Zoom lens

A zoom lens and lens technology, applied in the field of zoom lenses, can solve the problems of difficult to improve the overall pass rate, unfavorable yield pass rate, serious tolerance accumulation, etc., and achieve the effects of saving material cost, reducing tolerance accumulation, and improving production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

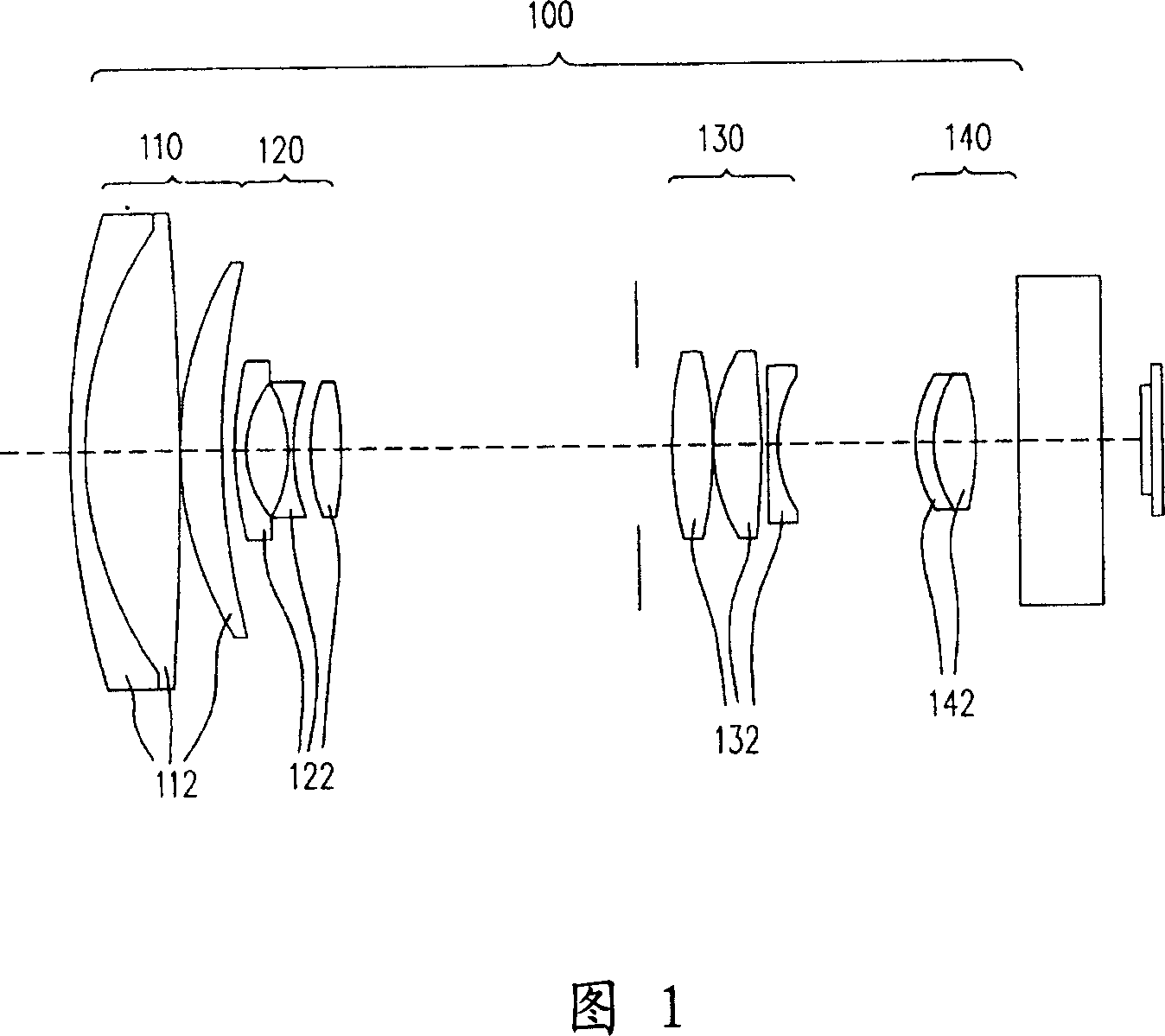

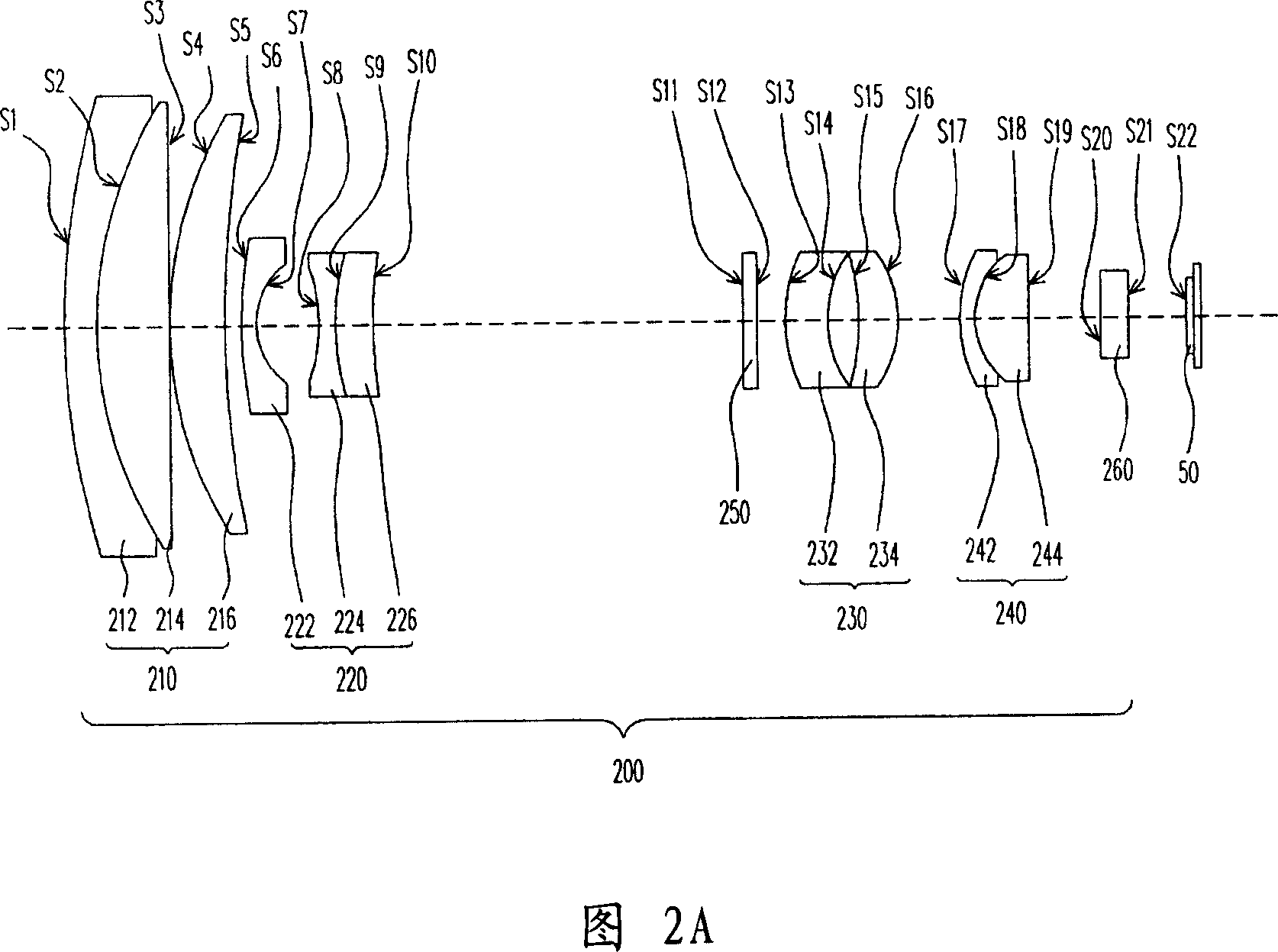

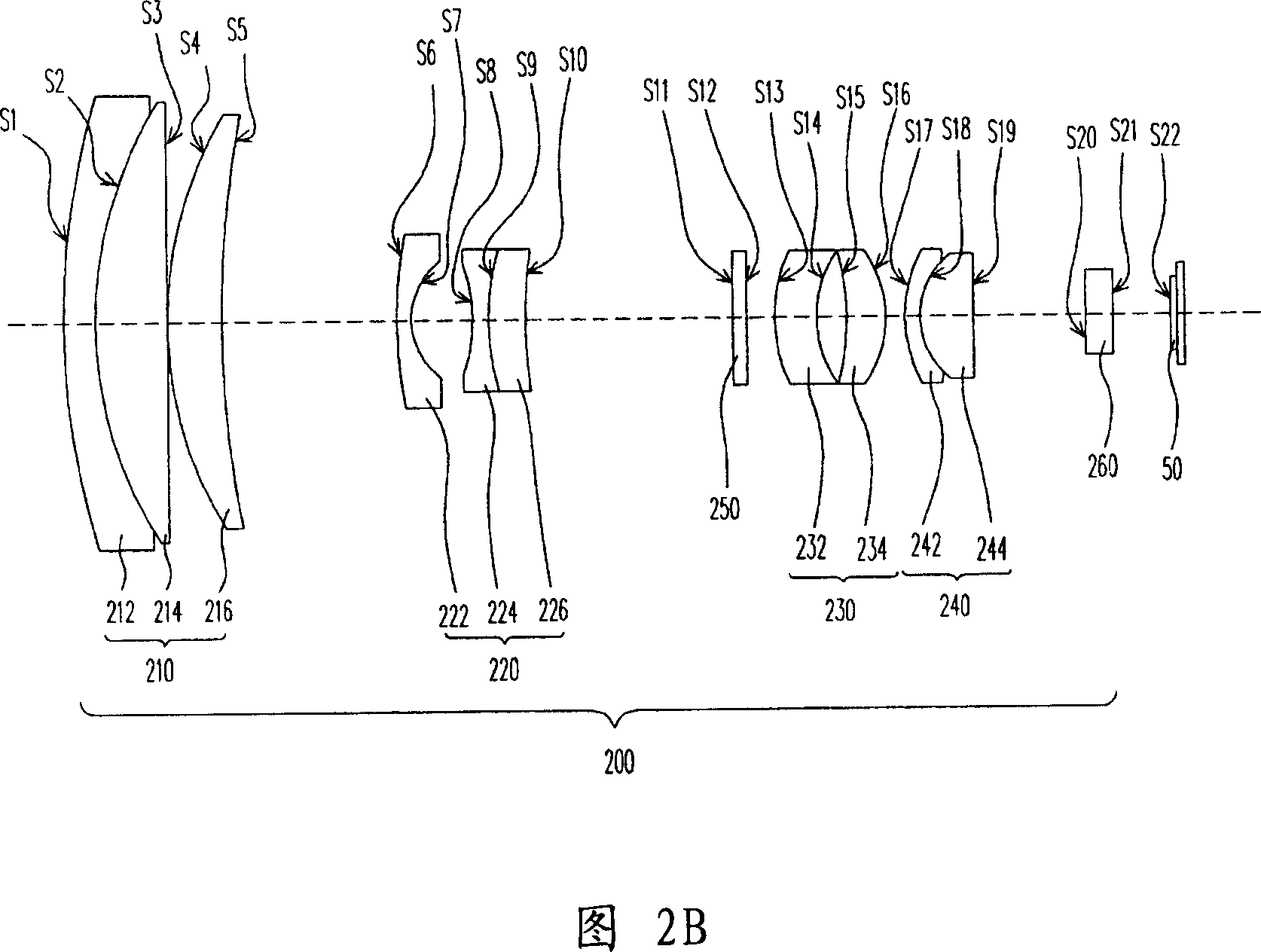

[0035] 2A to 2C are structural schematic diagrams of the zoom lens according to an embodiment of the present invention at different zoom ratios, wherein FIG. 2A shows the structure of the zoom lens at the wide-end (wide-end), and FIG. 2B shows the zoom lens The structure when the lens is in the middle position (middle), and Fig. 2C shows the structure when the zoom lens is in the tele-end (tele-end). Please refer to FIG. 2A to FIG. 2C at the same time. The zoom lens 200 of this embodiment is suitable for imaging an object on a photosensitive element 50, wherein the photosensitive element 50 is, for example, a charge-coupled device or a complementary metal-oxide semiconductor (Complementary Metal-Oxide Semiconductor, CMOS ). The zoom lens 200 includes a first lens group 210 , a second lens group 220 , a third lens group 230 and a fourth lens group 240 . Wherein, the second lens group 220 is located between the first lens group 210 and the photosensitive element 50, the third l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com