Quick feeding device for feeding waste steel into electric furnace and feeding method thereof

A feeding device and scrap steel technology, applied in the field of metallurgy, can solve problems such as poor control of material thickness, impact on scrap steel transportation and processing, impact of long feeding tank materials, etc., and achieve the effects of improved production environment, convenient maintenance, and short equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

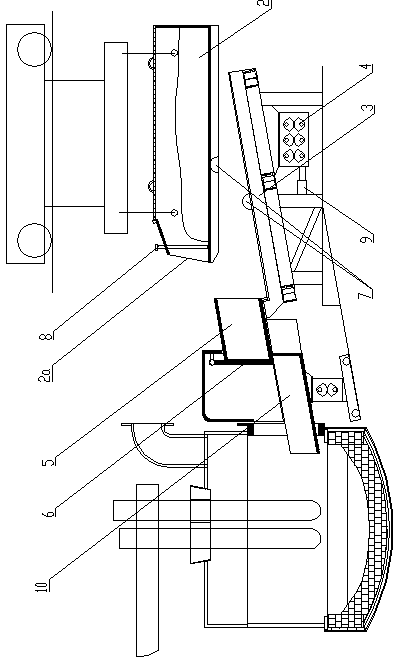

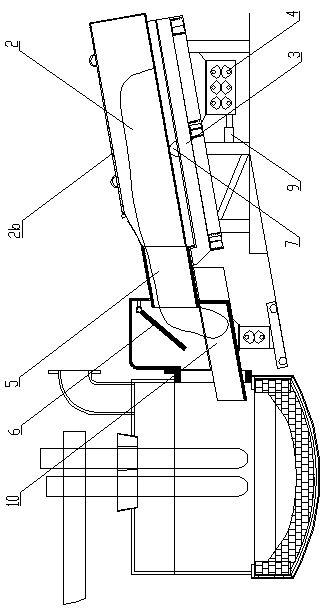

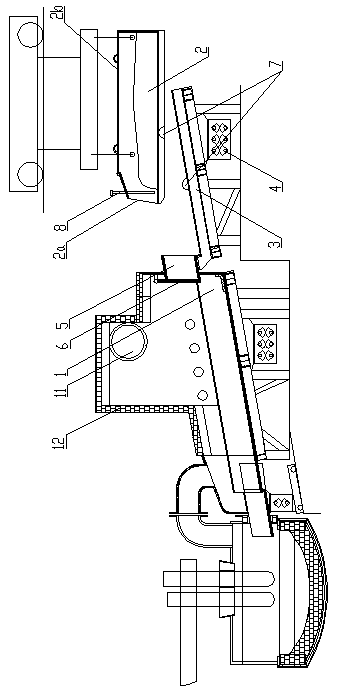

[0030] The present invention will be described in detail below in conjunction with accompanying drawing, as shown in the figure: be used for adding the fast feeding device of steel scrap in the electric furnace, comprise the high-temperature connection groove 10 that communicates with electric furnace and be used for the cold receiving conveying device of scrap steel loading, The cold receiving conveying device includes a long feeding trough 2 that can be lifted and moved. The front end of the long feeding trough 2 is provided with a discharge port 2a that can be sealed and communicated with the feed port of the high-temperature connecting tank 10. When feeding, the scrap steel is laid In the long feeding tank 2, the long feeding tank 2 is hoisted by the hoisting equipment so that the discharge port communicates with the feed port of the high-temperature connecting tank. The method of hoisting and adding scrap steel by other tools has a fast feeding speed and is not easy to gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com