Electret microphone

An electret microphone and back electrode technology, applied in the field of microphones, can solve the problems of low surface flatness, low product qualification rate and high cost, and achieve the effects of simple production process adjustment, low material cost, and small number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

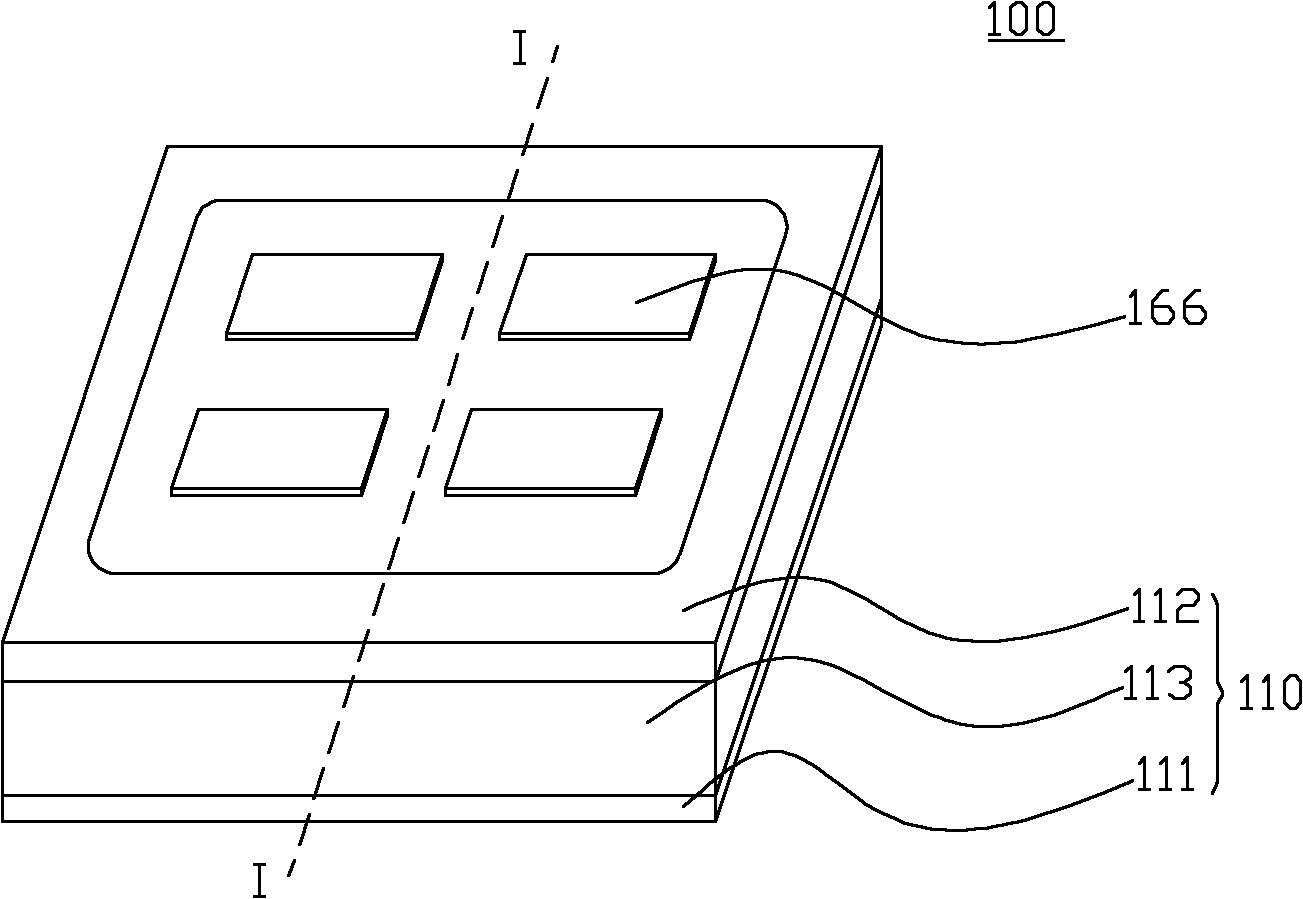

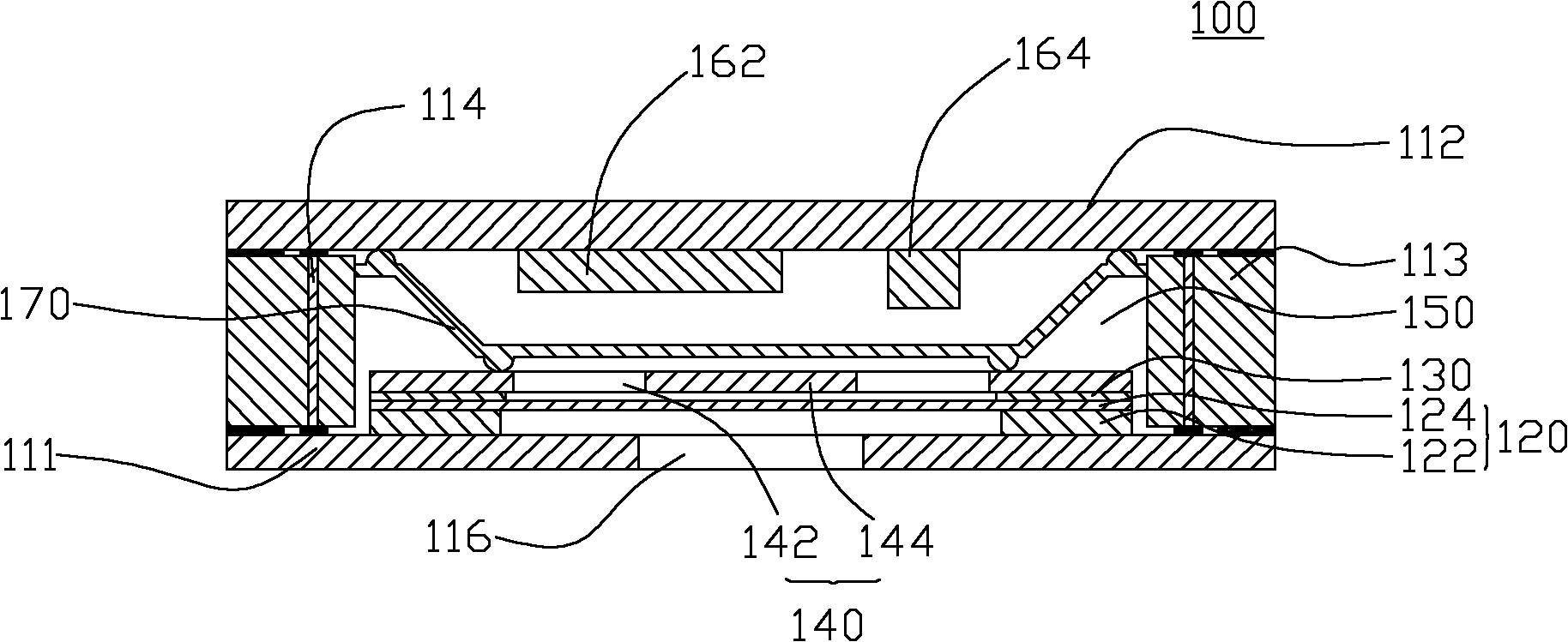

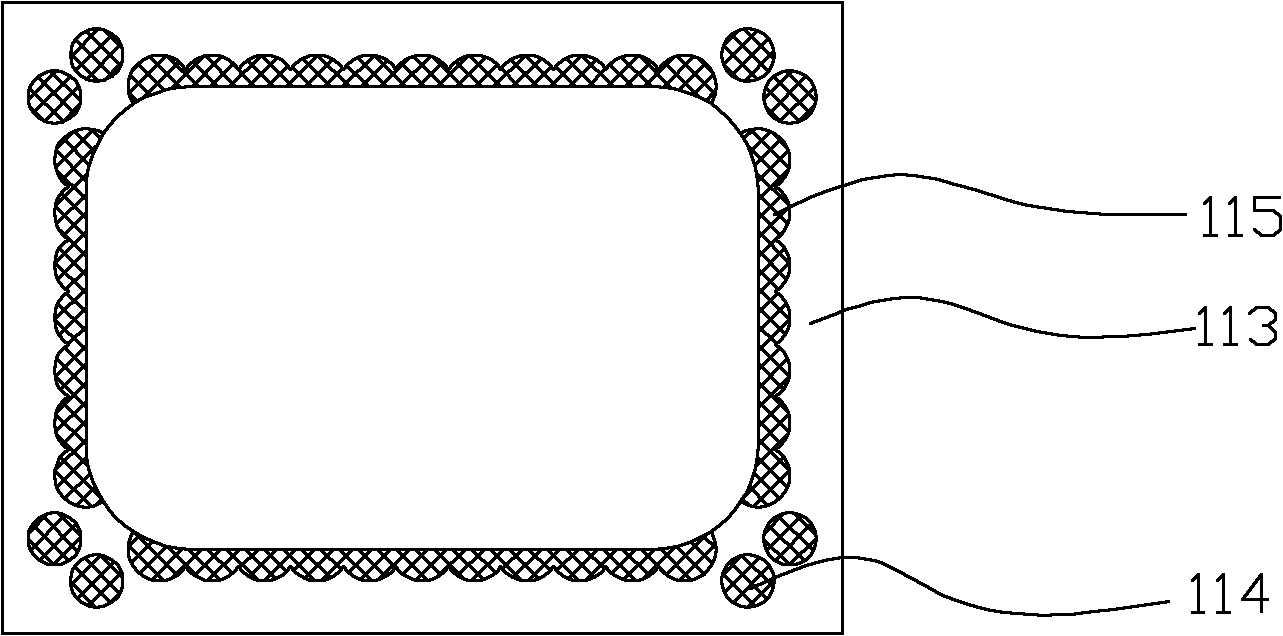

[0024] Such as figure 1 and figure 2 As shown, the electret microphone 100 of this embodiment includes a casing 110 and a diaphragm assembly 120 , an insulating gasket 130 and a back electrode assembly 140 sequentially arranged in the casing 110 . The housing 110 includes a square bottom plate 111 , a square circuit board 112 , and a square pillar-shaped support body 113 located between the bottom plate 111 and the circuit board 112 . The back electrode assembly 140 is electrically connected to the circuit board 112 .

