Method for manufacturing chip inductor and inductor thereof

A manufacturing method and inductor technology, applied in the manufacture of inductors/transformers/magnets, inductors, fixed inductors, etc., can solve the problems of large material consumption, low pass rate, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

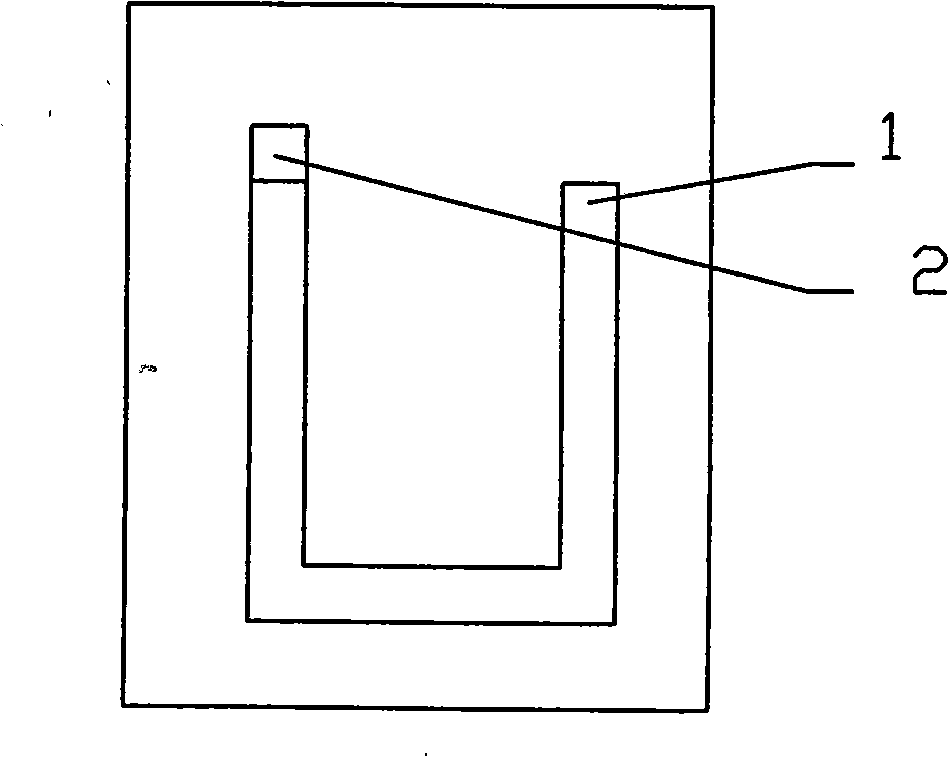

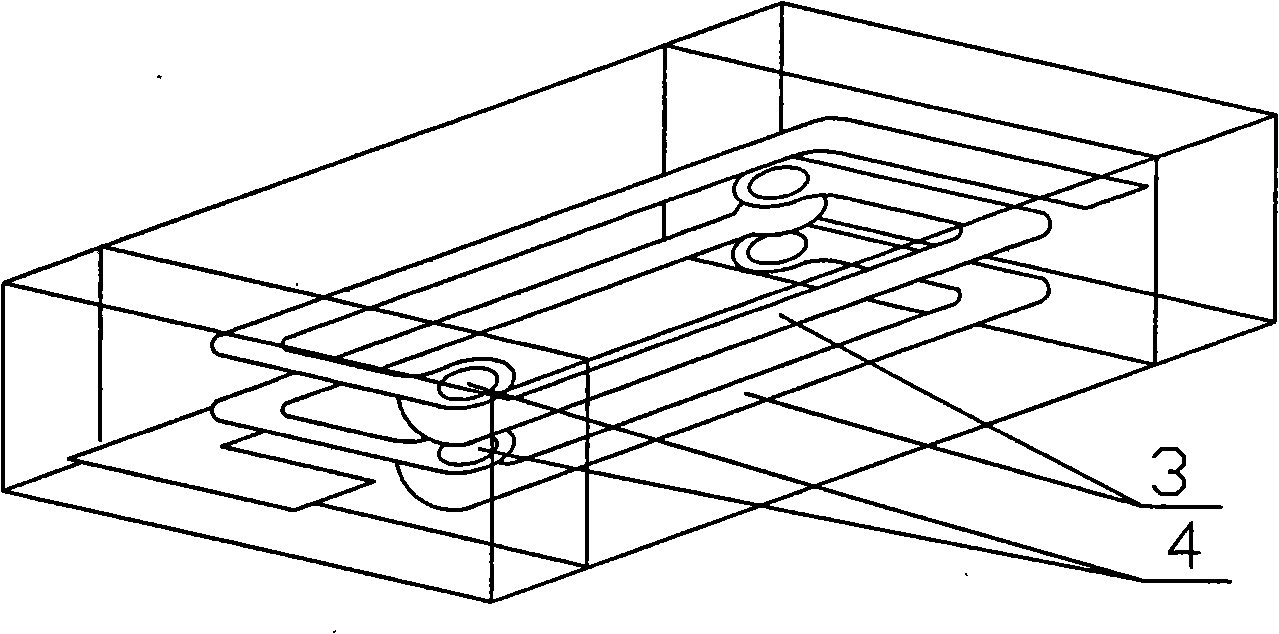

[0018] A method for manufacturing a chip inductor, comprising the steps of screen printing, tape casting, glue removal, and sintering. In the screen printing step, the wire groove of the screen printing frame is 0.5 to 0.85 weeks, preferably 0.75 weeks. There is a photosensitive latex column 2 at one end of the wire groove 1; a screen printing frame is placed on the base casting die, and a wire conductor paste is printed on the wire groove of the frame to form an internal electrode 3; The dielectric paste is printed on the frame surface to form a dielectric die. Since the photosensitive emulsion column blocks the dielectric slurry, a through hole is formed at the photosensitive emulsion column; that is, during the printing transfer process, there is no dielectric paste at the connection of the internal electrode, forming A through hole not covered with dielectric paste, so that when the next layer of electrode paste is printed, the paste automatically flows into the through ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com