Carton forming machine

A forming machine and forming mechanism technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of time-consuming and labor-intensive, low production efficiency, etc., to improve production efficiency and pass rate, make significant progress, and highlight the essence The effect of sexuality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

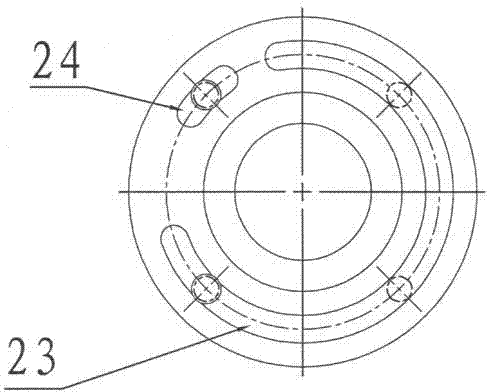

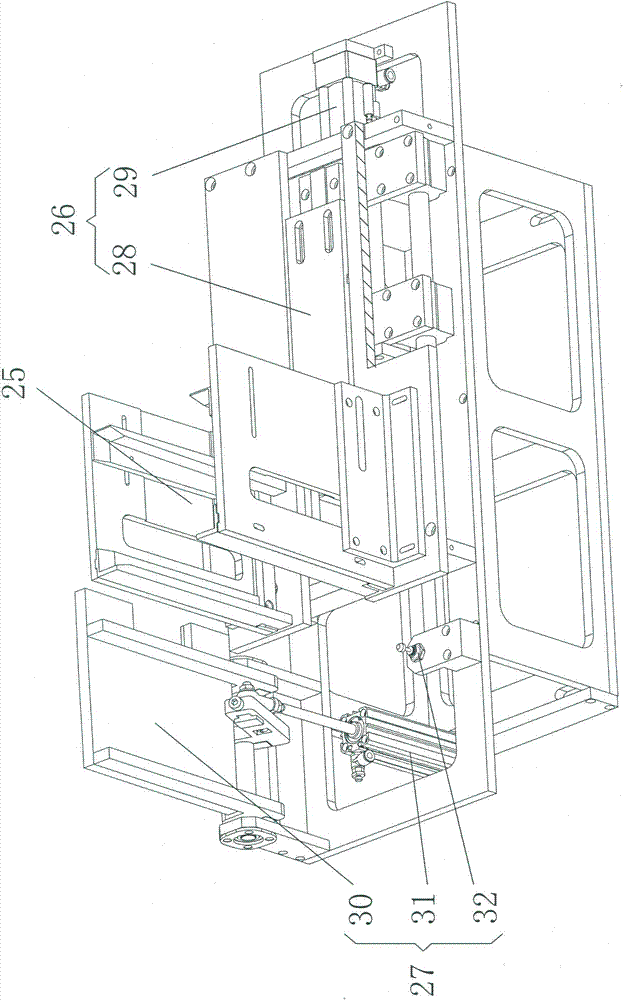

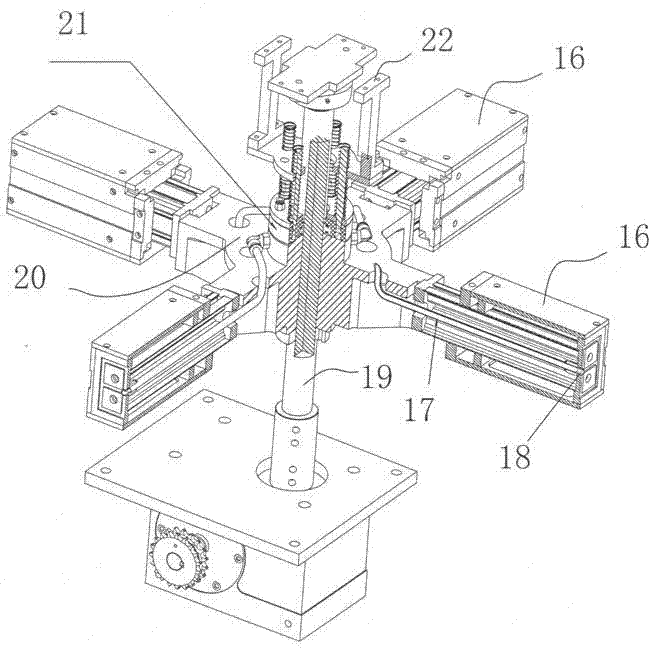

[0044]Referring to the accompanying drawings, in this embodiment, the carton forming machine includes a frame 1, and the frame 1 is provided with a three-port hemming mechanism 2, a turntable mold mechanism 3, an upper bottom plate mechanism 4, a cardboard transfer mechanism, and a carton forming mechanism. 6 and the box-out mechanism 7. The face paper and cardboard are pasted together, the cardboard is slotted, and the face paper and cardboard are pasted through a cover machine. The wine box or carton has four sides and a bottom, and the four sides are respectively connected to the four sides of the cardboard. corresponding side. In this application, the three sides on the right side of the face paper and the three sides on the left side of the cardboard are aligned and pasted, so that the three sides of the cardboard complete the cover, that is, a misaligned cover.

[0045] When starting to work, the cardboard with the misplaced cover is sent into the carton forming machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com