Single-shaft powerful stirring and kneading machine

A technology of strong mixing and kneading machine, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of lack of mud kneading and pre-extrusion treatment, insufficient healing ability and insufficient effect of improving molding quality. , to achieve the effect of improving the ability of stirring, refining and healing, which is beneficial to subsequent production and has a good degree of molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

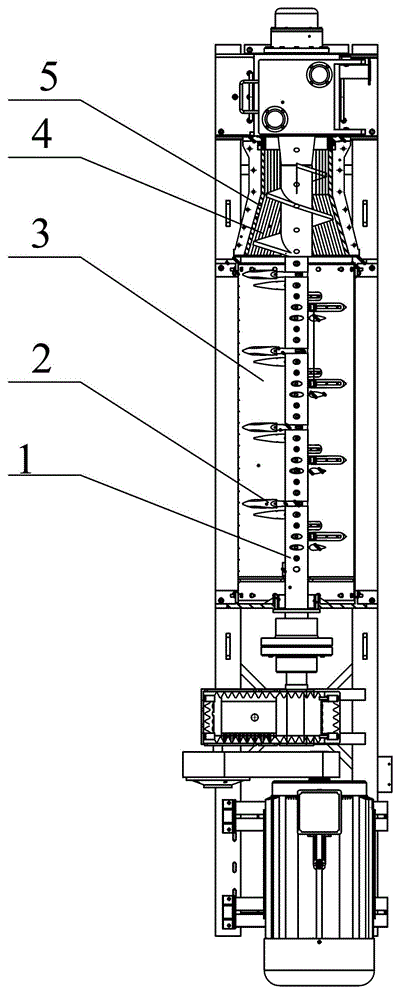

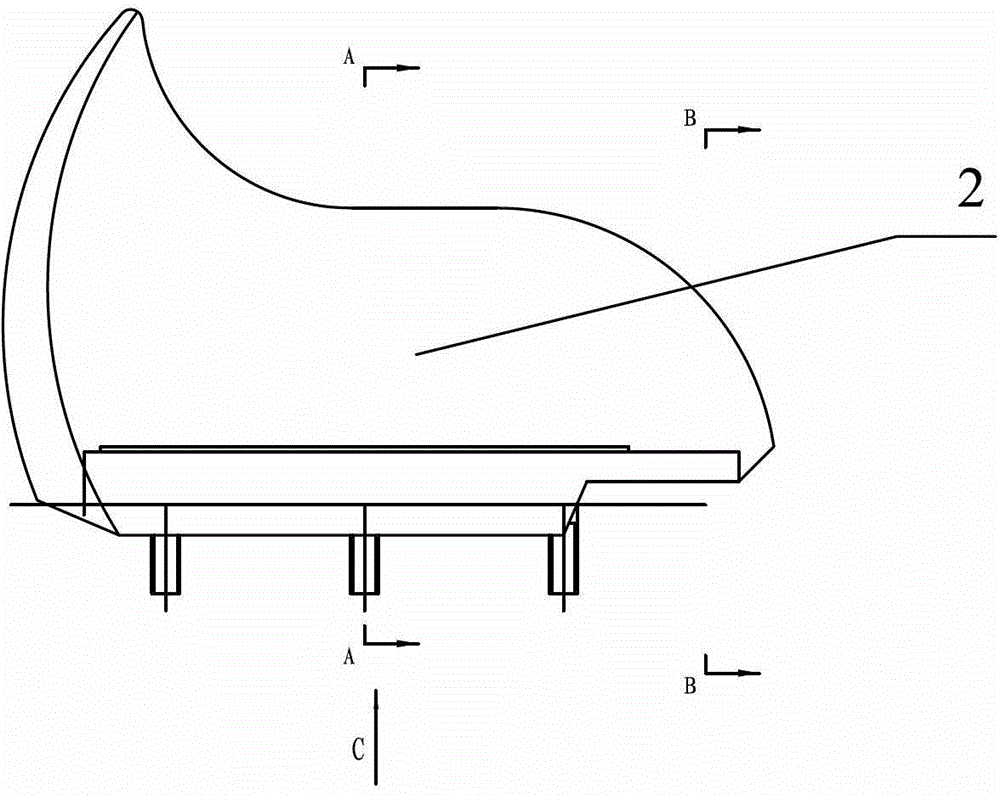

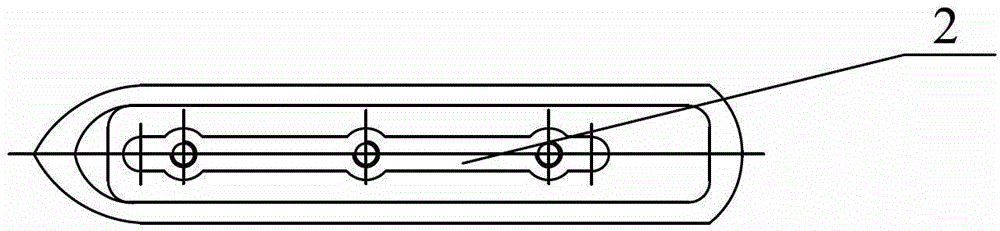

[0019] Such as Figure 1~Figure 2 The single-shaft strong mixing and kneading machine shown includes a mud stirring and homogenizing and kneading section, and a single stirring shaft 1 is arranged in the mud box 3 of the mud stirring and homogenizing and kneading section. 1 is provided with a plurality of hook head type stirring and kneading knives 2 alternately.

[0020] Thinning, pre-extrusion, and initial healing sections 4 are arranged at the discharge rear of the mud box 3 . The thinning, pre-extruding, and initial healing section 4 is trumpet-shaped, and the thinning, pre-extruding, and initial healing section 4 is covered with a wear-resistant bushing 5 . The hook-type stirring and kneading knives 2 are arranged and installed in a spiral progressive manner on the single stirring shaft 1. One side of the hook head type stirring and kneading knife 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com