High manganese high strength steel sheets with excellent crashworthiness, and method for manufacturing of it

A high-strength steel plate and crash-resistant technology, applied in the field of high machinability high-strength steel plate and its manufacturing, can solve problems such as low yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] Hereinafter, exemplary embodiments of the present invention will be described in detail.

[0053] [example]

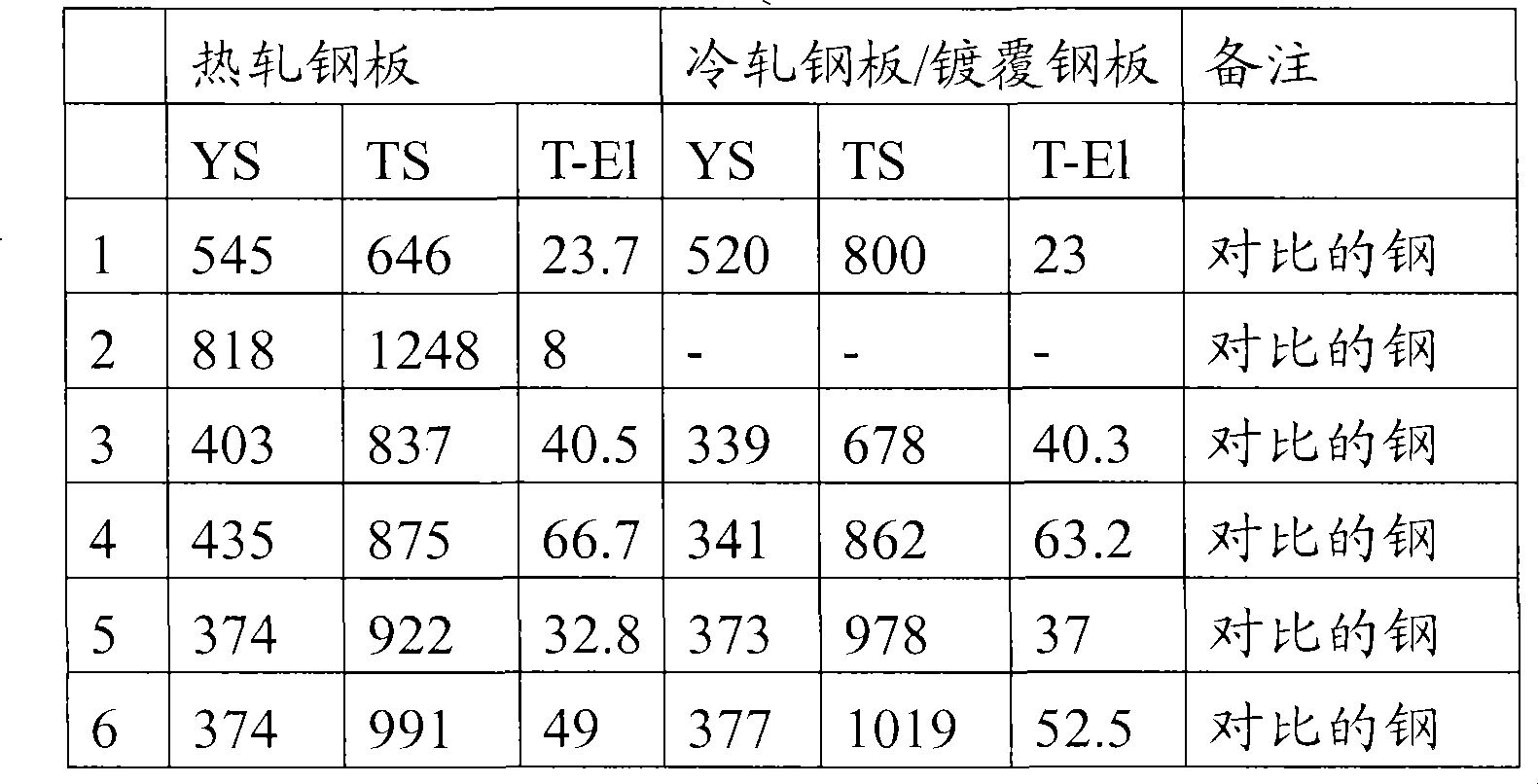

[0054] The steels of the present invention and comparative steels are listed in Table 1 below, and the molten steel ingots were kept in a heating furnace at 1200° C. for one hour, and then hot-rolled. At this time, the hot rolling finish temperature (hot rolling finish temperature) was 900°C, and the coiling temperature was 650°C. Some hot-rolled steel sheets were processed into tensile test samples according to the JIS5 standard, and the tensile strength of the tensile test samples was tested using a conventional general-purpose testing machine. Then, the hot-rolled steel sheet was pickled and cold-rolled at a cold reduction ratio of 50%. The cold-rolled test samples were successively annealed, simulated and heat-treated at an annealing temperature of 800°C and an overaging temperature of 400°C. After successive annealing, simulation and heat treatment proce...

