Preparation method of ultra-coarse-grain hard alloy

A hard alloy, coarse-grained technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of slurry precipitation, gun blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

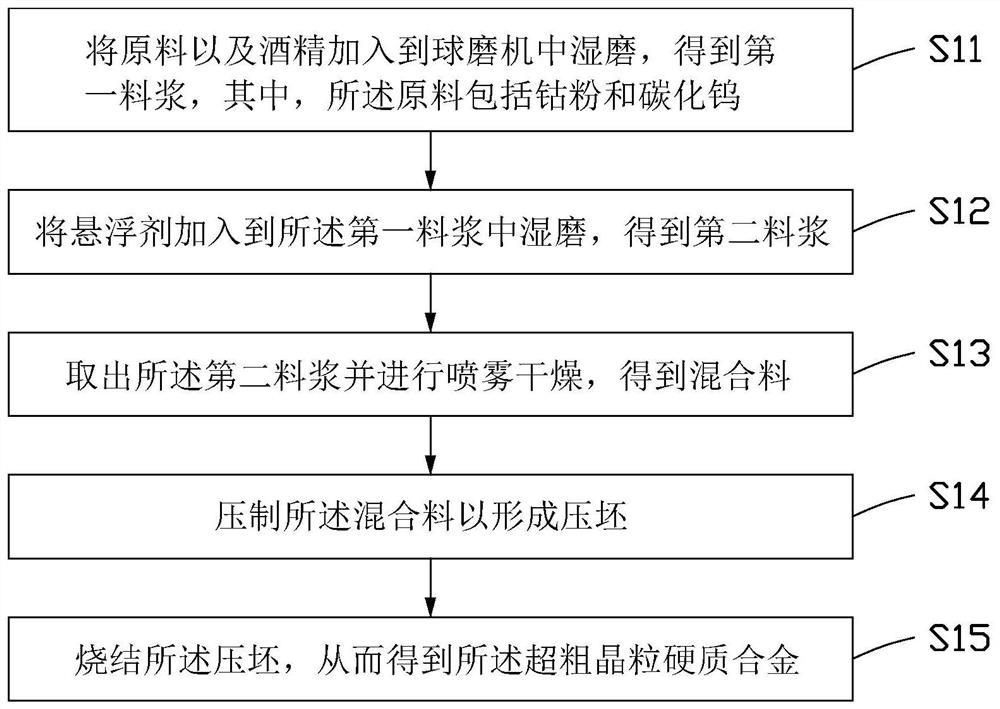

[0027] see figure 1 , some embodiments of the present invention provide a method for preparing ultra-coarse-grained cemented carbide, comprising the following steps:

[0028] Step S11, adding raw materials and alcohol into a ball mill for wet grinding to obtain a first slurry, wherein the raw materials include cobalt powder and tungsten carbide.

[0029] In some embodiments, the raw material further includes tungsten powder or carbon powder. The tungsten powder and the carbon powder can be used to adjust the carbon content of the raw material (that is, the mass ratio of carbon to the raw material). Specifically, when the carbon content of the raw material is too high, the tungsten powder can be added to reduce the carbon content of the raw material; when the carbon content of the raw material is too low, the carbon powder can be added to increase the carbon content of the raw material. The carbon content of the feedstock.

[0030] A plasticizer may also be added to the ball...

Embodiment 1

[0051] The first step, 20kg of 10-type cobalt powder and tungsten powder or carbon powder (the tungsten powder and the carbon powder are specifically added according to the carbon content of the raw material) and a small amount of alcohol are added to the tilting ball mill, fully wetted Grind and mix for 2 hours, then add 180kg of Jinlu 200 tungsten carbide, paraffin wax accounting for 2% of the mass of the raw material, oleic acid accounting for 1% of the mass of the paraffin wax, and alcohol into the ball mill to make the carbon content of the raw material The content is 6.10%, the ball-to-material ratio is 3:1, the solid-to-liquid ratio is 140ml / kg, and the wet grinding is continued for 12 hours to obtain the first slurry.

[0052] In the second step, stop the machine 1h-2h before the end of the wet grinding in step S11, add a suspending agent accounting for 0.2% of the mass of the raw material into the first slurry, and then complete the wet grinding to obtain the second S...

Embodiment 2

[0057] The difference between embodiment 2 and embodiment 1 is:

[0058] The time to continue wet grinding in the first step is 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com