High tensile strength cold-rolled steel sheet and method for production thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

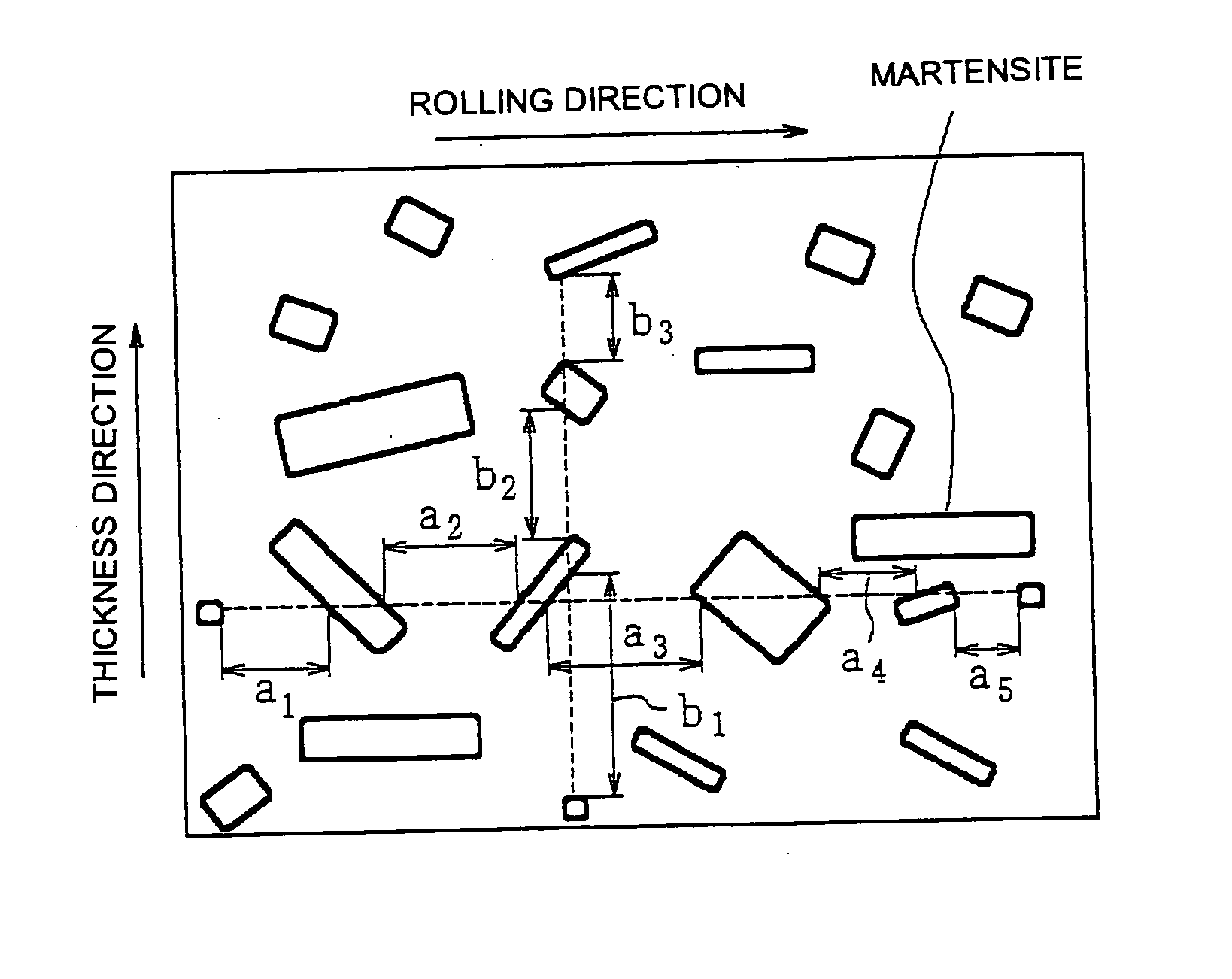

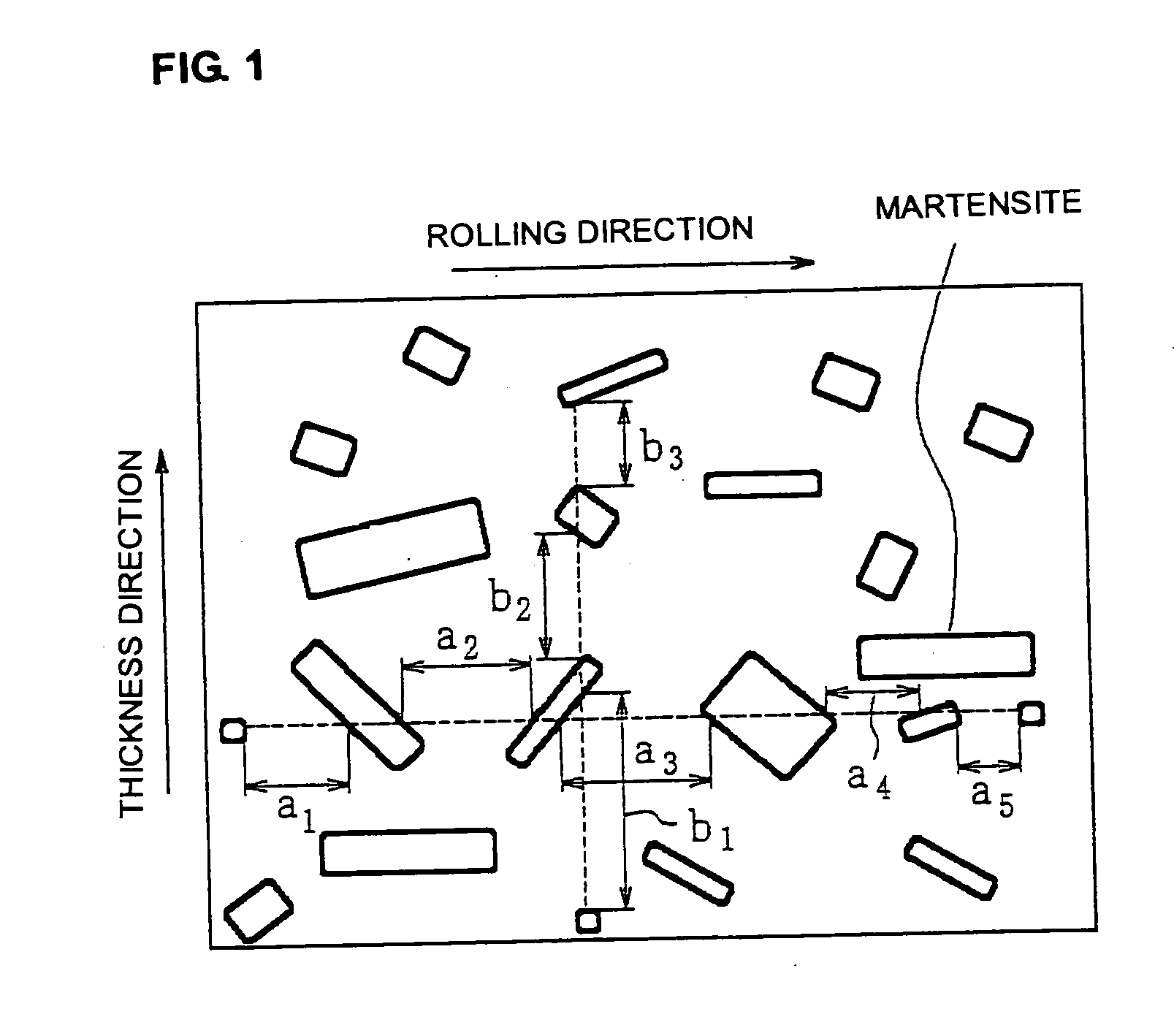

Image

Examples

example 1

[0070] Steel Nos. A to ZZ having the respective compositions given in Table 1-1 and Table 1-2 were ingoted by a converter, and then they were treated by continuous casting to prepare the respective slabs. These slabs were heated to temperatures ranging from 1100° C. to 1250° C., followed by hot-rolling, thus prepared the respective steel sheets having thicknesses given in Table 2-1 and Table 2-2. These steel sheets were coiled at the respective coiling temperatures given in Table 2-1 and Table 2-2. Then, cold-rolling, continuous annealing, and controlled cooling were given to these steel sheets under the conditions given in Table 2-1 and Table 2-2, thus obtained the respective high tensile cold-rolled steel sheet Nos. 1 to 39.

[0071] The Ac3 transformation point given in Table 1-1 and Table 1-2 was determined by preparing samples from the respective sheet bars after hot-rough-rolling, using Thermec Master Z of Fuji Electronics Industrial Co., Ltd.

[0072] Thus prepared respective hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com