example 2

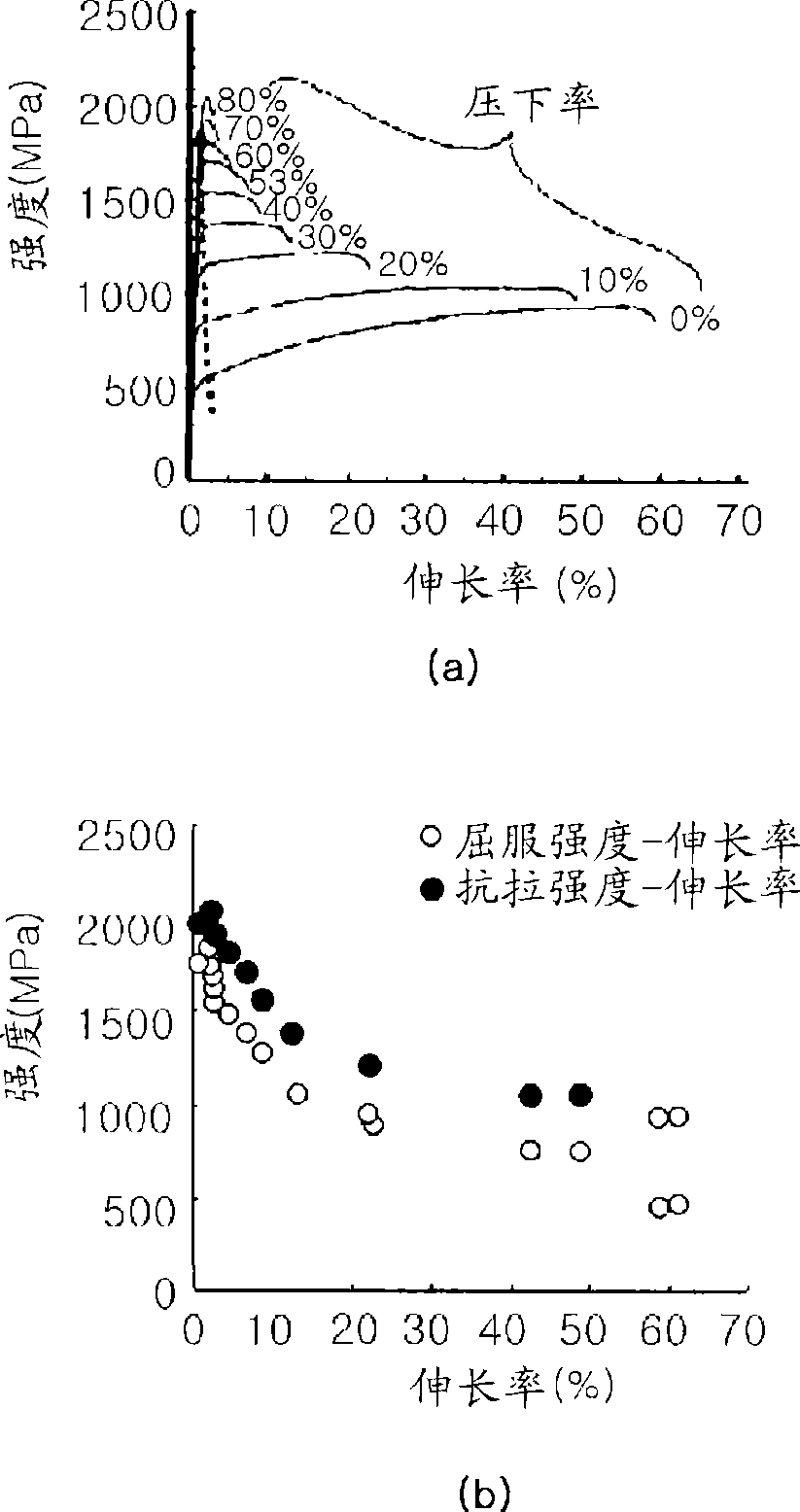

[0065] The high-strength steel sheet having an austenite single phase and having high workability and high manganese produced in Example 1 was cold-rolled again, and its mechanical properties were measured. The results are listed in Table 3 below.

[0066] table 3

[0067] YS TS T-El Rolling amount Remark 19 471.3 939.9 60.4 0 contrasting steel 19-1 750.5 1047.2 44.6 10 steel of the invention 19-2 930.5 1209.7 22.2 20 steel of the invention 19-3 1088.3 1371.3 12.5 30 steel of the invention 19-4 1247.7 1554.2 8.6 40 steel of the invention 19-5 1388.2 1704.1 6.8 50 steel of the invention 19-6 1503.6 1808.6 4.6 60 steel of the invention 19-7 1612.8 1924.5 2.8 70 steel of the invention

[0068] As shown in Table 3, it was shown that the yield strength of the high-strength steel plate was improved. It is generally seen that the yield strength increases to 750 MPa or more in 10% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com