Method for improving dissolving property of high molecular weight polyacrylonitrile produced by dry method

A technology of polyacrylonitrile and high molecular weight, which is applied in the direction of single-component synthetic polymer rayon, spinning solution preparation, textiles and papermaking, etc. It can solve the problems of poor solubility of high molecular weight polyacrylonitrile and achieve improved solubility , the effect of solving the difficulty of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

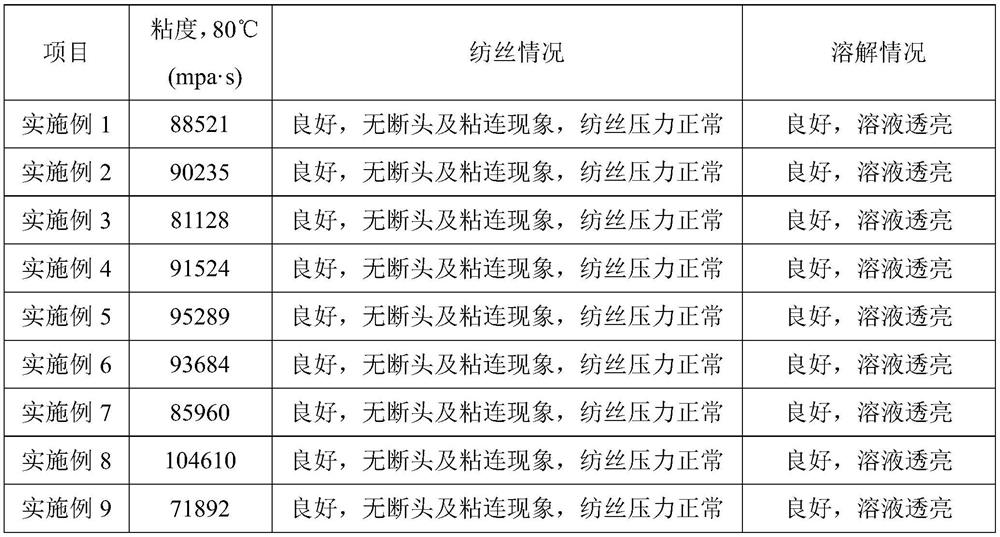

Examples

Embodiment 1

[0030] Weigh 50g of DMAC and 30g of DMF, slowly heat up to 65°C, add 43g of polyacrylonitrile powder with a weight average molecular weight of 200,000, stir at a speed of 150rpm, after stirring for 20min, slowly add 20g of DMSO, and heat up to 80°C, It was prepared as a homogeneous solution with a concentration of 30%, its viscosity was measured, and a spinning test was carried out.

Embodiment 2

[0032] Weigh 50g of DMAC and 30g of DMF, slowly heat up to 65°C, add 43g of polyacrylonitrile powder with a weight-average molecular weight of 250,000, stir at a speed of 150rpm, after stirring for 20min, slowly add 20g of DMSO, and heat up to 80°C. It was prepared as a homogeneous solution with a concentration of 30%, its viscosity was measured, and a spinning test was carried out.

Embodiment 3

[0034] Weigh 60g of DMAC and 30g of DMF, slowly heat up to 65°C, add 43g of polyacrylonitrile powder with a weight-average molecular weight of 200,000, stir at a speed of 200rpm, after stirring for 20min, slowly add 10g of DMSO, and heat up to 80°C and continue Stir for 40 minutes, configure it into a homogeneous solution with a concentration of 30%, measure its viscosity, and conduct a spinning test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com