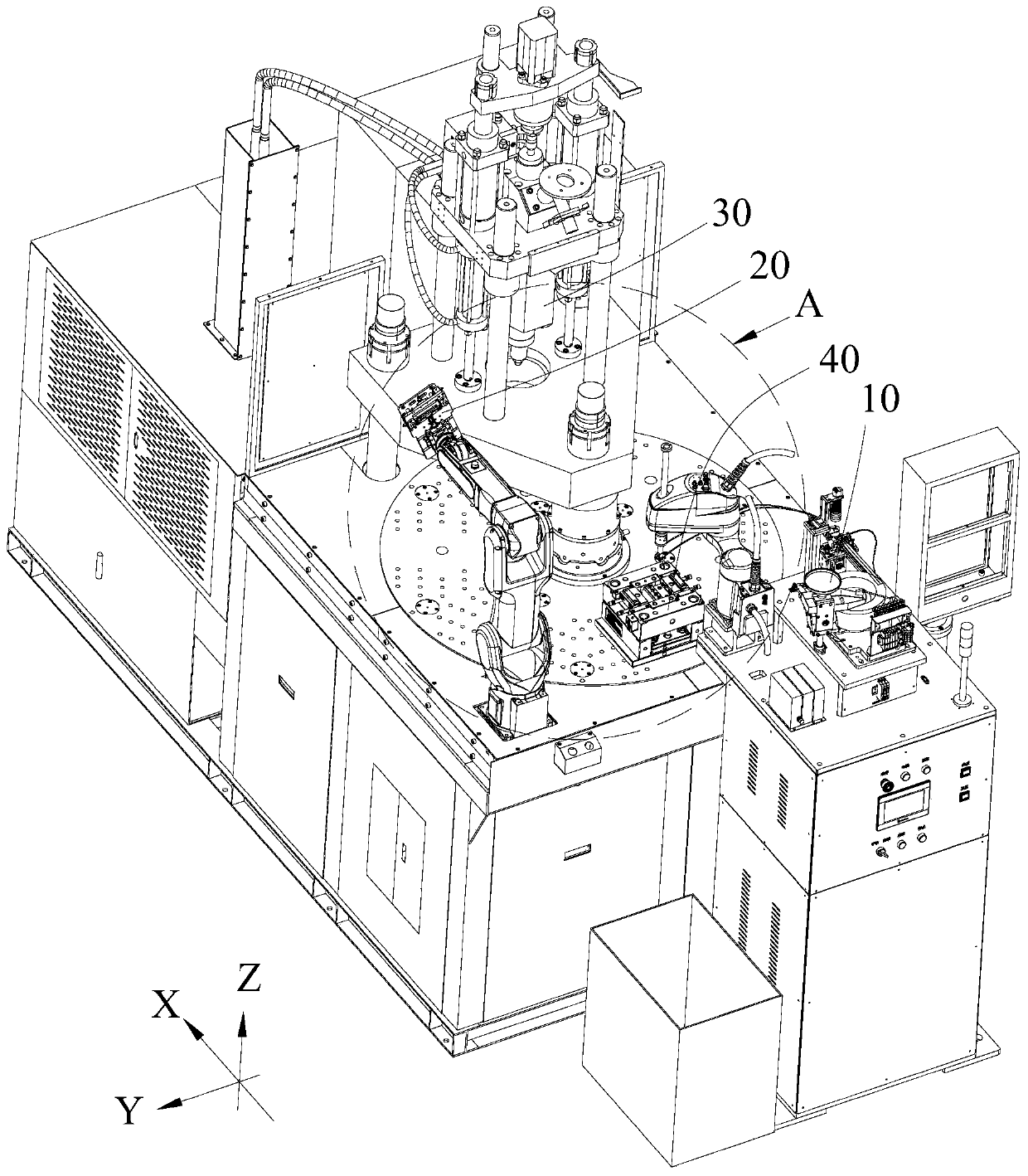

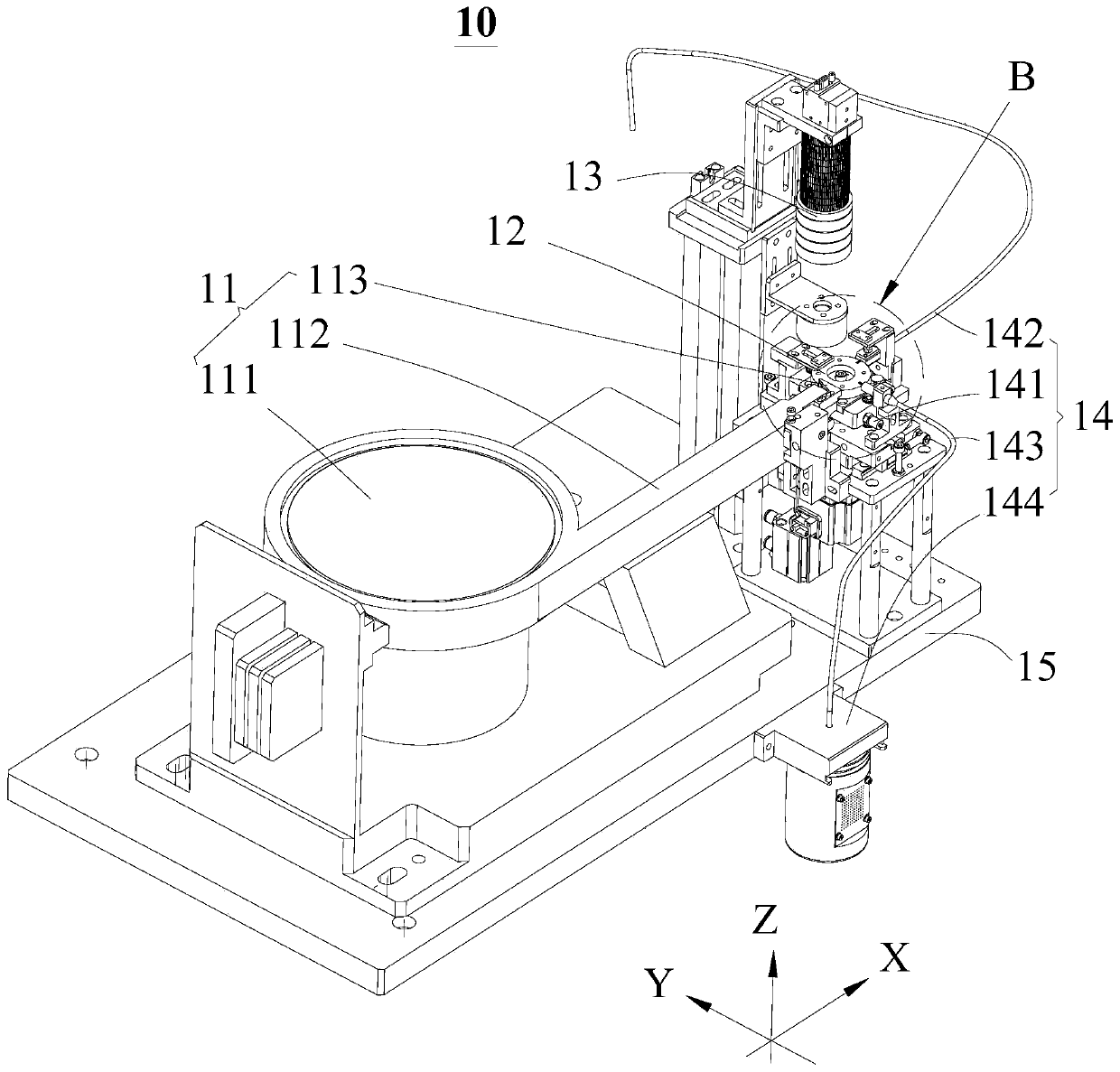

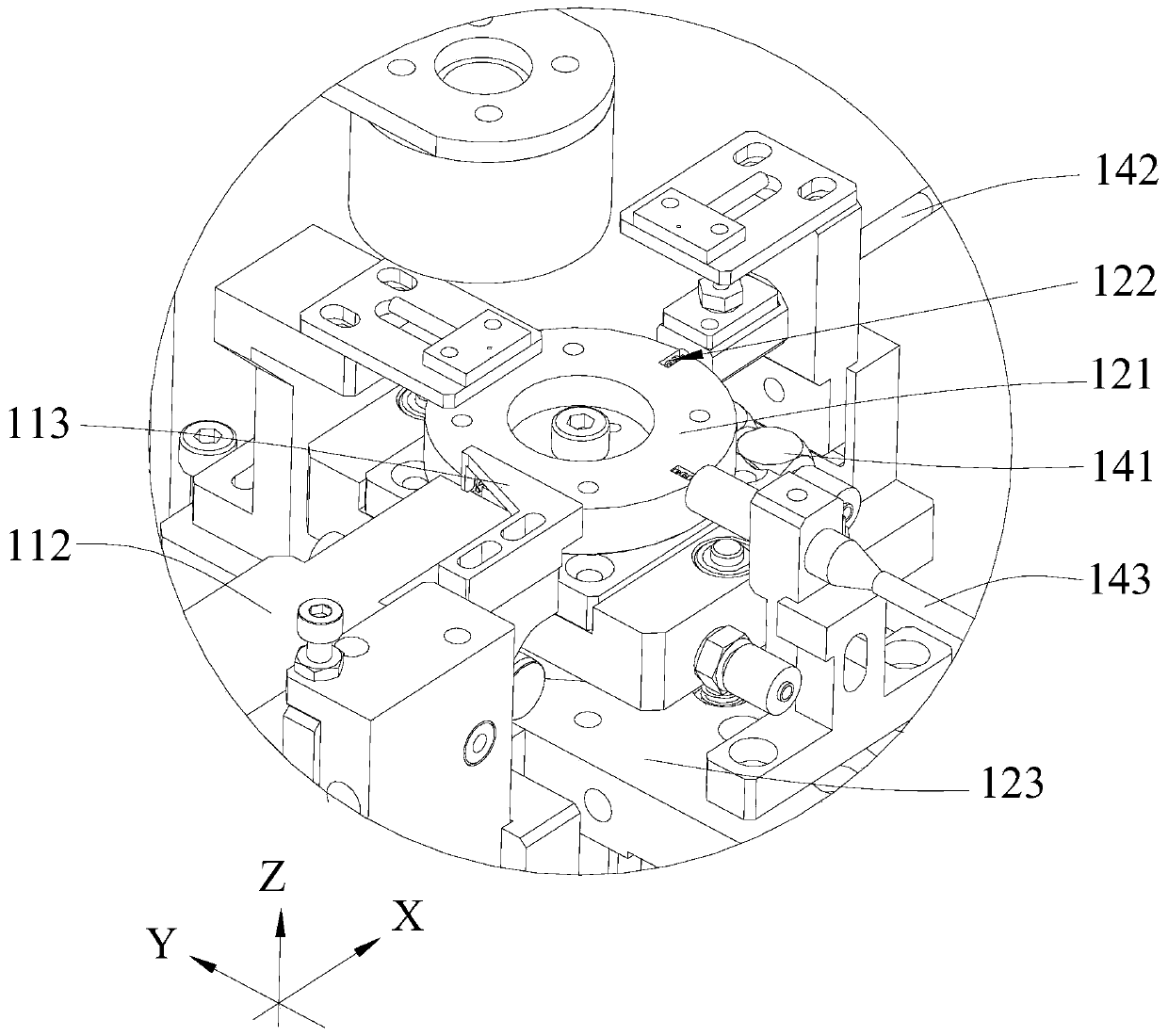

[0053] like Figure 1 to Figure 10 As shown, this embodiment provides an implanting device, which is used in conjunction with a receiving object 40 having at least one implanting hole, and is used for implanting fine materials into the implanting hole for injection molding. The fine materials have or are provided with The first characteristic part and the second characteristic part; the first characteristic part and the second characteristic part have different characteristics, and can be distinguished by the detection unit 13 described later, in the embodiment of the present invention, the fine material is a fine copper column, the first The outer diameter of the characteristic part is different from the outer diameter of the second characteristic part, wherein the first characteristic part is the small end of the fine material, and the second characteristic part is the large end of the fine material;

[0054] Of course, in other embodiments, the receiving object 40 for recei...

Embodiment 2

[0087] Please refer to Figure 11 , this embodiment provides an implantation method, which is a screening method applied to implantation equipment. For the specific structure of the implantation equipment, please refer to Embodiment 1.

[0088] The implantation method provided in this embodiment includes:

[0089] Adjustment: the vibrating plate 111 adjusts the length direction of each fine material to the front and back direction and transports them to the feeding track 112 in sequence;

[0090] Receiving: the transfer unit 12 receives fine materials from the feeding track 112 one by one and transfers them to the preset position;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com