Organic treatment method of sludge

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increased investment cost, reduced sludge, inconvenient transportation, etc., to reduce transportation costs , reduce sludge weight and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

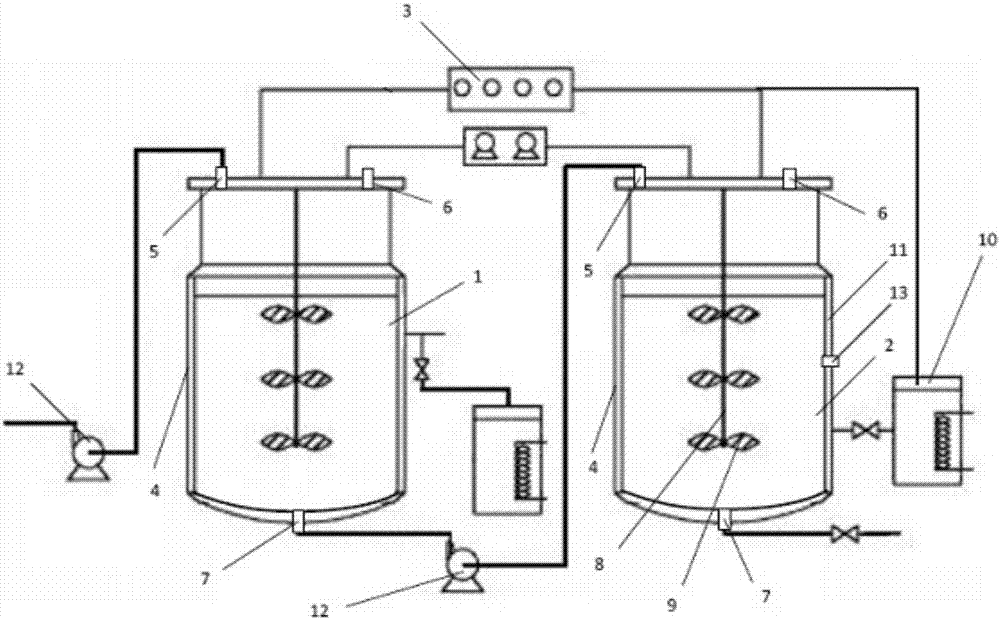

[0040] The sludge organic treatment method provided in this embodiment comprises the following steps:

[0041] (1) 500Kg of wet sludge and 130g of triethylamine are added to the box-type thin laminated filter press at the same time, and the wet sludge is subjected to deep dehydration treatment until the moisture content in the sludge is reduced to 60%, and dewatered sludge is obtained;

[0042] (2) Transport the dewatered sludge to the digestion and treatment site, crush the dewatered sludge, take the 10-mesh sieved product, and spray 0.5% decanyl alcohol by weight of the dewatered sludge during the crushing and sieving process to deodorize the sludge ;

[0043] (3) The dewatered sludge after deodorization is added to the sludge pretreatment tank 1 from the first feed port 5 of the sludge pretreatment tank 1 of the aerobic digestion silo, and is fed from the second inlet of the sludge pretreatment tank 1. Feed port 6 is added with a carbon source / nitrogen source ratio regulat...

Embodiment 2

[0046] The sludge organic treatment method provided in this embodiment comprises the following steps:

[0047] (1) Mix 1000kg of wet sludge and 300g of hydrogen peroxide with a concentration of 2% evenly, then add it into a box-type thin laminated filter press, and carry out deep dehydration treatment on the wet sludge until the water content in the sludge drops to 62%. sludge;

[0048] (2) Transport the dewatered sludge to the digestion and treatment site, crush the dewatered sludge, take the 10-mesh sieved product, and spray 0.1% lauryl alcohol by weight of the dewatered sludge during the crushing and sieving process to deodorize the sludge ;

[0049] (3) The dewatered sludge after deodorization is added to the sludge pretreatment tank 1 from the first feed port 5 of the sludge pretreatment tank 1 of the aerobic digestion silo, and is fed from the second inlet of the sludge pretreatment tank 1. Feed port 6 is added with 3% carbon source / nitrogen source ratio regulator of d...

Embodiment 3

[0052] The sludge organic treatment method provided in this embodiment comprises the following steps:

[0053] (1) Mix 500Kg of wet sludge, 100g of hydrochloric acid and 100g of hydrogen peroxide with a concentration of 0.5% evenly, and then add it to a box-type thin laminated filter press, and perform deep dehydration treatment on the wet sludge until the water content in the sludge drops to 65% , to obtain dewatered sludge;

[0054] (2) Transport the dewatered sludge to the digestion and treatment site, crush the dewatered sludge, take the 10-mesh sieved product, and spray 0.05% vanillin by weight of the dewatered sludge during the crushing and sieving process to deodorize the sludge ;

[0055] (3) The dewatered sludge after deodorization is added to the sludge pretreatment tank 1 from the first feed port 5 of the sludge pretreatment tank 1 of the aerobic digestion silo, and is fed from the second inlet of the sludge pretreatment tank 1. Feed port 6 adds a carbon source / ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com