[0025] The bottom plate 111 and the circuit board 112 are approximately the same in area and shape. The supporting body 113 defines an inner cavity (not shown in the figure) for accommodating the diaphragm assembly 120 , the insulating gasket 130 and the back electrode assembly 140 . Both ends of the support body 113 are closed by the bottom plate 111 and the circuit board 112 .

[0026] Preferably, the bottom plate 111 , the circuit board 112 and the supp...

Embodiment 2

[0039] Such as Figure 4 and Figure 5 As shown, the electret microphone 200 of this embodiment includes a casing 210 and a diaphragm assembly 220 , an insulating gasket 230 and a back electrode assembly 240 arranged in sequence in the casing 210 . The housing 210 includes a square bottom plate 211 , a square circuit board 212 , and a square pillar-shaped support body 213 located between the bottom plate 211 and the circuit board 212 . The back electrode assembly 240 is electrically connected to the circuit board 212 .

[0040]The bottom plate 211 and the circuit board 212 are approximately the same in area and shape. The supporting body 213 defines an inner chamber (not shown in the figure) for accommodating the diaphragm assembly 220 , the insulating gasket 230 and the back electrode assembly 240 . Both ends of the support body 213 are closed by the bottom plate 211 and the circuit board 212 . The dimensions of the bottom plate 211 , the circuit board 212 and the support...

Embodiment 3

[0046] Such as Figure 7 As shown, the electret microphone 300 of this embodiment includes a casing 310 and a diaphragm assembly 320 , an insulating gasket 330 and a back electrode assembly 340 arranged in sequence in the casing 310 . The housing 310 includes a square bottom plate 311 , a square circuit board 312 , and a square pillar-shaped support body 313 located between the bottom plate 311 and the circuit board 312 . The back electrode assembly 340 is electrically connected to the circuit board 312 .

[0047] The bottom plate 311 and the circuit board 312 are approximately the same in area and shape. The supporting body 313 is provided with an inner cavity (not shown in the figure) for accommodating the diaphragm assembly 320 , the insulating gasket 330 and the back electrode assembly 340 . Both ends of the support body 313 are closed by the bottom plate 311 and the circuit board 312 . The dimensions of the bottom plate 311 , the circuit board 312 and the support body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com