Automatic assembling and detecting mechanism for X-shaped sealing ring and operation method thereof

A detection mechanism and automatic assembly technology, which is applied in injection devices, metal processing, metal processing equipment, etc., can solve the problem of manual operation errors, the inability of the fixture to efficiently press the X-shaped sealing ring, the inability to guarantee the qualified rate of finished products and their quality, and the consumption of problems such as large labor costs, to achieve the effect of improving poor uniformity, improving production efficiency and pass rate, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

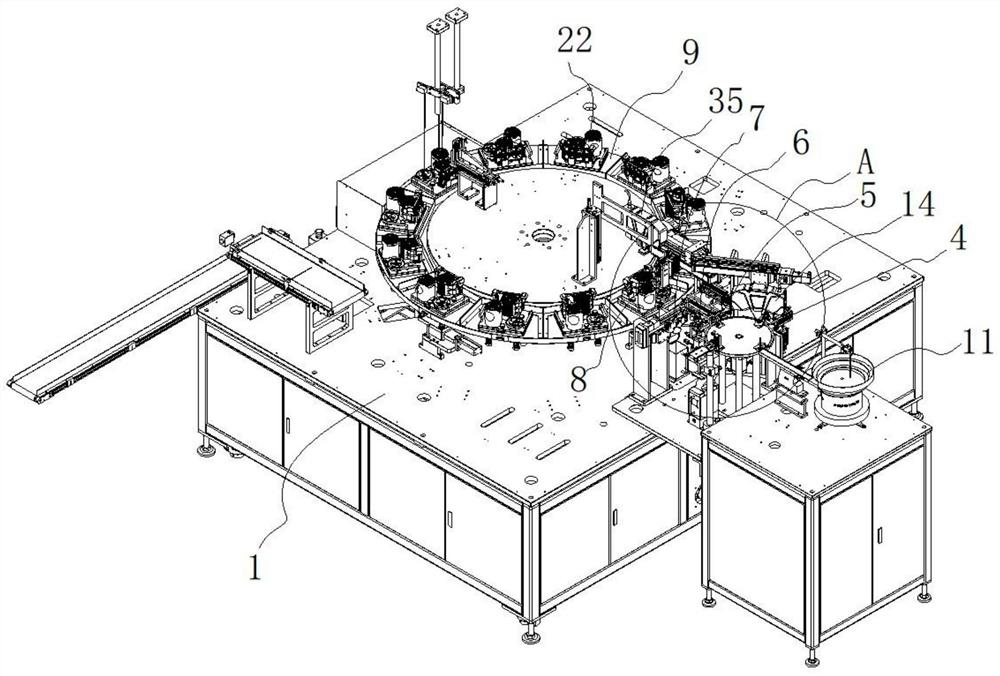

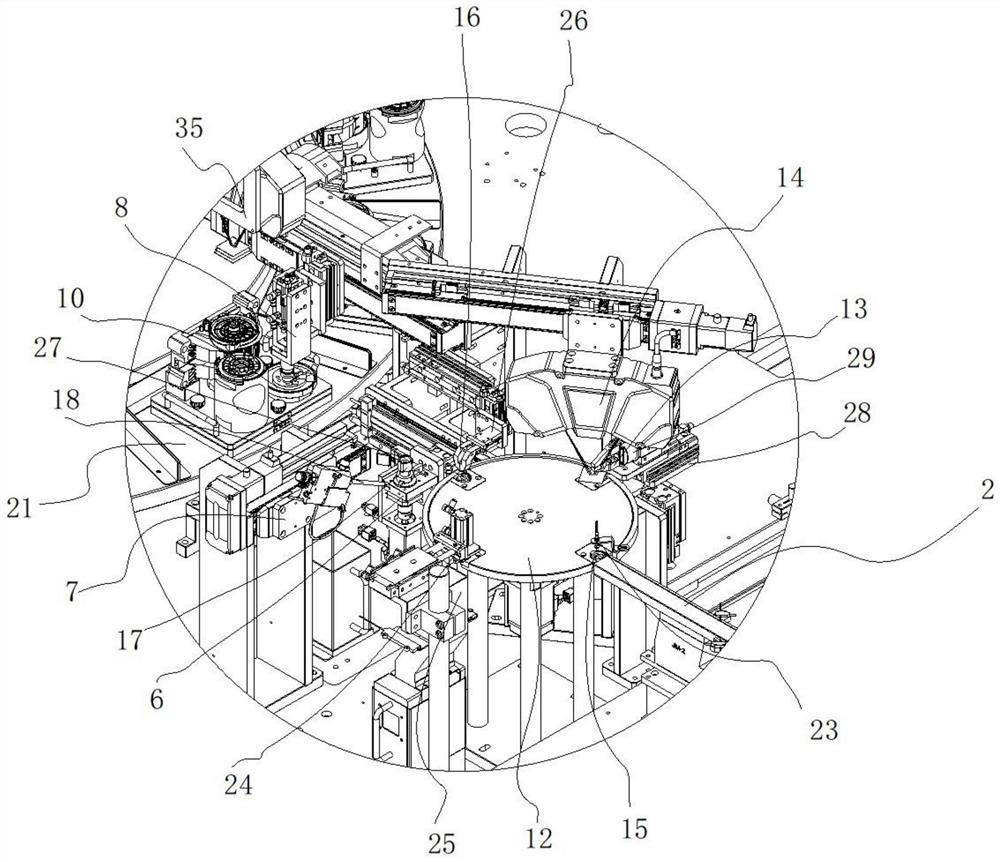

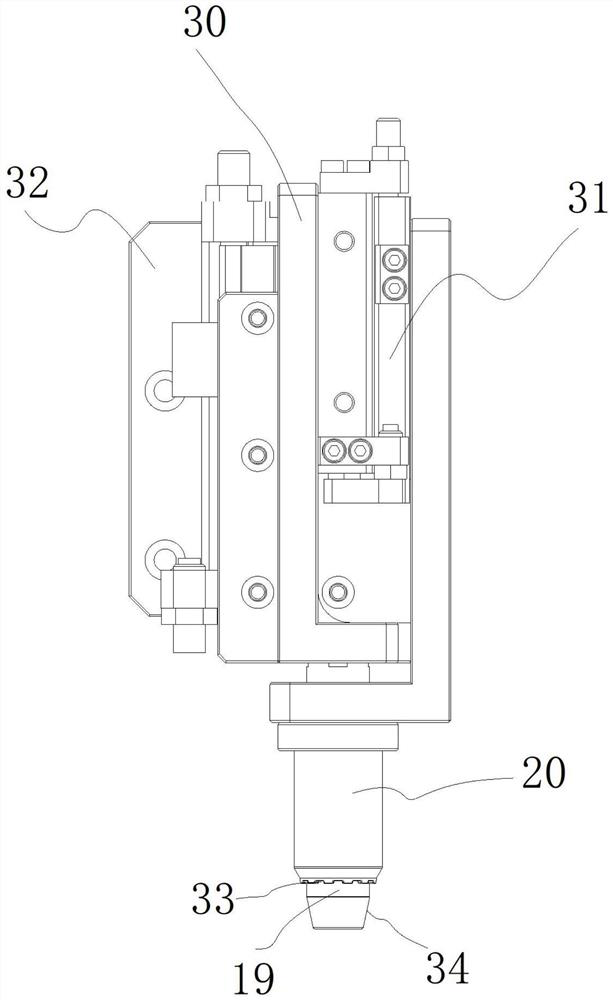

[0040] Embodiment 1: As shown in the figure, an X-shaped seal ring automatic assembly detection mechanism includes a frame 1 and a seal ring 2. The upper part of the frame 1 is provided with a feeding component 3, a detection flip component 4, a transport Component 5, rotating oiling jig 6, oiling jig 7, feeding and pressing component 8 and turntable jig 9, the sealing ring 2 enters the detection turning component 4 through the feeding component 3, and the detection The overturn assembly 4 detects and overturns the sealing ring 2, and sends the qualified sealing ring 2 to the rotating oiling jig 6 through the handling assembly 5, and the rotating oiling jig 6 drives the sealing ring 2 to rotate, and the oiling treatment The tool 7 performs oiling operation on the rotating sealing ring 2, and puts the sealing ring 2 oiled on the front and back sides into the valve cover 10 of the turntable jig 9 through the feeding and pressing assembly 8;

[0041] The feeding assembly 3 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com